PowerTech KIT PL600 User manual

SLIDING GATE OPENER

DESIGNED

FOR

RESIDENTIAL

APPLICA

TION

KIT

PL600/PL1000

SLIDING

GATE

OPENERS

PL600/PL1000 electro-mechanical sliding gate openers are designed for residential application.

The strongest solution

for sliding gates

Stylish appearance of the gear motors with innovative design of motor release by the key in case of power failure.

Magnetic limit switch and spring limit switch are available for customer’s choice.

Over-current function with adjustable setting provides various choices for the gate installation.

KIT

PL600/PL1000

PL600

Gear

Motor

PL1000

Gear Motor

Flashing Light Photocells Transmitter Key Selector Push Button

PRK-1

Rack

1

INSTRUCTIONS PL600/PL1000

Index

1. Warnings 2

2. Product Description and Applications 3

2.1 Applications...........................................3

2.2 Description of The Automation...............3

2.3 Description of Devices............................3

2.3.1 PL600/PL1000 Electromechanical

5. Testing 20

6. Maintenance and Disposal 21

6.1 Maintenance.........................................21

6.2 Disposal................................................21

7. Additional Information 21

7.1 Adding or Removing Device.................21

Gearmotor

..............................................

4

2.3.2 Release Keys.........................................4

2.3.2.1 Release Gearmotors……………............4

2.3.3 PH-1 Photocells......................................5

2.3.4 PR-1 Radio Transmitter..........................5

2.3.5 PF-1 Flashing Light................................5

2.3.6 PKS-1 Key selector................................5

2.3.7 PPB-1 Push Button…….........................5

3. Installation 6

3.1 Notes of Motors in Operation.................6

3.1.1 Tools in Installing....................................6

3.1.2 Motors, Components and Its Installation

in Illustration...........................................6

3.2 Power Connection..................................6

3.2.1 Notes for Power Connection..................6

3.3 Preparation for Motor Installation...........7

3.3.1 Installation of The Gearmotor.................9

3.3.1.1 Installing on Gates without Rack............9

3.3.1.2 Installing on Gates with Rack…...........11

3.3.2 PH-1 Photocells....................................12

3.3.3 PF-1 Flashing Light..............................13

3.3.4 PKS-1 Key selector..............................14

3.3.5 PPB-1 Push Button…...........................15

3.4 Power Supply Connections..................15

4. Final Checks and Start Up 16

4.1 Initial Checks........................................16

4.1.1 Design of PL600/PL1000 control unit...16

4.1.2 Recognition of LED Indication…….......17

4.1.3 Checking the Gate Movements…….....17

4.2 Programmable Functions List..............17

4.2.1 Programmable Functions of

LED Display..........................................19

4.2.2 Operations for Function Settings……...20

8. Technical Characteristics 21

8.1 PL600/PL1000......................................21

8.2 PH-1 Photocells....................................21

8.3 PR-1 Transmitter...................................22

8.4 PF-1 Flashing Light...............................22

8.5 PKS-1 Key Selector..............................22

8.6 PRB-1 Push Button..............................22

CE Declaration of Conformity 23

2

INSTRUCTIONS PL600/PL1000

1) Warnings

Please read this instruction manual carefully before the

installation of gate-automated system.

This manual is exclusively for qualified installation

personnel. Powertech Electronics Inc. is not responsible for

improper installation and failure to comply with local

electrical and building regulations.

Keep all the components of PL600/PL1000 system and this

manual for further consultation.

In this manual, please pay extra attention to the contents

marked by the symbol:

Be aware of the hazards that may exist in the procedures

of installation and operation of the gate-automated

system. Besides, the installation must be carried out in

conformity with local standards and regulations.

If the system is correctly installed and used following all

the standards and regulations, it will ensure a high degree

of safety.

Make sure that the gates works properly before installing

the gate-automated system and confirm the gates are

appropriate for the application.

Do not let children operate or play with the

gate-automated system.

Do not cross the path of the gate-automated system when

operating.

