PowerBoss, Inc. Copyright 2010

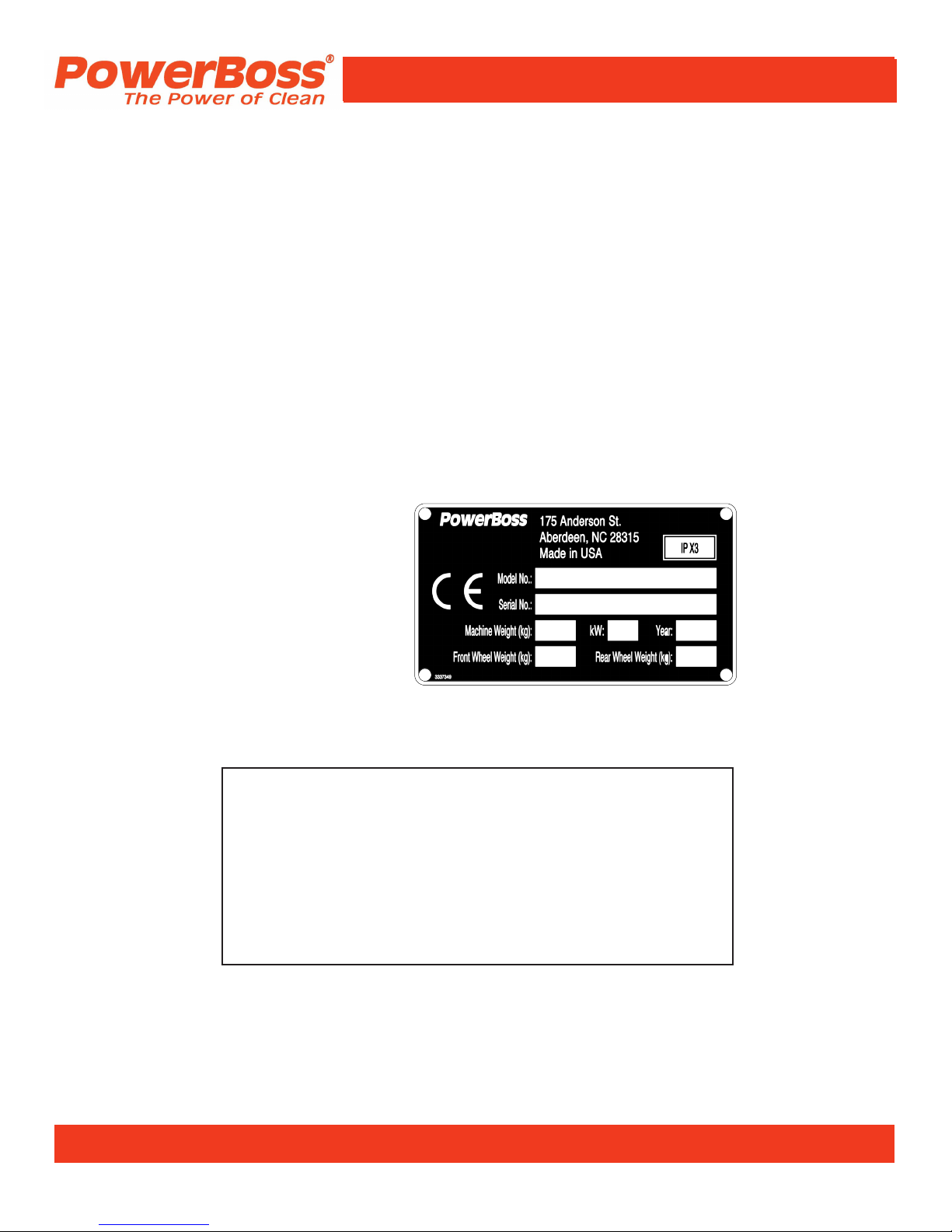

PB# 4100039 Rev.* 06/10 Armadillo 9X Series Sweeper

Page 6

TABLE OF CONTENTS

PREFACE .............................. 2

TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . 4

DIMENSIONS & WEIGHT ........................ 4

SWEEPING SYSTEM ........................... 4

CE DECLARATION OF CONFORMITY . . . . . . . 5

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . 8

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . 8

FOR SAFETY DURING OPERATION. . . . . . . . . . . . . . . 8

FOR SAFETY WHEN SERVICING OR

MAINTAINING MACHINE ........................8

SAFETY SYMBOLS ............................ 8

SAFETY DECALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BASIC POWERBOSS® SAFETY. . . . . . . . . . . . 10

