2PowerBox-Systems − World Leaders in RC Power Supply Systems

Dear customer,

We are delighted that you have decided to purchase this PowerBox accessory from

our range.

We hope you have many hours of pleasure and great success with your PowerBUS

devices.

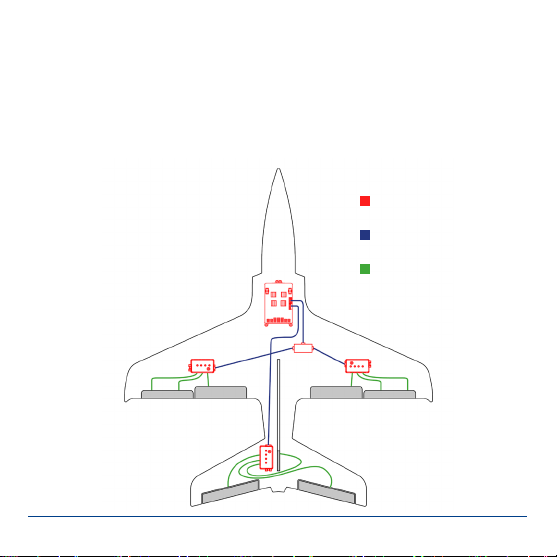

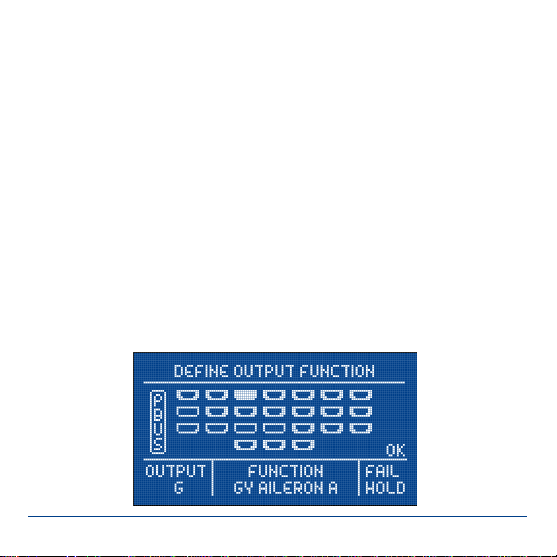

The PowerBUS is the basis of a completely new method of wiring servos. The

PowerBUS consists of a three-core cable which supplies current and signal to the

servos connected to it. At rst glance this is nothing unusual, but the big difference

lies in the signal wire. When conventional servo signals are transferred, the signal

wire always carries the information for one individual servo only - this is a PWM

(Pulse Width Modulated) signal. In a servo bus system the signal wire carries posi-

tional information for multiple servos in digital form. The information for individual

servos includes address data, and since each servo is assigned its own individual

address, it can read out „its“ information from the data stream, and convert it into a

movement of the control surface. PowerBus to PWM adapters can also be emplo-

yed to enable the use of servos without their own decoder; in this case the adapter

carries out the decoding.

The advantage of this arrangement is obvious: all you need is one three-core lead

in order to supply the essential information to several servos. The wiring is much

simpler, and there is also a signicant weight saving.

However, until now there has always been one disadvantage to bus systems: a

short-circuit in one servo causes the bus lead to be blocked, and all the servos

connected to it stop working. Here at PowerBox-Systems we have completely eli-

minated this former drawback:

The servo distributors which we have developed are protected against short-cir-

cuits in the power supply lines and the signal line! This means that, if one output is