Powrmatic HEM-NVx Series User guide

Stamm International Corporation

PO Box 1929

Fort Lee, NJ 07024

Tel: 201-947-1700

Fax: 201-947-9662

E-mail: stamminc@pobox.com

Stamm International HQ

www.powrmatic.co.uk

www.powrmatic.co.uk

®

Powrmatic Limited

Hort Bridge, Ilminster

Somerset

TA19 9PS

tel: +44 (0) 1460 53535

fax: +44 (0) 1460 52341

e-mail: [email protected]

web: www.powrmatic.co.uk

Powrmatic Ireland

45 Broomhill Close

Tallaght

Dublin 24

tel: +353 (0) 1452 1533

fax: +353 (0) 1452 1764

e-mail: [email protected]

web: www.powrmatic.ie

Getting In Touch

Powrmatic pursues a policy of continues improvement in both design and performance of its products and therefore reserves the right to change, amend or

vary specifications without notice. Whilst the details contained herein are believed to be correct they do not form the basis of any contract and interested

parties should contact the Company to confirm whether any material alterations have been made since publication of this brochure.

EURO-AIR

QUALITY

ICOM

Energy Association

More information is available from our website by scanning the following QR code.

HEM

User, Installation & Servicing Manual

Issue 3.6 Mar 2020

Doc Ref: M103 Issue 3.6 Mar 2020

ErP COMPLIANT

SEPTEMBER 2018

(NVx & SL)

page no. 2 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

www.powrmatic.co.uk

Important: This certificate

must be kept with the appliance

Failure to provide a copy of the commissioning sheet invalidates the heater warranty

----------------------------------------------------

Powrmatic Ltd, Hort Bridge, Ilminster, Somerset, TA19 9PS

Tel: 01460 53535 Fax: 01460 52341

This is to certify that this heater is guaranteed for two years parts and one year labour from the date

of original commissioning. The heater must be commissioned within 4 weeks of installation.

To make a claim

In the first instance you must contact your appliance supplier, or installer and provide:-

1. The appliance type and serial number.

2. The original commissioning documentation. As much detail as possible on the fault.

3. Your supplier, or installer, will then contact Powrmatic to make a guarantee claim on your behalf.

Conditions of Guarantee

1. The heater must have been installed by a competent qualified installer, and in

accordance with the manufacturer’s instructions, building regulations and local regulations.

2. The heater has been professionally commissioned, within 4 weeks of installation, and a copy of

the commissioning sheet returned to Powrmatic.

3. The heater has been maintained on a yearly basis by a competent and qualified servicing

company.

4. The heater has been used in accordance with the manufacturer’s instructions.

5. The correct specification fuel has been used.

6. No unauthorised repairs of modifications have been made. Powrmatic ‘General Conditions of

Sales’ have been observed.

7. Except for the obligation of Powrmatic Ltd to perform warranty repairs during the guarantee

period, Powrmatic will not be liable in respect of any claim for direct or indirect consequential

losses, including loss of profits or increased cost arising from loss of use of the heater, or any

event arising there from.

Exclusions

Consumables such as gaskets, ignition electrodes, flame rectification electrodes, fusible links, control

batteries are all excluded from guarantee.

CertificateOfGuarantee

Certificate of Guarantee

®

page no. 3 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

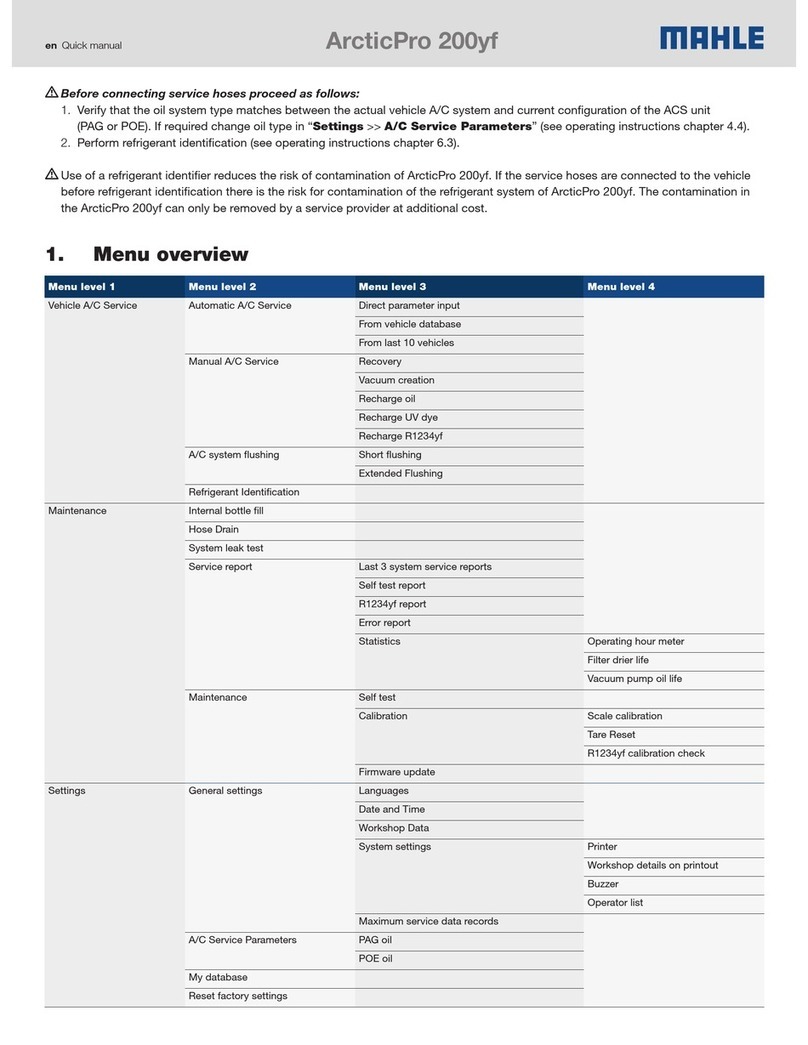

Title Section Contents Page

User Instructions 4

Pre Installation

1.1 Introduction 5

Duties 6

Dimensions 6

1.2 Technical data 10

1.3 General Requirements 12

Installation

2.1 Fitting the unit 15

2.2 General Identification of Items 19

2.3 Electrical Cable Installation 20

2.4 Wiring Terminal Connections 20

2.5 Wiring Diagrams 22

2.6 Commissioning and Testing 26

2.7 Servicing 30

Additional Documents

3.1 Fault Finding Flow Chart 33

3.2 List of Parts 34

Appendices

1. Information required for ecodesign (ErP) Directive 2009/125 HEM NVx 36

2. Information required for ecodesign (ErP) Directive 2009/125 HEM SL 37

3. Flueing and Ventilation requirements for 'stand alone' units 38

Users,InstallationandServicingInstructions

CONTENTS

Contents

page no. 4 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

D) Description of Operation

Important: The heater must NOT be

controlled by switching ON and OFF the

main electrical supply to it.

