Powervault G200 User manual

1

Cover

G200

INSTALLATION

MANUAL

WINNER:

Innovator of the Year

Solar Innovation of the Year

2

Safety

Case: The case is essential to ensure

the safety of the device. Do not open

unless qualified. If the case becomes

damaged contact an authorised

Powervault engineer. The Powervault

unit weighs 50kg and should be

handled with appropriate lifting

techniques and pallet trucks, if

required.

Location: It is essential Powervault

G200 is installed in an appropriate

location according to its Technical and

Environmental specifications (see

Technical Specifications document)

with at least 10cm of space behind the

unit to allow for appropriate ventilation.

Installation: The installation of

Powervault G200 must only be

undertaken by approved Powervault

installers/qualified electricians.

Batteries: This equipment is heavy

and contains potentially hazardous

voltages that may cause personal

injury if handled incorrectly. This

equipment must be installed and

serviced only by qualified electrical

service personnel. The batteries

should be disposed of or recycled

according to your local code of

conduct.

Only use batteries supplied or

approved by Powervault. Do not mix

and match Li-Ion and Lead Acid

batteries in a unit. These actions will

result in loss of warranty on the

equipment.

ELECTRONIC DEVICE:

DO NOT THROW AWAY

Proper disposal of device and batteries is required.

Please refer to our website for details on how to recycle and replace

your batteries. www.powervault.co.uk/recycling

3

Register your Powervault G200

Log-in to your Powervault Installer Portal to register your customer’s

Powervault, place the Powervault under Warranty and automatically set-up

your customer on their Powervault Customer Portal:

portal.powervault.co.uk

Download the warranty terms

Remember! The Warranty is only valid when your customer’s Powervault has

been registered via your Powervault Installer Portal and is connected to the

internet either via the Wi-Fi adaptor or Ethernet cable:

www.powervault.co.uk/warranty

Product List

2.0 2.54.0

6.0

3.04.0

2.0 2.5

4.0

6.03.04.0

2.0 2.5

4.0

6.03.04.0

2.0 2.5

4.0

6.03.04.0

2.0

2.54.06.03.04.0

2.0

2.5

4.06.03.04.0

2.0 2.54.06.0

3.0

4.0

Lithium-ion Lead Acid (Tubular Gel) Lead Acid (AGM) Powervault overview 4

Part 1: Wiring 5

Part 2: Preparing the Powervault 8

Part 3: Emergency Power Socket 9

Part 4: Loading batteries

Option A: Lead Acid batteries 12

Option B: Lithium-ion cells 14

Part 5: Replacing the Powervault G200 panels 17

Part 6: Connecting the current clamp 18

Part 7: Connecting the Powervault G200 to the internet 20

Part 8: Registering your customer’s Powervault G200 21

Part 9: Commissioning 23

Record your serial numbers 25

Contents

4

Powervault overview

Parts included with

your delivery:

Powervault G200

Lithium-ion battery packs / Lead Acid

batteries (amount and type dependent

on product purchased)

Accessory Box

Current (CT) clamp

Current clamp extension cable

Battery connectors

Powervault G200 User Manual

Powervault G200 Technical Specification

Powervault G200 Installation Manual

Parts not included with

your delivery:

7A/10A fused spur (fuse size dependent

on Powervault type)

Rotary isolator

Associated wiring

Wi-Fi nano-router

5

ELECTRICAL SAFETY

To reduce the risk of fire, connect only to a circuit

provided with a 7A / 10A maximum branch circuit

overcurrent protection in accordance with BS1362.

Do not work alone under hazardous conditions.

Check that the power cord(s), plug(s), and sockets

are in good condition.

To reduce the risk of electric shock, disconnect

the equipment from the AC power outlet before

installing or connecting to other equipment.

Reconnect after all electrical connections are made.

Use one hand, whenever possible, to connect or

disconnect signal cables to avoid a possible shock

from touching two surfaces with different

electrical grounds.

Connect the equipment to a three wire AC connection

(live, neutral and ground). The unit must be connected

to appropriate branch circuit/mains protection

(fuse or circuit breaker). Connection to any other

type of connection may result in a shock hazard.

In order to maintain compliance with the EMC

directive, wires attached to the Powervault

should not exceed 25 meters in length.

