Powermate Aluminum LE Series User manual

T20-030.07 For Serial Numbers 34000 and higher. PN 013900 Rev.D2

PN 339570 Rev.D2

Eng. 12/ 12/ 12

TABLE OF CONTENTS

PowerMate

®

Operation Manua

l

Section 1 - General

Warning Page............................................................................

PowerMate Description.............................................................

Delivery and Warranty Registration..........................................

Operator Training Guideline......................................................

Section 2 - Safety

Hazard Graphical Symbols........................................................

Mandatory Safety Decal Placement...........................................

Safety Precautions....................................................................

Safety Inspection......................................................................

Environment Safety.....................................................................

Loading Safety..........................................................................

Safety in Motion........................................................................

Battery Safety...........................................................................

Battery Charging Safety...........................................................

Section 3 - Instructions

LE-Series PowerMate Charging Instruction..............................

Load Recommendation Instructions........................................

Load Recommendation Chart.................................................

Loading onto a Vehicle or Loading Dock..................................

Unloading from a Vehicle or Loading Dock...............................

Taking a Load Up a Stairs.........................................................

Taking a Load Down a Stairs....................................................

Storage Procedure and Battery Care.........................................

Section 4 - LE-Series PowerMate Component Identification

LE-Series Replacement Component Drawing...........................

LE-Series Replacement Component List.................................

LE-Series with Battery Switch Component Drawing.................

LE-Series with Battery Switch Component List.......................

Screw Assembly L-1, LE-1........................................................

Screw Assembly L-2, LE-2........................................................

Screw Assembly LE-2 Carriage.................................................

Brake Assembly Kit..................................................................

Bearing Override Kit.................................................................

Section 5 - Maintenance

Maintenance After Every Year of Operation.............................

Procedure for Repairing Drive Screw Assembly......................

Override Bearing Assembly...................................................

Drive Screw Removal and Installation.....................................

Procedure to Reassemble Machine.......................................

Ballnut Removal and Replacement........................................

Installation of Sealed Batteries..............................................

Bottom Rubber Guard Replacement........................................

Switch/Charge Plug Replacement............................................

Strapbar Assembly for L-Series..............................................

Replacement Strap Installation.................................................

LE-Series Wiring Diagram.......................................................

LE-Series Wiring Diagram for Battery Switch............................

Section 6 - Specifications

LE-Series Specifications............................................................

Solidstate Controller.................................................................

Battery Specifications...............................................................

Section 7 - Accessory Installations

Battery Charger Remote Installation.........................................

PowerMate RT Cart Attachment Instruction...........................

Section 8 - Accessories

Accessories..............................................................................

Warranty...................................................................................

Declaration of Conformity............................................................

Daily Maintenance Schedule....................................................

1.01

1.02

1.02

1.03

2.01

2.02

2.04

2.05

2.05

2.06

2.06

2.07

2.08

3.01

3.02

3.03

3.04

3.05

3.06

3.07

3.08

4.01

4.02

4.03

4.04

4.05

4.06

4.07

4.08

4.09

5.01

5.03

5.04

5.04

5.05

5.06

5.07

5.08

5.09

5.10

5.10

5.11

5.12

6.01

6.02

6.03

7.01

7.02

8.01

8.03

8.04

8.05

PN 013020D2

Eng. 12/ 12/ 12

i

PowerMate

®

Operation Manua

l

WARNING

Failure to obey the Instructions and Safety

rules in this manual could result in death or

serious injury.

Read the Operating Manual completely.

Only competent, trained operators may use

this equipment.

Training is essential to understanding all

the features and capabilities of your

PowerMate, and ensure good safe work

practices.

Training courses are available through

L P INTERNATIONAL INC., please call

1-800-697-6283

PN 013100 Rev.D2

Eng. 12/ 12/ 12

1.01

Manufactured By:

L P INTERNATIONAL INC.

P.O. Box 696, 151 Savannah Oaks Drive

Brantford, Ontario, Canada N3T 5P9

TEL: (519) 759-3292 FAX: (519) 759-3298

1-800-697-6283

PowerMate

®

Operation Manua

l

PowerMate

®

MODEL L-SERIES

DELIVERY AND WARRANTY REGISTRATION

When your PowerMate

®

Motorized Stairclimber is delivered, unpack and inspect

the unit for damage or shortage of parts. If required, make note of any deficiencies on

the Delivery Acceptance Form. Registering your unit for the Warranty can be done

online at www.powermate.info. Click on Service, fill in the required fields under

Warranty and click Send Now.

Standard Equipment

2 Strapbars

Battery Charger

Wheel Brakes

Optional Equipment

Barrel Attachment

Extended Depth or Width Toe Plate

Hot Water Tank Attachment

Cylinder Attachment

WARNING The use of this equipment with any options other than

those specified in this manual may create a hazard.

The PowerMate

®

Model LE-1 is a motorized electric hand truck used for

the safe movement of heavy and awkward loads. It can move loads up and

down stairs, on and off of vehicles or loading docks and across flat surfaces.