Please keep all the control devices and any other pulse

generator away from children to avoid the gate-automated

system being activated accidentally.

Do not make any modifications to any components except

that it is mentioned in this manual.

Do not try to manually open or close the gates before you

release the gear motor.

If there is a failure that cannot be solved and is not

mentioned in this manual, please contact qualified

installation personnel.

Do not use the gate-automated system before all the

procedures and instructions have been carried out and

thoroughly read.

Test the gate-automated system weekly and have

qualified installation personnel to check and maintain the

system at least every 6-month.

Install warning signs (if necessary) on the both sides of

the gate to warn the people in the area of potential

hazards.

3

INSTRUCTIONS PL600/PL1000

Table 1: List of small parts for PL600 & PL1000

Bent bins / Washers / Nut

2 pcs / 6 pcs / 4 pcs

Foundation Plate

1 pce

Screws with no head

4 pcs

Limit Switch

2 sets

2) Product Description and Applications

2.1 Applications

PL600/PL1000 is applied for residential automation of sliding gates. PL600/PL1000 has to be operated with electricity

and it’s forbidden to be operated by back-up batteries for normal use. Back-up batteries (optional) are only allowed

for emergent operation when there is a power failure, and the gearmotor can be released by the key to move the gate

manually.

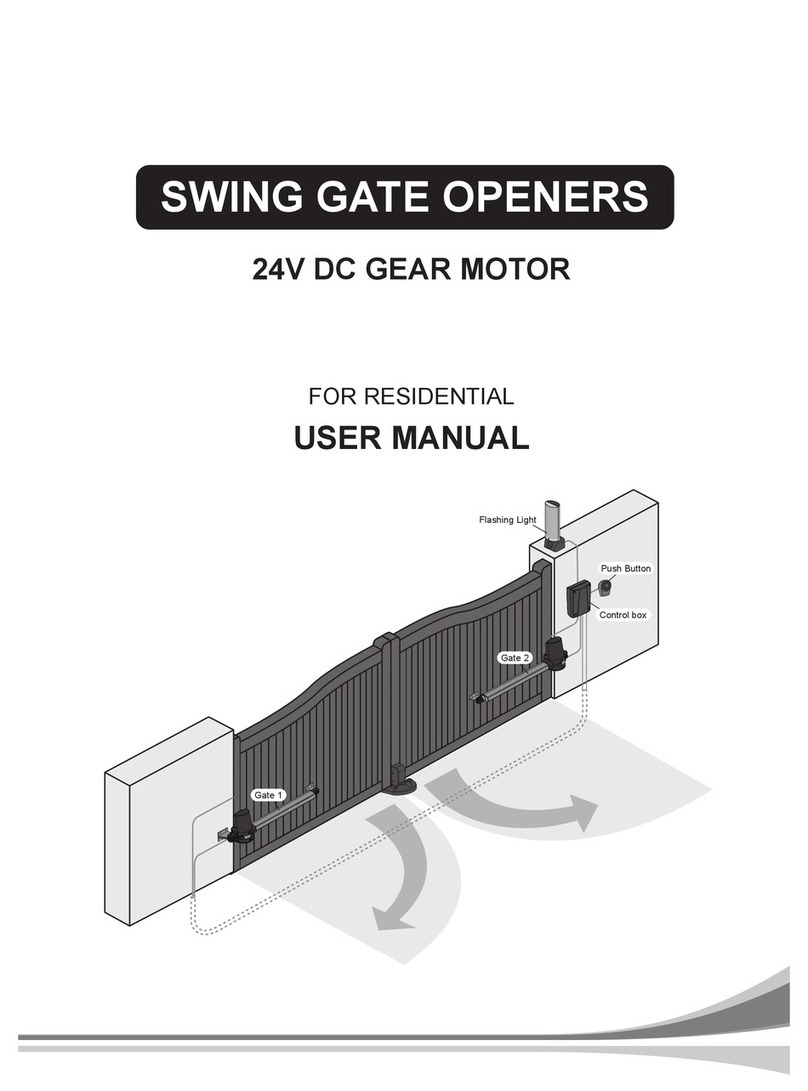

2.2 Description of the Automation

The following diagram of PL600/PL1000 typical installation describes some terms live in whereever you are and

whenever you are and accessories of a gate automation system:

G F C C E

Figure 1

H I A H

2.3 Description of Devices

PL600/PL1000 may include the accessories shown in Figure 2.