1) Standard Units

The ignition sequence commences each time the

external controls e.g. Time clock, room thermostat etc.

call for heat. The internal exhaust fan will run and, when

sufficient combustion airflow is proved by the air pressure

switch, the ignition spark will be generated, the main gas

valve opens and the burners light. The heater fan must

start a maximum of 2 minutes after the burners light.

When the external controls are satisfied the burners

will be turned off and the main fan is required to run on

sufficiently to dissipate the heat from the unit. If the

burners fail to light the control box will make another four

attempts at ignition.

2) High / Low & Modulating Units

When the burners are alight, the heat output will be

controlled either to high fire or low fire or, in the case of

modulating units, to any point between high and low fire;

depending on the requirements of the space being heated

and the external controls fitted.

3) Overheat Thermostat

This operates if high temperatures within the heater are

detected, the burners are turned off and a Red indicator

switch light on the front panel is illuminated. The fault

condition must be identified and rectified.

When the unit has cooled, push the Red indicator switch

inside the front panel to reset the limit thermostat

interlock relay, the red indicator light will go out and the

unit is operational again.

Note: The limit thermostat(s) can only be reset

once the unit has cooled down.

Unless the cause of the fault condition is

readily obvious, for example a power cut whilst

the heater was operating, a service engineer should be

contacted.

E) Maintenance

To maintain efficient, reliable and safe operation of the

heater it must serviced annually by a qualified person.

If the heater has not been left operational

proceed as follows.

A) Checks before operating the Air

Heater

The following preliminary checks should be made before

lighting the heater(s)

a) Ensure that the ELECTRICAL supply to the heater is

switched OFF.

b) Check that any warm air delivery outlets are open.

c) Check that the thermostat is set.

d) Check that the clock control is set to an ON period.

e) Check that any other controls are calling for heat.

B) Operating the Air Heater

1. Switch on the electrical supply at the isolator

2. If the Red Limit indicator lamp is illuminated, identify

the limit stat, remove the black cap and press the reset

button.

3. The startup sequence will commence. After a short

delay the burners will light and the green ‘ON’ indicator on

the front of the heater will be illuminated.

4. If the burners fail to light the control box will

automatically restart the ignition sequence. If after 5

attempts at ignition the burners have still failed to light

the control box will go to lockout and the Amber lockout

lamp on the front of the heater (or on the low level remote

reset, or MC200/MC300 if fitted) will be illuminated. To

restart the ignition sequence depress the reset button on

the low level reset for about 1-2 seconds.

WARNING: If it is not possible to light the

heater after several attempts, contact the

installer or local service company.

C) To Shut Down the Air Heater

1) For Short Periods:

Turn the room thermostat to the OFF, or set to 'Summer

Mode'.

2) For Long Periods:

Complete step 1 above. Wait for 5 minutes and then turn

OFF the electrical supply at the isolator.

UserInstructions

page no. 5 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

F) IMPORTANT

Free access must be maintained to and around the heater

for servicing purposes and the air supply to the heater

must not be restricted in any way. Combustible materials

must not be stored adjacent to the heater.

If at any time a gas leak is suspected, turn OFF the gas

supply at the meter and contact the local gas undertaking

immediately.

All Powrmatic heaters use gas and electricity to power

them, they may also contain moving parts such as pulleys

and belts. It would be hazardous to tamper with or

attempt to service unless you are a competent person in

the field of Gas and Electrical work.

If you have any safety questions reference the servicing

and installation of any of our heaters please do not

hesitate to contact our head office for expert advice. Your

safety is paramount to us.

Gas Safety (Installation & Use) (Amendment)

Regulations

It is law that all gas appliances are installed,

adjusted and, if necessary, converted by

qualified persons* in accordance with the

current issue of the above regulations.

Failure to install appliances correctly can lead to

prosecution. It is in your own interests and that of safety

to ensure that the law is complied with.

* Gas Safe Registered Engineer

The HEM Range are gas-fired insertion heaters covering

a range of heat outputs from 10.0kW to 200.0kW. They

are certified for use on Natural Gas, Group H - G20**.

Appliance Categories are Cat II2H (GB, IE). All units are

CE certified and conform to all the European directives

stated in section 1.3.1

HEM heaters are based on aluminised mild steel tube

heat exchanger elements with each tube having dedicated

inshot burners, a closed combustion circuit and have an

internal exhaust fan, mounted downstream of the heat

exchanger, to evacuate the products of combustion and

draw in air for combustion, a fully automatic control for

ignition, flame sensing, gas supply control and safety

functions.

Standard units are for internal use and are supplied

without a burner/controls housing for insertion into air

handling units or duct sections. Each unit is fitted with a

condense drain point from an all stainless steel exhaust

box. Optional items include a room sealed burner/controls

housing, T316 stainless steel heat exchanger tubes and

units specifically designed for fresh air input and where

condensate may be generated.

IMPORTANT

Service and Maintenance Engineers shall

ensure that replacement items are fitted,

adjusted and set in accordance with the

data and detail set out in these instructions. If in doubt

consult Powrmatic Technical Department.

Gas Safety (Installation & Use) Regulations 1998

It is law that all gas appliances are installed,

adjusted and, if necessary, converted by

qualified persons* in accordance with the

current issue of the above regulations.

Failure to install appliances correctly can lead to

prosecution. It is in your own interests and that of safety

to ensure that the law is complied with.

* Gas Safe Registered Engineer

* LPG conversion kits available.