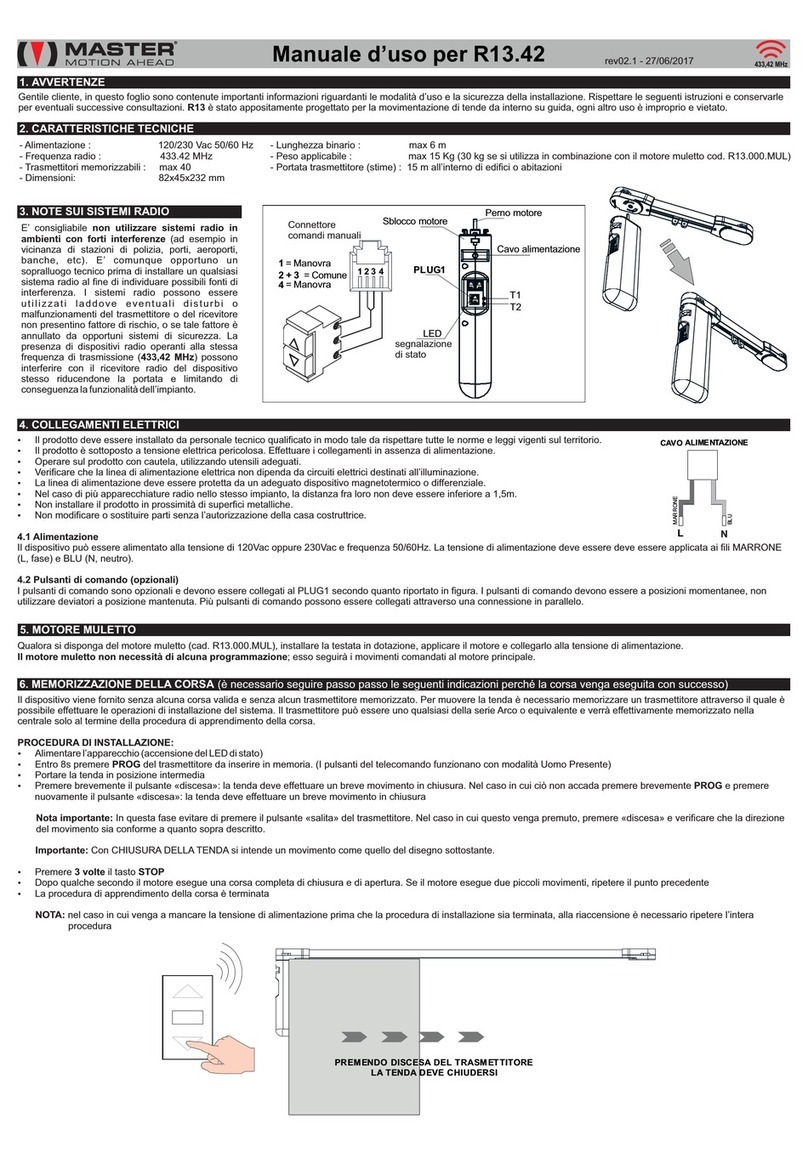

• Prepare the electrical wiring according to figure 1 or figure 2. All wiring to be perform in strict accordance with

local building regulations.

• The ideal installation will feature a separate RCBO block splitting from the Henley Block as shown in figure 1.

• If this is not possible connecting to consumer unit is acceptable as long as it is on a dedicated 16A RCBO can be

inserted into the unit as shown in figure 2.

• The rotary isolator will need to be installed directly downstream of the dedicated RCBO.

• If a power socket needs to be added for the Powervault internet connection then the additional power socket

should be installed downstream of the rotary isolator as shown in figure 1.

• The fused spur should be rated according to table 1.

TABLE 1

Unit Fused Spur Rating (amps)

