10- 2

FOREWORD

This manual describes procedures for operation, handling, lubrication, maintenance,

checking, and adjustment. It will help an operator or anyone to make the machine realizing a

good performance through effective, economical and safe operation and maintenance.

Please read this manual carefully BEFORE operating the machine.

Please continue studying this manual until proper operation is completely reinforced into

personal habit.

This manual describes the basic techniques. Skill is performed as the operator or anyone

get the correct knowledge and performance of the machine.

Operation, inspection and maintenance should be carefully carried out, and the safety

must be given the first priority. Safety precautions are indicated with “ ” marks and

technical precautions with “★” marks in this manual. The safety information contained

in this manual is intended only to supplement safety codes, insurance requirements, local

laws, rules and regulations.

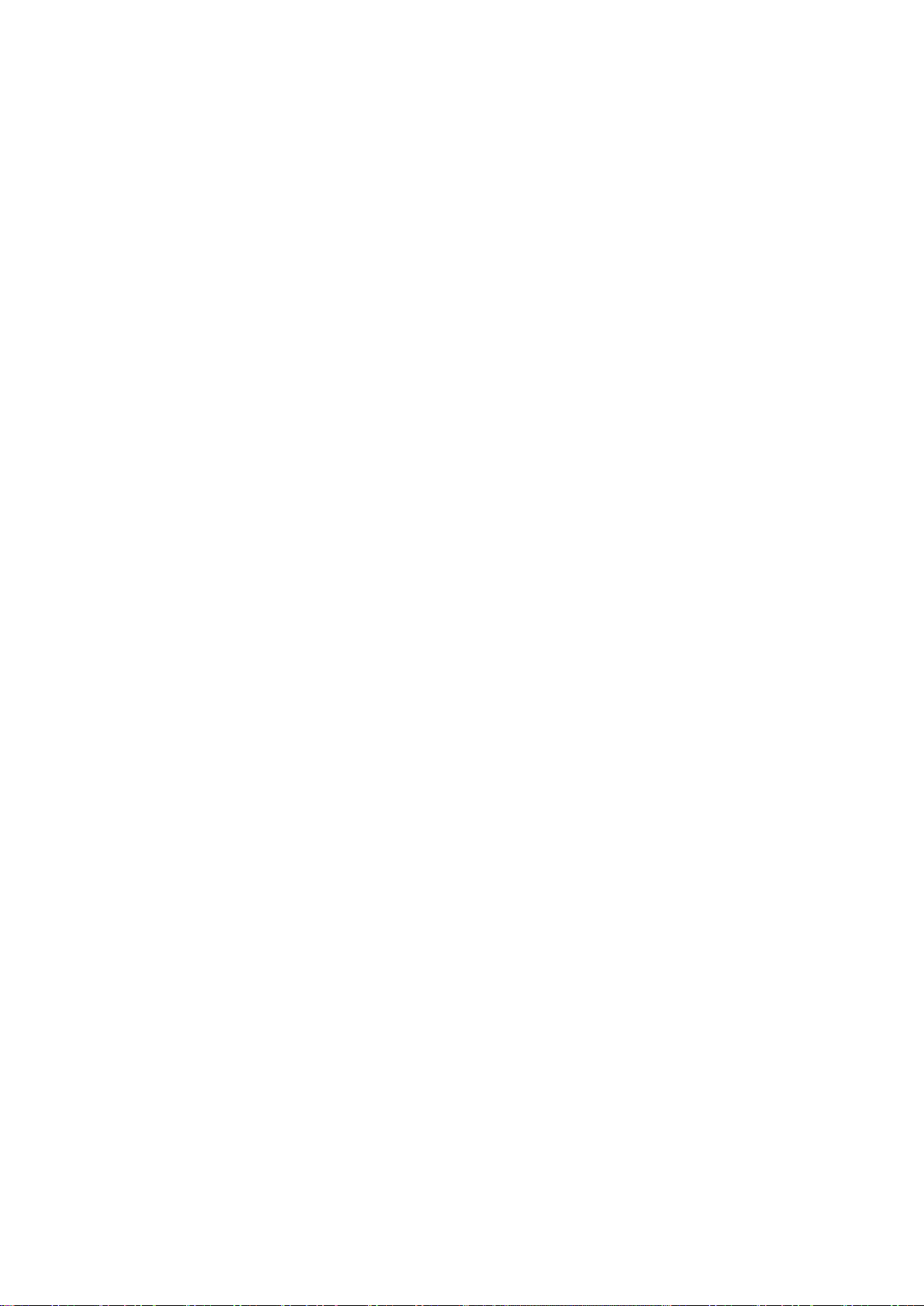

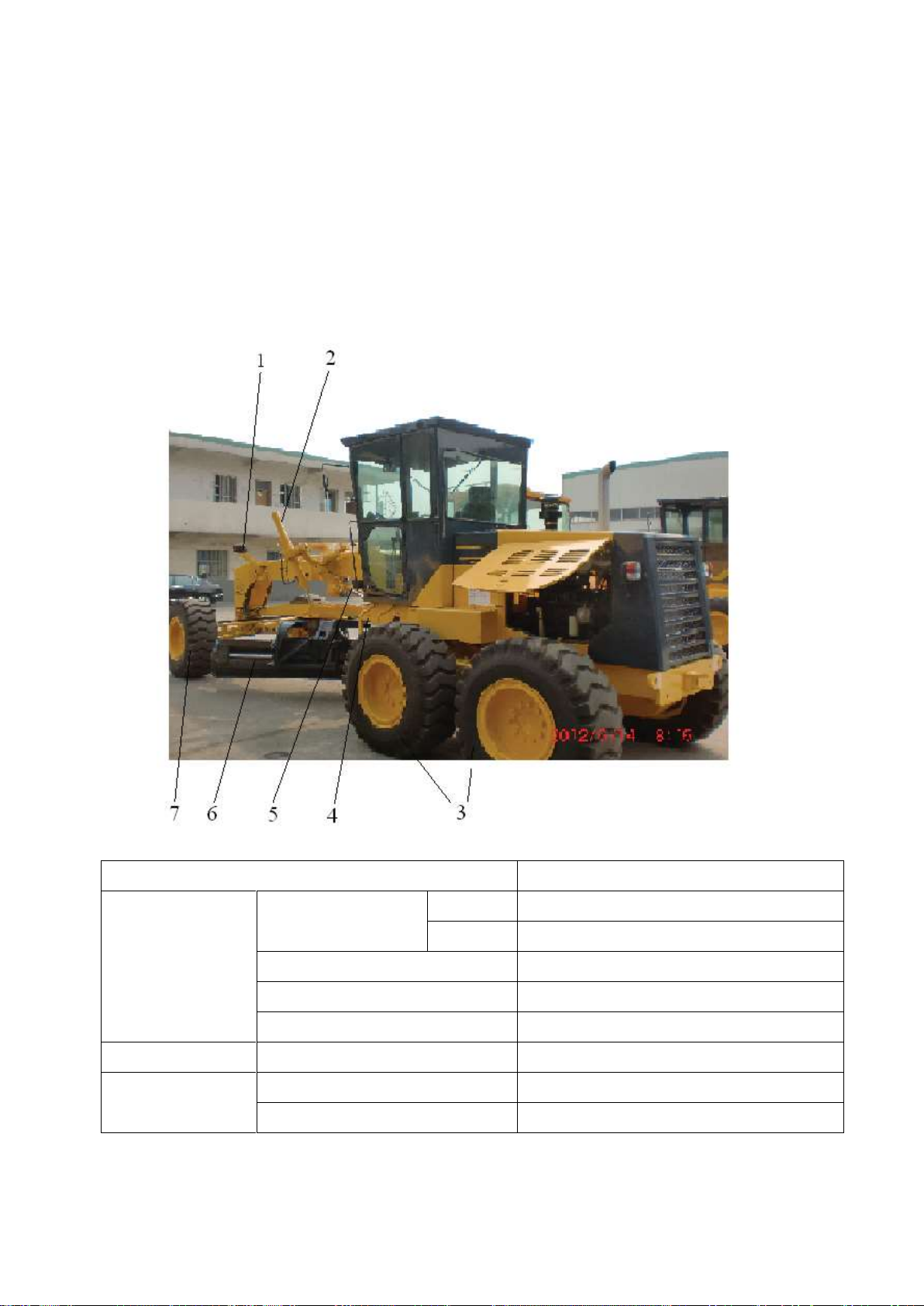

Some photographs and illustration pictures are different from your machine as technical

improvement is continuously reflected on it. Revision to up-to-date manual’s content is

performed in later editions.

This operation and maintenance manual may contain attachment and optional equipment

that are not available in your area. Please contact us for those items you may require.

About engine and transmission instructions in this manual, if thy are different from the

“ENGINE OPERATION INSTRUCTION” and the “TRANSMISSION OPERATION

INSTRUCTION” provided for your machine, the latest operation instructions should be

taken as the standard.

Materials and specifications are subject to change without notice.