1.1Introduction

UserInstructions

page no. 6 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

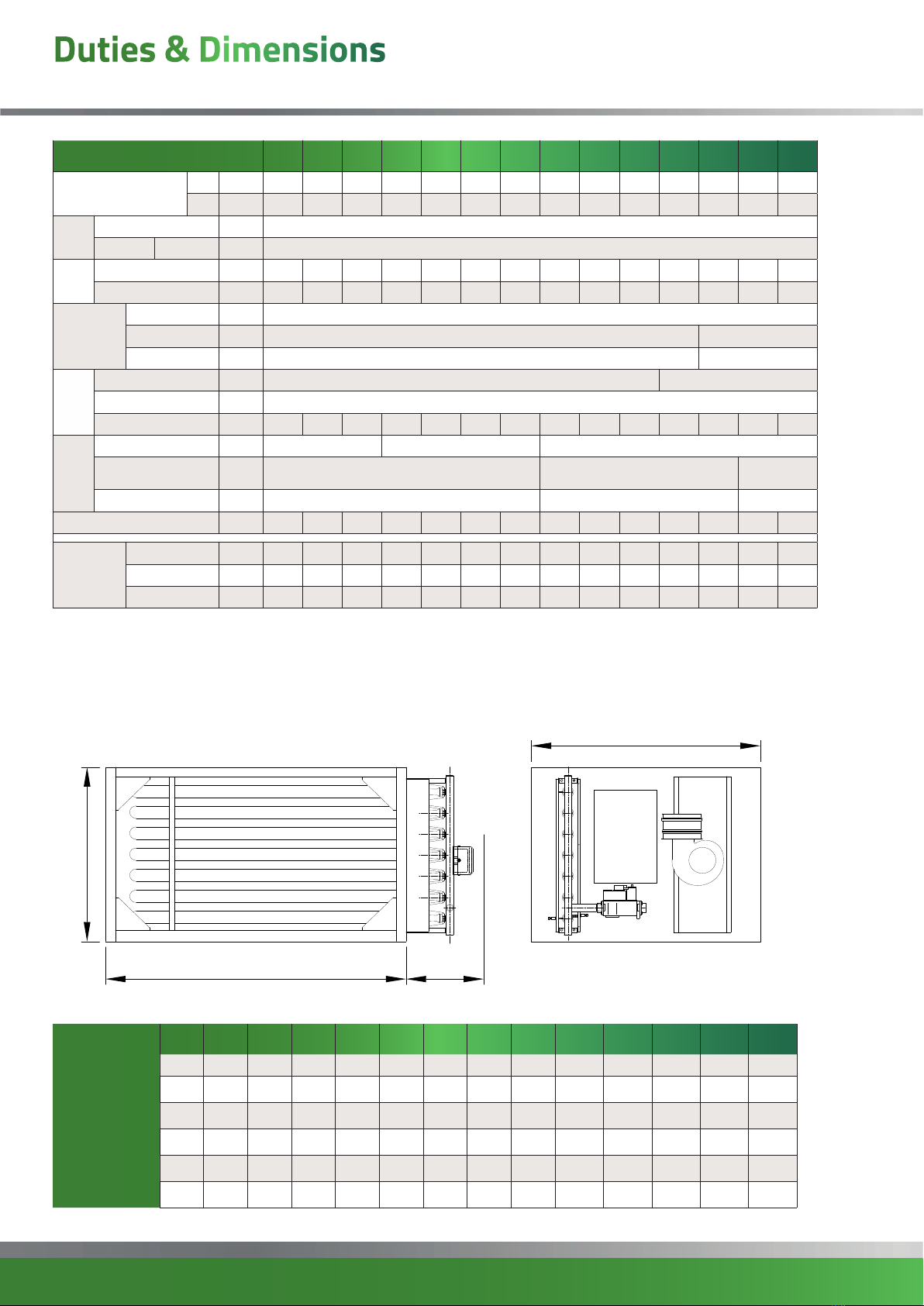

C

B

A D

Model 10-3 15-4 18-5 25-5 30-6 40-8 50-6 60-7 75-9 100-12 110-13 125-15 150-18 175-21

Dimension

A550 550 550 680 680 680 1050 1050 1050 1050 1050 1050 1050 1050

B305 458 458 531 531 741 531 601 741 950 1132 1272 1482 1690

C590 590 590 648 648 648 800 800 800 800 930 930 930 930

D400 400 380 400 380 380 400 400 400 400 500 500 500 500

Flue Diameter 80 80 80 100 100 100 100 130 130 130 130 130 130 130

Model HEM-NVx 10-3 15-4 18-5 25-5 30-6 40-8 50-6 60-7 75-9 100-12 110-13 125-15 150-18 175-21

Output Max kW 9.6 14.5 17.7 23.6 27.4 36.0 44.8 54.2 67.6 91.9 98.0 112.0 134.9 154.4

Min. kW 5.0 9.8 11.9 15.7 18.2 23.2 29.0 36.4 49.6 62.5 66.0 76.5 78.8 112.8

Temp Rise Δt °C 35

Air Off Max °C 70

Airflow Min. Airflow m3/s 0.34 0.44 0.58 0.71 0.86 1.01 1.55 1.94 2.28 2.78 2.99 3.39 4.14 4.67

Min. Airflow ΔP Pa 43 26 45 32 47 31 59 67 59 54 43 43 47 45

Electrics

V/ph/Hz 1N/230V/50~

Current A/pha 0.30 0.9

Power kW 0.07 0.21

Fuel

Natural

Gas

Connection BSP/Rc ¾1¼

Minimum Inlet Pressure mbar 20.0

Rate m3/h 1.09 1.72 2.09 2.77 3.22 4.18 5.26 6.52 8.10 10.92 11.62 13.37 16.27 18.40

Flue

Diameter mm ø 80 100 130

Max Length Type B m 14 16 3m max @

Ø130mm**

Max Length Type C m 14* 16* n/a

Nett Weight (single units) kg 38 45 53 60 68 74 91 114 123 140 145 168 195 230

Two

Modules in

Series

Max Δt = 70°C

Heat Output kW 19.2 29.1 35.4 47.2 54.9 72.0 89.5 108.4 135.2 183.8 196.0 224.0 269.7 308.8

Min. Airflow m3/s 0.34 0.44 0.58 0.71 0.86 1.01 1.55 1.94 2.28 2.78 2.99 3.39 4.14 4.67

Min. ΔP Pa 87 52 91 65 95 62 117 134 119 108 86 86 93 91

* length shown is maximum calculated length see section 2.1.4.2 ** see section 2.1.4.1 for longer flue runs