3kWh Lead Acid (AGM Gel) 7

4kWh Lead Acid (AGM Gel) 7

2.5kWh Lead Acid (Tubular Gel) 10

4.0kWh Lead Acid (Tubular Gel) 10

2kWh Lithium-ion 10

4kWh Lithium-ion 10

6kWh Lithium-ion 10

Part 1: Wiring

6

25m maximum wiring distance

Live

Neutral

Solar inverter

Solar panels Electricity supply mete

r

Grid supply

Current

clamp

Henley Block connection

RCBO Consumer Unit Not included,

dedicated for Powervault

Not included

Additional power socket if

required for nano-router

Rotary

Isolator

RCBO

7A / 10A

fused spur

Powervault

Wi-Fi/internet

Household ring main

Installation schematic

Current clamp with

arrow indication

FIGURE 1

Recommended Installation

7

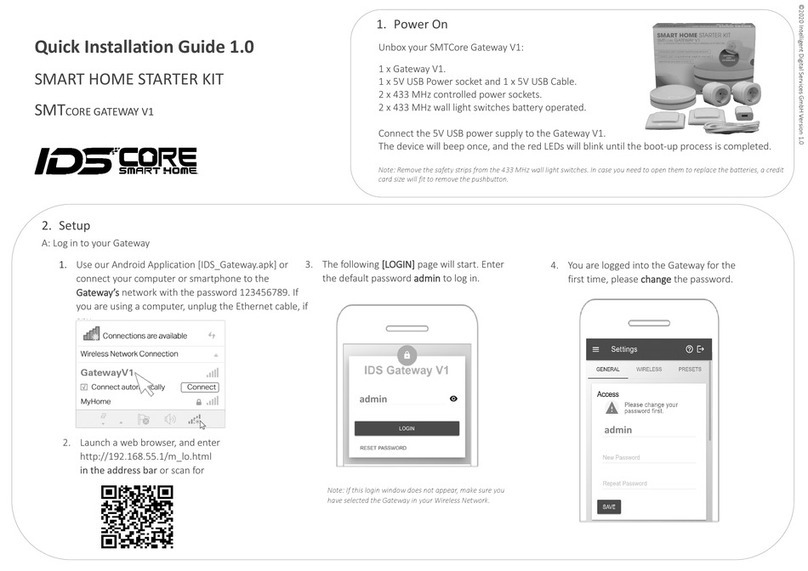

25m maximum wiring distance

Neutral

Solar inverter

Solar panels

Electricity supply mete

r

Grid supply

Henley Block connection

RCBO Consumer Unit

Not included, dedicated for Powervault

Not included

Additional power socket if

required for nano-router

Rotary

Isolator

7A / 10A

fused spur

Powervault

Wi-Fi/internet

Household ring main

w/ Dedicated RCBO

for the Powervault

Current

clamp

Installation schematic

FIGURE 2

Possible Installation (Check with local regulations)

Current clamp with

arrow indication

8

i

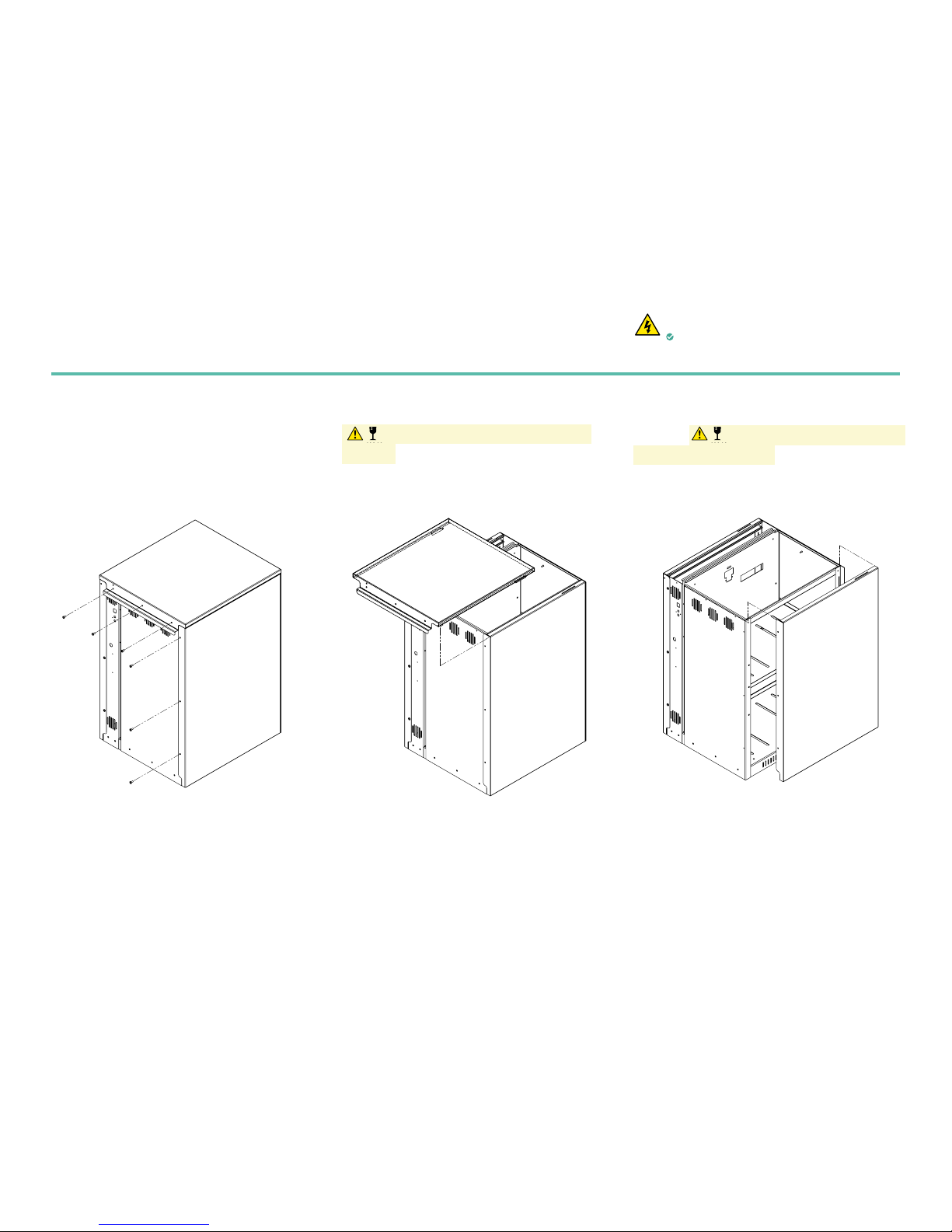

Remove 6 screws to the top and left side panel.

Keep the screws in a safe place.

ii

Slide the top panel backwards and lift carefully

Caution: delicate wiring connected to the

top cover. Disconnect the earth connection and

place the panel in a safe place for the duration of

the battery pack installation.

iii

Carefully lift the left-hand side panel and slide

outwards. Caution: delicate wiring connected

to the left-hand side panel. Disconnect the earth

connection and place the panel in a safe place for

the duration of the battery pack installation.

