Installation Instructions

PowerFlex®700L Frame 3A and 3B Input Filter

Precharge Resistor Kit (20L-RESPRE-A1)

Where This Kit Is Used This kit can only be used with PowerFlex 700L Frame 3A and 3B complete

drives. It is used to increase the precharge power capacity of the drive. This

kit may be required when powering another drive from the DC bus of a

Frame 3A or 3B complete drive. Only one kit per drive is permitted. See the

tables below for comparisons of maximum DC bus capacitance.

!

ATTENTION: To avoid an electric shock hazard, ensure that all

power to the complete drive cabinet has been removed before

performing any steps of these instructions.

!

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has completely discharged before

performing any work on the complete drive cabinet. After

removing power, wait 5 minutes for the power module bus

capacitors to discharge. Remove the lower front cover of the

power module. Measure the DC bus voltage at the DC+

TESTPOINT and DC- TESTPOINT sockets on the front of the

power module. The voltage must be zero.

!

ATTENTION: HOT surfaces can cause severe burns. Do not

touch the heatsink surface during operation of the power module.

After disconnecting power allow time for cooling.

!

ATTENTION: The complete drive cabinet contains ESD

(Electrostatic Discharge) sensitive parts and assemblies. Static

control precautions are required when installing, testing,

servicing or repairing the complete drive. Component damage

may result if ESD control procedures are not followed. If you are

not familiar with static control procedures, refer to Allen-Bradley

publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

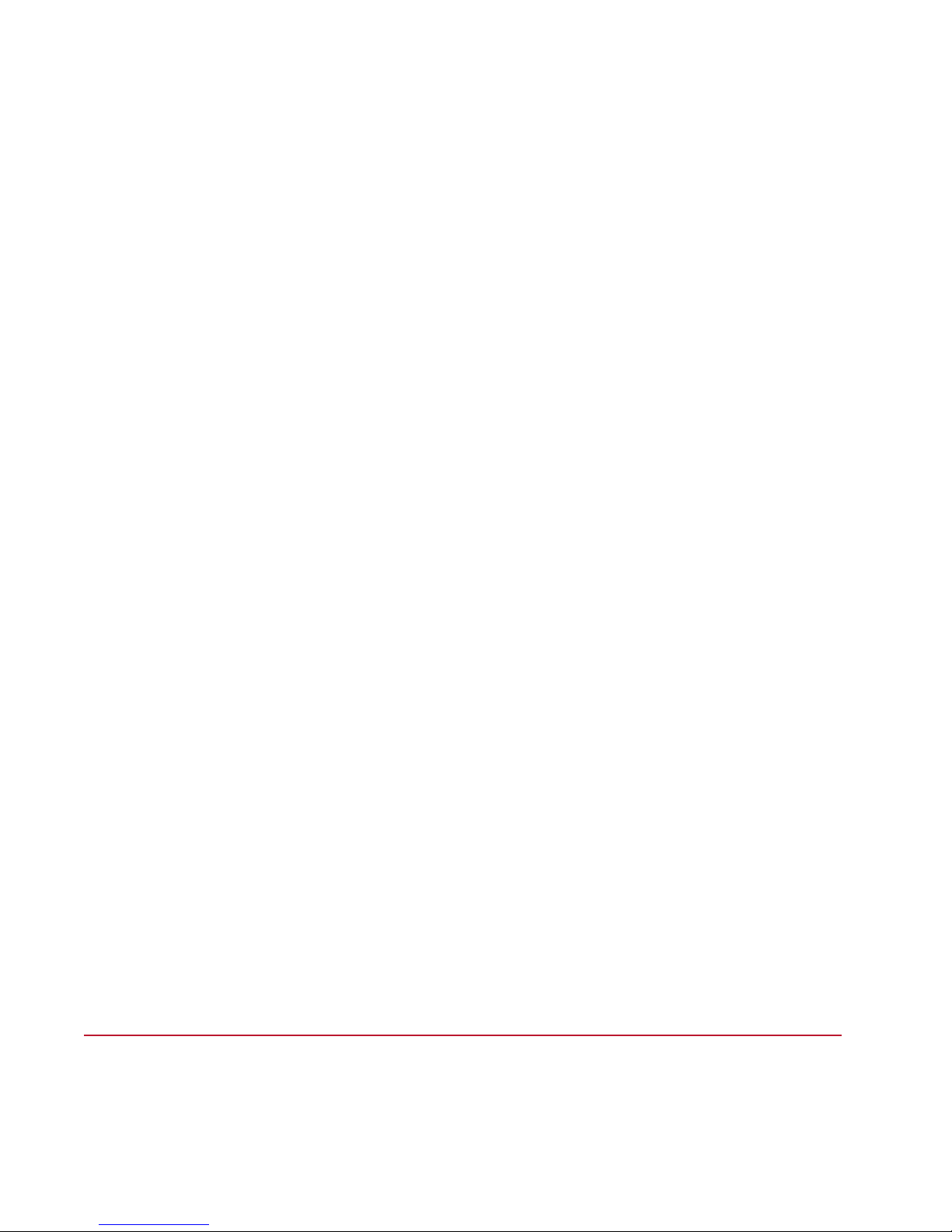

Table A Maximum DC Bus Capacitance with Existing Precharge

Input Voltage 400V AC 480V AC 600V AC 690V AC

Frame Size 3A 3B 3A 3B 3A 3B 3A 3B

Drive’s Internal DC Bus Capacitance (µF) 16,200 32,400 16,200 32,400 10,800 21,600 10,800 21,600

Maximum External DC Bus Capacitance (µF) 19,150 38,301 8,349 16,698 4,911 9,823 1,080 2,160

Maximum Total DC Bus Capacitance (µF) 35,350 70,701 24,549 49,098 15,711 31,423 11,880 23,760

Table B Maximum DC Bus Capacitance with Precharge Kit Plus Existing Precharge

Input Voltage 400V AC 480V AC 600V AC 690V AC

Frame Size 3A 3B 3A 3B 3A 3B 3A 3B

Drive’s Internal DC Bus Capacitance (µF) 16,200 32,400 16,200 32,400 10,800 21,600 10,800 21,600

Maximum External DC Bus Capacitance (µF) 89,851 109,002 57,447 65,796 36,334 41,245 24,840 25,920

Maximum Total DC Bus Capacitance (µF) 106,051 141,402 73,647 98,196 47,134 62,845 35,640 47,520