The design takes advantage of the principle of leverage. All of the lifting of

the load is performed by the equipment.

The PowerMate®LE-1 has been designed specifically to move loads with

a very low center of gravity location. The feature of a moveable load carriage

enable the load to be kept in a controlled well-balanced position at all times.

PN 013910 Rev.D2

Eng. 12/ 12/ 12

1.02

The PowerMate

®

LE-Series Model has been tested and inspected by both the

manufacturer and the distributor to ensure the quality of manufacture and

operation. The equipment is delivered by the distributor, fully assembled and

ready for use.

The PowerMate®LE-Series Model is unique in its operation and is used to move

heavy and awkward loads. For these reasons, classroom and hands-on training

in safe and efficient operating procedures for all operators is absolutely

necessary. During the training, the operator should

LEARN HOW TO DO THE FOLLOWING:

General Use the Load Recommendation Instructions

Follow the General Safety Rules

Strapbars Adjust the location of the strapbars.

Adjust, tighten and release the straps.

Stow loose strapping when not in use.

Flat Surface Raise the wheels to incline the load back.

Reposition the load in balance over the wheels.

Move over obstacles on the floor.

Bring the load back to an upright position.

Stairclimbing Position the wheels and heelplate on a stair.

Climb up and down stairs.

Rest safely in a balanced position on stairs.

Pivot on tight landings.

Lifting Load and unload onto vehicles or loading docks.

Load and unload small vans.

Load Elevation Place loads in elevated locations.

Remove loads from elevated locations.

Two Operators Work as a team with another operator.

PowerMate

®

Operation Manua

l

PN 013190 Rev.D2

Eng. 12/ 12/ 12

OPERATOR TRAINING

1.03

The PowerMate

®

products use graphical symbols, safety colours, and signal words

throughout the Operators Manual and on the units themselves. Operators using the

PowerMate®must familiarize themselves with these symbols.

NOTICE: The signal word to address practices not

related to personal injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death

or serious injury.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Safety Alert Symbol: This symbol indicates a potential personal

injury hazard. Safety information following

this symbol must be followed to avoid

possible injury or death.

HAZARD GRAPHICAL SYMBOLS

SAFETY LABEL MAINTENANCE

Safety of the operator and surrounding environment must be considered at all times.

To that end, safety labelling on the PowerMate®must be maintained to provide

legible safety information. Clean the labels with soap and water. Do not use solvent-

based cleaners because they may damage the labels. Replace damaged or missing

labels. Replacement labels may be purchased from L P International Inc. Customer

Service Phone number 1-800-697-Mate.

