CAUTION

RISK OF ELECTRICK SHOCK

DO NOT OPEN

WE RECOMMEND THAT ALL SERVICE OPERATIONS

ARE CARRIED OUT BY A TECHNICIAN IN THE MANNER

DESCRIBED IN THIS GUIDE.

IF NOT EXPLICITLY STATED OTHERWISE, DISCONNECT THE

AMPLIFIER FROM THE MAINS BEFORE OPERATING THE

AMPLIFIER.

WARNING! INTERNAL CAPACITORS BANK COULD BE CHARGED

AND HARMFUL: TAKE CARE OF COMPLETELY DISCHARGE

INTERNAL CAPACITORS BANK BEFORE HANDLING THE DEVICE

This technical document aims to be a support guide in repairing

and low-voltage testing the X8 power amplier.

The troubleshooting approach will help you characterize the kind

of fault you incur. A recovery method and the related assembly

outline detail is thoroughly explained for the most common faults.

The components to be replaced are clearly shown to help their

identication. At the end of this guide you can nd a detailed

list with the description and the respective Powersoft internal

reference code of the spare parts.

Always use an anti-static wrist band while servicing the amplier.

This documentation contains proprietary information which is the

sole property of Powersoft S.p.A.

These documents are condential and reserved and may not be

disclosed, reproduced and shared with third persons or used

without the express written permission from Powersoft S.p.A.

Should the service centre agreement between the two companies

be interrupted these documents must be returned to Powersoft

S.p.A. Italy or proof of their destruction be provided.

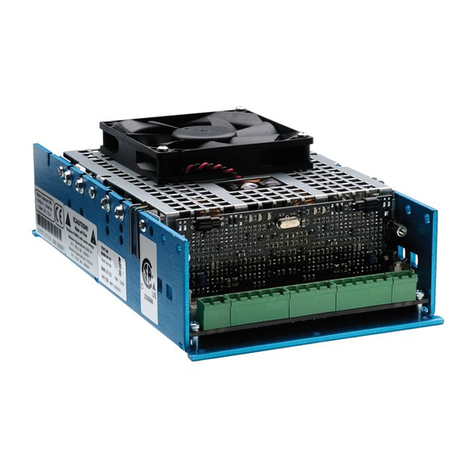

X8 | SERVICE MANUAL

Data are subject to change without notice.

For the latest release please refer to the online version available on

www.powersoft-audio.com.

INDEX

Tools:

LED Congurations and Further References 4

1. Removing the Amplier’s Cover 8

AC Wiring Diagrams 9

2. Removing The Slot Ethernet Board 10

Dante Board FW reset procedure 10

3. Removing the Wi-Fi Module 11

4. Removing the X/Front 11

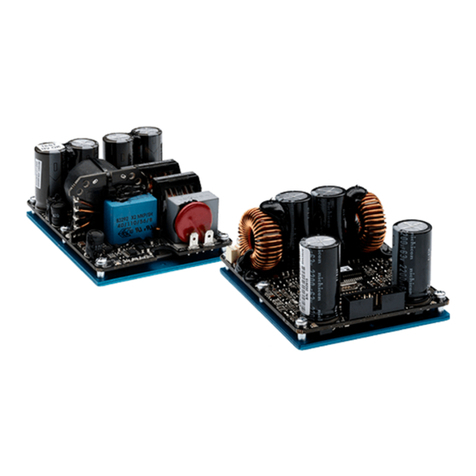

5. Extracting the Modules 11

6. Removing the DIGI and ADLINK Boards 14

Flat Cable Replacement 15

SD Card Removal 16

7. Front Panel Disassembly 16

8. Power Supply Verication Procedure 17

Replacing the Fuses 20

Internal Mains Connection 20

9. Amp Modules Verication 21

10. Replacing the Fans 23

Fan PWS 23

Fan AMPS 23

11. Updating the Software 23

Formatting a FAT32 USB Pen Drive 23

Updating the FW via Pen Drive 24

Installing the Serial Number and Mac Address 25

Extracting the Log Files via Pen Drive 26

Extracting the Log Files via SD Card 26

12. SD Card Recovery Procedure 26

13. Soft Reset - Resetting the IP Address 27

14. Hard Reset 27

15. Testing the Unit via Armonìa 27

16. Reworking Screws 30

17. Final Checklist 30

18. Restoring the Amplier to its Factory Settings

(Copying the PAM les) 32

19. Troubleshooting Diagrams 33

20. Repair Kit List 38

Appendix A: X Series Front Panel 39

Index:

T10 Torx Screwdriver

T20 Torx Screwdriver

M5 Socketed Hex Screwdriver

M7 Socketed Hex Screwdriver

6mm Hex Screwdriver

Long Nose Pliers

Required Instrumentation Q.ty Example/Comments

Dual stabilized power supply 30 Vdc 5 A 2 APLHA Electronica mod. AL852D or equivalent

Digital Oscilloscope 50 Mhz 1 TEKTRONIK TBS – 1052B-EDU or equivalent

Signal generator 1 Rigol DG1022, Feeltech FY3200S

Variac 1 Toroidal 3 KW (Mono phase)

Dummy load 1500 W 8 Ohm 1 TE CONNECTIVITY / CGS TE1500B10RJ Resistor

Soldering Station 1 WELLER PU81 + WSP80 or equivalent

SMD rework soldering station 1 GORDAK 952 or equivalent

Digital Multimeter 1 FLUKE 179 or equivalent

Pc with at least 1 eth board 1

Any evidence of tampering by unathorized personnel results

in immediate termination of the warranty.