Please check the accessories the same as the package provided.

Attention: Some accessories of PL600/PL1000 are not included due to local regulations or customized order.

A) 1 PL600/PL1000 electromechanically gearmotor

including control unit

B) 2 release keys A

C) 1 pair of PH-1 photocells

D) 2 PR-1 radio transmitters

E) 1 PF- flashing light

F) 1 PKS-1 key selector with two keys

G) 1 PPB-1 push button

H) 2 limit switch brackets

I) Various small parts: screws, nuts, etc. (see table1)

J) 4 PRK-1 Rack

Figure 2

B

C

D

E

F

G

H

I J

4

INSTRUCTIONS PL600/PL1000

2.3.1 PL600/ PL1000 Electromechanical Gearmotor

PL600/PL1000 consists of an electronic control unit and

connector for the optional radio control receiver. The

gearmotor could be released manually by special

release keys when there is power failure. Besides, it has

a back-up battery (optional) which can be used during

the power failure as well.

2.3.2 Release Keys

The two keys enable the

gearmotor

to be

released

when

thereis powerfailure.

Figure 3

A

B

E

D

C

F

Figure 4

Fuse

knob

Terminals for

devices

RF leaning

button

Digital led

display

Function setting

buttons

Back-up

batteries

(optional)

2.3.2.1 Release Gearmotor

1) Slide the lock cover disc. 2) Insert and turn the key clockwise.

3) Pull the release handle. 4) Move the leaf manually.

5

INSTRUCTIONS PL600/PL1000

2.3.3 PH-1 Photocells

The pair of PH-1 photocells has to be installed on the

wall and connected to the control panel. The function of

the photocells is to detect the obstacles found on the

optical axis between the transmitter (TX) and the

receiver (RX).

Figure 5

TX

RX

2.3.4 PR-1 Radio Transmitter

PR-1 radio transmitter is used for the remote control of

the gate movement. To use the transmitter, press and

hold the button for 1 second. There are two buttons on

the transmitter and (A) button is “open-stop-close

mode” and (B) button is “pedestrian mode”.

2.3.5 PF-1 Flashing Light

PF-1 flashing light is controlled by PL600/1000 control

unit and blinks when the gate is moving or blinks 3

seconds before the gate moves. The flashing light stops

blinking when the gates

Table 2: List of small parts for PPB-1 Quantity

3*20 Screw

3 pcs

Nylon screw anchor

3 pcs

2.3.6 PKS-1 Key selector

The PKS-1 key selector is used for opening the gate

outdoors without the radio transmitter. PKS-1 key

selector is supplied with two keys

Table 3: List of small parts for PKS-1 Quantity

3*20 Screw

3 pcs

Nylon screw anchor

3 pcs

Keys

3 pcs

2.3.7 PPB-1 Push Button

The PPB-1 push button is used for opening the gate

indoors without the radio transmitter.

Figure 6

Figure 7

Figure 8

Figure 9

Table 4: List of small parts for PPB-1 Quantity

3*20 Screw

3 pcs

Nylon screw anchor

3 pcs

6

INSTRUCTIONS PL600/PL1000

3) Installation:

3.1 Notes of Motors in Operation

The PL600/PL1000 gate openers are applicable to per gate leaf of 600/1000 kg in weight for residential use; where

the performance shall be influenced by the factors such as gate dimension, weight and climate that the driven torque

is necessarily to be adjusted properly.

3.1.1 Tools in Installing

Please make sure all tools and cables are ready and conform to the industrial safety standard before installation.

Please refer to Figure 10.

Figure 10

3.1.2 Motors, Components and Its Installation in Illustration

The installation procedure of PL600/PL1000 may be changed due to various accessories and quantities installed.