PowerMate

®

Operation Manua

l

2.01 PN 013090 Rev.D2

Eng. 12/ 12/ 12

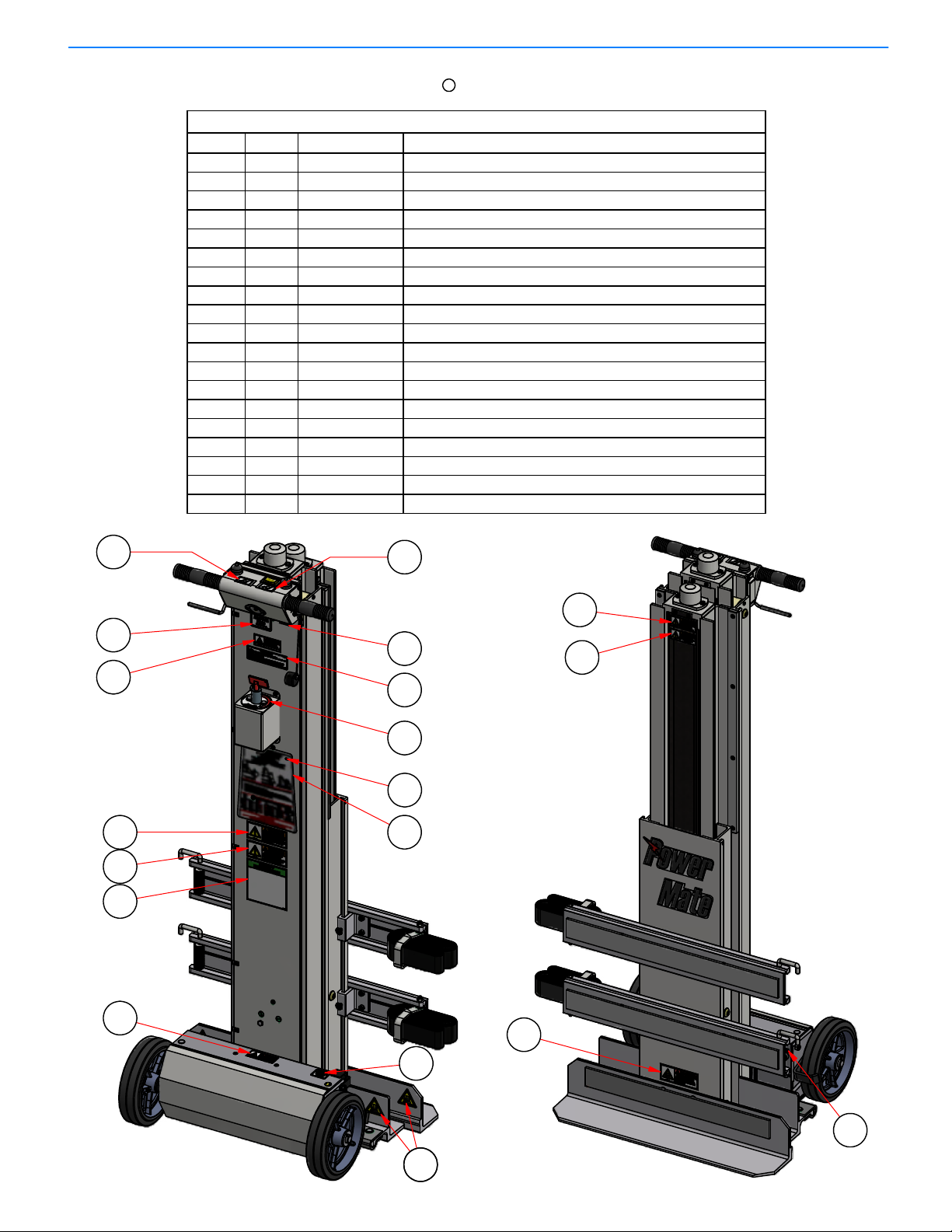

MANDATORY SAFETY LABEL PLACEMENT

Standard LE-1/LE-2 PowerMate Units

PowerMate

®

Operation Manua

l

PARTS LIST

DESCRIPTION

PART No.

QTY

ITEM

DECAL LS DISTRIBUTED BY LP055840C

11

DECAL MAINTENANCE LE-1/LE-2

065870/8012

DECAL LS LOAD DOWN/UP

05583013

DECAL LS ON/OFF055850A1

4

DECAL LS CHARGER PLUG

055820B1

5

DANGER DECAL - EXPLOSIVE ENVIRONMENT057040A16

DANGER DECAL - CRUSH HAZARD FOOT

057020A1

7

DANGER DECAL - ELECTRICAL SHOCK

057030A18

WARNING DECAL - KEEP OFF057050A19

WARNING DECAL - CRUSH HAZARD FOOT PICTOGRAM

057140A410

WARNING DECAL - SCREW GUARD057070A111

WARNING DECAL - ROTATING SHAFT/HAIR Large

057110A112

WARNING DECAL - ROTATING SHAFT/HAIR PICTOGRAM

057130A113

WARNING DECAL - PINCH POINT HAZARD

057090A114

WARNING DECAL - ROTATING SHAFT PICTOGRAM

057100A115

DECAL - SAFETY INSTRUCTION LS057190A116

DECAL - FAULT ALERTS

057160A117

DECAL - FUSE 10 AMPS057170A118

DECAL - CIRCUIT BREAKER PRESS OFF

057150A119

33

5

1

17

2

9

6

16

8

10

19 7

10

18

PN 013030 Rev.D2

Eng. 12/ 12/ 12

2.02

11

13

15

12

14

Load Down Load Up

R

NOTE: Model LE-1 shown.

MANDATORY SAFETY DECAL PLACEMENT Fo

r

LE-1/LE-2 PowerMate Units with Battery Switch

PowerMate

®

Operation Manua

l

PARTS LIST

DESCRIPTION

PART No.

QTY

ITEM

DECAL MAINTENANCE LE-1/LE-2065870/80

11

DECAL LS CHARGER PLUG055820B12

DECAL LS LOAD DOWN/UP

05583013

DECAL LS ON/OFF

055850A14

DANGER DECAL - EXPLOSIVE ENVIRONMENT057040A1

5

DANGER DECAL - CRUSH HAZARD FOOT

057020A16

DANGER DECAL - ELECTRICAL SHOCK057030A1

7

WARNING LABEL CRUSH FOOT PICTOGRAM

057140A48

WARNING DECAL - SCREW GUARD

057070A19

WARNING DECAL - PINCH POINT HAZARD

057090A110

WARNING DECAL - MOVING PARTS Large

057060A111

WARNING DECAL - KEEP OFF057050A112

DECAL - SAFETY INSTRUCTION LS

057190A113

DECAL - FAULT ALERTS057160A114

DECAL - FUSE 10 AMPS

057170A115

DECAL - CIRCUIT BREAKER PRESS OFF

057150A116

DECAL - ROTARY SWITCH

057180A117

DECAL - DATE OF MANUFACTURE

057210A118

DECAL - CE MARK APPROVAL055860119

6

15

2.03 PN 013040 Rev.D2

Eng. 12/ 12/ 12

9

R

Load Down Load Up

12

33

2

14

18

17

19

1

5

11

10

13

7

16

88

NOTE: Model LE-1 shown.

Read all safety and operating instructions before anyone operates your PowerMate

®

Unit. Use the PowerMate®unit only as described in this manual.