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 1 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 2 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 3 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

Part 2: Preparing the Powervault

ELECTRICAL SAFETY

Ensure the Powervault G200 is completely

isolated from the mains supply.

FIGURE 3 FIGURE 4 FIGURE 5

9

i

Ensure the Powervault G200 is completely isolated

from the mains supply and from the rotary isolator.

Follow local lock-out tag-out procedures

ii

If installation of emergency power socket (EPS) is

taking place after battery installation see Part 2 for

panel removal. Remove 3 screws on the right side

panel as shown in figure 6.

iii

Slide right side panel up and lift carefully (figure 7)

Caution: delicate wiring connected to the top

cover. Disconnect the earth connection and place

the panel in a safe place for the duration of the EPS

installation.

Powervault’s Emergency Power Socket (EPS) is not fitted as standard and Installers are therefore

occasionally required to fit this accessory to the Powervault if the customer has ordered it. The EPS gives

customers access to power available in the batteries during black outs; the EPS will be able to power basic

electrical appliances, provided the batteries have energy stored in them at the time, during emergencies and

when there is grid failure.

Part 3: Emergency Power Socket (if purchased)

ELECTRICAL SAFETY

Ensure the Powervault G200 is completely

isolated from the mains supply.

FIGURE 6 FIGURE 7

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A03_8_500 Assembly Remove Side and Cover

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A03_8_500 Assembly Remove Side and Cover

10

v

Remove the EPS from its box and identify the enclosed

metal bracket (x1), nuts (x2), and washers (x2).

vi

Using the metal bracket, 4 x nuts and 4 x washers,

secure the EPS on the Powervault G200 further by

placing the bracket around the EPS but under the

wiring and fixing the washers and nuts onto the

two screws located above and beneath the EPS on

the Powervault G200 casing. See figure 9.

iv

Facing the front of the Powervault G200, locate

the plastic cover for the EPS in the bottom-right

corner. Remove the cap by pushing it firmly

outwards from inside the unit. See figure 8.

A

DETAIL A

SCALE 2 : 5

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A01_8_500 Assembly with Socket

FIGURE 8

FIGURE 9

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A03_8_500 Assembly Remove Side and Cover

