Powr-Kraft Betstco ATKSP120 Application guide

1 Revision 11-22-17

1

Specificationssubjecttochangewithoutnotice.

POWER SWEEPER ATKSP120

www.Betstco.com

Phone: 541-895-3083

E-mail [email protected]

83371 Melton Rd, Creswell OR 97426

Rugged Labor Saving Equipment Since 1995

FOR YOUR SAFETY!

Please read these instructions carefully before using! Check all fluid

levels before each use! GREASE ALL FITTINGS BEFORE OPERATING!

OPERATION & PARTS MANUAL

Never store any machine

with raw, unstabilized gas

in it unless it's packaged

fuel, which does not

contain ethanol or

additives and is sold in

steel cans at hardware

stores, home centers, and

outdoor-power-equipment

dealerships. Storing an

engine with unstabilized

gas in it for more than 30

days will void the engine

manufacturers warranty.

Save This Manual for Future Reference

2 Revision 11-22-17

2

Specificationssubjecttochangewithoutnotice.

With the purchase of your Power Sweeper you have made an excellent choice.

This machine should give first class service for a long time, if used correctly, and maintained as described in this

manual.

Fitted with an easy to start engine it has been designed to cope with a wide range of conditions. The ATKSP120 Power

Sweeper incorporates easy height adjustment, range of engine options and a full width anti-scalping roller to avoid

damage to machine and sward.

The sweeper is constructed from 4mm steel for added strength; all fittings are of high quality to ensure years of trouble

free use.

Engines used may wary, but all are accompanied by the maker′s usual warranty.