Retain all safety and operating instructions for future reference. Ensure they are readily

available.

Heed all warnings in the safety and operating instructions.

Follow all installation, operation, service, and safety instructions.

Operator must have received approved training on the PowerMate®unit to be used.

Training shall include theory, practice, and testing.

Never allow unqualified or un-authorized personnel to operate the equipment.

Operator must be familiar with normal operating practices and procedures. Whenever

there is any doubt as to safety, the operator should stop the operation and not proceed

until safe conditions are restored.

Operator is responsible for maintaining proficiency on PowerMate®equipment.

Familiarity with instructions, safety procedures, maintenance practices, controls,

operation, loading, are required at all times.

WARNING: Only trained personnel shall operate PowerMate®equipment. Failure to

comply may result in possible severe injury to the operator and/or others, and damage

and/or loss of property.

Wear safety shoes. Keep hair, loose clothing, fingers and all parts of the body away

from pinch points and moving/rotating parts. Use equipment handles and controls for

manoeuvring and operation.

Operator must have good hearing and vision (with or without correction) and must have

good depth perception.

Operator must not be afflicted with any health condition(s) that might cause loss of

control or ability.

Do not operate the equipment when using alcohol or taking medication that will affect

your physical performance or judgement.

Do not eat or drink during the operation of PowerMate®equipment.

Stay alert when operating PowerMate®equipment.

No horseplay or practical jokes when operating the equipment.

Do not lift people and never ride on the PowerMate®Unit.

Do not abuse the equipment. Use PowerMate®equipment only for their intended use.

SAFETY PRECAUTIONS

READ THE MANUAL (Mandatory)

PowerMate

®

Operation Manua

l

2.04 PN 013110 Rev.D2

Eng. 12 / 12/ 12

WARNING: Do not use PowerMate

®

equipment if it is damaged. Check for

corrosion. Failure to do so may result in catastrophic failure, which may lead to

injury, damage or loss of property, and loss of life.

Inspect the PowerMate®unit (see maintenance section) prior to using to ensure the

operation can be safely completed. Insure all components of the unit are secure

and functioning.

Do not use accessories or attachments not recommended by the manufacturer, as

this may increase risk of damage and cause hazards.

Use only PowerMate®accessories best suited for the application ie: Strapbar

Attachment for box type loads, Cylinder attachment for cylindrical loads, etc.

Insure that the PowerMate®unit is charged and ready for the operation.

CAUTION: Barriers, warning signs, designated walkways or other safeguards must be

provided where pedestrians are exposed to the risk of collision.

Plan your work. Make a plan of action from picking up the load to the point where the

load is delivered. Check for doorway size, pathway surfaces, ceiling heights, tight

corners, stair step size and integrity, turn radius considerations, etc.. Always use the

recommended number of operators for a load.

Check the work site. Inspect the area to be traversed with the PowerMate®unit. Avoid

debris, rough surfaces, pot holes, bumps, steep grades, etc.. Avoid spills of any kind,

slippery surfaces, soft ground, and standing water. Observe any condition that may

cause loss of control of the PowerMate®unit leading to injury and/or property damage.

Ensure planned route for PowerMate®operation is clear of obstacles and un-involved

personnel. When visibility is obstructed use spotter person for direction instruction

and/or clear path of obstacles and un-involved personnel.

Do Not Place the PowerMate®Unit on an unstable surface. Supporting surface must

be capable of carrying the loaded PowerMate®Unit with Operator(s). Check the

condition of stairs and the edges of loading docks and vehicle beds. When moving on

or off a vehicle, be prepared for movement in the vehicle suspension system.

Do not use PowerMate®equipment in an enclosed space where oxygen, flammable,

explosive or toxic vapours are present and/or are given off by oil base paint, paint

thinner, some mothproofing substances, or in an area where flammable dust is

present.

SAFETY INSPECTION

ENVIRONMENT SAFETY

PowerMate

®

Operation Manua

l

2.05 PN 013120 Rev.D2

Eng. 12/ 12/ 12

LOADING SAFETY

SAFETY IN MOTION

CAUTION: When transiting a surface, avoid high speed turns that may cause the load

and PowerMate®unit to tip. Remember that the load must be secure to the PowerMate®

unit to ensure the load cannot shift.

When transiting the unit without a load, ensure the load strapping devices are secure,

not dangling, to prevent a trip hazard and prevent entanglement in the PowerMate®

moving parts.

Always keep your attention in the direction you are moving, monitoring clearances

above, below, and each side of the PowerMate®and load. When visibility is obstructed

use spotter person for directional instruction and/or clear path of obstacles and un-

involved personnel.

PowerMate

®

Operation Manua

l

CAUTION: Never lift a load that is over the rated capacity of the PowerMate

®

unit.

Estimate the weight and center of gravity position of the load and refer to the unit Load

Capacity Chart to ensure the load is within the loading envelope. The capacity may be

limited by the weight and strength of the operator(s). Do not operate with a load that is

beyond the operator's physical ability.