Duties & Dimensions

HEM-NVx

page no. 7 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

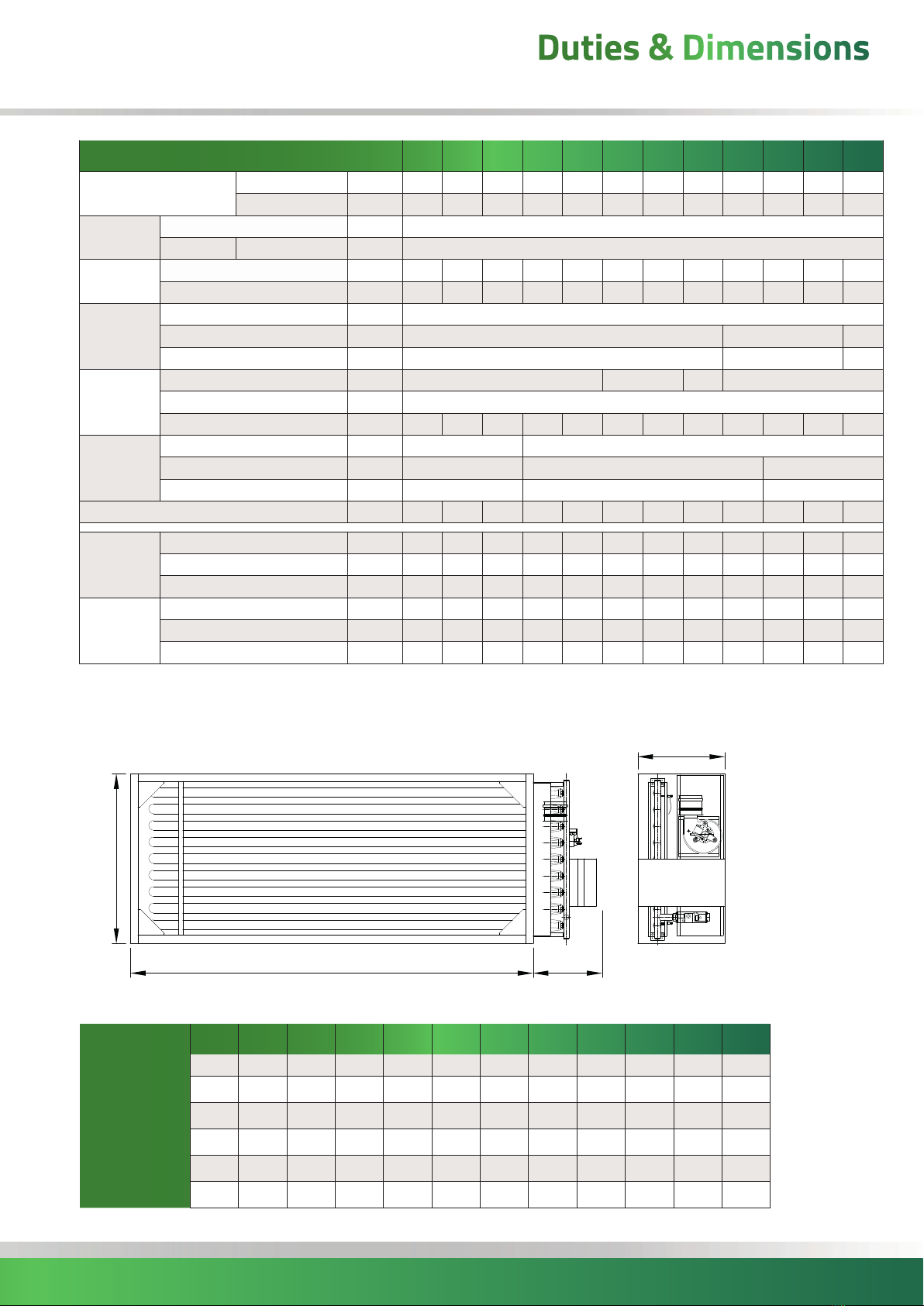

C

B

A D

Model 30-6 45-9 50-6 60-12 75-9 75-15 90-18 100-12 125-15 150-18 175-21 200-24

Dimension

A1250 1250 1850 1250 1850 1250 1250 1850 1850 1850 1850 1850

B531 741 531 950 741 1272 1482 950 1272 1482 1690 1900

C400 400 400 400 400 400 400 400 400 400 400 530

D450 450 450 450 450 450 450 450 500 500 500 550

Flue Diameter 100 100 100 130 130 130 130 130 130 130 130 130

Model - HEM-SL 30-6 45-9 50-6 60-12 75-9 75-15 90-18 100-12 125-15 150-18 175-21 200-24

Output Max kW 27.0 40.5 45.0 54.2 68.5 67.5 80.4 88.7 116.7 135.7 160.8 178.3

Min kW 15.0 23.5 23.9 36.4 44.6 41.5 41.6 62.4 70.5 79.9 82.6 108.3

Temp Rise Δt °C 35

Air Off Max °C 70

Airflow Min. Airflow m3/s 0.97 1.45 1.61 1.94 2.42 2.42 2.90 3.23 4.03 4.84 5.64 6.45

Min. Airflow ΔP Pa 16 17 20 18 21 15 19 22 19 19 20 21

Electrics

V/ph/Hz 1N/230V/50~

Current A 0.30 0.90 3.50

Power kW 0.07 0.21 0.80

Fuel

Natural Gas

Connection BSP/Rc ¾ 1¼ ¾ 1¼

Minimum Inlet Pressure mbar 20

Rate m3/s 3.35 4.76 5.29 6.52 8.15 8.26 9.59 10.31 13.76 16.22 19.43 21.81

Flue

Diameter mm ø 100 130

Max. Length Type B m 14 16 3m max @ Ø130mm**

Max. Length Type C m 14* 16* n/a

Nett Weight (single units) kg 59 85 79 118 106 139 165 130 185 204 235 265

Two Modules

in Series

Max Δt @ 50°C

Heat Output kW 54.0 81.0 90.0 108.4 137.0 135.0 160.8 177.3 233.4 271.4 321.5 356.6

Min. Airflow m3/s 0.97 1.45 1.61 1.94 2.42 2.42 2.90 3.23 4.03 4.84 5.64 6.45

Min. ΔP Pa 27 29 33 30 35 25 31 37 31 32 34 35

Three Modules

in Series

Max Δt @ 75°C

Heat Output kW 81.0 121.5 135.0 162.6 205.5 202.5 241.2 266.0 350.1 407.1 482.3 535.0

Min. Airflow m3/s 1.04 1.56 1.73 2.08 2.59 2.59 3.11 3.46 4.32 5.18 6.05 6.91

Min. ΔP Pa 46 49 56 51 59 43 52 63 52 54 57 58

length shown is maximum calculated length see section 2.1.4.2 * see section 2.1.4.1 for longer flue runs

Duties & Dimensions

HEM-SL

page no. 8 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

Note:

HEM NVx

The above data refers to a single module pressure drop. For twin models, refer to manufacturer.

