PowerBoss, Inc. Copyright 2011

Armadillo 10X Sweeper PB# 4100046UM Rev.* 05/11

Page 8

WARRANTY

Revision G

Effective September 2010

PowerBoss Made Simple Industrial Limited Warranty

Minuteman International owner of PowerBoss warrants to the original purchaser/user that the product is free from defects in workmanship and materials under

normal use. PowerBoss will, at its option, repair or replace without charge, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care. Parts not manufactured by PowerBoss are covered by and subject to the

warranties and/or guarantees of their manufacturers. Please contact Minuteman International for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement parts not manufactured by PowerBoss or its designated licensees, will void all warranties expressed or

implied. A potential health hazard exits without original equipment replacement.

All warranted items become the sole property of Minuteman International or PowerBoss or its original manufacturer, whichever the case may be.

PowerBoss disclaims any implied warranty, including the warranty of merchantability and the warranty of fitness for a particular purpose. PowerBoss assumes no

responsibility for any special, incidental or consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this product. Customers outside the U.S.A.

and Canada should contact their local distributor for export warranty policies. PowerBoss is not responsible for costs or repairs performed by persons other than

those specifically authorized by PowerBoss. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or abuse of

the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the product. If a difficulty develops with this

machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights, which vary from state to state. Some states do not allow the exclusion or limitation of

special, incidental or consequential damages, or limitations on how long an implied warranty lasts, so the above exclusions and limitations may not apply to you.

