Warranty & Service

TheWMH ToolGroup warrantsevery productit sells. Ifone ofour toolsneeds serviceor repair, oneof our

AuthorizedRepairStations locatedthroughout theUnited States cangive youquick service.

In most cases, any one of these WMH Tool Group Repair Stations can authorize warranty repair, assist you in

obtainingparts,or performroutine maintenanceand majorrepaironyour JET, Powermatic,Performax,or

Wilton tools.

Forthe nameof anAuthorizedRepair Stationin yourarea, pleasecall1-800-274-6848.

More Information

Remember, the WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

productinformation, checkwith yourlocal WMHTool Groupdistributor.

WMH Tool Group Warranty

The WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

andwarrants tothe originalretail consumer/purchaserof ourproducts thateach productbe freefrom defectsin

materialsand workmanshipas follow: 1YEARLIMITED WARRANTYONALLPRODUCTS UNLESSSPECI-

FIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligenceor accidents,normal wear-and-tear, repair oralterations outsideour facilities,or toa lackof mainte-

nance.

THEWMH TOOLGROUPLIMITSALLIMPLIEDWARRANTIESTOTHEPERIOD SPECIFIEDABOVE,FROM

THEDATETHEPRODUCT WASPURCHASEDATRETAIL.EXCEPTASSTATEDHEREIN,ANYIMPLIED

WARRANTIESORMERCHANTIBILITYANDFITNESSAREEXCLUDED.SOMESTATESDONOT

ALLOWLIMITATIONS ONHOWLONGTHE IMPLIEDWARRANTYLASTS,SOTHEABOVELIMITATIONMAY

NOTAPPLYTOYOU.THE WMHTOOLGROUP SHALLINNO EVENTBELIABLE FORDEATH,INJURIES

TOPERSONS ORPROPERTY, ORFORINCIDENTAL, CONTINGENT,SPECIAL, ORCONSEQUENTIAL

DAMAGESARISING FROMTHEUSEOFOURPRODUCTS. SOMESTATESDO NOTALLOWTHEEXCLU-

SIONORLIMITATIONOFINCIDENTALORCONSEQUENTIALDAMAGES,SOTHEABOVELIMITATIONOR

EXCLUSIONMAYNOTAPPLYTOYOU.

To take advantage of this warranty, the productor part mustbe returned forexamination, postage prepaid, to an

AuthorizedRepairStation designatedby ouroffice. Proofof purchasedate andan explanationof thecomplaint

must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the

product,or refundthe purchaseprice ifwe cannotreadily andquickly providea repairor replacement,if youare

willing to accept a refund. We will return repaired product or replacement at WMH's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of WMH's warranty,

then the user must bear the cost of storing and returning the product. This warranty gives you specific legal

rights; you may also have other rights which vary from state to state.

The WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

maydeem necessaryfor anyreasonwhatsoever.

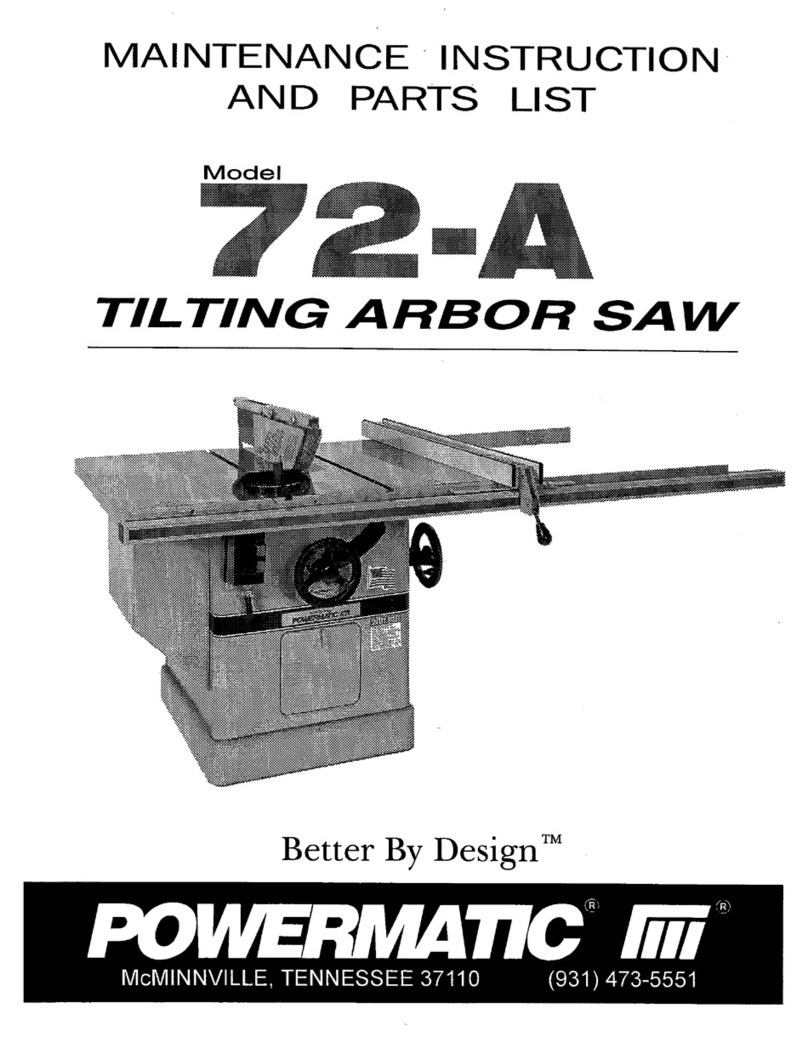

This manual has been prepared for the owner and operators of a Powermatic Model 74ATilting

Arbor/Scoring Saw. Its purpose, aside from machine operation, is to promote safety through the

use of accepted correct operating and maintenance procedures. Completely read the safety

and maintenance instructions before operating or servicing the machine. To obtain maximum

life and efficiency from your table saw and to aid in using the machine safely, read this manual

thoroughly and follow all instructions carefully.