10-3

720

1800

2880

3960

5040

6120

7200

7200

8280

9360

10440

11520

12600

13680

14760

14760

15840

16920

18000

19080

20160

21240

22320

22320

23400

24480

25560

26640

27720

28800

29880

29880

30960

32040

33120

34200

35280

36360

37440

37440

38520

39600

40680

41760

42840

43920

45000

45000

46080

47160

48240

49320

50400

51480

52560

52560

53640

54720

55800

56880

57960

59040

60120

60120

Airflow m³/h

15-4

18-5

25-5

30-6

40-8

50-6

60-7

75.9

100-12

110-13 125-15

150-18

175-21

200-24

Pressure Drop Graph

HEM-NVx

Airow m³/h

10-3

15-4

18-5

25-5

30-6

40-8

50-6

60-7

75.9

100-12

110-13 125-15

150-18

175-21

page no. 9 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

30-6

45-9

50-6

60-12

75-9

75-15

90-18

100-12

125-15

2160

3600

5040

6480

7920

9360

10800

10800

12240

13680

15120

16560

18000

19440

20880

20880

22320

23760

25200

26640

28080

29520

30960

30960

32400

33840

35280

36720

38160

39600

41040

41040

42480

43920

45360

46800

48240

49680

51120

51120

52560

54000

55440

56880

58320

59760

Airflow m³/h

150-18

175-21

200-24

Note:

HEM-SL

The above data refers to a single module pressure drop. For twin & triple models, refer to manufacturer.

Pressure Drop Graph

HEM-SL

Airow m³/h

page no. 10 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

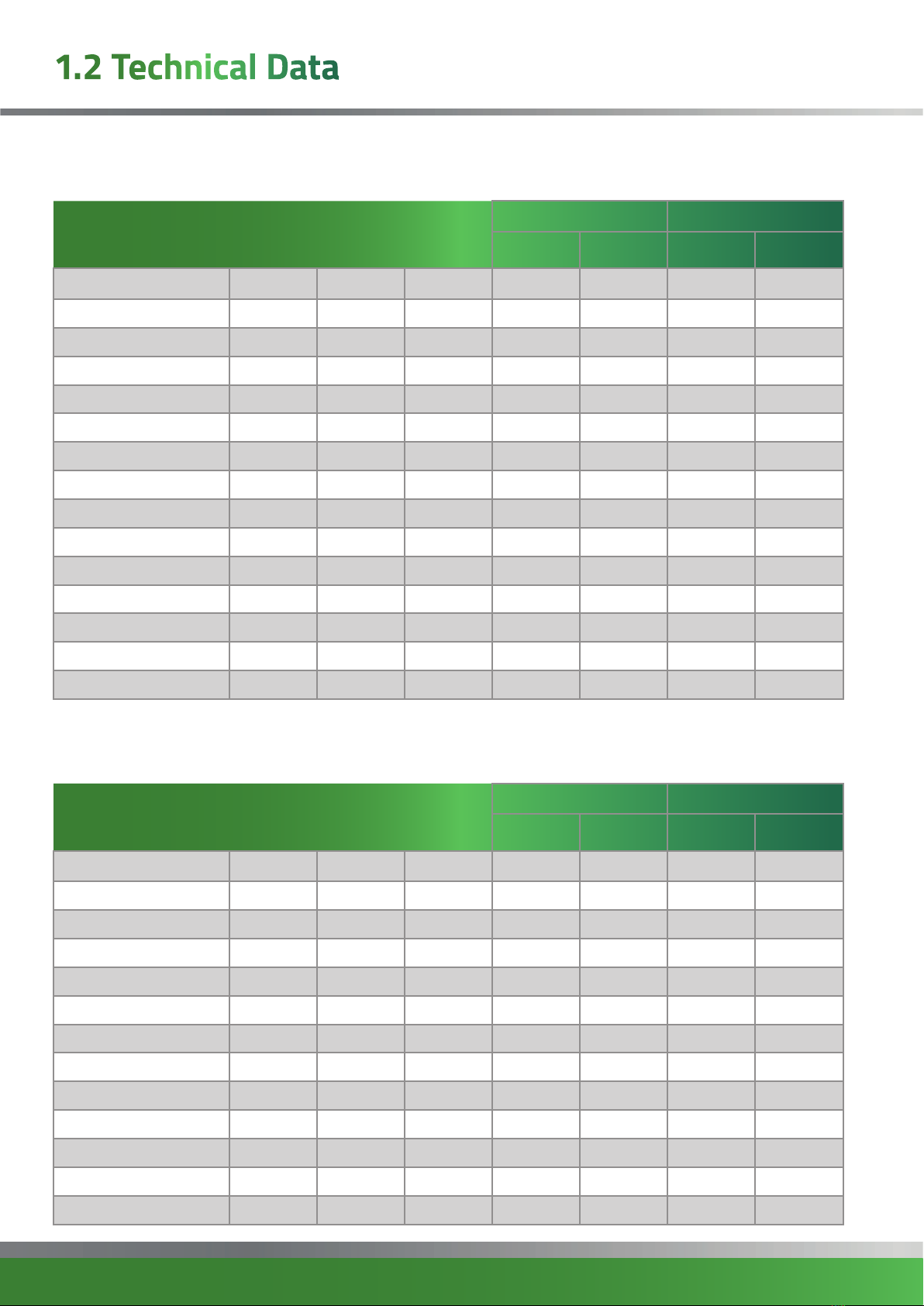

HEM-NVx Injectors

(Max) (Min)

Burner

Pressure Gas Rate

(nominal) Burner

Pressure Gas Rate

(nominal)

