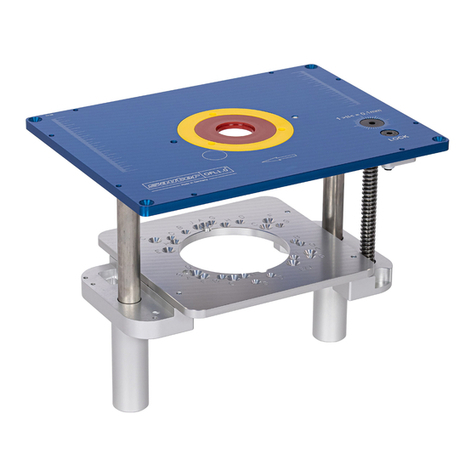

Power Tec 71536 User manual

Owner’s Manual

Model No. 71536

24" Router Table Fence

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

Visit us on the web at powertecproducts.com

QUESTION...

1•847•780•6120

20-0616

TABLE OF CONTENTS

SAFETY RULES 1

ASSEMBLY 3

MAINTENANCE 6

General Maintenance

WARRANTY 7

SECTION PAGE

Unpacking

Assembly

Adjusting theFence Faces

Jointing

SAFETY RULES 1

1

SAFETY RULES

WARNING

For your own safety, read all of the rules and precautions before

operating tool.

WARNING

Always follow proper operating procedures as defined in this

manual even if you are familiar with use of this router table

fence or any tool used with this router table fence. Remember

that being careless for even a fraction of a second can result in

severe personal injury.

Before using another tool with this product, always read,

understand and follow the instructions and safety warnings in

the owner’s manual for that tool. If you do not have the owner’s

manual, obtain one from the tool’s manufacturer before using it

with this product.

You must be familiar with the use of any tool or accessory

used with this router table fence. The supplier cannot be held

responsible for any accident, injury or damage incurred while

using this router table fence with any tool.

It is the responsibility of the purchaser of this product to ensure

that any person using this product reads and complies with all

instructions and safety precautions outlined in this manual prior

to use.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. To reduce your exposure

to these chemicals, work in a well ventilated area and work

with approved safety equipment. Always wear OSHA/NIOSH

approved, properly fitting face mask or respirator when using

such tools.

CAUTION

Do not modify or use this router table fence for any application

other than that for which it was designed.

FOLLOW ALL STANDARD SHOP SAFETY

PRECAUTIONS, INCLUDING:

• Keep children and visitors at a safe distance from work area.

• Keep work area clean. Cluttered work areas invite accidents.

Work area should be properly lit.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of the tool.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses have only impact resistant lenses.

They are NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

• A guard or any other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs.

• Use the right tool for your job. Do not force your tool to do a

job for which it was not designed.

• Use safety equipment such as featherboards, push sticks and

push blocks, etc., when appropriate.

• Maintain proper footing at all times and do not overreach.

• Do not use the router table as a step or seat.

WARNING

• To avoid serious injury, turn off and unplug the router before

attaching the router base, changing accessories or adjusting

the cutter height/fence position.

• Assemble the featherboard(s) at least 1" (2.5 cm) from the

saw blade to prevent kickback.

• Do not use the featherboard as a push block.

CAUTION

Think safety! Safety is a combination of operator common sense

and alertness at all times when tool is being used.

WARNING

Do not use the router table fence until it is completely assembled

and you have read and understood this entire operating manual

and the operating manual of the tool being used with this router

table fence.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

SPECIFIC SAFETY WARNINGS

2

DANGER

• To avoid serious injury, keep hands and fingers away from the

spinning router bit. Be aware of the bit at all times.

WARNING

AVOID THIS SITUATION!

Fence

Workpiece

Direction

of Feed

Bit Rotation

-NEVER FEED YOUR WORKPIECE BETWEEN THE

BIT AND THE FENCE. Because of the direction of

the bit’s rotation, the bit could “grab” the workpiece

and propel it away from the table at a high velocity,

potentially resulting in property damage and serious

injury to anyone in its path.

-When the bit grabs the workpiece, your hands could

be drawn into the bit, resulting in serious injury

• Turn off and unplug your router before installing or adjusting

the bit or adjusting the router table fence and accessories.

• BEFORE beginning any routing operation, ALWAYS make

sure ALL knobs on the router table fence and accessories are

tightened and the fence will not shift during use.

• Always feed the workpiece against the rotation of the bit.

A table-mounted router spins the bit counterclockwise, so

feed the workpiece from right to left as you face the table.

This provides better control because the rotation of the bit is

backward and toward the fence instead of forward and away

from it.

• NEVER attempt to machine a workpiece at the router table

without using the router table fence or a starter pin with a

bearing-guided bit. Failure to use these guides diminishes

your ability to control the workpiece and greatly increases

the chance of damage to the workpiece and/or serious

personal injury.

• BEFORE plugging in and turning on the router, always make

sure the MDF adjustable fence faces are fully secured and

the bit can rotate freely without touching the fence faces. An

exception to this is if the infeed fence face is set to provide

zero-clearance support for the workpiece, as described in the

Adjusting the Fence Faces.

CAUTION

• Set the bit guard directly over the router bit, at least 1/2" above

the top of the bit or the top of the workpiece (whichever is

highest), make sure the bit doesn’t cut into the bit guard.

• When adjusting the position of the router table fence, make

sure no part of the aluminum fence will contact the router bit.