1 INTRODUCTION

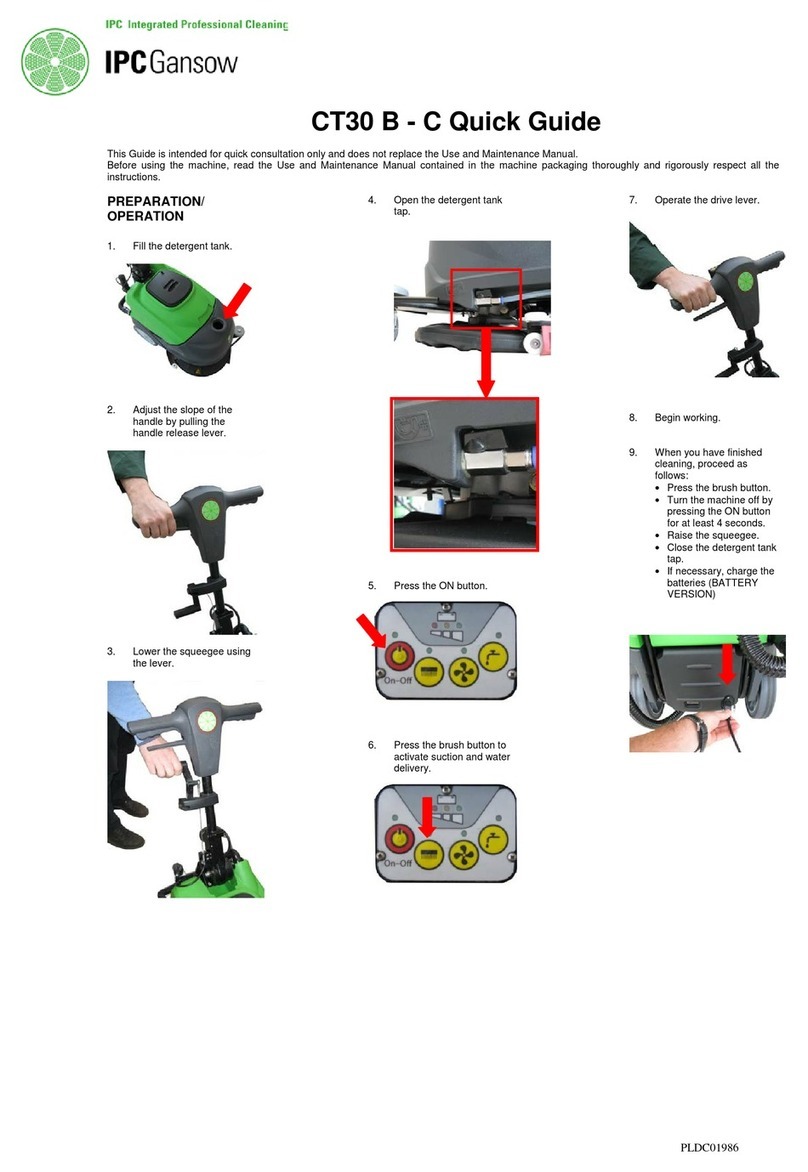

QUICK START GUIDE:

Park the unit on level ground with the sweeper slightly raised.

- Check the oil level in the engine.

- Grease all wheels and bearings according to the maintenance section.

- Check all bolts and hardware as per maintenance section.

- Clear the working area of all foreign objects and make sure all bystanders are clear before starting.

- Adjust working height.

OPERATION

Operating Parameters

The sweepers are designed to be towed by a tractor, quad, ATV, gator, etc.

For sweeping grass clippings, leaves and other debris, adjust the brush so that it is approximately half way into the

grass. For de-thatching and removing gravel, keep the brush approximately ½” off of the soil.

WARNING: Do not lower the brush too far into the soil. Doing so will over-torque and burn out the gear box clutch. This

damage is not covered by warranty.

Operating Procedures

- Adjusting the brush height determines how aggressively you will clean the area. Use the handle to set your

brush.

- When the basket is full, stop the sweeper. Drive to the dump area and raise the basket (using rope) until it is

completely emptied of debris. Lower the basket and resume clean-up.

- Do not lower the brush so low that the bristles bend.

DISCONNECTING & STORING

Park the unit on level ground and clean the sweeper. Always store the unit in a dry, clean environment.

MAINTENANCE

Service & Maintenance Safety

- Stop engine, set brake and remove key before servicing.

- Block up unit before working beneath unit.

- Replace all shields and guards before operating.

- Use 10W30 synthetic oil in the engine.

Lubrication

- Grease spindles and wheels after every 8 hours of use.

- Grease wheel bearings so that grease squeezes out of the wheel hub.

- Clean all grease nipples before greasing. Replace if damages occurs.

- Check all guards and shields, making sure they are secure. Replace or repair damaged components.

- Check brushes and housing. Clean if required so that it does not plug up.

- Check all bolts periodically.

3 Revision 11-22-17

3

Specificationssubjecttochangewithoutnotice.

Selecting and using equipment for all terrain

Venicles (ATVs)

Introduction

This information sheet gives advice to users on how to use all Terrain vehicles(ATVs) safely

with towed and mounted equipment.

Plan the use of an ATV carefully and take particular note of ground conditions and slopes, as

these may vary considerably, depending on the terrain, weather conditions, ground surface

and the crop under the wheels.

Towed equipment

Choose equipment which matches your ATV. Stability of towed equipment is affected by:

Weight ratios

1. The safe ratio between the trailed laden maximum weight and un–laden weight of the

ATV must be assessed for each operation.

2. Always take note of information given in the manufacture′s handbook when making this

assessment.

3. As a guide research shows that on level ground, 4 x un-laden weight of the ATV for braked

trailed equipment and 2 x un-laden weight of the ATV for un-braked trailed equipment are

the appropriate maximum retios.

Note: For work on slopes or uneven ground the ratio will need to be reduced.

Braking

Fit:

1. Brakes to trailed equipment. This helps prevent jack-knifing when braking or traveling

downhill;

2. Over-run brakes which come into action whenever the ATV brakes are applied;

3. A manually operated parking brake operable from the driving position. This provides control

for use when going up slopes.