No wiring cables for accessories are supplied with KIT PL600/PL1000.

3.2 Power Connection

The users are advised to read the installation manual carefully before going for it. After getting to know all accessories

and their positions, suggest starting from cable conduit arrangement to prevent the cables from being broken or

damaged.

3.2.1 Notes for Power Connection

1).The installation of power supply cable to the motor should be implemented by a qualified professional electrician.

2).The power supply cable of the motor should be equipped with short circuit protection and leakage protection.

Please make sure to shut off the power before going installation or maintenance.

7

INSTRUCTIONS PL600/PL1000

50mm

287mm

91mm

50mm

3.3 Preparation for Motor Installation

PL600/PL1000 is not applicable to a gate which is inefficient or unsafe, neither to solve the defects due to incorrect

installation nor poor maintenance.

Check the following items before going for installation:

1). Make sure the weight and dimensions of the gate conform to the operation range of PL600/PL1000. Don’t use

PL600/PL1000 if the gate specifications do not meet the requirements.

2). Make sure the gate structure conform to the criteria of automatic operation and force regulations.

3). Make sure there is no serious friction existing in the opening or closing travel of the gate.

4). Make sure the gate is at horizontal level that the gate will not move aside at any position.

5). Make sure the gate can bear the impact of the motor torque when it is installed on the plate which the surface is

sufficiently sturdy.

6). Make sure that the installation area is not easy to be invaded by flood. If necessary, mount the raised from the

ground.

7). Make sure the photo sensors (optional) are installed on flat surfaces to ensure the two ends of receiving and

transmitting corresponded to each other.

8). Make sure the installation area is suitable to the size of and the area is safe and easy to release the gearmotor.

Check the dimensions of the motors as below:

Figure

11

332mm 216mm

9). The installed at the left side and at the right site as below:

Gate without rack: the distances indicated in

Figure 12.

Figure

12

SX

DX

50mm 50mm

8

INSTRUCTIONS PL600/PL1000

10mm

86-88mm

10mm

Gate with rack: the distances indicated in

Figure 13

.

Figure

13

SX

50mm

DX 50mm

10) To install the limit switch brackets, the rack must project from the axis of the pinion by distances indicated in

Figure 14

(Left opening) and

Figure 15

(Right opening).

Figure 14

(Left opening)

170mm

200mm

Figure 15

(Right opening).

170mm

200mm

11) If the rack is already installed on the gate, make sure the position of the rack is fitted for the size limits indicated in

Figure16

.

Figure

16

9

INSTRUCTIONS PL600/PL1000

25~35mm

3.3.1 Installation of the Gearmotor

The PL600/PL1000 can be installed in two situations:

1). Installing on gates without rack; in this condition must be installed first, followed by PRK-1 rack.

2). Installing on a gate with rack; in this condition must be connected to the existing rack.

3.3.1.1 Installing on Gates without Rack

1). Dig the foundations based on “Preparation for Motor Installation” and please notice the distances indicated in

Figure 12

.

2). Lay the conduits for the power cables and leave 30-50 cm longer as

Figure 17

.

3). Fit the two bent bins (as below Bpart in

Figure 18

) into the foundation and fix them above and below with two

nuts (as below A

Figure 18.

part in

Figure 18

); make sure the outstanding part does not exceed the maximum height as

Figure 17

Figure 18

A

B

4). Put the foundation plate and make sure the gate keeping the distances shown as

Figure 12

.

5). Fit the conduits through the hole of the foundation plate.

6). Pour the concrete.

7). Sink the plate into the concrete and make sure it is parallel to the leaf.

8). After the concrete is dry enough, remove the two upper nuts form the plate and cut the cable conduits above the

plate if the conduits are too long.

9). Remove the two caps beside the left and right sides of the gearmotor as shown in

Figure 19

.

10). Put gearmotor on the plate and then screw the two nuts and washers as

Figure 20.

Figure 19 Figure 20

10

INSTRUCTIONS PL600/PL1000

11). Release the gearmotor by using the release key if necessary.