2

SAFETY RULES

3

ASSEMBLY

ASSEMBLY 3

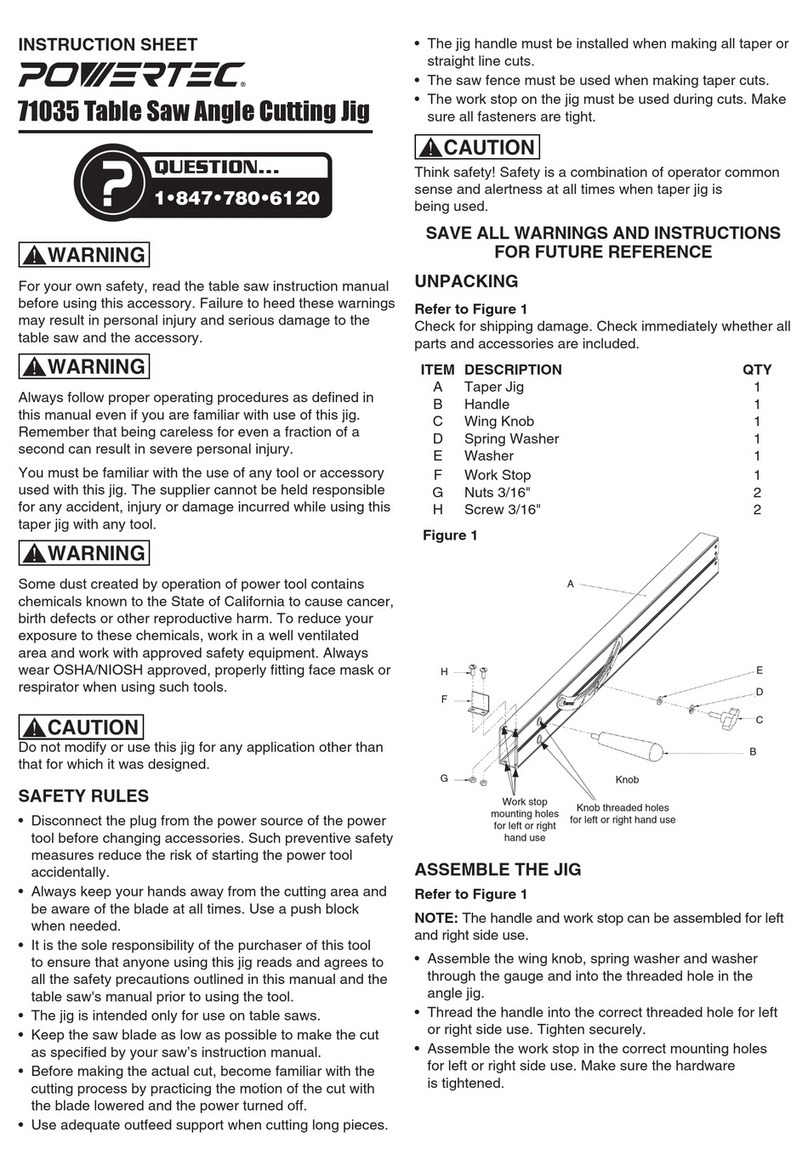

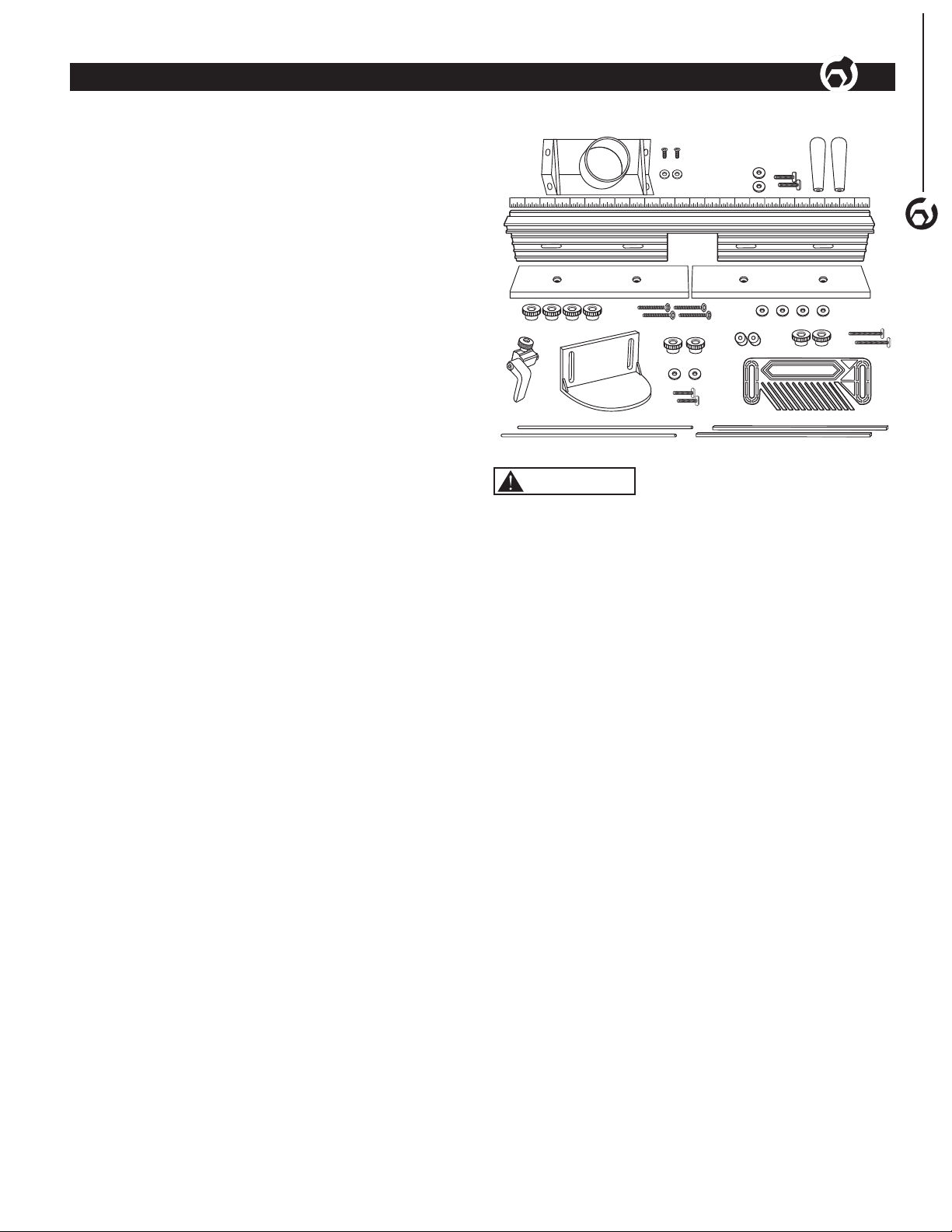

UNPACKING

