www.dumbwaiters.com

1-800-409-5438

1. Anyone planning to use this dumbwaiter should read the Owner’s Manual prior to operating. If you do not

have an Owner’s Manual, please visit our website to download a copy or call us to have one sent to you.

2. DO NOT allow children to use the dumbwaiter without adult supervision!

3. DO NOT operate dumbwaiter if you are under the influence of any drugs, alcohol or medication

that could affect your ability to use the dumbwaiter properly.

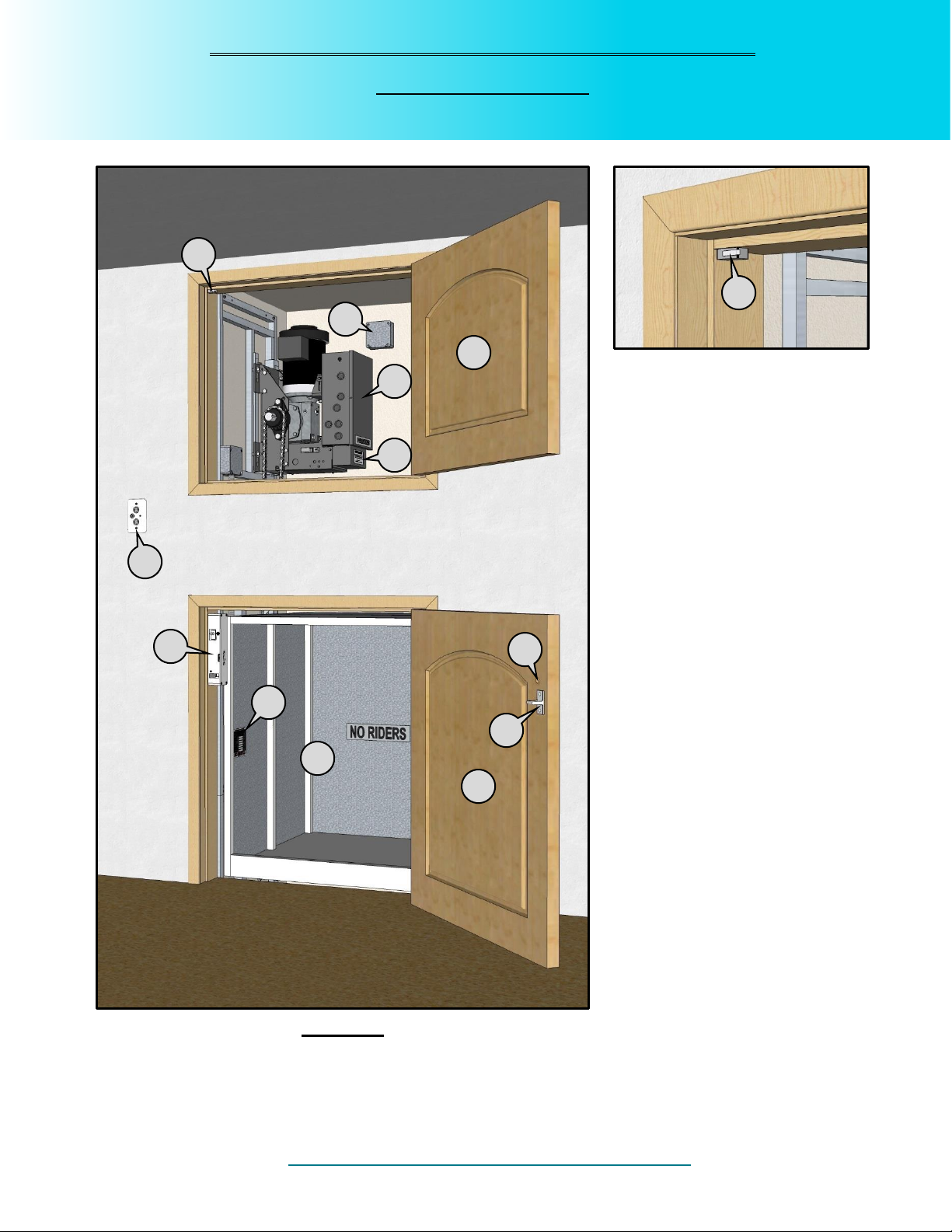

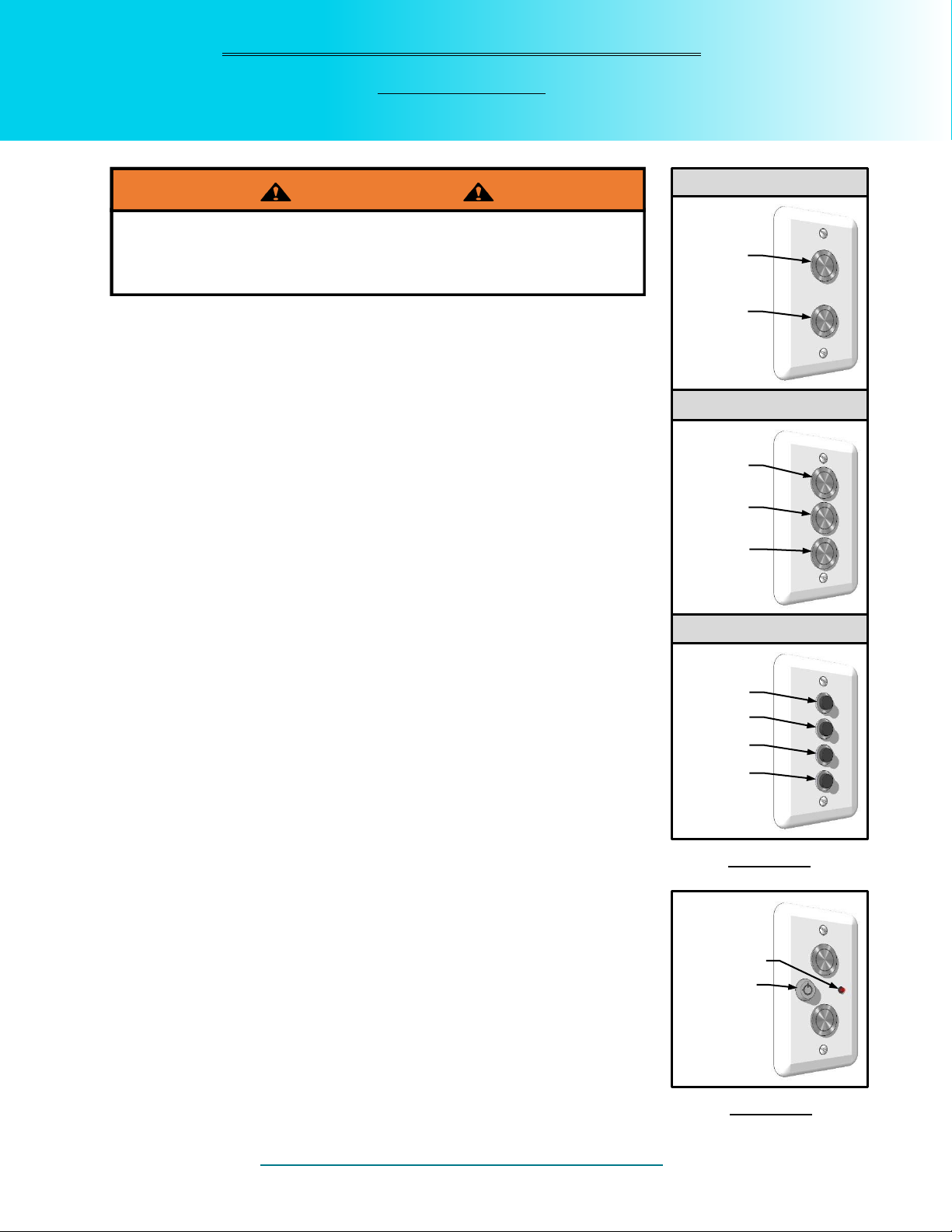

4. NEVER OPERATE DUMBWAITER if door safety switches are not working properly. Every

dumbwaiter includes door safety switches, which prevent the dumbwaiter from operating if any door is not

properly closed. The switches will also stop the dumbwaiter if any door is opened while the dumbwaiter is

in operation. If your door safety switches are not working properly, immediately unplug the dumbwaiter

and call Powerlift Dumbwaiters, Inc. to request replacement door safety switches, free of charge for the

life of the dumbwaiter. Ensure that the switches are replaced by a qualified technician.

5. NEVER OPERATE DUMBWAITER if door locks are not working properly. Every dumbwaiter includes

door locks, which prevent the doors from being opened while the dumbwaiter is in operation. If your door

locks are not working properly, immediately unplug the dumbwaiter and call Powerlift Dumbwaiters, Inc. to

request replacement door locks. Ensure that the door locks are replaced by a qualified technician.

6. NEVER USE THE DUMBWAITER if it is not operating properly. Call your service technician,

installation contractor, or Powerlift Dumbwaiters, Inc.

7. NEVER USE THE DUMBWAITER when smoke and/or fire is present.

8. DO NOT REMOVE, BYPASS, OR ALTER any switches, controls, and/or restraining devices. These

are mandated by national and local codes and safety regulations. Any tampering will void your warranty

and could result in serious injury and/or death.