12). Fully open the gate and place the first piece of the rack on the pinion so that it projects from the axis of the pinion

by distance followed as

Figure 14

or

Figure 15

, which means, the space reserved for the limit switch brackets.

13). To keep the rack level with the pinion, mark the hole for fixing when the slot matches the axis of the pinion.

Repeat this operation for each fixing point

Figure 21

.

14). Keep 1~2 mm space as

Figure 22

between the rack and pinion so that the gate does not weigh on the

gearmotor. Continually install the other pieces of the rack until the racks are sufficient for work.

Figure

21

Figure 22

15). After fixing the last piece, cut away the unnecessary parts of racks by a hacksaw if necessary.

16). Open and close the gate several times manually and make sure that the rack goes with the pinion smoothly

within a maximum tolerance of 5mm.

17). Fix the two limit switch brackets with the relative dowels as the Epart in

Figure 23

.

Slide the gate in the open position keeping at least 2~3 cm from the mechanical stop. And then slide the bracket

along the rack in the opening direction until the limit switch cuts-in. The brackets should be located at a sufficient

distance from mechanical stops in order to keep the gate from crashing.

Operate the same steps for the limit switch in the closed position.

E

Figure 23

18). For electricallyconnections of the various devices, please see

“4.1.1 Design of PL600/PL1000 control unit”

.

11

INSTRUCTIONS PL600/PL1000

25~35mm

3.3.1.2 Installing on Gates with Rack

1). Dig the foundations based on “Preparation for Motor Installation” and please notice the distances indicated in

Figure 12

.

2). Lay the conduits for the power cables and leave 30-50 cm longer as

Figure 24

.

3). Fit the two bent bins (as below Bpart in

Figure 25

) into the foundation and fix them above and below with two

nuts (as the A

as

Figure 25

.part in

Figure 25

);make sure the outstanding part does not exceed the maximum height 25~35 mm

Figure 24

Figure 25

A

B

4). Put the foundation plate and make sure the gate keeping the distances shown as

Figure 12

.

5). Fit the conduits through the hole of the foundation plate.

6). Pour the concrete.

7). Sink the plate into the concrete and make sure it is parallel to the leaf as below

Figure 26

.

8).After the concrete is dry enough, remove the two upper nuts (which will no longer be used) form the plate and cut

the cable conduits above the plate if the conduits are too long.

9). Open the cap by the rear of the gearmotor as shown in

Figure 27

.

Figure 26 Figure 27

10). Put the gearmotor onto the plate and underneath

the rack. This step of installation can be operated

by tilting the gearmotor so that the pinion can be

easily under the rack. Make sure the gearmotor

lies ideally parallel with the gate. Then fix it by

Figure 28

C

fastening the two nuts and washers. (as the

parts in

Figure 28

)C & D D

11). If necessary, adjust the height of the gearmotor

(Max. 10mm) with the 4 dowels. It is better to fix

the gearmotor without dowels as it is fastened

firmly and securely on the plate.

12

INSTRUCTIONS PL600/PL1000

12). Keep 1~2 mm space as

Figure 29

between the rack and pinion so that the gate does not weigh on the gearmotor.

Continually install the other pieces of the rack until the racks are sufficient for work.

13). Release the gearmotor by using the release key if necessary.

14). Open and close the gate several times manually and make sure that the rack goes with the pinion smoothly

within a maximum tolerance of 5mm

15). Fix the two limit switch brackets with the relative dowels as the Epart in

Figure 30

.

Slide the gate in the open position keeping at least 2~3 cm from the limit switch. And then slide the bracket along

the rack in the opening direction until the limit switch cuts-in. The brackets should be located at a sufficient

distance from mechanical stops in order to keep the gate from crashing.

Operate the same steps for the limit switch installed in the closed position.

16). For electrically connections of the various devices, please see

“4.1.1 Design of PL600/PL1000

Control Unit”

.

Figure 29 Figure 30

E

3.3.2 PH-1 Photocells

1). Decide the installation position of the photocells. See

Figure 3.3.2 (1)

.