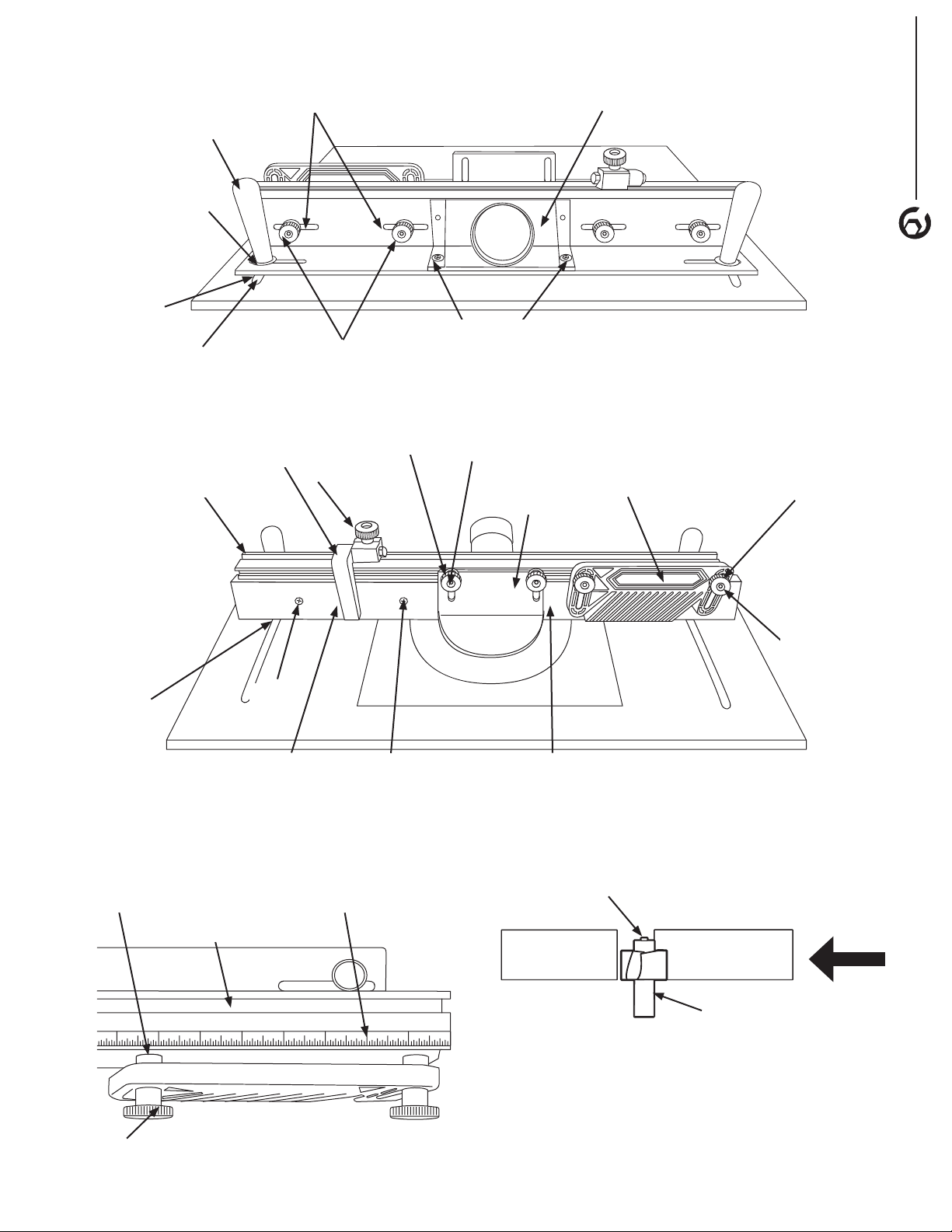

Refer to Figure 1

Check for shipping damage. Check immediately whether all

parts and accessories are included.