Do not attempt to increase the load capacity of the equipment by the use of chains,

rope, or other means of securing the equipment to the bed or bodies of vehicles, and

rails, wall brackets, etc.

Operators shall determine the balance of unfamiliar loads prior moving the load. Work

performed in a balanced condition is done easier and safer. New operators should gain

practice experience with lighter loads of approximately 250 lbs. with a medium center of

gravity before progressing to heavier loads. Do not raise or lower the load too far past

the balance point. Jog the equipment control switches so as not to transfer the load

weight too quickly. Training is mandatory!

Ensure the load is not damaged, properly packaged, no loose items such as tools used

in packaging the load and sharp items (such as nails) projecting from the load.

Protect the PowerMate®strapping material from sharp edges to prevent strap failure.

A

lways inspect straps prior to use. Insure the strapping latching mechanism is fully

engaged.

Verify load secureness at the beginning of use, and prior to climbing or descending with

the load. Check for any loose items or load shifting.

Never unstrap a load with the PowerMate®unit in an open (extended) condition. The

unit will fall over backwards if the wheels are not in contact with a stable surface when

the unit is unloaded.

Do not load the PowerMate®unit with a load center of gravity that is outside the side to

side limits of the unit wheels.

2.06 PN 013130 Rev.D2

Eng. 12/ 12/ 12

Stay alert. Should something break, loosen, or malfunction, on your machine, stop work

and seek qualified assistance to correct the condition. When going down a ramp or

incline, always walk ahead of the machine and use the open/close controls to engage

the rubber guard (foot) with the ground to act as a brake. Do not allow the loaded

PowerMate®to attain an un-controllable speed. When moving a PowerMate®unit down

a stair without a load, always push the wheels off the step before lowering the wheels to

the next step.

Do not compress the top urethane bumper when the machine is under load.

Lead-acid batteries contain hydrogen-oxygen gases that can be explosive and sulphuric

acid that can cause severe burns.To help avoid risk of danger and injury, observe

these precautions when handling or working with a lead-acid battery.

Wear ANSI approved safety glasses or goggles and a face shield. Wear proper clothing to

protect hands, and body. Wear appropriate rubber gloves and apron.

Never lean over a battery when testing or charging. Cigarettes, flames or sparks, could

cause a battery to explode. Keep all ignition sources away from battery. Do not strike the

sides of a battery with any spark producing item. Make sure work area is well-ventilated.

Never touch both battery terminals with bare hands at the same time. Remove rings,

watches and dangling jewelry when working with batteries. The metal in the jewelry can

cause a shock and burns if contacted with the battery terminals.

Only use insulated/non-conducting tools when making connections on a battery. Never lay

tools or other parts on top of a battery.

Because the batteries used in L P International products are of the sealed type, the battery

should be replaced if there is evidence of spillage. If there is spilled sulphuric acid present,

neutralize with baking soda. Never remove vent caps on a sealed battery. In the event of an

accident, flush with water and call a physician immediately. If venting gas is significantly

inhaled, seek immediate medical attention.

Never store batteries with explosives, flammable materials, chemicals, or food.

Protect batteries from crushing, punctures and shorting.

Do not charge or use booster cables or adjust battery connections without proper

instructions and training.

Keep batteries out of reach of children.

Do not accumulate used batteries. Dispose used batteries in accordance with local

environmental laws.

BATTERY SAFETY

SAFETY IN MOTION continued

PowerMate

®

Operation Manua

l

2.07 PN 013140 Rev.D2

Eng. 12/ 12/ 12

Before using the battery charger, read all instructions and cautionary markings on the

battery charger, battery, and product using the battery.

DANGER: Electrical equipment may be hazardous if misused. Operation of this product,

and the device it is used on, must always be done with complete knowledge of the

product instructions and safety information. Failure to do so may cause serious injury.

DANGER: RISK OF ELECTRICAL SHOCK, BURNS, OR FIRE - The battery charger

must be used as supplied. Do not use charger units if the input or output cord is cut or

frayed, or damaged in any way. Never replace, splice, or repair cables or connectors

supplied with the charger. Do not use the charger if case is damaged in any way. Do not

open the charger case for any reason. There are no user serviceable parts. Always be

sure that the charger is disconnected from the power source and battery being charged

before handling.

Your AC cord came equipped with a three-wire grounding plug (a plug that has a third

grounding pin). This plug will only fit only a grounded AC outlet. If you are unable to

insert the plug into an outlet because the outlet is not grounded contact a licensed

electrician to replace the outlet with a properly grounded outlet. Do not defeat the

purpose of the grounding plug. Pay particular attention to convenience of receptacles. If

an extension cord is necessary, use a cord with a current rating at least equal to that of

the charger. Cords rated for less amperage than the charger may overheat. Ensure the

pins of the extension cord plug are the same number, size, shape, as those on the

charger. Ensure the extension cord is wired properly and in good condition.