MODEL No. Size mm Marked mbar m³/h mbar m³/h

HEMNVx 10-3 31.67 380 8.6 1.1 2.7 0.6

HEMNVx 15-4 41.67 380 12.0 1.7 5.0 1.2

HEMNVx 18-5 51.67 380 12.0 2.1 5.0 1.4

HEMNVx 25-5 51.94 500 12.1 2.8 5.0 1.9

HEMNVx 30-6 61.94 500 12.0 3.2 5.0 2.2

HEMNVx 40-8 81.94 500 10.3 4.2 5.0 2.8

HEMNVx 50-6 62.54 750 10.2 5.3 4.7 3.5

HEMNVx 60-7 72.54 750 11.3 6.5 5.0 4.3

HEMNVx 75-9 92.54 750 10.8 8 .1 6.3 6 .1

HEMNVx 100-12 12 2.54 750 11.4 10.9 5.0 7.6

HEMNVx 110-13 7+6 2.54 750 10.4 11.6 5.0 7.9

HEMNVx 125-15 9+6 2.54 750 10.8 13.4 5.0 9.2

HEMNVx 150-18 9+9 2.54 750 10.5 16.3 4.6 10.6

HEMNVx 175-21 12+9 2.54 750 11.0 18.4 5.0 13.3

Injector Sizes & Burner Pressures - Natural Gas - Group H - G20 Net CV (Hi = 34.02MJ/m³)

HEM-SL Injectors

(Max) (Min)

Burner

Pressure Gas Rate

(nominal) Burner

Pressure Gas Rate

(nominal)