Hitching and loads

Stability is also improved if:

1. Some weight is transferred from the trailer onto the ATV draw-bar;

2. The draw-bar has a swivel hitch and the ATV a ball hitch having a large head to neck ratio.

This makes it easier for the draw-bar hitch to swivel and cope with undulating ground;

3. The load is positioned as near to the center of the trailer as possible.

tires and wheels

1. Check tire pressures regularly with a pressure gauge capable of reading low pressures

accurately;

2. Check tires regularly for damage and wear;

3. Select equipment which has tires and wheels that can cop with speeds over 20mph and

occasional higher speeds;

4. Use wheels with bead locks on the rims if the main use is going to be on sloping ground.

This prevents tire run-off on side slopes.

4 Revision 11-22-17

4

Specificationssubjecttochangewithoutnotice.

Maximum towed weight

Follow the advice given by manufacturers on the maximum trailed weight. This will be found

on the equipment or in the instruction handbook.

Note: Universal road going trailers will normally have the maximum gross weight stated on a

separate notice.

Mounted equipment

ATVs using mounted equipment are safer if the equipment has:

·a low center of gravity. This improves stability.

·a gross weight within the limits approved by ATV manufacturer.

·no dangerous projections to injure the operator or bystanders;

·no forward projections which stop head protection being worn;

·controls which are easy to work and which do not creat e a hazard to the operator;

Instructions for mounted and trailed equipment

Take note of the manufacturer′s instructions on:

·operating on slopes;

·where to place loads so as to give fore/aft and lateral stability;

·the risks of using equipment with negative drawbar nose weight, ie loss of traction;

·the maximum operating speed;

·the effect that equipment carried on front and/or rear racks will have on longitudinal and

lateral stability;

·securing loads;

·the use of ballast, if any, to improve stability;

·the need to select and use safe routes.

Using an ATV

·read the manufacturers instruction book and take note of the safety advice given;

·Choose an ATV with enough power for the work you want it to do. four-wheel driver will give

better traction and mobility and may provide a margin of safety;

·Choose a safe route;

·Be aware that increased speed greatly increases the risk of instability and risk of and

overturn;

Training

Train everyone who has to use an ATV whether with mounted or trailed equipment or as a

solo machine. The training should emphasize the factors affecting stability, the need for care

and concentration, and how to recognize the conditions which may affect the safety of

operation, It is important for trainees to familiarize themselves with the handing and control of

the machine on level open ground before tackling rough hill terrain.

Suitable training courses are run by bodies such as ATB Landbase and the forestry Authority.

Helmets

Wear head protection which protects the head and neck. Helmets are suitable. Some users

find open faced helmets more suitable than full face helmets.

This symbol means WARNING or CAUTION Personal safety or damage will be at

risk if these instructions are ignored. Most accidents are caused by neglect of

carelessness; Avoid needless accidents by following the safety precautions listed

below.

5 Revision 11-22-17

5

Specificationssubjecttochangewithoutnotice.

2IN THE INTEREST OF SAFETY:DO NOT

1. DO NOT~ Operate the sweeper without all the correct guards fitted.

2. DO NOT~ Alter engine settings unless stated by Engine manufacturer.

3. DO NOT~ Touch any moving or rotating parts, during working conditions

4. DO NOT~ Stop the engine immediately after heavy use, (See section 5.6)

5. DO NOT~ Operate the sweeper without suitable ear and eye protection

6. DO NOT~ Allow passengers.

7. DO NOT~ Leave machine un-attended while operating

8. DO NOT~ Run the engine in an enclosed area, exhaust gases contain Carbon Monoxide

and are fatal if inhaled.

9. DO NOT~ Operate the sweeper on excessively steep slopes.

10. DO NOT~ Operate the sweeper unless all safety features are fitted to the sweeper and

are

used correctly

11. DO NOT~ Operate the sweeper until you have read and understood the entire

operators

manual

12. DO NOT~ Wear loose fitting clothing, to avoid catching on parts of the machine

13. DO NOT~ Try to remove blockages while the engine is running. Ensure engine is

stopped and the rotor has finished rotating, before any servicing takes place to your

mover.