CAUTION: Position the charger and charger cords so that it is not tripped over, pulled,

or placed in contact with heated surfaces. Route charger cords so that they are not

likely to be walked on or pinched by items placed upon or against them. Protect the

charger from dampness or wet weather, such as rain, snow, and so on. Keep charger

away from sources of liquids, such as drinks, washbasins, bathtubs, shower stalls,

solvents, flowing water, and so on. Do not allow the charger, or any of its cords and

connectors lie in standing water such as a puddle.

CAUTION: Charge only properly maintained and rechargeable lead acid batteries of the

same voltage rating that is printed on the charger. Other battery types or voltages,

damaged batteries, or improperly maintained batteries may burst or emit dangerous

gases.

CAUTION: Only use the supplied charger on PowerMate

®

products. The charger units

supplied by L P International are internally protected against battery polarity reversal

and overload. This limits potential damage to the charger. However, the charger does

not protect against shorting or overload of external wiring or of the battery being

charged. Integrity of the PowerMate®unit wiring should be monitored during routine

inspections.

CHARGING SAFETY INSTRUCTIONS

Battery Charger

PowerMate

®

Operation Manua

l

2.08 PN 013150 Rev.D2

Eng. 12 / 12/ 12

CAUTION: Do not operate the PowerMate

®

unit while connected to the charger.

Do not overload wall outlets or extension cords, as this can result in a risk of fire or

electrical shock.

Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in anyway.

To reduce risk of electrical shock, unplug the charger from the outlet before attempting

maintenance or cleaning.

Disconnect the power plug by pulling the plug, not the cord.

Do not handle the plug with wet hands.

Unplug the charger when not in use.

CHARGING SAFETY INSTRUCTIONS continued

12V IN-VEHICLE CHARGER

WARNING: The In-vehicle charger cannot protect against vehicle damage caused by

faults in the wiring from the vehicle battery to the charger or faults in any other portion of

the vehicle wiring harness. The user must ensure that the wiring to the charger adheres

to the same vehicle wiring standards and safety precautions required for all vehicle

wiring.