ITEM DESCRIPTION QTY

A Fence 1

BFence lock knobs 2

CWashers 5/16" 2

DT-Bolt 5/16"-18 x 1" 2

EMDF adjustable fence faces 2

FFlat head screws 1/4"-20 x 1-1/2" 4

GWashers 1/4" 4

HLocking knobs 4

IBit guard 1

JBit guard knobs 1/4" 2

KT-Bolts 1/4"-20 x 1" 2

LWashers 1/4" 2

MRouter dust port 1

NPan head screws M4 x 10 mm 2

OWashers 1/4" 2

PFeatherboard 1

QT-Bolts 5/16"-18 x 1-1/2" 2

RSpacers 2

SLocking knobs 5/16" 2

TTape measure with adhesive backing

(right to left)

1

U3" Flip stop 1

V1/4" Square Rods 2

W4 mm Round Rods 2

Figure 1

2324 22 21 1520 1319 111218 91017 7

8

16 56 314 14 2

U

H

K

M

A

B

NC

O

GF

T

L

J

Q

R

P

E

I

S

D

E

W V

WARNING

Do not use the router table fence until it is completely assembled

and you have read and understood this entire operating manual

and the operating manual of the tool being used with this router

table fence.

4

ASSEMBLY

ASSEMBLY

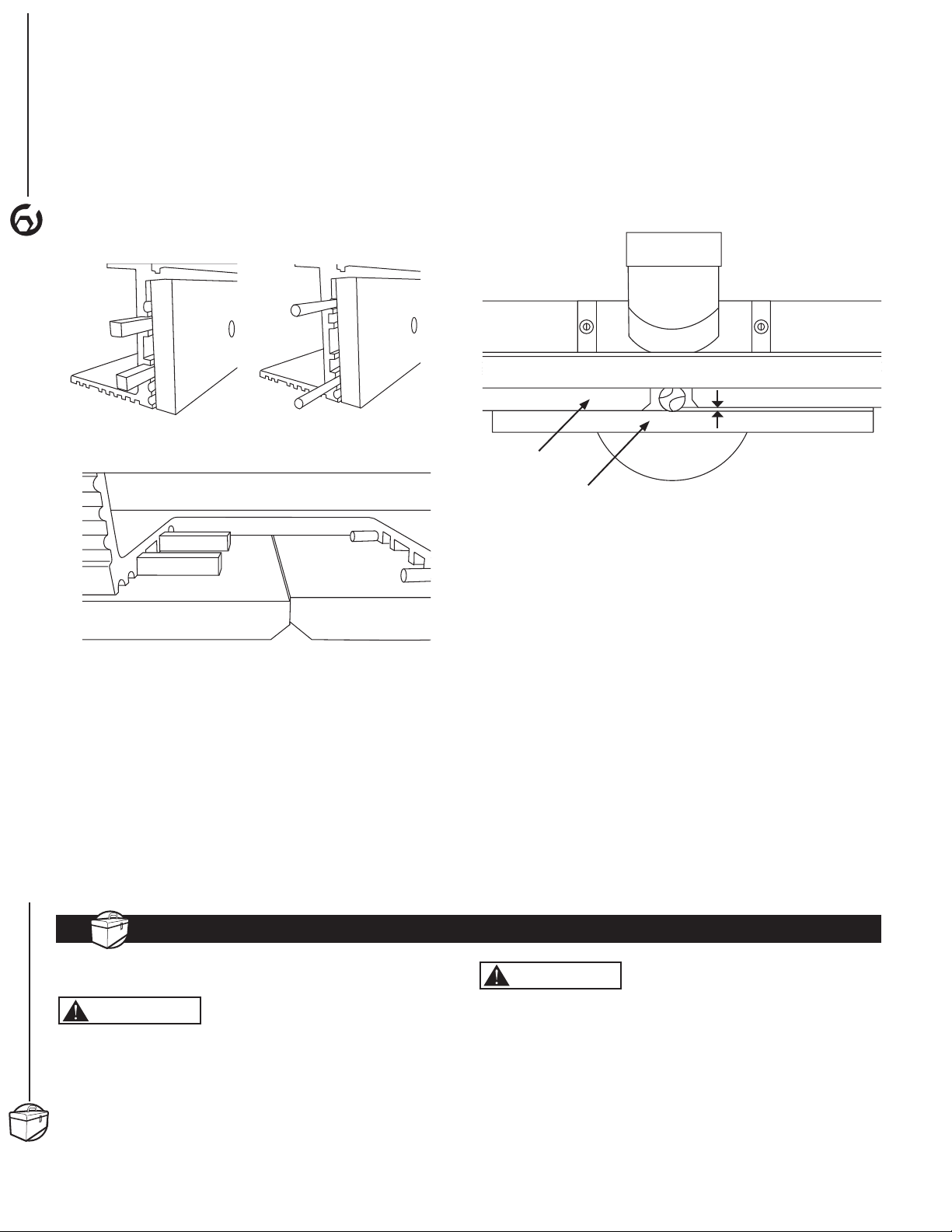

Refer to Figure 2–4

• Remove the adhesive backing from the right to left tape

measure and press into place. Start on the right end and

carefully place the tape along the front edge of the fence. Use

scissors to cut the excess tape from the left end.

• Attach the dust port to the back of the fence using the pan

head screws and 1/4” washers.

• From the front of the MDF adjustable fence faces, insert the

1/4"-20 x 1-1/2” screws through the MDF adjustable fence face

and fence, place a 1/4” washer over each screw and secure

in place with the round locking knobs. The MDF adjustable

fence faces can be adjusted left or right, after adjustment

has been made for the operation to be performed, tighten all

knobs securely.

• From the bottom of the fence insert the two 5/16"-18 x 1”

T-Bolts through the fence slot. Place a 5/16” washer and fence

locking knob on each T-Bolt. Place the fence onto the router

table and align the T-Bolts in the fence with the slots in the

router table. Tighten the knobs after adjusting the fence to the

operation being preformed.