14. DO NOT~ Operate the sweeper in Dark conditions unless suitable artificial light is used.

15. DO NOT~ Operate if excessive vibration occurs, stop the machine immediately and view

maintenance chart.

16. DO NOT~ Climb on the sweeper.

3 IN THE INTEREST OF SAFETY:DO

1. DO~ Follow Engine manufactures guideline.

2. DO~ Ensure all spectators are a safe distance away when operating.

3. DO~ Carry out regular servicing and checks before use.

4. DO~ Clear cutting area from potential damaging components.

5. DO~ Reduce speeds when working on hillsides or rough terrain

6. DO~ Be aware components can be hot after operation

7. DO~ Follow any towing guidelines stated by ATV manufacturer.

8. DO ~ Show some caution when filling the tank with gasoline, especially if

engine components are hot.

9. DO~ Ensure all safety decals are in good condition, replace any that are damaged.

10. DO~ Keep hands and feet away from rotating blades

6 Revision 11-22-17

6

Specificationssubjecttochangewithoutnotice.

4 INSTRUCTION / WARNING DECALS

KEEP WHEEL NUTS TIGHT

CHECK DAILY

REFER TO THE OPERATORS MANUAL

FOR CORRECT tire INFLATION PRESSURE

OBSERVE TOWING VEHICLE MAX TOWING LIMITS OR TRAILER MAX WEIGHTS

ATTENTION

Your responsibilities before operating this machine are:

· Read Understand and Follow the safety procedures manual

· Train operators before using & review safety procedures regularly

· Ensure that all guards are in place before operating

· Keep Hand, Feet, Hair and Clothing away from all moving parts

· Avoid waring loose clothing whenever possible

· Maintain as per schedule in the safety procedures. Especially Blades and Securing Hardwar,

due to hazard they present should any part break loose during operation

· During maintenance, use suitable support stands

· DO NOT allow any persons to ride on the equipment

7 Revision 11-22-17

7

Specificationssubjecttochangewithoutnotice.

The above decals should be located on your AT – Power Sweeper. If any of the

above

decals are not located on your AT or are damaged in damaged in any way contact

for some replacement decals before use.

5 OPERATING INSTRUCTIONS AND

ADJUSTMENTS

The AT Power Sweeper is designed to give safe and dependable service if operated

according to instructions and intended use.

Read and understand this manual before operating the sweeper, as failure to do so could

result in personal injury or equipment damage.

When used with and A.T.V or compact tractor, ear protectioin should be worn. Under

normal working conditions a noise level of 83 decibels would be usual, ear protection is

advised.

5.1 INITIAL CHECK

1. Make sure that all nuts, bolts and fittings are securely fixed, and that all packaging

materials e.g. wire bands, tape etc have been removed.

2. Check the there is oil in the engine and gas in the tank.

3. Check tire pressures.

8 Revision 11-22-17

8

Specificationssubjecttochangewithoutnotice.

The main cutting height adjustment is achieved by using the screw jack, to raise or lower the

cutting deck as necessary.

HEIGHT ADJUSTMENT:

Turn the handle to raise or lower as necessary.

5.4 STARTING THE ENGINE

READ AND UNDERSTAND THE ENGINE OPERATORS MANUAL

BEFORE USE

Observe all safety precautions; keep hands and feet away from rotor and other

moving parts. Keep spectators at a safe distance.

1. Make sure there is a gap between the blades and the ground / crop

2. Select an area clear of loose debris that could be picked up.

3. Set the engine choke, and suitable idling speed with the throttle.

4. Place one foot on top of the deck body to give a firm and balanced position. Pull the

starter cord firmly, allowing the cord to return to return to the housing slowly (one or two

strong pulls should start the engine).

5. After a few seconds warming up at idling speed, move the throttle to the factory pre-set

working position to give a normal/working engine R.P.M of 3600 max.