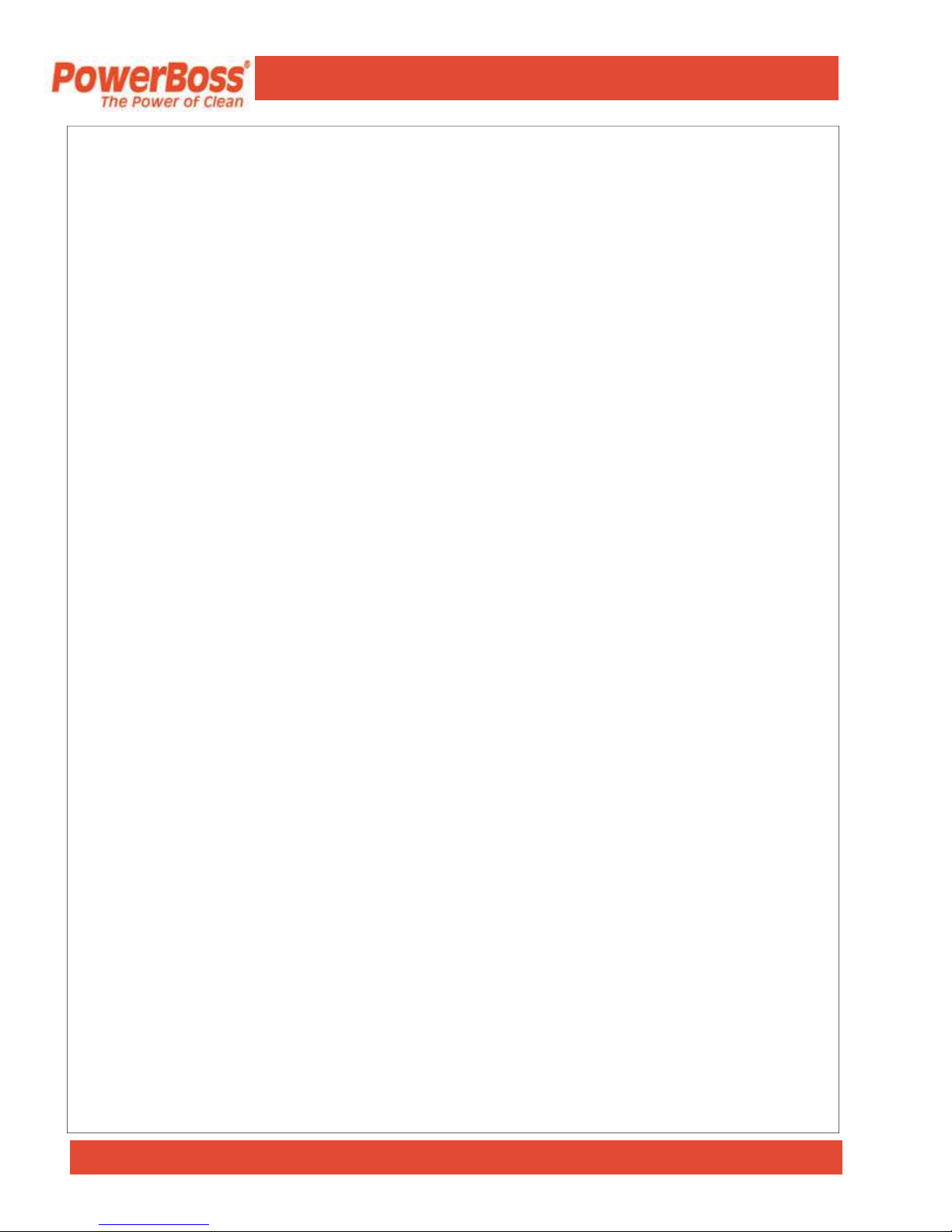

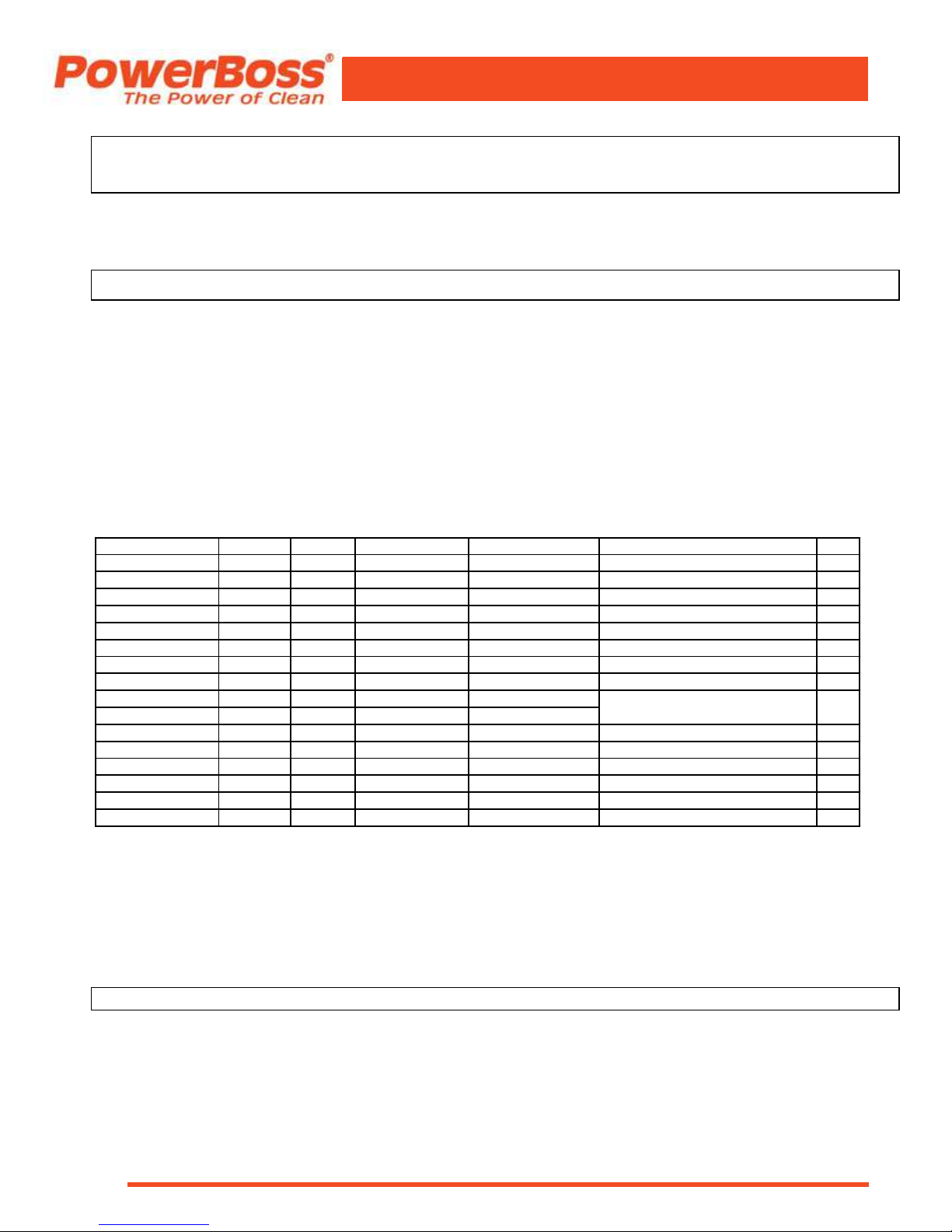

Travel* Labor Parts Engine Extended Warranty Costs

Walk behinds

Battery sweepers Ninety days One year One year N/A 2 years Parts + Labor (or 2000 Hours 2%

IC sweepers Ninety days One year One year Through manufacturer 2 years Parts + Labor (or 2000 Hours 2%

Battery scrubbers Ninety days Two years Three years N/A 3 Years Parts + Labor (or 3000 Hours) 2%

Riders

Battery scrubbers Ninety days Two years Three years/2000 hrs N/A 3 Years Parts + Labor (or 3000 Hours) 2%

IC sweeper/scrubbers Ninety days Six months Two years/2000 hrs Two years/3000 hrs** 2 years Parts + Labor (or 2000 Hours 3%

IC sweepers Ninety days Six months Four years/3000 hrs Five years/3000 hrs**

Exceptions

Apex series sweeper Ninety days One year One year/1000 hrs One year/1000 hrs** 2 years Parts + Labor (or 2000 Hours) 3%

6X sweeper Ninety days Six months Two years/2000 hrs Two years/2000 hours** 2 years Parts + Labor (or 2000 Hours) 3%

Other Products

QRE-3001A Ninety days Six months Two years/2000 hrs Two years/3000 hours** 2 years Parts + Labor (or 2000 Hours) 3%

4 Years Parts + 2 Years Labor (or 4000

Hours) 3%

Tank Bladders Eight years/ no additional labor

Polyethylene plastic tanks Ten years/ no additional labor

Batteries 0-3 months full replacement, 4-12 prorated credit

Chargers One-year replacement

Replacement parts Ninety days

*Two-hour cap

**Through engine manufacturer. See section 3 of warranty manual for engine warranty exceptions

*** Based upon dealer’s certification status

Extended Warranty MUST be signed up within 30 days of delivery to End User (Dealer has 1Year from Receiving Machine to Sign up extended Warranty)

Extended Warranty Cost is based on Invoice Price multiplied by the Percentage listed in the Extended Warranty Column

All above labor and travel reimbursed at 65 or 75% of the published shop rate.