• From the back of the bit guard insert the two 1/4"-20 x 1”

T-Bolts, place 1/4" washers and round lock knobs on each

T-Bolt. Place the T-Bolts into the T-Slot on the face of the

fence and slide the bit guard onto the fence. NOTE: To

adjust the bit guard, loosen the knobs, slide the bit guard up

and down to desired application and tighten knobs. When

changing bits, slide the bit guard left or right of the opening.

WARNING

To prevent kickback make sure the featherboard is at least 1”

(2.5 cm) from the saw blade.

• Place a spacer on each 5/16"-18 x 1-1/2" long T-Bolt and

insert through the slot in the featherboard, thread a round

locking knob on each T-Bolt and slide the T-Bolts into the

T-slot in the front of the fence. Position the featherboard(s)

and tighten locking knobs.

• Slide the T-Bolt on the flip stop into the T-Slot in top of the

fence, tighten the knob. The arm on the flip stop functions

as an easily adjustable stop and can be flipped up when not

needed. NOTE: The flip stop is multi-functional, please see flip

stop instructions for details. To prevent chip build up, the stop

does not extend the full width of the fence. However when

using a stop with material 3/8" thick or less, a longer stop

will need to be fabricated and can be mounted in the T-slot

located in the front of the fence.

IMPORTANT: Every routing operation is different, adjust the

various parts of the router fence and accessories as needed and

then tighten all knobs securely.

ADJUSTING THE FENCE FACES

Refer to Figure 5

The two MDF adjustable fence faces are designed to slide about

2" along the fence. This allows the opening for the router bit to be

adjusted from 0” up to 4".

Generally, the infeed and outfeed adjustable fence faces should

be adjusted as close to the bit as possible without contacting

the cutter. This will help prevent the ends of the workpiece from

drifting too far into the cutter at the beginning and end of the cut to

provide quality and safe cut.

Sometimes the “zero-clearance” support is needed to deliver an

even cleaner cut. In this case the router bit profile cuts into the

front edge of the infeed adjustable fence face so there is virtually

no gap between the cutter and the fence face. It delivers a cleaner

cut because the workpiece fibers are fully supported throughout

the cut.

If a zero clearance setting is necessary, follow these steps:

1. Set the bit height and fence position. Set both of the MDF

adjustable fence faces close to the bit without touching it,

the fence faces MUST NOT contact the bit at this time.

CAUTION

Set the bit guard directly over the router bit, at least 1/2” above

the top of the bit or the top of the workpiece (whichever is

highest), make sure the bit doesn’t cut into the bit guard.

2. Install, adjust and secure the bit guard.

3. On the back of the fence, slightly loosen the locking knobs

on the infeed MDF adjustable fence face. Start the router

and slowly slide the infeed MDF adjustable fence face into

the spinning router bit, stopping when the edge reaches

the bit’s guide bearing or midpoint (for bits that don’t have a

guide bearing).

4. Tighten the locking knobs on the back of the MDF

adjustable fence face to secure it in position.

5

ASSEMBLY

BACK

Fench

Locking

Knob

5/16"

Washer

Slot in Router Table

Dust Port

T-Bolt

Slot in

Fence

Round Locking Knobs

with 1/4" Washers

Washer and Pan

Head Screw

Figure 2

FRONT

Bit Guard

Featherboard Round Locking Knob

Round Lock

Knobs with

Washers

MDF Adjustable Infeed Fence Face

Flip

Stop

Knob

T-Slot in Top

of Fence

1/4"-20 x 1"

T-Bolts

MDF Adjustable

Outfeed Fence Face

1/4-20

x 1-1/2"

Screws

1/4"-20 x 1-1/2" Screws

Flip

Stop

T-Slot in

Face of

Fence

Figure 3

2 1345678

87654321

T-Slot on Top of Fence

Right to Left Tape Measurer

NOTE: Use the tape measure

to position stops for routing

stopped cut.

Round

Locking

Knob

Spacer

Figure 4

5/16"-18 x 1-1/2"

T-Bolts

OUTFEED Adjustable

Fence Face

INFEED Adjustable

Fence Face

Router Bit

Router Bit Bushing Guide

Figure 5

GENERAL MAINTENANCE

WARNING

When servicing, use only identical replacement parts. Use of

any other parts may create a hazard or cause product damage.

To ensure safety and reliability, all repairs should be performed

by a qualified service technician.

MAINTENANCE

6

MAINTENANCE

6

WARNING

Keep the router table fence dry, clean, and free from oil and

grease. Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum based products or any

strong solvent to clean the router table fence. Chemicals can

damage, weaken or destroy plastic which may result in serious

personal injury.