MODEL No. Size mm Marked mbar m³/h mbar m³/h

HEMSL 30-6 61.94 500 12.0 3.4 4.0 1.9

HEMSL 45-9 91.94 500 10.9 4.8 2.9 2.8

HEMSL 50-6 62.54 750 10.0 5.3 1.6 2.9

HEMSL 60-12 12 1.94 500 11.3 6.5 5.0 4.3

HEMSL 75-9 92.54 750 10.6 8.2 4.6 5.3

HEMSL 75-15 15 1.94 500 12.1 8.3 4.0 4.6

HEMSL 90-18 18 1.94 500 10.5 9.6 3.1 4.9

HEMSL 100-12 12 2.54 750 10.0 10.3 5.0 7.4

HEMSL 125-15 15 2.54 750 10.0 13.8 5.0 9.6

HEMSL 150-18 18 2.54 750 9.70 16.2 5.0 10.6

HEMSL 175-21 21 2.54 750 9.70 19.4 5.0 12.1

HEMSL 200-24 24 2.54 750 10.3 21.8 5.5 14.1

1.2 Technical Data

Minimum Inlet Pressure = 20mbar

page no. 11 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

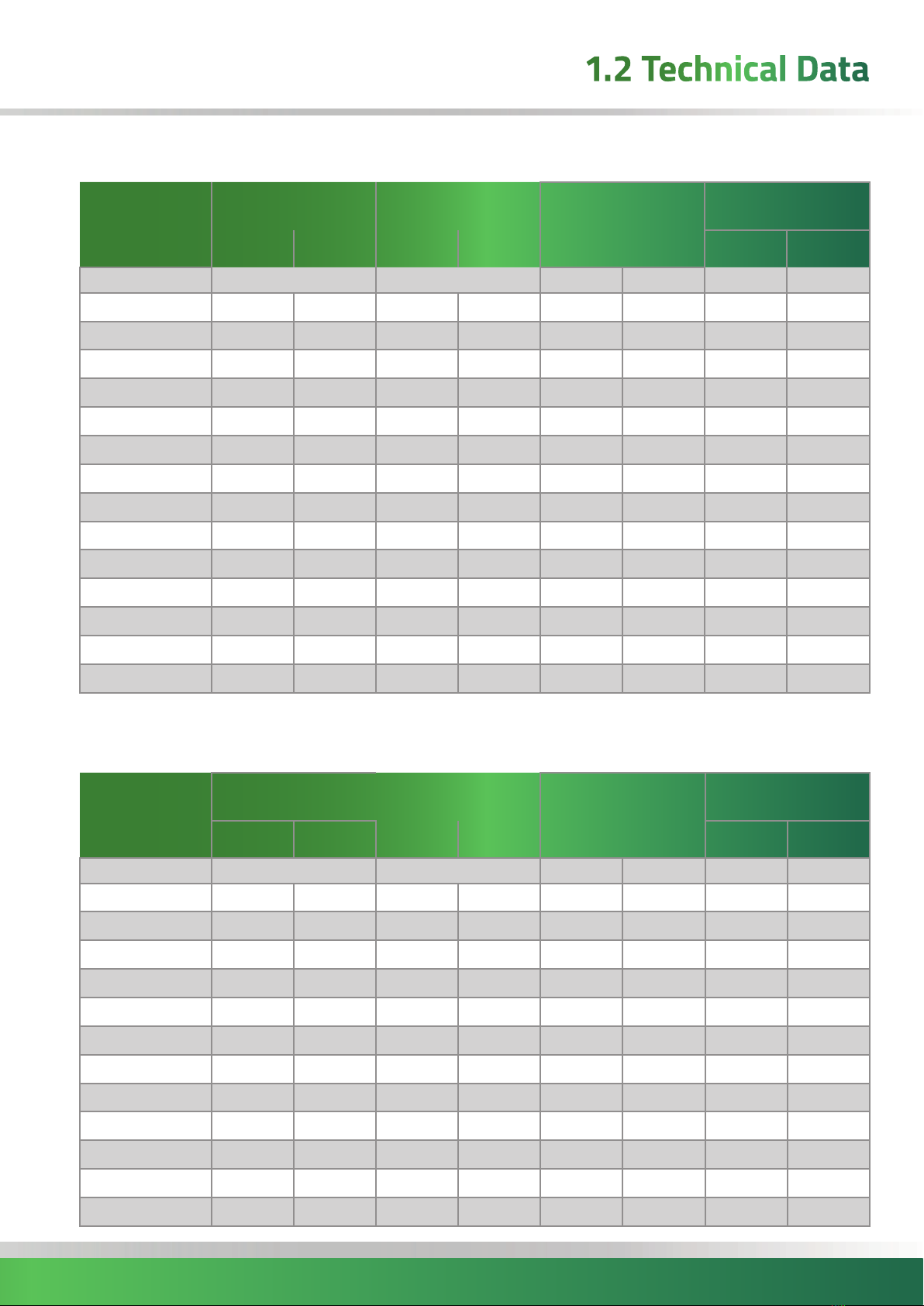

Heater Specifications cont - Natural Gas

HEM-NVx High Fire Low Fire

Min Air Flow

Weights

Input

(Nett) Output Input

(Nett) Output Module

only Packaging

MODEL kW kW m³/s m³/h kg kg

HEMNVx 10-3 10.3 9.6 5.6 5.0 0.34 1220 38 12

HEMNVx 15-4 16.3 14.5 11.0 9.8 0.4 1600 45 12

HEMNVx 18-5 19.8 17.7 13.4 11.9 0.6 2070 53 15

HEMNVx 25-5 26.2 23.6 17.8 15.7 0.7 2550 60 15

HEMNVx 30-6 30.5 27.4 20.6 18.2 0.9 3100 68 15

HEMNVx 40-8 39.6 36.0 26.4 23.2 1.0 3650 74 15

HEMNVx 50-6 49.7 44.8 33.0 29.0 1.5 5570 91 18

HEMNVx 60-7 61.6 54.2 41.0 36.4 1.9 6984 114 18

HEMNVx 75-9 76.6 67.6 57.7 49.6 2.3 8208 123 18

HEMNVx 100-12 103.3 91.9 71.9 62.5 2.8 1000 140 21

HEMNVx 110-13 109.9 98.0 75.0 66.0 3.0 10750 145 21

HEMNVx 125-15 126.4 112.0 86.5 76.5 3.4 12200 168 25

HEMNVx 150-18 153.9 134.9 100.2 78.8 4.1 14900 195 30

HEMNVx 175-21 174.0 154.4 125.7 112.8 4.7 16800 230 32

HEM-SL High Fire Low Fire

Min Air Flow

Weights

Input

(Nett) Output Input

(Nett) Output Module

only Packaging

MODEL kW kW m³/s m³/h kg kg

HEMSL 30-6 31.7 27.0 17.9 15.0 1.0 3492 59 15

HEMSL 45-9 45.0 40.5 26.3 23.5 1.5 5220 85 15

HEMSL 50-6 50.0 45.0 27.3 23.9 1.6 5796 79 18

HEMSL 60-12 61.6 54.2 41.0 36.4 1.9 6984 118 15

HEMSL 75-9 77.0 68.5 50.2 44.6 2.4 8712 105 18

HEMSL 75-15 78.0 67.5 43.6 41.5 2.4 8712 139 18

HEMSL 90-18 90.6 80.4 46.2 41.6 2.9 10440 165 18

HEMSL 100-12 97.5 88.7 69.5 62.5 3.2 11628 130 21

HEMSL 125-15 130.0 116.7 85.4 70.5 4.0 14508 185 25

HEMSL 150-18 153.2 135.7 99.8 79.9 4.8 17424 204 30

HEMSL 175-21 183.6 160.8 114.0 82.6 5.6 20304 235 32

HEMSL 200-24 20 6.1 178.3 133.2 108.3 6.5 23220 265 35

1.2 Technical Data

page no. 12 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

1.3.1. Related Documents

All HEM heaters comply with the following European

Directives:

Energy Related Product Directive: 2009/125/EC*

Gas Appliance Directive: 2009/142/EC

Electromagnetic Compatibility Directive: 2004/108/EC

Low Voltage Directive: 2006/95/EC

Machinery Directive: 2006/42/EC

Air heater(s) must be installed in accordance with BS6230

and BS5440 plus any relevant requirements of local and

national building codes. * where appropriate.

1.3.2 Electrical Supply

Wiring external to the air heater must be installed in

accordance with the I.E.E. Regulations for Electrical

Installations and any local regulations which apply.

All standard heaters are supplied by 230V - 1ph, 50Hz.

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the unit(s)

via a suitable fused isolator (see section 2.4.5 for ratings)

- be in a readily accessible position adjacent to the unit(s)

- serve only the unit(s)

- have a contact separation of at least 3mm in all poles.

See the accompanying wiring diagram for the heater

electrical connections.

1.3.3 Gas Supply

A servicing valve and union to facilitate servicing must

be fitted to the gas inlet pipe work of the heater. The

gas supply must be completed in solid pipe work and be

adequately supported.

WARNING: When completing the final gas

connection to the heater do not place undue

strain on the gas pipe work of the heater.

1.3.3.1 Service Pipes

The local gas undertaking should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas to suit the

building requirements. An existing service pipe must not

be used without prior consultation with the local gas

undertaking.

1.3.3.2 Meters

An existing meter should be checked, preferably by the

gas undertaking, to ensure that the meter is adequate

to deal with the total rate of gas supply required by all

connected equipment.

1.3.3.3. Installation Pipes

Installation pipes should be fitted in accordance with IGE/

UP/2. Pipe work from the meter to the air heater must be

of adequate size.

Do not use pipes of a smaller size than the inlet gas

connection of the heater.

The complete installation must be tested for soundness

as described in the above Code.

1.3.4VentilationRequirementsfor

AHU's

Refer to tables detailed on next page for calculated free

areas of ventilation grilles.

Refer to Index 1 for Air inlet/exhaust flue and ventilation

sketches

1.3.4.1 Type B flued installations.

Where AHU's are installed within the heated space

(ie not in a plant room) and having a building design air

change rate of greater than 0.5/h, additional provision for

ventilation is not required.

If the building design air change rate is less than 0.5/h,

additional provision for natural or mechanical ventilation

is required.

These being:

Natural Ventilation: Grilles having a free area of at least

2cm² per kW of rated heat input shall be provided at low

level i.e. below the level of the heater flue connection.

or

Mechanical Ventilation: Must ensure that the space air

change rate is at least 0.5/h, must be of the ‘input’ type

and interlocked to ensure the heaters cannot work if the

input system is not working.

1.3GeneralRequirements

page no. 13 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

1.3.4.1 Type B flued installations.

Where AHU's are installed in a plant room (ie not

within the heated space) having combustion air drawn

directly from the room and connected to a flue that

evacuates the products of combustion directly from

the room additional provision for natural or mechanical

ventilation is required.

These being:

Natural Ventilation:

There must be permanent air vents communicating

directly with the outside air, at high level and at low level.