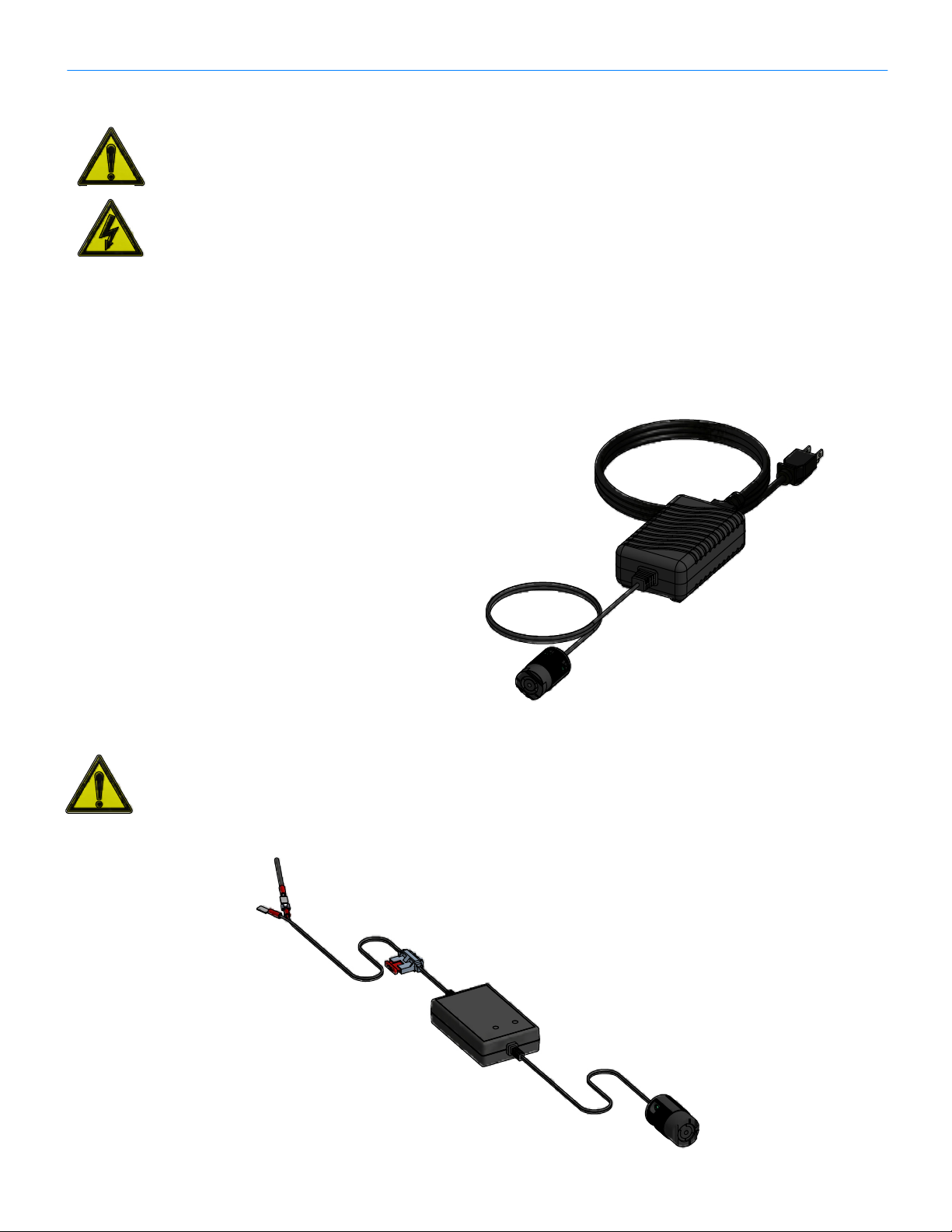

BATTERY CHARGER

PN 400210

IN-VEHICLE REMOTE

BATTERY CHARGER

PN 400216

2.09 PN 013160 Rev.D2

Eng. 12/ 12/ 12

INSTRUCTION:

1. Provide electrical power to the Battery Charger being used.

2. De-activate the PowerMate®by depressing the Circuit Breaker Pedal located on top

of the Battery Box, moving the Circuit Breaker Toggle to the down (off) position.

Move the Control Toggle Switch to the "O"(off) position.

3. Insert the Charger Twist Lock Plug into the Charging Receptacle located in the

Handle Housing. The Plug will lock in place with a slight clockwise turn.

The charge cycle is fully automatic. The Wall Charger and the In-vehicle Electronic

Charger will indicate the charge status by LED indicators. Refer to the specific

Charger documentation.

4. To discontinue the charge cycle, dis-engage the Charger Plug from the Receptacle

by using a slight counter clockwise turn and pull.

5. The PowerMate®can be re-activated for use by moving the Circuit Breaker Toggle

to the on (up) position and moving the Control Toggle Switch to the "I"(On) position.

NOTE: The PowerMate®can remain on the Battery Charger at all times, ensuring a

fully charged unit when called upon. In any case, the Circuit Breaker Toggle

should always be in the off (down) position when the PowerMate®is not in use.

LE-SERIES POWERMATE CHARGING INSTRUCTION

PowerMate

®

Operation Manua

l

Battery Box

Circuit Breaker Pedal

Circuit Breaker Toggle

Center Prong

Small Tang Terminal

Large Tang Terminal

Small Slot Terminal

Center Hole

Large Slot Terminal

FLANGE TWIST

LOCK RECEPTACLE

TWIST LOCK

PLUG

Wall Charger

400210 In-Vehicle

Electronic

Charger

400215/6

PN 013360 Rev.D2

Eng. 12/ 12/ 12

Control Toggle Switch

3.01

LOAD RECOMMENDATION INSTRUCTIONS

The following Load Recommendation Chart (next page) outlines the recommended

maximum weight that can be moved safely by one operator in three different moving

configurations.

1. On and off vehicles or loading docks.

2. Up and down stairs.

3. Over flat surfaces.

The PowerMate®LE-1 has been designed to move loads with center of gravity

locations shown inside the shaded areas of the Load Recommendation Chart. Loads

with center of gravity locations above these areas can also be moved but do not

generally require the use of the moveable carriage.

In order to determine if your load and its specific center of gravity location can be

moved safely, complete the following three steps:

1. Determine the weight of your load in pounds (lbs.)

2. Establish where the weight is concentrated in the load. This center of gravity

location is measured in inches (in.) and is determined by

A) The distance forward from the back of the load

B) The distance up from the bottom of the load

3. On the Load Recommendation Chart locate center of gravity location for your

load. From this determine that your load does not exceed the recommended

maximum weight for that center of gravity location.

If your specific move requires two or three different moving configurations, then use

the least of the recommended maximum loads.

NOTE: Load recommendations are calculated for trained and experienced

operators and should be used accordingly.

PowerMate

®

Operation Manua

l

PN 013300 Rev.D2

Eng. 12/ 12/ 12

3.02

LE-SERIES LOAD RECOMMENDATION CHART

TAILGATE LIFTING

STAIRCLIMBING

FLAT SURFACE MOVING

PowerMate

®

Operation Manua

l

150 lbs

68 kgs

200 lbs

90 kgs

250 lbs

114 kg

200 lbs

92 kgs

250 lbs

114 kgs

350 lbs

159 kg

400 lbs

182 kgs

500 lbs

227 kgs

600 lbs

272 kg

500 lbs

227 kgs

600 lbs

272 kgs

700 lbs

318 kg

400 lbs

182 kgs

500 lbs

227 kgs

600 lbs

272 kg

150 lbs

68 kgs

250 lbs

113 kgs

450 lbs

204 kg

150 lbs

68 kgs

150 lbs

68 kgs

150 lbs

68 kg

200 lbs

91 kgs

200 lbs

91 kgs

200 lbs

91 kg

150 lbs

68 kgs

200 lbs

90 kgs

250 lbs

114 kg

200 lbs

92 kgs

250 lbs

114 kgs

350 lbs

159 kg

400 lbs

182 kgs

500 lbs

227 kgs

600 lbs

272 kg

500 lbs

227 kgs

600 lbs

272 kgs

700 lbs

318 kg

400 lbs

182 kgs

500 lbs

227 kgs

600 lbs

272 kg

150 lbs

68 kgs

250 lbs

113 kgs

450 lbs

204 kg

150 lbs

68 kgs

150 lbs

68 kgs

150 lbs

68 kg

200 lbs

91 kgs

200 lbs

91 kgs

200 lbs

91 kg

20 in

[50.8 cm]