2). Unscrew the screws and secure the photocells on the post A, B or C. See

Figure 3.3.2 (2)

and

(3)

.

Figure 3.3.2 (1) Figure 3.3.2 (2) Figure 3.3.2 (3)

B

A

C

13

INSTRUCTIONS PL600/PL1000

R

E

E

3). Wiring connection:

TX: Connect the (1) and (2) terminals on the transmitter with the terminals +12V and GND on the PL600/ 1000 PCB.

RX: Connect the (1), (2) and (4) NC terminals on the receiver with the terminals+12V、GND and PH1 on the

PCB600/1000 PCB. And use an extra wire to connect terminal (2) and (5) on the receiver as bridge.

See

Figure 3.3.2 (4) Figure 3.3.2 (5)

.

Figure 3.3.2 (4)

Figure 3.3.2 (5)

Transmitter

Receiver

CA

CC O

V

V

R

R

NA NC C I T

T

1 2 3 4 5 Z

NA: Normal Open

NC: Normal Close

: DC(+) Input Voltage

: DC(-) Input Voltage

C: Common CA:

AC(12~24) CC:

DC(12~24)

VERT:Vertical

ORIZ:Horizontal

CA

CC

O

NA NC

C

R

1 2 3 4 5

I

Z

CA

CC

O

NA NC C

R

1 2 3 4 5

I

Z

Power LED: Green

Vertical Adjustment

Horizontal Adjustment

LED:Red(Beam Alignment)

3.3.3 PF-1 Flashing Light

1). Decide the installation position of the flashing light. The flashing light has to be installed near the gate and easy

to be seen by users and passersby. The flashing light can be installed horizontally or vertically. See

Figure 3.3.3 (1)

.

2). Unscrew the four screws on the light base and separate the base with the bottom as shown in

Figure 3.3.3 (2)

.

3.) Connect the wires and penetrate the wires into the hole of the base. See

Figure 3.3.3 (3)

.

4.) Drill the holes in the wall and fix the bottom to the wall by three screws. See

Figure 3.3.3 (4)

.

Figure 3.3.3 (1) Figure 3.3.3 (2) Figure 3.3.3 (3) Figure 3.3.3 (4)

14

INSTRUCTIONS PL600/PL1000

1000mm

5). Connect the four wires of the light and the antenna to the PCB terminals and place the wires into the conduit if

necessary. See

Figure 3.3.3 (5)

.

6). Tighten the four screws back on the light base.

Figure 3.3.3 (6)

7). Replacing the bulb set. See

Figure 3.3.3 (7)

7.1) Unscrew the flashing light wires from the PCB terminals and make sure the power of the light is off.

7.2) Release the three screws (A)、(B)、(C) of the flashing light cover.

7.3) Separate the flashing light cover and replace the bulb set with a new one.

7.4) Tighten the three screws (A)、(B)、(C) of the flashing light cover.

Figure 3.3.3 (5) Figure 3.3.3 (6) Figure 3.3.3 (7)

A

C

B

3.3.4 PKS-1 Key Selector

1). PKS-1 key selector is installed outside and close to the gate at the height of about 100cm, so that it could be used

by most people. Decide the installation position of PKS-1 first. See

Figure 3.3.4 (1)

.

2). Remove the round cover (A) by prizing it out with a screwdriver. See

Figure 3.3.4 (2)

.

3). Unscrew the two screws beside the lock body. See

Figure 3.3.4 (3)

.

4). Turn the key and separate the bottom of the shell with the lock body. See

Figure 3.3.4 (4)

.

Figure 3.3.4 (1) Figure 3.3.4 (2)

A

Figure 3.3.4 (3) Figure 3.3.4 (4)

15

INSTRUCTIONS PL600/PL1000

5). Breach the three holes at the bottom and mark the points by the holes as reference.

6). Drill the holes in the wall and fix the bottom to the wall by three screws. See

Figure 3.3.4 (5)

.

7). Connect the electric wires to the terminals as shown in

Figure 3.3.4(6)

, and it’s not required to distinguish any

polarity. The terminals can be removed for connecting the wires easily.