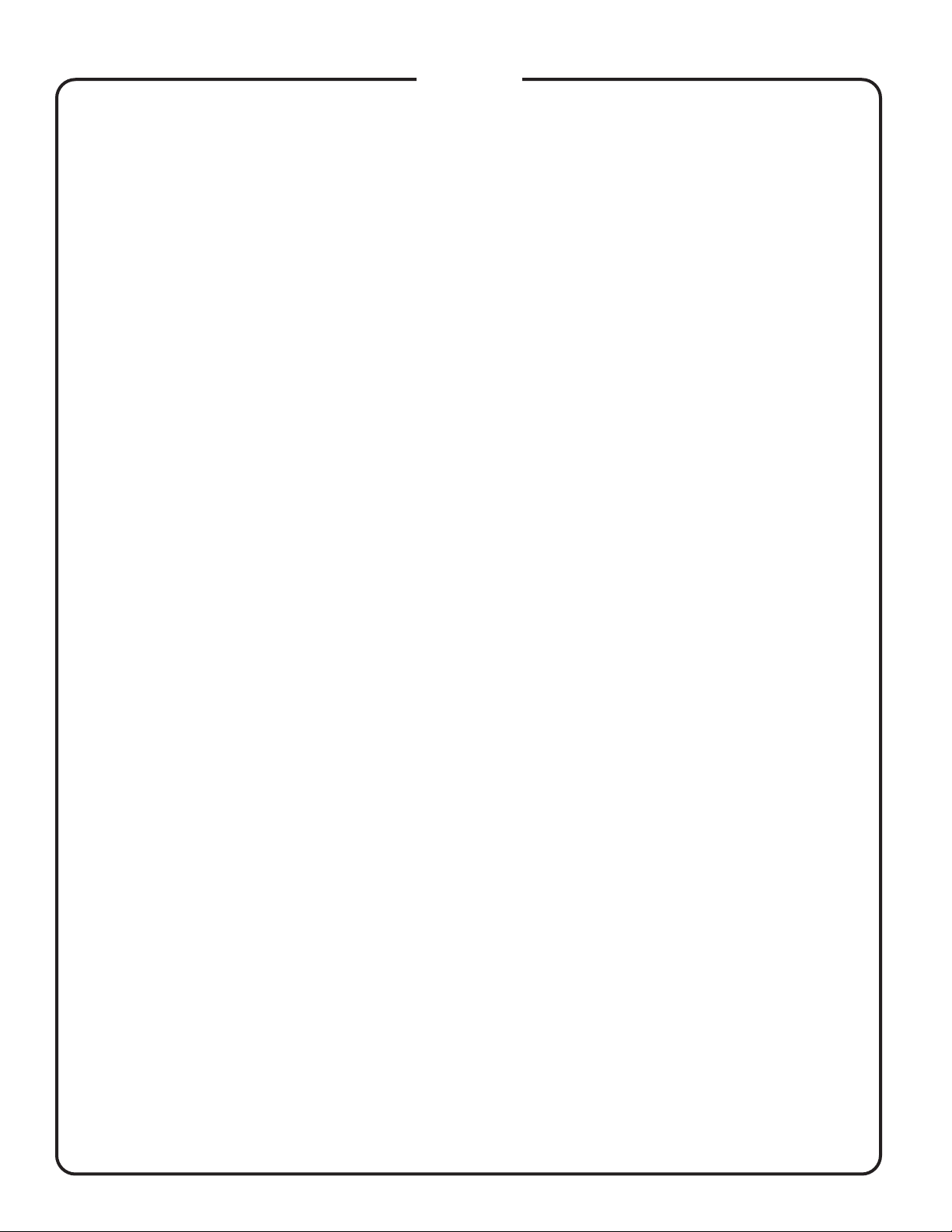

JOINTING

Refer to Figure 6–9

The independently adjustable fence faces allow the router table

to be used as a vertical jointer by offsetting the outfeed fence

face 3/128", 1/16", 5/64" from the infeed fence face.

Two sets of grooves are located in the fence behind the fence

faces, slide the jointing rods into these grooves to offset

the outfeed fence face 3/128", 1/16", 5/64" from the infeed

fence face.

Figure 7

Square Jointing Rods Shown in

the Square Grooves

Round Jointing Rods Shown in

the Round Grooves

Square Jointing Rods Shown in the Square Grooves on the

Outfeed Fence and the Round Jointing Rods in the Round Grooves

on the Infeed Fence for the 1/64" Offset

Figure 6

Figure 8

NOTE: It is best to make light passes when jointing, the

3/128" and 1/16" offset will be used more frequently than the

5/64" offset.

1. Loosen the round locking knobs securing the outfeed fence

face. Slide the jointing rods into the desired groove on

the fence.

a. For a 5/64" offset slide the square jointing rods into the

square grooves on the outfeed fence. Figure 6.

b. For a 1/16" offset, slide the round jointing rods into the

round grooves on the outfeed fence. Figure 7.

c. For a 3/128" offset, slide the round jointing rods into the

round grooves on the infeed fence and slide the square

rods into the square grooves on the outfeed fence.

Figure 8.

2. With the rods in place, tighten the outfeed fence face

locking knobs.

Jointing Offset

Outfeed Fence

Face

Workpiece

Figure 9

3. Install a straight bit in the router. Place a straight edge

against the outfeed fence face and position the fence so the

bit just grazes the straight edge.

NOTE: Any straight bit can be used for jointing. A flush-trim bit is

the easiest to set up because the bit guide bearing is the same

diameter as the cutter and it can be aligned to the outfeed fence

face with the bearing. An up-cut spiral bit produces an almost

chatter-free surface, but it is more difficult to align with the

fence face.

Always use a scrap piece of wood to test the setup.

• If the scrap is fed past the bit and it runs into the leading end

of the outfeed fence face, the fence is too far forward and

not enough material is being removed. Move the fence back

a little.

• If there is snipe at the trailing edge of the scrap, the fence is

too far back and too much material is being removed. Move

the fence forward.

6

ASSEMBLY

WARRANTY 7

WARRANTY

7

Thank you for investing in a POWERTEC power tool. This product has been designed and manufactured to meet high

quality standards and is guaranteed for domestic use against defects in workmanship or material for a period of 12

months from the date of purchase. This guarantee does not affect your statutory rights.

