2

with combustion engines in enclosed areas, tunnels, adits and deep

trenches.

12.Floor saws must be used in connection with water (wet cutting) in

order to avoid the formation of fine dusts which are injurious to your

health. Make sure that the water supply is sufficient during wet cutting.

13.Don not operates this machine in areas where explosions may occur.

14.When working in the vicinity of inflammable materials, always have

water or a fire extinguisher handy. Take extra special care when there

is danger of explosive fumes.

15.During operation always wear goggles and long leather gloves. Also

wear tight fitting clothes, firm high boots to protect against sparks and

a helmet.

16.No not twist, thrust, knock or drop the machine during operation,

otherwise the cutting blade will be dam aged. The cutting blade is only

designed for radial load.

17.Fix protective hood in lowest position before starting engine.

18.No persons are to be in the vicinity of the floor saw, in front of the floor

saw during operation.

19.The operator has to stop the blade before starting a new cut.

20.Work calmly and cautiously so as not to endanger others.

Safety checks

1. Floor saws may only be operated with all safety devices installed.

2. Before starting operation, the operator has to check that all control and

safety devices function properly.

3. Daily, before starting operation makes sure that: the cutting blade is in

proper condition.

4. The cutting blade fits tightly.

5. In case of defects of the safety devices or other defects reducing the

operational safety of the floor saw, the supervisor has to be informed

immediately.

6. In case of defects jeopardizing the operational safety of the saw, the

machine has to be switched off immediately.

Maintenance

1. Only use original spare parts. Modifications to this machine including

the adjustment of the maximum speed set by the manufacturer. In

case of nonobservance all liabilities shall be refused.

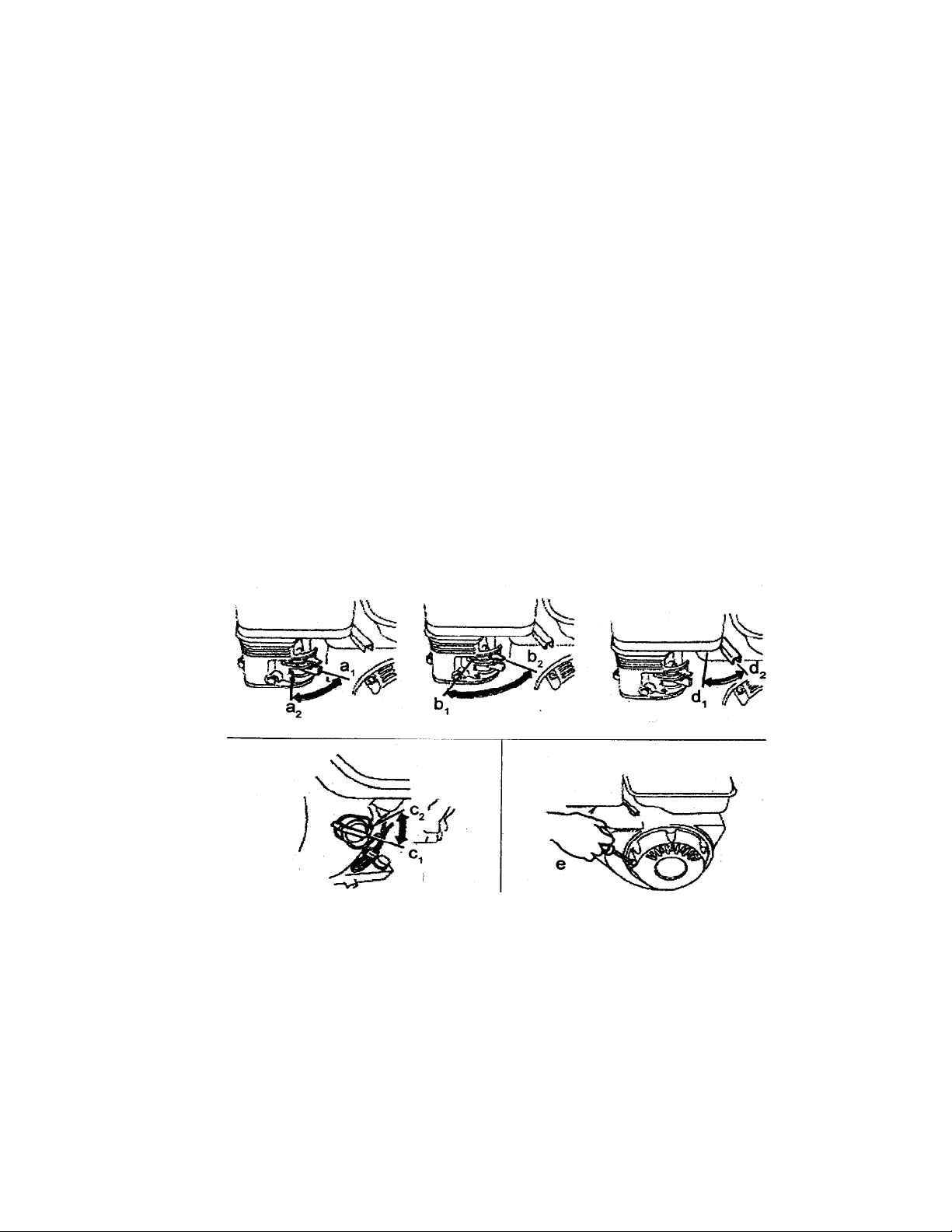

2. Switch off the motor and remove spark plug cap from spark plug

before carrying out maintenance jobs to avoid unintentional operation

of the machine. Deviations from this are only allowed if the

maintenance jobs require a running motor.

3. Caution when checking the ignition system. The electronic ignition

system produces a very high voltage.

4. as soon as maintenance and repair jobs have been completed all

safety devices have to be reinstalled