8). Turn the key and insert the shell on the bottom.Turn the key back to the center position and the shell will be fixed

to the bottom.

9). Tighten the lock body with the two screws and insert the round cover by pressing it to attach to the whole unit.

Figure 3.3.4 (5)

Figure 3.3.4 (6)

3.3.5 PPB-1 Push Button

1). PPB-1 push button is installed indoors at the height of about 100cm, so that it could be used by most people.

2). Remove the round cover (A) by prizing it out with a screwdriver. See

Figure 3.3.5 (1)

.

3). Unscrew the two screws beside the button.

4). Separate the upper shell with the bottom. See

Figure 3.3.5 (2)

.

5). Breach the three holes at the bottom and mark the points by the holes as reference.

6). Drill the holes in the wall and fix the bottom to the wall by three screws. See

Figure 3.3.5 (3)

.

Figure 3.3.5 (1) Figure 3.3.5 (2)

A

Figure 3.3.5 (3)

3.4 Power Supply Connections

Please kindly notice that the operation of power connection should be carried out by a qualified electrician with

following steps:

1). Make sure the gearmotor is not connected to the power supply before the installation is done.

2). Make sure all the wires are firmly connected.

3). Supply the gearmotor with the power.

16

INSTRUCTIONS PL600/PL1000

4) Final Checks and Start Up

4.1 Initial Checks

4.1.1 Design of PL600/PL1000 control unit

LED1 Photocells

LED2 Photocells

LED3 RF Learning

3 2

1

Jumper4

RF LEARN

UP

SET

DOWN

ON/OFF

ANT

GND

RF Learn (SW1)

LED Display

UP (SW3)

SET

(SW4)

DOWN (SW5)

SW2

4 5

6

3

1

2

9

10

7

8

11

12

13

14

ON OFF

10

11

6 9 6

9

3

4

6 7 9 6 8

9

If the Led display is in normal performing refer to “4.2.1”, you can control the gate by either transmitters or the button

on the board: “UP”-clockwise moving, “SET”- stop and “DOWN”- Counterclockwise moving.

Notice 1: Reset function- In any condition of gate moving and stop, press SW3 and SW5 (clockwise moving and

counterclockwise moving) for 3 secs, then the LED will display “CLR” meaning “reset successfully”. All functions

including system learning will return to the factory setting and the status before system learning.

17

INSTRUCTIONS PL600/PL1000

1). The transmitter Reaction

Channel/Functions SW2 switch on SW2 switch off

2 channel transmitter

(A)Button:“Open- Stop- Close- Stop”

(B)Button:“Pedestrian mode”

(A)Button:“Open- Stop- Close- Stop”

(B)Button:Long Press for other device

turn-on, like garage door

system

4 channel transmitter

(A) Button:“Open- Stop- Close- Stop”

(B) Button:“Pedestrian mode”

(C) Button:Long Press for other device turn-on,

like garage door system

Or

(D) Button:Long Press for other device turn-on,

like garage door system

(A) Button:“Open- Stop- Close- Stop”

(B) Button:Long Press for other device

turn-on, like garage door

system

(C) Button:“Pedestrian mode”

Or

(D) Button:“Pedestrian mode”

Important notice:

(1) Jumper 4: ②and ③in place: remote control button (C) usable

; Jumper 4: ①and ②in place: remote control button (D)

usable.

(2) Pedestrian mode follows function “F6-0~F6-5”settings.

Button (C) Usable Button (D) Usable

3 2 1 3 2

1

2). Transmitter Memorizing and Erasing Process

(1) Transmitter Memoring: Press “RF LEARN”button for 2 seconds, and the LED3 is on; then press the

transmitter (A) button; the LED3 will blink twice and then be off. The system learning is complete.

(2) Transmitter Memory Erasing: Press “RF LEARN”button for 5~6 seconds as LED 3 is on, then wait for LED3 off.

4.1.2 Recognition of LED

LED Indication Descriptions

LED1 Photocells

LED1 will be on when the first pair of the photocells are activated.