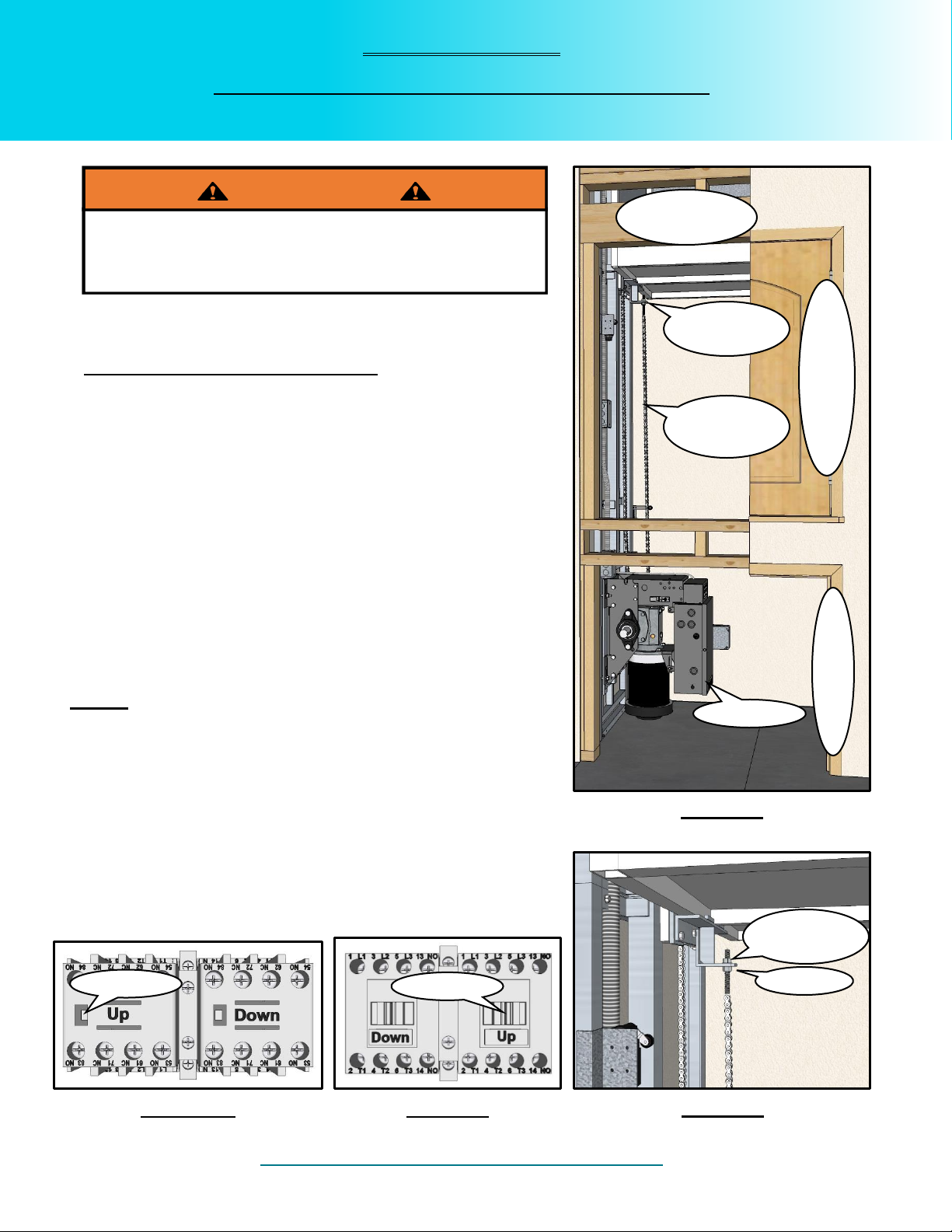

9. NEVER EXTEND YOUR HANDS, ARMS, LEGS, FEET, HEAD, OR BODY INTO OPEN HOISTWAY!

Doing so could cause serious injury and/or death! Never extend foreign objects of any kind into open

hoistway. Doing so can cause damage to your dumbwaiter and/or serious injury to you!

10. NO RIDING IN DUMBWAITER CAR! Your dumbwaiter car is not intended to transport people and/or

animals. Doing so could cause serious injury and/or death!

11. NEVER OVERLOAD YOUR DUMBWAITER CAR! Your dumbwaiter is rated for a certain capacity.

Please see data plate in car.

12. Your dumbwaiter is not designed for continuous operation. Too many “starts” and “stops” could overheat

the motor and trip the breaker.

13. The dumbwaiter should be on a dedicated circuit. Too many appliances operating from the same power

source reduces the available amperage and may cause the dumbwaiter to malfunction. If your

dumbwaiter does not seem to be operating at its optimum, stop using it until it can be inspected by a

qualified technician.

14. To prevent unauthorized use, a keyed on/off switch can be obtained from Powerlift Dumbwaiters, Inc.

15. Observe, read, and obey the warning labels, tags, and symbols, as they are provided by the manufacturer

for your safety and protection.

16. DO NOT ATTEMPT TO REPAIR the dumbwaiter yourself. Immediately stop use, disconnect power

supply and call Powerlift Dumbwaiters, Inc. to determine whether you need to contact your service

technician or installation contractor.

17. Check your local fire code. Swing Hoistway doors may be required to be fire rated and have self

closing hinges.

Important Information You Should Know

Please Read