3

SERVICING OF A DOUBLE-INSULATED

APPLIANCE

In a double-insulated

product, two systems of

insulation are provided

instead of grounding. No

grounding means are

provided for a double-insulated product, nor

should grounding means be added to the

product. Servicing a double-insulated product

requires extreme care and knowledge of the

system, and should be done only by qualified

service personnel. Replacement parts for a

double-insulated product must be identical to

the original parts. A double-insulated product

is marked with the words “Double Insulation”

or “Double Insulated”. Product may also be

marked with symbol shown in Figure 1.

Do not use pressure that

exceeds the operating pressure of any of

the parts (hoses, fittings, etc.) in the

pressurized system. Ensure all equipment

and accessories are rated to withstand the

maximum working pressure of the unit.

Explosion hazard.

•NEVER spray flammable liquids or use

pressure washer in areas containing

combustible dust, liquids or vapors.

•Never operate this machine in a closed

building or in or near an explosive

environment.

Do not spray electrical

apparatus and wiring.

•Never disconnect the high pressure

discharge hose from the machine while

the system is pressurized. To depressurize

machine, turn power and water supply off,

then press gun trigger 2-3 times.

•Never permanently engage the trigger

mechanism on the gun.

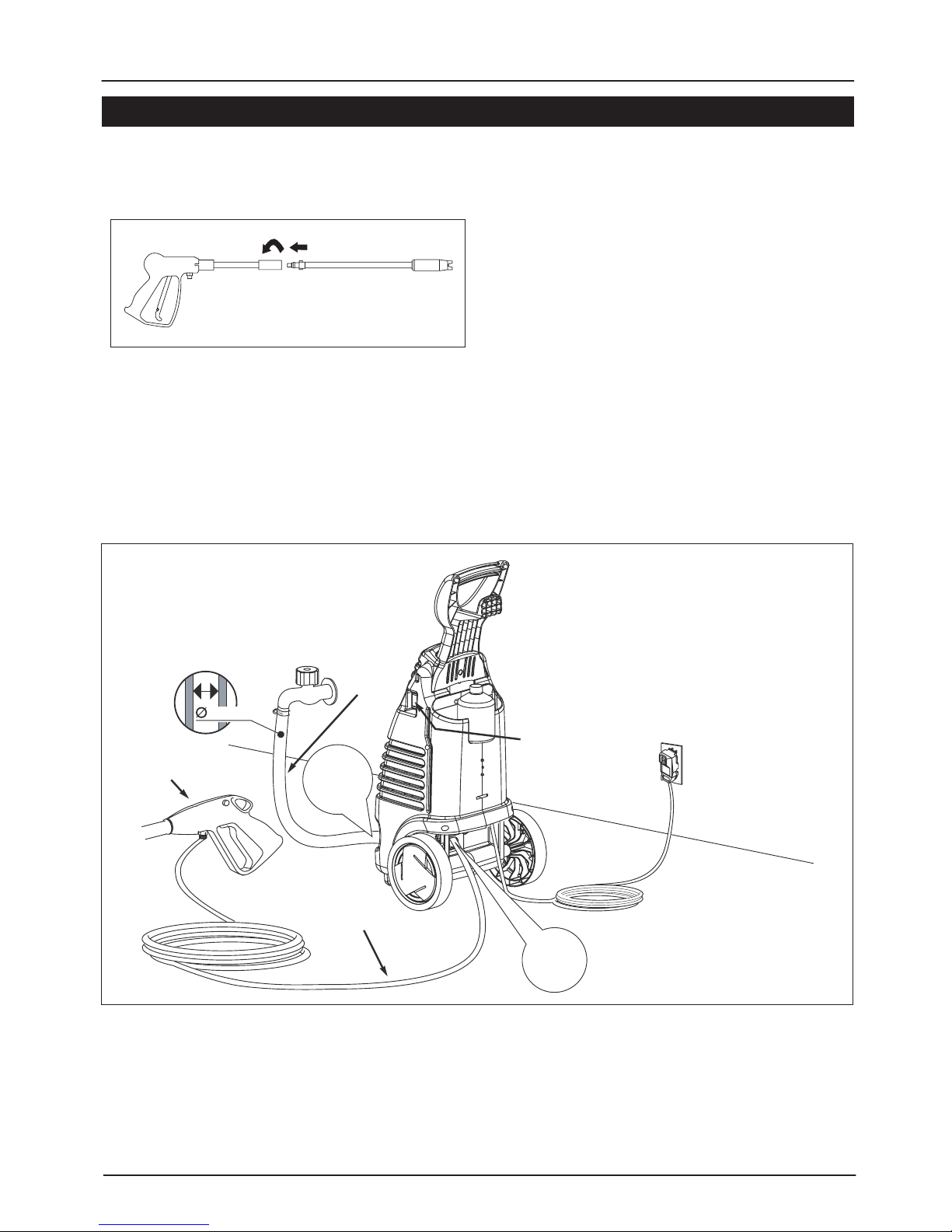

•Never operate the machine without all

components properly connected to the

machine (handle, gun/wand assembly,

nozzle, etc.).

Equipment damage.

•ALWAYS turn water supply “ON” before

turning pressure washer “ON”. Running

pump dry causes serious damage.

•Do not operate the pressure washer with

the inlet water screen removed. Keep

screen clear of debris and sediment.

•NEVER operate pressure washer with

broken or missing parts. Check equipment

regularly and repair or replace worn or

damaged parts immediately.

•Use only the nozzle supplied with this

machine.

•Never leave the wand unattended while

the machine is running.

•Never attempt to alter factory settings.

Altering factory settings could damage the

unit and will void the warranty.

•Always hold gun and wand firmly when

starting and operating the machine.

•NEVER allow the unit to run with the trigger

released (off) for more than one (1) minute.

Resulting heat buildup will damage pump.

•Pressure washer is not meant to pump hot

water. NEVER connect it to a hot water

supply as it will significantly reduce the life

of the pump.

•NEVER store the pressure washer

outdoors or where it could freeze. The

pump will be seriously damaged.

•Release trigger when changing from high

to low pressure modes. Failure to do so

could result in damage.

Keep hose away from sharp

objects. Bursting hoses may cause injury.

Examine hoses regularly and replace if

damaged. Do not attempt to mend a

damaged hose.

EXTENSION CORDS

If using an extension cord,

use only grounded, three wire extension

cords that are in good condition.

Use of an extension cord is not recommended.

If one is used, then use only wire sizes and

lengths shown in chart below.

Safety and Warning Information (Continued)

Pressure Washer

!WARNING

!CAUTION

!WARNING

!WARNING

!WARNING

!WARNING

Figure 1 - Double

Insulated symbol

!DANGER