11

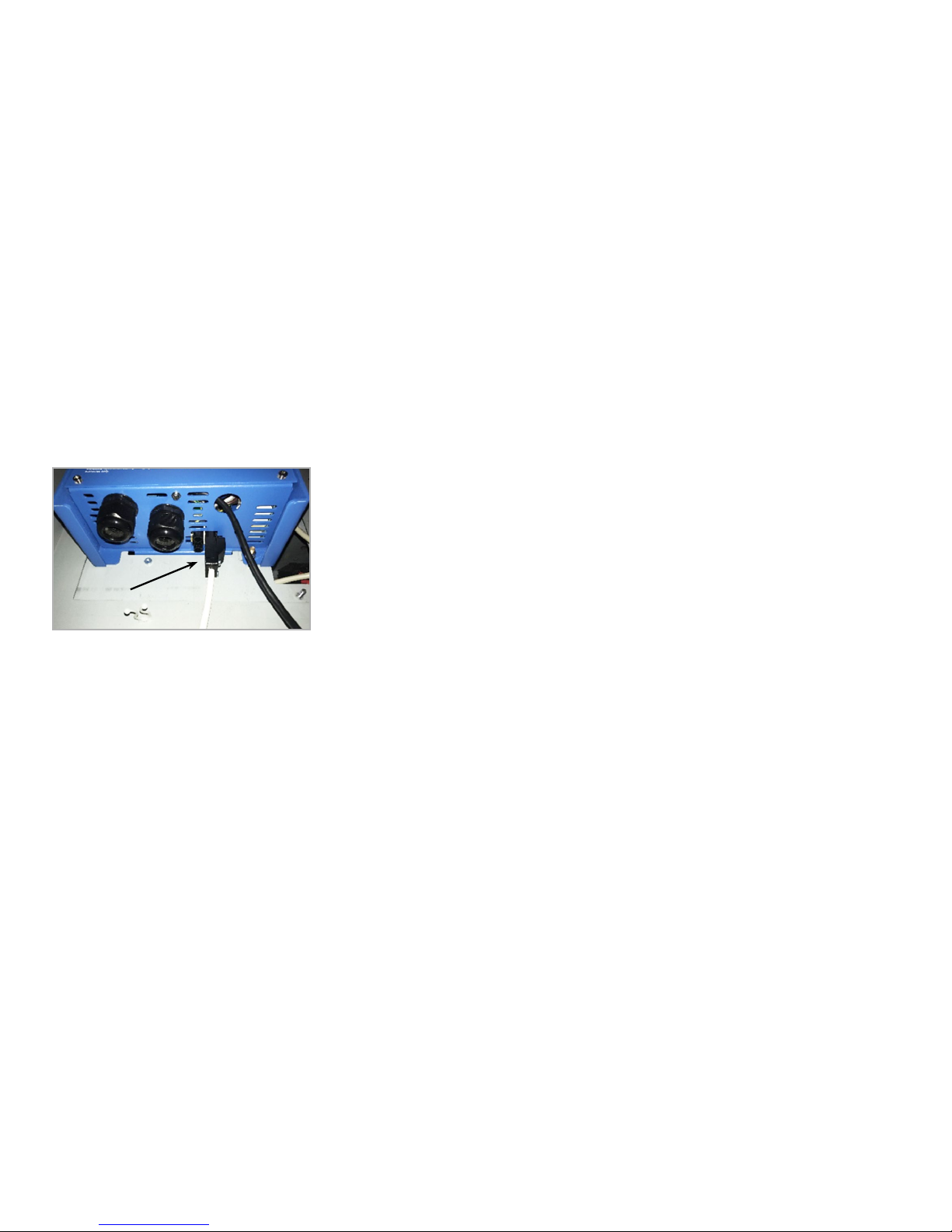

vii

Plug the AC-out power cable into the bottom of the

inverter.

viii

Reinstall right side earth wire to panel, attach panel

to unit and reinstall screws see (if finished reinstall

earth wire to top and reinstall screws).

12

Part 4: Loading batteries

ELECTRICAL SAFETY

Ensure the Powervault G200 is completely

isolated from the mains supply.

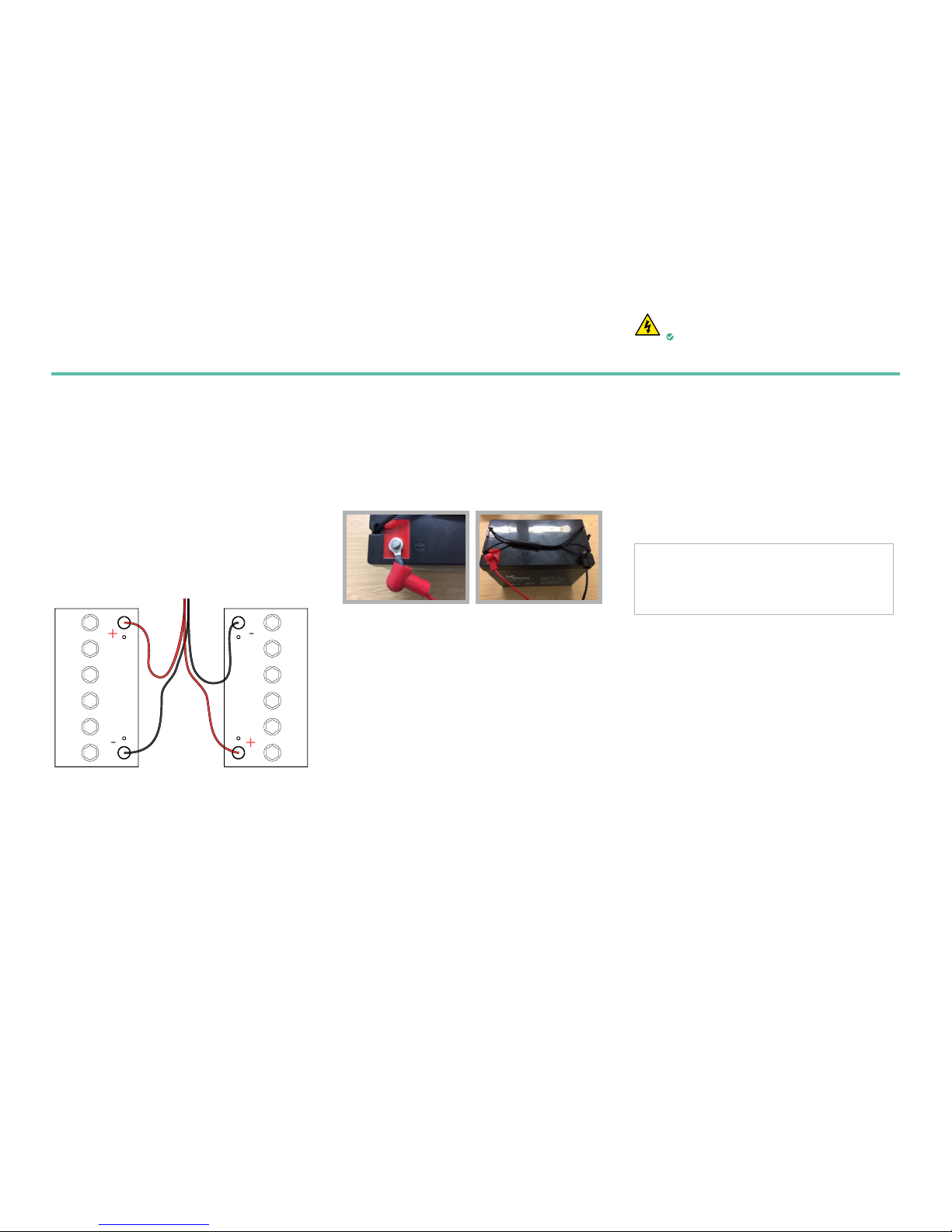

i

Connect the battery cables to the batteries prior to

the loading the batteries into the unit. Connect the

RED cable to the positive terminal and the BLACK

cable to the negative terminal using a socket wrench.

ii

Place the battery terminal covers over the terminals.

iii

Remove screws from top tray to allow for 2nd row

of batteries to slide in place. Keep the screws in a

safe place for re-installation.

