INTRODUCTION

Machine description

1

1-2 doc042321 INTRODUCTION

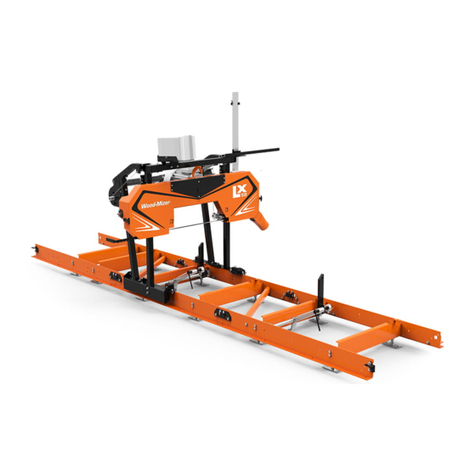

1.1 Machine description

The Wood-Mizer planer/moulder is designed for straight and profiled planing of wooden elements used

for the production of wooden houses and other construction elements used in building industry and

garden programs. All other uses of the planer are forbidden.

The MP220 is a planer/moulder that can work two sides of a workpiece in one action. The

planer/moulder is contained in a stable and strong chassis. The planer/moulder table is made of planed

cast iron.

The workpiece is fed, lying on the planer table, through the planer by feed rollers as well as an outfeed

roller. The rollers are driven by a chain transmission with separate motor. The workpiece is controlled

laterally with adjustable fences and pressure rollers.

The work is done using a top cutter and side circular blade. The cutter and circular blade are driven by

separate motors, using a belt transmission.

The cutter and feed rollers are covered by a protective cover plate. The cover plate is supplied with a

safety switch. A 100 mm (4”) dia. hose is connected to circular blade. A 125 mm (5”) dia. hose is

connected to the cutter.

TABLE SURFACE

Table is made with a highest quality cast. The table surface is specially processed for the highest

precision and the best anti-friction qualities.

When the planer/moulder is new, it requires a breaking-in period until the table gets a slightly shinier

surface to optimize the anti-friction qualities. During this period it is recommended to use a lubricant or

wax on the table.

Using the machine correctly, you will obtain a perfectly smooth surface and a high degree of accuracy.

The planer/moulder should be operated only by an adult who has read and understood the entire

operator’s manual.

Planer/moulder is built to be durable and easy to operate and maintain.

MACHINE AND SITE PREPARATION

The machine is delivered on pallet. Due to the weight, it has to be transported with auxiliary carrier

equipment and in accordance with general safety rules.

Check your planer/moulder as soon as you receive it. Any transport damage must be reported to the

transport company immediately.

Most of the planer/moulder is protected against rust, but it will require extra maintenance in the form of

lubrication for all the parts not protected against rust. See the Maintenance section.