40 in

[101.7 cm]

60 in

[152.5 cm]

6 in

[15.3 cm]

12 in

[30.5 cm]

18 in

[45.7 cm]

24 in

[61.0 cm]

PN 013310 Rev. D2

Eng. 12/ 12/ 12

3.03

LOADING ONTO A VEHICLE OR LOADING DOCK

1. Place the equipment in a safe well balanced position with the load carriage

between the heelplate and the main frame wheels.

2. Locate the equipment with the heelplate and main frame wheels out from

the rear of the vehicle or the edge of the loading dock. This will provide

clearance for the main frame wheels when they are raised. (See Diagram

“A”)

3. Pivot the equipment the equipment forward on the heelplate, just enough to

clear the vehicle/loading dock. Jog the left hand pushbutton thumb switch

“Load Down” to raise the main frame wheels until they are resting securely

on the vehicle or loading dock. Set the main frame wheel brakes. (See

Diagram “B”)

4. Jog the right hand side of the center rocker switch “Load Up” to raise the

load carriage to a more balanced position ahead of the main frame wheels.

5. Pivot the equipment backwards on the main frame wheels to raise the

heelplate off of the ground.

6. Jog the right hand pushbutton thumb switch “Load Up” to partially raise the

load. (See Diagram “C”)

7. Jog the left side of the center rocker switch “Load Down” to lower the load

carriage to a more balanced position ahead of the main frame wheels.

8. Alternate between steps #6 & 7 until the heelplate is securely resting on

the vehicle/loading dock. (See Diagram “D”)

9. Place the equipment in a safe well balanced position with the load carriage

between the heelplate and the main frame wheels.

PowerMate

®

Operation Manua

l

PN 013320 Rev.D2

Eng. 12/ 12/ 12

3.04

UNLOADING FROM A VEHICLE OR LOADING DOCK

1. Place the equipment in a safe well balanced position with the load carriage

between the heelplate and the main frame wheels.

2. Locate the equipment at the edge of the vehicle/loading dock with the

heelplate overhanging and clear of the edge. Set the main frame wheels.

3. Jog the left hand pushbutton thumb switch “Load Down” to partially lower

the heelplate.

4. Jog the right side of the center rocker switch “Load Up” to raise the load

carriage to a more balanced position ahead of the main frame wheels. (See

Diagram “D”)

5. Alternate between steps #3 & 4 to lower the heelplate to the ground out

from the rear of the vehicle or the base of the dock. (See Diagram “C”) This

will provide clearance for the main frame wheels when they are lowered.

6. Push the left side of the center rocker switch “Load Down” to lower the load

carriage to the ground. (See Diagram “B”)

7. Pivot the equipment forward on the heelplate just enough to clear the main

frame wheels.

8. Push the right hand pushbutton thumb switch “Load Up” to lower the main

frame wheels. (See Diagram “A”)

9. Place the equipment in a safe well balanced position with the load carriage

between the heelplate and the main frame wheels.

PowerMate

®

Operation Manua

l

PN 013330 Rev.D2

Eng. 12/ 12/ 12

3.05

TAKING A LOAD UP STAIRS

1. Place the equipment in a safe well balanced position with the load carriage

between the heelplate and the main frame wheels.

2. Locate the equipment with the heelplate and main frame wheels out from

the first step. This will provide clearance for the main frame wheels when

they are raised. (See Diagram “A”) Set the main frame wheels.

3. Pivot the equipment forward on the heelplate just enough to clear the step.

Jog the lift hand pushbutton thumb switch “Load Down” to raise the main

frame wheels until they are resting securely on the second step. Set the

main frame wheel brakes.

4. Jog the right side of the center rocker switch “Load Up” to raise the load

carriage to a more balanced position ahead of the main frame wheels.

(See Diagram “B”)

5. Pivot the equipment backwards on the main frame wheels to raise the

heelplate off of the ground. Jog the right hand pushbutton thumb switch

“Load Up” to raise the load until the heelplate is resting securely on the

first step up. (See Diagram “C”)

6. Alternate between steps #3 & 5 until the top of the stairs is reached. (See

Diagram “D”)

7. Place the equipment in a safe well balanced position with the load

carriage between the heelplate and the main frame wheels.

PowerMate

®

Operation Manua

l

PN 013340 Rev.D2

Eng. 12/ 12/ 12

3.06

This manual suits for next models

2

Table of contents