Option A:

Loading Lead Acid batteries

Lead Acid Unit

+

-

+

-

Power Connection

To Powervault

Cables Supplied as Part of Accessory Box

Connect Red to positive and Black to Negative

Note: 2 Batteries must be connected on any shelf

Connection Detail 2 Batteries Per Shelf

Cables supplied as part of accessory box

connect RED to positive and BLACK to negative

Power connection

to Powervault

Note: Two batteries should be plugged into the

socket on each level. The unit will not work if

only one battery is plugged into a socket.

FIGURE 10

13

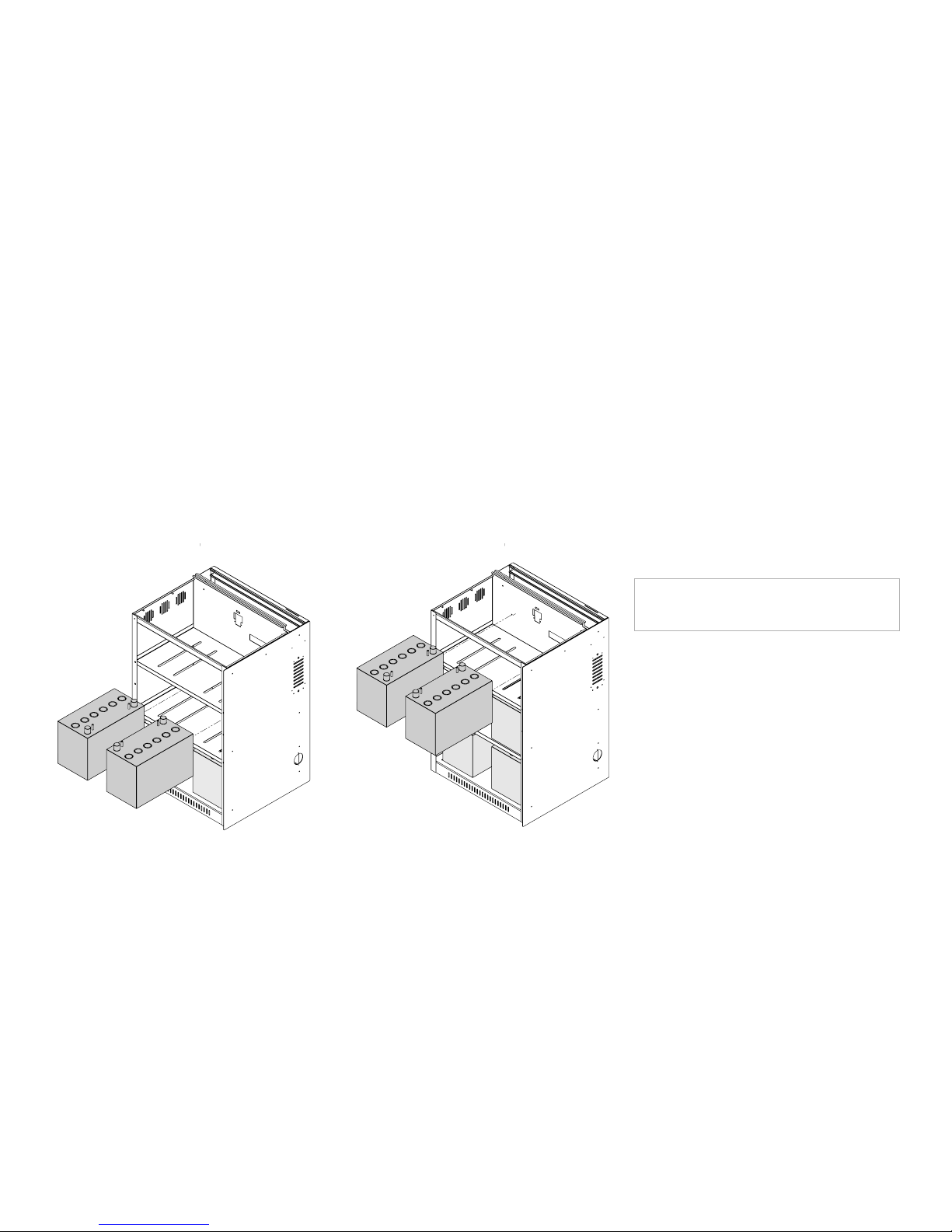

iv

Place the lead acid batteries onto each shelf as shown

in figure11 and 12. For the 3kWh unit place 4 total

batteries. For the 4kWh unit place 6 total batteries.

v

Plug the battery leads into the connectors inside the

Powervault. Insert the plastic end into the Powervault

unit placing the connections on top of each other.