NOTE

If the throttle is altered to increase the engine R.P.M beyond the recommended level, the

guarantee may become invalid. In addition to this, cutting efficiency will be reduced, fuel

consumption will increase and excessive vibration could be caused, resulting in a potential

danger to personnel and damage to components.

ELECTRIC START

Push button electric start engine options can be supplied if required. Simply hitch up the

sweeper, connect the electrical supply plug to the ATV socket and turn the ignition key to

start

the mover. Observing all the precautions mentioned above in ‘Starting the sweeper’.

REMOTE THROTTLE CONTROL

When a remote throttle control option is fitted, normally to the rear carrier frame of an ATV or

other suitable site on the towing vehicle, it gives the operator the facility of controlling the

sweeper engine from the operating position.

5.3 SWEEPER HEIGHT

9 Revision 11-22-17

9

Specificationssubjecttochangewithoutnotice.

The facility is most beneficial when moving from one cutting site to another close to it, by

reducing the engine revs to allow the sweeper brush to come to rest, no harm will be caused

to the sweeper or ground surface during transport, often over rough or difficult terrain when

stones and loose objects may be encountered.

5.5 FORWARD SPEED

The amount of grass or weeds to be cut dictates the forward speed; slow forward speeds give

better results in most cases. Ensure you follow the procedure below.

NORMAL FORWARD SPEED (1 kph~ very heavy use~ 10 kph ~ very light use)

Start off in the slowest speed possible, ensure the sweeper is working efficiently with the

engine set at maximum RPM and not laboring. (If this is not possible due to very heavy

conditions, raise height of brushes and be prepared to go over twice with machine set

lower on 2nd pass. Increase forward speed until the RPM of the engine starts to slow down

(This is working the engine too hard for conditions) – slow down, let the engine regain full

RPM and go through the same process but stop short of speed which made engine labor

previously. It is important always to listen to note of engine to ensure engine and sweeper

are working efficiently, slow down or stop once engine starts to labor.

FAILURE TO DO THIS WILL RESULT IN CLUTCH SLIP AND

ULTIMATELY SEVERE DAMAGE TO THE CLUTCH AND DRIVE

BELTS.

5.6 STOPPING THE SWEEPER

When stopping the sweeper after a period of heavy use. Run the machine at half working

speed in a stationary position, for at least 2 minutes, to allow the drive belts to cool down.

1. Show caution to hot parts e.g. engine exhaust, belts etc after engine is switched off.

2. Ensure the sweeper drawbar has been adjusted to allow the sweeper to run directly

behind the towing vehicle and is not in an offset position

3. When the sweeper has cooled down (Min 1hr after last used) Ensure all grass has been

removed from engine cooling fins, drive belt area, and rotors before operating again.

5.7 TRANSPORT POSITION

When the sweeper is being moved from one site to another it is advisable to raise the deck to

the highest position (Transport position, See section 5.3 “sweeper cutting height”)

The engine must be stopped and the blades at a standstill before adjusting to the transport

position.

Remove any crop debris from the deck before leaving the field.

Never move from one site to another with the engine running.

Please note the AT – Power Sweeper is not road legal, and should not be used on public

roadways

When moving from normal working conditions to heavier cutting, it may be

evident that the engine dies down and loses revs. SLOW DOWN IMMEDIATELY to allow the

engine revs to build up again to normal working speed. Follow the procedure detailed above

in “Normal Forward Speed”. Expected forward speed will be much lower in heavy conditions.

FAILURE TO DO THIS WILL RESULT IN CLUTCH SLIP AND

ULTIMATELY SEVERE DAMAGE TO THE CLUTCH AND DRIVE BELTS.

10 Revision 11-22-17

10

Specificationssubjecttochangewithoutnotice.

