PowerBoss C82 User manual

Other PowerBoss Blower manuals

PowerBoss

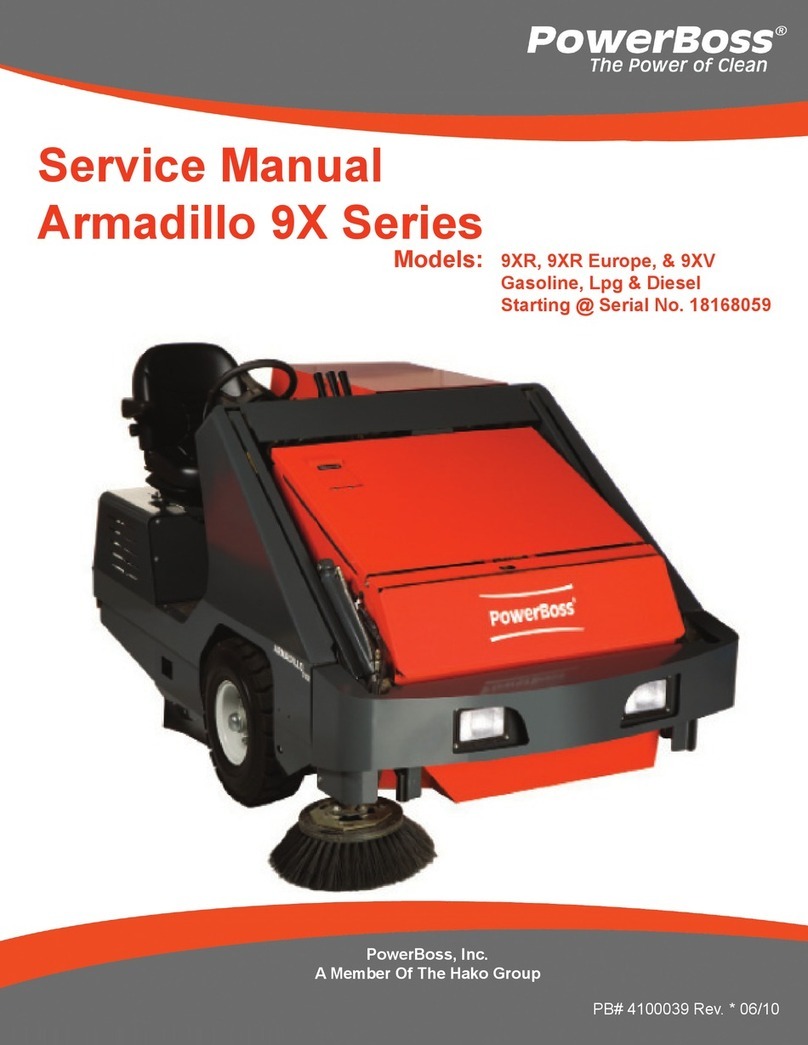

PowerBoss Armadillo 9X Series User manual

PowerBoss

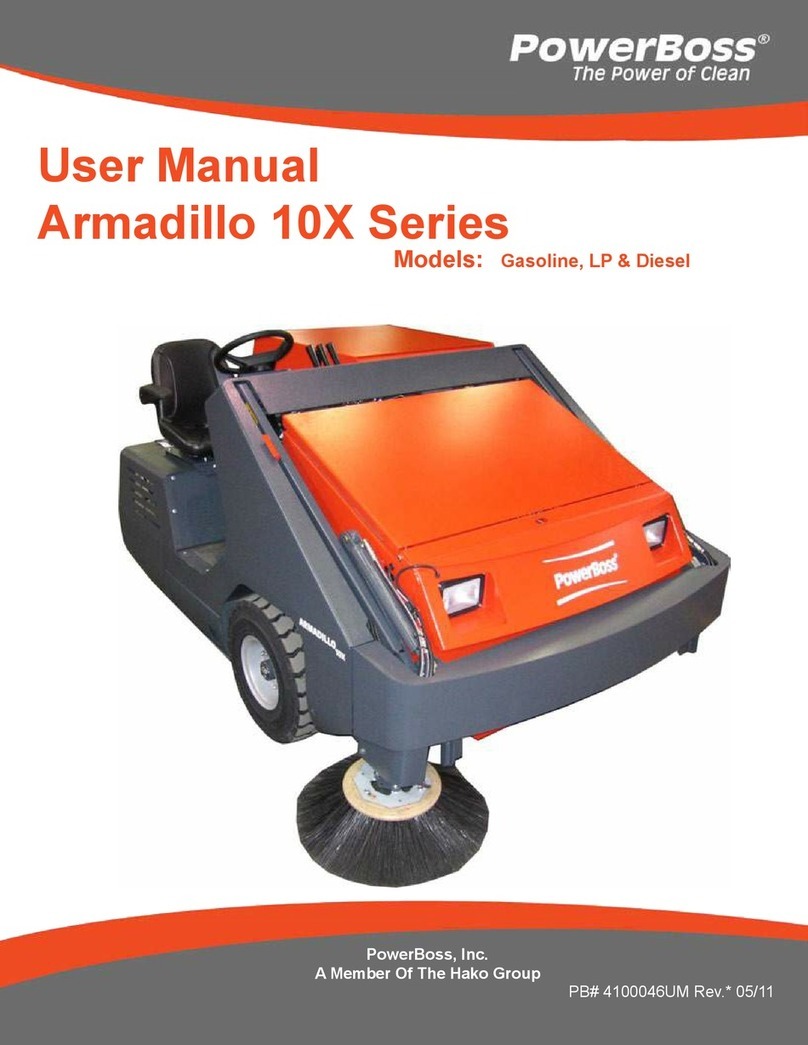

PowerBoss armadillo 10x series User manual

PowerBoss

PowerBoss 82 Europe User manual

PowerBoss

PowerBoss Armadillo SW/9XR User manual

PowerBoss

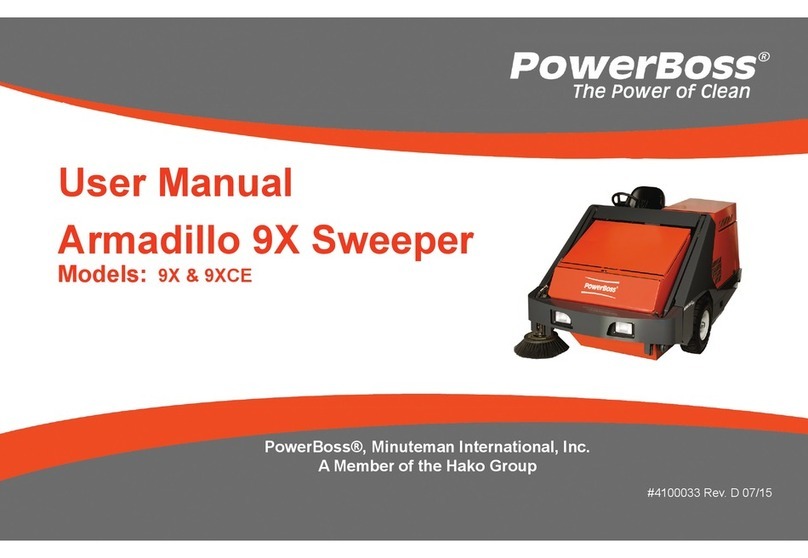

PowerBoss Armadillo 9X User manual

PowerBoss

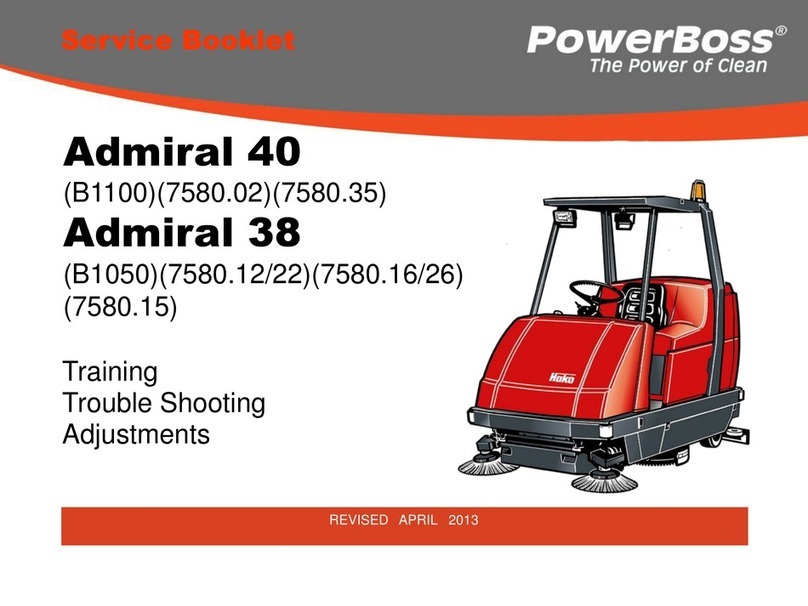

PowerBoss Admiral 38 Installation and operation manual

PowerBoss

PowerBoss PB620DSL User manual

PowerBoss

PowerBoss apex 47 g User manual

Popular Blower manuals by other brands

Lithium Earthwise

Lithium Earthwise LB20024 Operator's manual

EINHELL

EINHELL GE-CL 36 Li E Original operating instructions

EINHELL

EINHELL VENTURRO 18/210 operating instructions

Troy-Bilt

Troy-Bilt 657 Operator's manual

Weed Eater

Weed Eater VS2000BV instruction manual

KRAUSMANN

KRAUSMANN U37020-00 Operation manual