TROUBLESHOOTING AND REPAIR . . . . . . . . . 12

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

GENERAL SERVICE INFORMATION . . . . . . . . . . . . . . 12

TRANSPORTING THE MACHINE. . . . . . . . . . . . . . . 12

Using a Trailer or Transport Vehicle . . . . . . . . . . . 12

Pushing the Machine . . . . . . . . . . . . . . . . . . . . . . 12

TROUBLESHOOTING .......................... 12

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . 13

TROUBLESHOOTING PROCEDURES . . . . . . . . . . . . . 16

AIR INTAKE SYSTEM ........................ 16

Check Air Filter Service Indicator . . . . . . . . . . . . . 16

Air Filter Element Removal . . . . . . . . . . . . . . . . . 16

Air Filter Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Filter Inspection . . . . . . . . . . . . . . . . . . . . . . . 16

Air Filter Installation . . . . . . . . . . . . . . . . . . . . . . . 16

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . 17

Battery Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . 17

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . 17

Circuit Breakers .......................... 17

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

COOLANT SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . 18

Blowing Out Radiator Fins . . . . . . . . . . . . . . . . . . 18

Reverse Flow Flushing. . . . . . . . . . . . . . . . . . . . . 18

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . 18

LUBRICATION POINTS . . . . . . . . . . . . . . . . . . . . . . 19

Rear Drive Rotary Actuator . . . . . . . . . . . . . . . . . 19

Engine Mount Pivot . . . . . . . . . . . . . . . . . . . . . . . 19

Latches & Hinges . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hopper Lift Arm Mounts . . . . . . . . . . . . . . . . . . . . 20

HYDRAULICS SYSTEM . . . . . . . . . . . . . . . . . . . . . . 21

Filling The Fluid Reservoir . . . . . . . . . . . . . . . . . . 21

Hydraulic Fluid Viscosity Specications . . . . . 21

Maintaining Hydraulic Oil Cooler Efciency . . . . . 21

Changing The Hydraulic Fluid . . . . . . . . . . . . . . . 21

Changing The Hydraulic Fluid Filter. . . . . . . . . . . 21

ADJUSTING THE DIRECTIONAL CONTROL

RETURN SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HOPPER ..................................22

High Dump Hopper Removal . . . . . . . . . . . . . . . . 22

High Dump Hopper Replacement . . . . . . . . . . . . 22

Filter Removal ........................... 23

Filter Cleaning ........................... 23

Filter Replacement ........................ 23

WEEP COMPONENTS .......................24

Broom Door Flap Inspection . . . . . . . . . . . . . . . . 24

Broom Door Flap Replacement and

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Main Broom Adjustment . . . . . . . . . . . . . . . . . . . . 24

Main Broom Height Adjustment . . . . . . . . . . . . . . 24

Main Broom Taper Adjustment . . . . . . . . . . . . . . . 25

Main Broom Replacement . . . . . . . . . . . . . . . . . . 25

Side Broom Angle Adjustment . . . . . . . . . . . . . . . 26

Side Broom Height (Wear) Adjustment . . . . . . . . 26

To Adjust The Side Broom Height

For a 9XR or 9XV model: . . . . . . . . . . . . . . . . 26

To Adjust The Side Broom Height

For a 9XR Europe model: . . . . . . . . . . . . . . . . 26

Side Broom Lift Cable Adjustment . . . . . . . . . . . . 26

Side Broom Replacement . . . . . . . . . . . . . . . . . . 26

Floor Clearance and Dump Angle Adjustment 27

Vacuum Gasket Mount Adjustment . . . . . . . . . . . 29

Flap Replacement ........................ 29

Frame Seal Replacement . . . . . . . . . . . . . . . . . . 29

Front Frame Seal . . . . . . . . . . . . . . . . . . . . . . 29

Side Frame Seal. . . . . . . . . . . . . . . . . . . . . . . 29

TABLE OF CONTENTS