6 MAINTENANCE

Maintenance Schedule

Maintenance Operation: Hourly Daily Weekly Seasonal

Engine (See Engine manufacturers manual) ● ● ● ●

Remove excess crop gathered on deck ● ● ● ●

Remove excess crop wrapped around rotor

ends ● ● ● ●

Visual check to ensure nothings loose ● ● ●

Grease Height Adjuster ● ● ●

Grease Rear Roller ● ● ●

Grease Rotor Bearings ● ● ●

tire Pressures ● ●

Drive belt inspection ● ●

Rotor Bearing inspection ● ●

Wheel bearing inspection ● ●

Oil 50mm coupling ● ●

Swivel hitch Bush Wear ● ●

Check All Fasterner′s are tight and intact ● ●

Safety Chain Guard inspection ● ●

Safety Decals intact ● ●

Safety Guards Intact ● ●

Check Blade wear / condition ●

Check Metal Fatigue ●

Clutch Wear / Function ●

6.1 ENGINE

Refer to engine manufacturers manual, for servicing and maintenance of the engine.

11 Revision 11-22-17

11

Specificationssubjecttochangewithoutnotice.

6.2 VISUAL CHECK

Make a visual check around the sweeper, check for missing / loose parts or damaged /

worn

components. All-faults must be either repaired or replaced.

6.3 TIRE PRESSURES

DO NOT exceed recommended type pressures

22×1100 -8 7 – 10 PSI

16.5×6.50 -8 28 PSI (Max)

6.4 ROTOR BEARING INSPECTION

Rotate rotor shaft by hand and feel for any roughness in the bearings. Also try to pull the shaft

from side to side to see if any movement is found. If symptoms persist strip down the

rotor-housing unit and inspect bearings.

6.5 WHEEL BEARING INSPECTION

Jack one side of the sweeper body up, so the wheel is just off the ground. Rotate the wheel by

and, and check the wheel alignment. To check the bearing, try to move the wheel from left to

right and feel for any play in the bearings (A), ensure the wheel-locating bolt is tight before

you start and follow any jacking procedures. If any play is found remove the wheel and

inspect bearings. Replace any faulty bearings.

6.6 OIL 50mm COUPLING/BUSH WEAR

Check coupling for signs of damage or wear, swivel the coupling 36. degrees and check that

the bushes are not too worn. Replace any worn or damaged parts.

Oil the coupling regularly as shown below.

6.7 GENERAL INSPECTION

Check the sweeper to ensure all fasteners are tight and all safety guards / chains are intact

and fitted securely. Check all safety-warning decals, Replace any defective guards or

damaged

12 Revision 11-22-17

12

Specificationssubjecttochangewithoutnotice.

1

2

3

4

5

1

Speci f i cat i on: KP120. 01

Ver si on: 2017- 8

Page : 1/ 7

13 Revision 11-22-17

13

Specificationssubjecttochangewithoutnotice.

KP120.01 Whole Machine Part

No. Item No. Name Qty Remark

1 KP120.02 wheel bracket part 2

2 KP120.03 tipper-hopper part 1

3 KP120.04 hood part 1

4 KP120.05 traction part 1

5 KSP120.022 rear beam 1

14 Revision 11-22-17

14

Specificationssubjecttochangewithoutnotice.

Speci f i cat i on: KP120. 02

Ver si on: 2017- 8

Page : 2/ 7

1

2

3

6 5

8

9

1

1

1

1

1

1

1

7

1

9

3

15 Revision 11-22-17

15

Specificationssubjecttochangewithoutnotice.