Each connector should click into place. This will be

the case on each shelf.

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A00_8_Full 500 Assembly with Batteries

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A00_8_Full 500 Assembly with Batteries

FIGURE 11

Battery installation for 3kWh & 4kWh units.

FIGURE 12

Battery installation for 4kWh units only.

Note: The powervault will not function properly if

only 1 battery is plugged in per shelf.

14

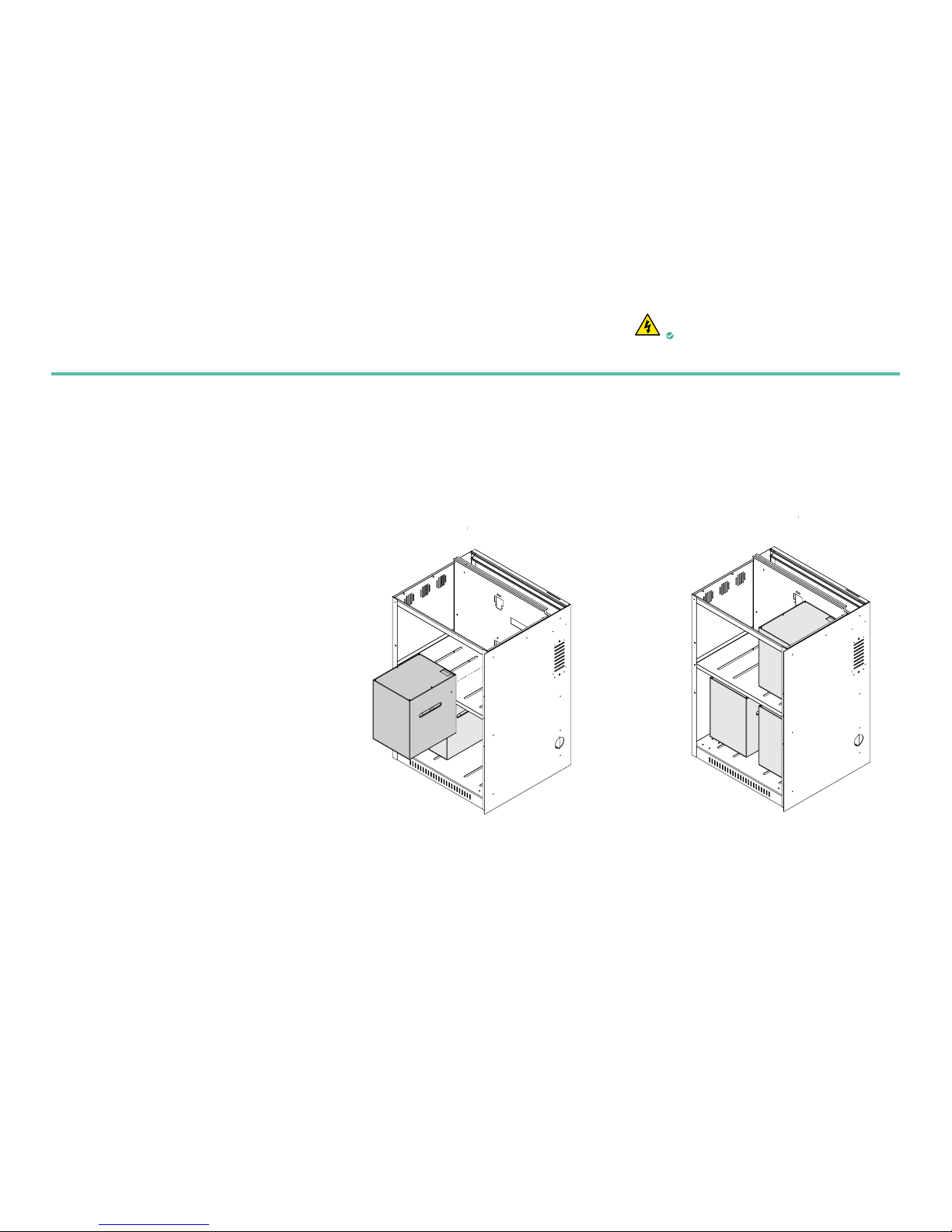

FIGURE 13

4kWh Li-Ion Unit

FIGURE 14

6kWh Li-Ion Unit

Part 4: Loading batteries

ELECTRICAL SAFETY

Ensure the Powervault G200 is completely

isolated from the mains supply.

i

Unpack Li-ion batteries. Record the battery 5 digit

serial numbers on the back page of this manual. It

will be needed for registration later.

ii

For the 4kWh unit place 2 batteries as shown in

figure 13. (One battery per shelf).

iii

For the 6kWh unit place 3 batteries as shown in

figure 14. (Two batteries on the bottom shelf and

one on top shelf).