SOUTHERN TECHNOLOGIES LLC. BENCH TOP AND STATIONARY POWER TOOL

LIMITED 1 YEAR WARRANTY AND 30-DAY SATISFACTION GUARANTEE POLICY

POWERTEC products are designed and manufactured by Southern Technologies LLC. All warranty communications

should be directed to Southern Technologies LLC by calling 847-780-6120, 9 AM to 5 PM, Monday through Friday,

US Central Time.

30- DAY SATISFACTION GUARANTEE POLICY

During the rst 30 days after the date of purchase, if you are dissatised with the performance of this POWERTEC tool

for any reason, you may return the tool to the retailer from which it was purchased for a full refund or exchange. You

must present proof of purchase and return all original equipment packaged with the original product. The replacement

tool will be covered by the limited warranty for the balance of the one year warranty period.

LIMITED ONE YEAR WARRANTY

This warranty covers all defects in workmanship or materials in this POWERTEC tool for a one year period from the

date of purchase. This warranty is specic to this tool. Southern Technologies, LLC reserves the right to repair or

replace the defective tool, at its discretion.

HOW TO OBTAIN SERVICE

To obtain service for this POWERTEC tool you must return it, freight prepaid, to POWERTEC. You may call

847-780-6120 for more information. When requesting warranty service, you must present the proof of purchase

documentation, which includes a date of purchase. POWERTEC will either repair or replace any defective part, at

our option at no charge to you. The repaired or replacement unit will be covered by the same limited warranty for the

balance of one year warranty period.

WHAT IS NOT COVERED

This warranty applies to the original purchaser at retailer and may not be transferred.

This warranty does not cover consumable items such as saw blades, knives, belts, discs, cooling blocks and sleeves.

This warranty does not cover required service and part replacement resulting from normal wear and tear, including

accessory wear.

This warranty does not cover any malfunction, failure or defect resulting from:

1) misuse, abuse, neglect and mishandling not in accordance with the owner’s manual.

2) damage due to accidents, natural disasters, power outage, or power overload.

3) commercial or rental use.

4) alteration, modication or repair performed by persons not recommended by POWERTEC.

DISCLAIMER

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or

FITNESS FOR A PARTICULAR PURPOSE, are disclaimed. Any implied warranties, that cannot be disclaimed under

state law are limited to one year from the date of purchase. Southern Technologies LLC. is not responsible for direct,

indirect, incidental or consequential damages. Some states do not allow limitations on how long an implied warranty

lasts and/or do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations

may not apply to you. This warranty gives you specic legal rights, and you may also have other rights which vary from

state to state. Southern Technologies LLC., makes no warranties, representations, or promises as to the quality or

performance of its power tools other than those specically stated in this warranty.