LED2 Photocells

LED2 will be on when the second pair of the photocells are activated.

LED3 RF Learning

LED3 will be on when RF-learn button is pressed.

4.1.3 Checking the Gate Movements

1). Release the gearmotor with the release key and move the gate to the middle so that it is free to move in both

opening and closing directions; then lock the gearmotor.

2). Perform the gate opening and closing several times and make sure the gates reaches the limit switch at least 2~3

centimeters before the mechanical stop.

4.2 Programmable Functions Lists

LED Display Definition Function Value Description

F1

Options of Gate

Opening direction

F1-0

Clockwise Opening

1. The function can adjust the

direction of gate opening.

2. The factory setting is "F1-1".

F1-1

Counterclockwise Opening

F2

Automatic Closing

F2-0

No automatic closing

1. This function can cause the gate

to close automatically after the

paused time.

2. The factory setting is

"F2-2”:

15secs as the pause

time.

F2-1

5 seconds

F2-2

15 seconds

F2-3

30 seconds

F2-4

45 seconds

F2-5

60 seconds

F2-6

80 seconds

F2-7

120 seconds

F2-8

180 seconds

18

INSTRUCTIONS PL600/PL1000

LED

Display

Definition

Function

Value

Description

F3

The

reactions

of

the

photocells/ safety

edge/ loop

detector

when they

detecting

obstacles

F3-1

Please

the

function setting

after

F8

1.

Please

the

function

setting after

F

2. The factory setting is

“F3-1”.

F3-2

F3-3

F4

Motor

Speed

F4-1

Slow

1. The

function

can adjust

the

running

speed of

motor.

2. The factory setting is

"F4-4".

F4-2

Medium

F4-3

Fast

F4-4

Very

Fast

F5

Motor

Force

F5-1

Light

Heavy

1. The

function

can adjust

the

running

force of motor to

be

compatible

with the gate

weight.

2. The factory setting is

"F5-4".

3. The motor force

value:

F5-1: 2A F5-6:

7A

F5-2: 3A F5-7:

8A

F5-3: 4A F5-8:

10A

F5-4: 5A F5-9:

13A

F5-5:

6A

F5-2

Light

Heavy

F5-3

Light

Heavy

F5-4

Light

Heavy

F5-5

Light

Heavy

F5-6

Light

Heavy

F5-7

Light

Heavy

F5-8

Light

Heavy

F5-9

Light

Heavy

F6

Open

Partially

F6-0

3

seconds

1. The

function

can adjust the

time

of

opening partially.

2. The factory setting is

"F6-1".

F6-1

6

seconds

F6-2

9

seconds

F6-3

12

seconds

F6-4

15

seconds

F6-5

18

seconds

F7

Pre-flashing

F7-0

The

flashing

light

blinks

when the gate starts to

move.

1. The factory setting is

"F7-0".

F7-1

The

flashing

light blinks

3

seconds

before the

gate

starts to

move.

F8

Deceleration point

programming

of

total

travel

distance

F8-0

75%

1. The factory setting is

“F8-0”.

F8-1

80%

F8-2

85%

F8-3

90%

F8-4

95%

F9

Deceleration speed

F9-1

50% full

speed

1. The factory setting is

“F9-1”.

F9-2

25% full

speed

8

●The position of safety devices:

Loop Detector

Photocell 1

Photocell 1

or

Photocell 1 / Photocell 2

Safety Edge

Photocell

Photocell 2

Other manuals for KIT PL600

1

This manual suits for next models

1

Table of contents

Other PowerTech Gate Opener manuals

PowerTech

PowerTech PA250 User manual

PowerTech

PowerTech PL500 User manual

PowerTech

PowerTech PW330L User manual

PowerTech

PowerTech PW320 User manual

PowerTech

PowerTech KIT PL600 User manual

PowerTech

PowerTech PL600H User manual

PowerTech

PowerTech PL300E User manual

PowerTech

PowerTech PW150 Guide

PowerTech

PowerTech PW220 User manual