KP120.02 Wheel Bracket Part

No. Item No. Name Qty Remark

1 KSP120.020 wheel bracket(left) symmetric

one each

2 GB/T 95-2002 plain washer 4 12

3 GB/T 859-1987 spring washer 6 12

4 GB/T 5783-2000 external hexagonal head bolt 4 M12x40

5 T9G5B/-2002 plain washer 4 16

6 GB/T 5781-2000 external hexagonal head bolt 2 M16x80

7 GB/T 889.1-2000 locking nut 2 M16

8 GB1152-89 nipple 2 M8x1

9 GB/T 95-2002 plain washer 8 10

10 GB/T 5780-2000 external hexagonal head bolt 4 M10x65

11 GB/T 6182-2000 locking nut 4 M10

12 KSP120.012 wheel bracket weldment part(left) 2

13 GB/T 95-2002 plain washer 4 M24x4

14 KSP120-120 wheel pressure spring 2

15 GB119-86 pin lock assembly 2 11Φ

16 13x5.00-6 small wheel 2

17 GB/T 276-94 deep groove ball bearing 4 6205-2Z

18 GB/T 96.2-2002 big plain washer 2 13.5x37x3

19 GB/T 5783-2000 external hexagonal head bolt 2 M1252×

20 AT120-114 end cap 2

16 Revision 11-22-17

16

Specificationssubjecttochangewithoutnotice.

2

3

4

5

6

7

8

9

1

1

1

1

Speci f i cat i on: KP120. 03

Ver si on: 2017- 8

17 Revision 11-22-17

17

Specificationssubjecttochangewithoutnotice.

KP120.03 Tipper-hopper Part

No. Item No. Name Qty Remark

1 KSP120.013 hopper weldment part 1

2 KSP120.023 hopper shrouding 1

3 KSP120.104 ear-hinge base 1

4 GB 825-88 lifting bolt 1 M12x22

5 KSP120.114 briquetting 2

6 GB/T 889.1-2000 locking nut 12 M8

7 GB/T 41-2000 normal nut 2 M8

8 GB/T 96.2-2002 big washer 4 9x24x2

9 GB/T 95-2002 plain washer 1 12

10 GB/T 889.1-2000 locking nut 1 M12

11 GB/T 95-2002 plain washer 20 8

12 GB/T 5783-2000 external hexagonal head bolt 10 M8x20

18 Revision 11-22-17

18

Specificationssubjecttochangewithoutnotice.

1

3

4

5

6

7

8

9

1

1

1

1

1

1

1

1

1

2

21

22

23

2

2

2

2

2

2

2

3

0

3

3

3

3

5

3

3

4

2

2

2

2

2

3

3

3

4

Speci f i cat i on: KP120. 04

Ver si on: 2017- 8

Page : 4/ 7

19 Revision 11-22-17

19

Specificationssubjecttochangewithoutnotice.

KP120.04 Hood Part

No. Item No. Name Qty Remark

1 KSP120.011 hood weldment part 1

2 KSP120.250 rubber 1

3 KSP120.234 rubber gasket 1

4 KSP120.015 pull wire support assembly 1

5 LC168F-B engine 1

6 winding disc 1

7 KSP120.016 belt cover 1

8 KSP120.251 spacer 1

9 KSP120.06 brush part 1

10 GB/T7810-1995 UC207 bearing with house 2

11 AT120-106 sleeve 1

12 GB13871-1992 sealing 1 55*80*8

13 KSP120.028 protecting baffle 1

14 KSP120.101 small pulley 1

15 KSP120.120 driving pulley 1

16 GBT 28701-2012 taper-lock 1 35*60

17 AT120-027 tensioner bracket assembly 1

18 KSP120.121 tensioning wheel 1

19 GB/T 276-94 deep groove ball bearing 2 6005-2Z

20 GB 893.1-86 circlip for hole 1 47

21 GB/T 5287-2002 extra large washer 2 9x28x3

22 GB/T 859-1987 spring washer 6 8

23 GB/T 5783-2000 external hexagonal head bolt 1 M852×

24 GB/T 6182-2000 locking nut 1 M10

25 A-1346 belt 2

20 Revision 11-22-17

20

Specificationssubjecttochangewithoutnotice.

Speci f i cat i on: KP120. 5

Ver si on: 2017- 8

Page : 5/ 7

1

2

3

4

5

6

7

8

9

1

1

12

13

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

2

Table of contents