NOTE

NOTE

Southern Technologies, LLC

Waukegan, IL 60087

Table of contents

Other Power Tec Power Tools Accessories manuals

Popular Power Tools Accessories manuals by other brands

Bosch

Bosch GTA 3800 Professional Operating/safety instructions

Hilti

Hilti DC-EX 125/5inch M operating instructions

Bubble Magic

Bubble Magic Pollen Tumbler Replacement manual

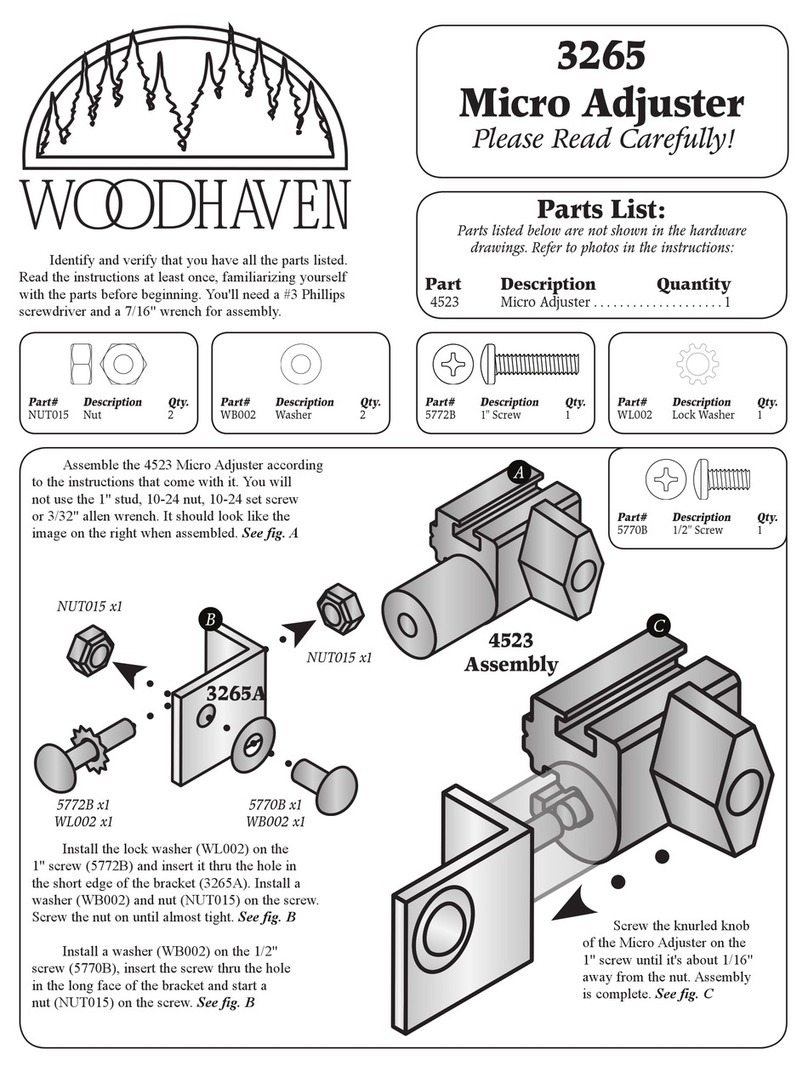

Woodhaven

Woodhaven Micro Adjuster 3265 Assembly instructions

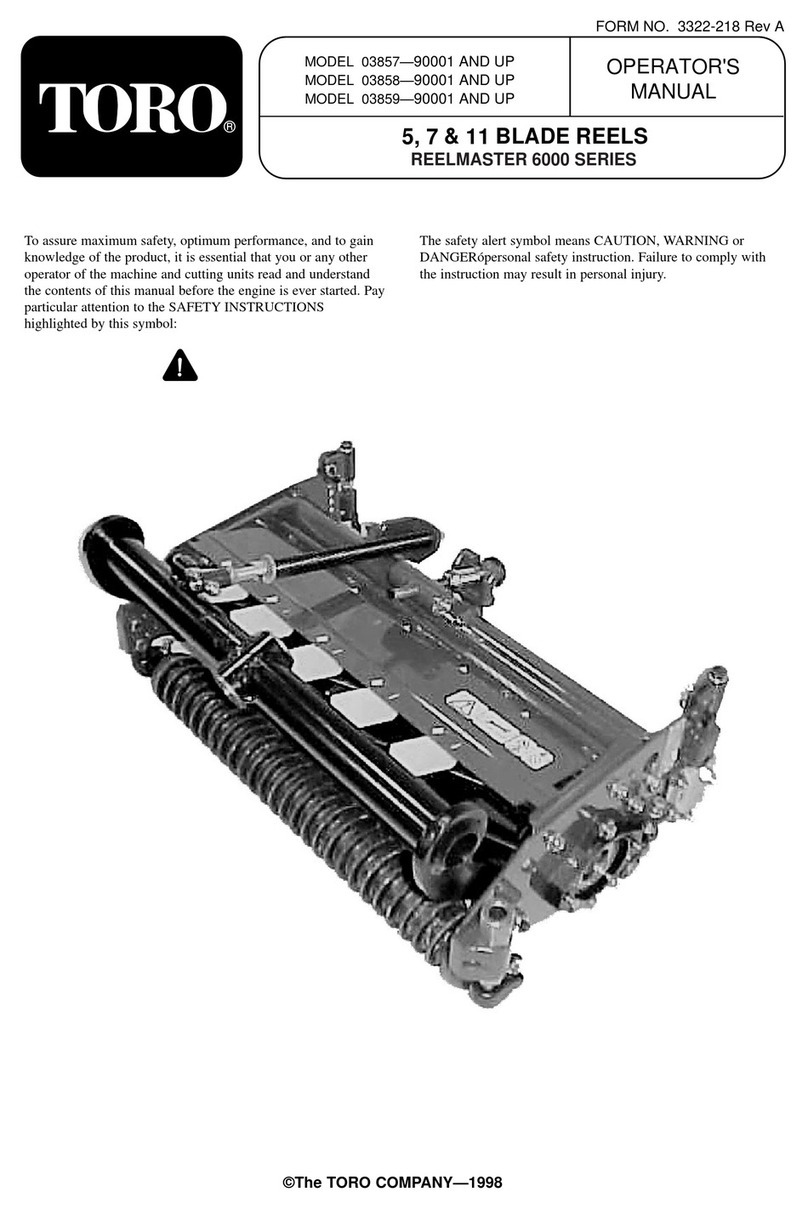

Toro

Toro 03857 Operator's manual

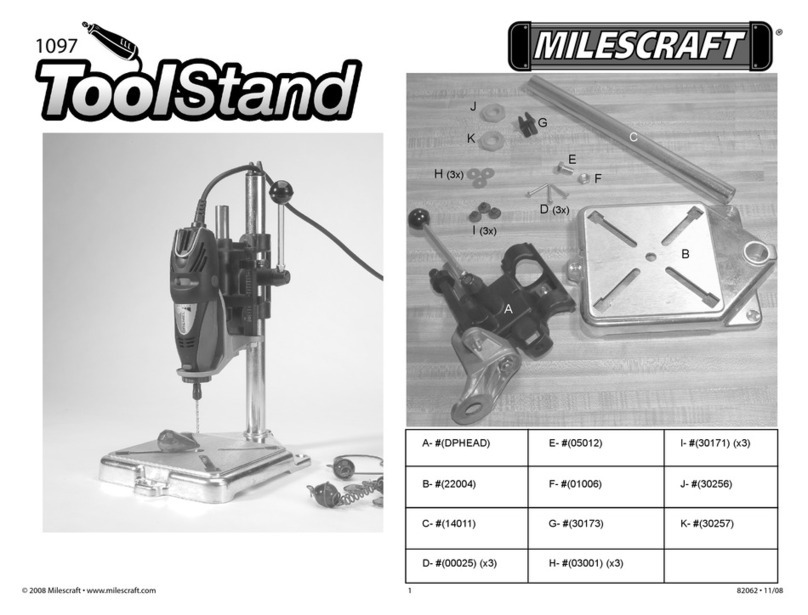

Milescraft

Milescraft ToolStand 1097 manual