Option B:

Loading Lithium-ion cells

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A00_8_Full 500 Assembly with Li - Ion Batteries

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

PV1_A00_8_Full 500 Assembly with Li - Ion Batteries

15

FIGURE 15

FIGURE 16

iv

Connect the power leads provided in the accessory

box to the battery. In the case of a 2 or 4kWh unit

the 4 wire connection piece will plug into the wall

of the Powervault while both of the 2 cable power

leads should plug into the battery See figure 15.

v

The 6kWh unit will require that the power leads be

split into the two battery packs on the lower shelf.

See figure 16.

Battery power cables Data cable connection

5 Digit Serial Number

Required for

commissioning of unit and

connecting to the portal

Data Jump Connection

Part of Accessory Box

Data connection

Left side in

Right side out

Power connections to Powervault

Part of Accessory Box

Data connection to Powervault

Hard wired into Powervault Unit

16

vi

Connect the data cable that is hardwired into the

Powervault unit to the right hand side of the data

connection see figure 17.

vii

The 6kWh unit will require that the lower shelf

have the batteries connected together via a data

cable see figure 16.

Note: The batteries will charge faster if all 4

power wires are connected into a battery which

is why this is recommended for the top shelf

and on the 4kWh unit.

Note: If the data connection is not made with all

of the batteries the Powervault will not

function.

5 Digit Serial Number

Required for

commissioning of unit and

connecting to the portal

Data Connection on right

hand side of battery

Power connection to Powervault

Use both connectors for 1 battery

Connector supplied in Accessory Box

Data connection to Powervault

Cable hardwired into Powervault unit

FIGURE 17

17

Part 5: Replacing the Powervault G200 panels

i

Slide left side panel down to reattach. Make sure

both hooks on the panel are placed inside the slots.

Caution: delicate wiring connected to the

top cover. Ensure you connect the earth wire to

the top panel before you slide it back into place.

ii

Slide top panel into place making sure to insert the

hooks on the panel into the slots on the frame.

Caution: delicate wiring connected to the

top cover. Ensure you connect the earth wire to

the top panel before you slide it back into place.

iii

Replace the screws that you removed at the

beginning of the installation to secure the panels.

Caution: the earth wire is a safety feature and

all care must be taken to ensure good contact.

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 1 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 2 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

A A

B B

C C

D D

E E

F F

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

DRAWN

CHK'D

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

TOLERANCES:

LINEAR: +/- 0.05

ANGULAR: +/- 0.5

FINISH:

DEBURR AND

BREAK SHARP

EDGES

NAME

SIGNATURE

DATE

MATERIAL:

DO NOT SCALE DRAWING

REVISION

TITLE:

DWG NO.

SCALE:1:20

SHEET 3 OF 5

A3

MATERIAL THICKNESS:

C. Tyler

A. Locke

10/05/17

10/05/17

Dynamic Marine Engineering

PV1_A00_8_Full 500 Assembly

Full 500 Assembly

1

mm

FIGURE 20FIGURE 19FIGURE 18

18

Part 6: Connecting the current clamp

i

Clamp the current sensor onto the main incomer

conductor (live feed), with the arrow pointing

in the direction of current flowing into the house

but away from the meter see figure 21. The

current clamp is used to measure all power coming

into and out of the house.

Note: We recommend a 10cm space between

the current clamp cable and any power wiring

for a long run. The cable can share a wall

penetration but should then branch away from

any power wiring to at least 10cm. Do not

install the current clamp cabling in same

conduit as power cables due to interference.

see figure 22.

FIGURE 21

Powervault socket for current clamp

ELECTRICAL SAFETY

Ensure the Powervault G200 is completely

isolated from the mains supply.

WALL WALL

Current clamp wiring 10cm Current clamp wiringPower wiring Power wiring

FIGURE 22

10cm space between current clamp and power wiring

On install No on install of current clamp

19

ii

Plug the 3.5mm jack into the top 3.5 mm socket.

See figure 23.

iii

After all previous steps are complete turn rotary

switch to on position and bring power to the

Powervault unit.

The current clamp wire is 10m in length. A

10m extension lead is provided free of charge. Note: If installing a lithium ion unit the lights

on the front will change colour after 20

seconds. If the colour is red please contact

Powervault or look at FAQs on the website.

FIGURE 4

Correct installation Incorrect installation

FIGURE 23

Current clamp installation example

20

Part 7: Connecting the Powervault G200 to the internet

Either: Connect the Powervault G200 to the

customer’s internet router via Cat5 or Cat6 cable

with RJ45 connectors.

Or: connect the Powervault via wireless wifi

connection a nano router will need to be purchased,

configured and connected directly to the Powervault

RJ45 port located on the back of the Powervault

via ethernet cable (not provided).

We recommend using one of four types of wireless

nano routers:

• TP-link, RE210 Wi-fi extender with Ethernet

output

• TP-link, PA4010KIT Powerline adapter kit.

Alternatively individual units can be purchased

(e.g. for 3 way networks).

• Netgear, WN3000RP Wi-fi extender with

Ethernet output

• Tenda P200 Powerline adapter kit

Table of contents