For Plant Rooms

Low level (inlet) 4cm²/kw of total rated net heat input

High level (outlet) 2cm²/kw of total rated net heat input

Mechanical Ventilation: The minimum flow rate of

ventilation shall be 4.14m³/h per kilowatt of total rated

heat input.

1.3.4.3 Type C flued installations.

Note Not applicable for models 175 and 200

Where AHU's are Installed within the heated space

(ie not in a plant room) having combustion air ducted

to the appliance and combustion products ducted to the

outside air, NO additional provision for the supply of

either combustion air or for combustion products dilution

or additional provision for the supply of air is necessary.

1.3.4.3 Type C flued installations.

Where AHU's are installed in a plant room (ie

not within the heated space) having g combustion

air ducted to the appliance and combustion products

ducted to the outside, air vents shall be provided and be

permanently open.

To room or internal space

Low level (inlet) 10cm²/kw of total rated net heat input

High level (outlet) 10cm²/kw of total rated net heat input

Direct to outside air

Low level (inlet) 5cm²/kw of total rated net heat input

High level (outlet) 5cm²/kw of total rated net heat input..

1.3.5 Burner/Controls Enclosure.

Where the flue system is a Type C12 or C32 the burner

and controls enclosure, whether it is part of the unit the

module is fitted in or an enclosure in its own right, must

meet the requirement of BS EN1020 Clause 6.1.1.24 i.e.

the air leakage rate from the enclosure shall not exceed

0.5m³/h per kW of heat input, with a maximum of 25 m³/h.

With the flue connected the terminal is sealed, any access

door is closed and the gas inlet is isolated. Air is passed

into the appliance via a flow meter and the air flow rate is

noted when the pressure inside the enclosure is steady at

0,5mbar above the atmospheric pressure.

NOTE A convenient method of testing the

appliance is to enclose the terminal in a plastic

bag into which an air entry pipe and tube

connected to a pressure gauge can be fitted.

1.3GeneralRequirements

page no. 14 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

Type B22 Installation (these refer to section

2.2 of these instructions)

Air vents shall be permanently open.

In all cases gures are per heater installed.

For multi heater installations the appropriate values for

each heater must be added together

Type C12 or C32 Installation (these refer to section 2.2 of

these instructions)

Air vents shall be permanently open.

Figures are for heaters in plant rooms or enclosures ONLY

In all cases gures are per heater installed.

For multi heater installations the appropriate values for each heater must be

added together.

Heat

Input

kW

In the heated

space

In a plant room, ventilation

to outside

Ventilation is to a room or

internal space

Ventilation is to a outside

air

Low level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm²

HEMNVx 10-3 10.3 20.6 41.2 20.6 103.0 103.0 51.5 51.5

HEMNVx 15-4 16.3 32.6 65.2 32.6 163.0 163.0 81.5 81.5

HEMNVx 18-5 19.8 39.6 79.2 39.6 198.0 198.0 99.0 99.0

HEMNVx 25-5 26.2 52.4 104.8 52.4 262.0 262.0 131.0 131.0

HEMNVx 30-6 30.5 61.0 122.0 61.0 305.0 305.0 152.5 152.5

HEMNVx 40-8 39.6 79.2 158.4 79.2 396.0 396.0 198.0 198.0

HEMNVx 50-6 49.7 99.4 198.8 99.4 497. 0 497. 0 248.5 248.5

HEMNVx 60-7 61.6 123. 2 246.4 123.2 616.0 616.0 308.0 308.0

HEMNVx 75-9 76.6 153.2 306.4 153.2 766.0 766.0 383.0 383.0

HEMNVx 100-12 103.3 206.6 413.2 206.6 1033.0 1033.0 156.5 156.5

H EMN Vx 110 -13 109.9 219.8 439.6 219.8 1099.0 1099.0 549.5 549.5

HEMNVx 125-15 126.4 252.8 505.6 252.8 2528.0 2528.0 1264.0 1264.0

HEMNVx 150-18 153.9 307.8 615.6 307. 8 n/a

HEMNVx 175-21 174.0 348.0 696.0 348.0

Type B22 Installation (these refer to section

2.2 of these instructions)

Air vents shall be permanently open.

In all cases gures are per heater installed.

For multi heater installations the appropriate values for

each heater must be added together

Type C12 or C32 Installation (these refer to section 2.2 of

these instructions)

Air vents shall be permanently open.

Figures are for heaters in plant rooms or enclosures ONLY

In all cases gures are per heater installed.

For multi heater installations the appropriate values for each heater must be

added together.

Heat

Input

kW

In the heated

space

In a plant room, ventilation

to outside

Ventilation is to a room or

internal space

Ventilation is to a outside

air

Low level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm² Low level grille.

Free area cm² High level grille.

Free area cm²

HEMSL 30-6 31.7 63.4 126.8 63.4 317.0 317.0 158.5 158.5

HEMSL 45-9 45.0 90.0 180.0 90.0 450.0 450.0 225.0 225.0

HEMSL 50-6 50.0 100.0 200.0 100.0 500.0 500.0 250.0 250.0

HEMSL 60-12 61.6 123.2 246.4 123.2 616.0 616.0 308.0 308.0

HEMSL 75-9 77.0 154.0 308.0 154.0 770.0 770.0 385.0 385.0

HEMSL 75-15 78.0 156.0 312.0 156.0 780.0 780.0 390.0 390.0

HEMSL 90-18 90.6 181.2 362.4 181.2 906.0 906.0 453.0 453.0

HEMSL 100-12 97. 5 195.0 390.0 195.0 975.0 975.0 4 8 7. 5 4 87. 5

HEMSL 125-15 130.0 260.0 520.0 260.0 1300.0 1300.0 650.0 650.0

HEMSL 150-18 153.2 306.4 612.8 306.4

n/aHEMSL 175-21 183.6 3 67. 2 734.4 3 67. 2

HEMSL 200-24 206.1 412.2 824.4 412.2

1.3.6.VentilationRequirements

HEM-NVx

HEM-SL

1.3GeneralRequirements

page no. 15 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

Before installation, check that the:

- local distribution conditions, nature of gas and pressure,

and the current state adjustment of the appliance are

compatible,

- local electrical supply conditions are compatible with the

electrical data given on the data plate.

2.1.1.Unpacking

The module has been fired and tested at the factory prior

to despatch. Check the despatch documents and the data

plate affixed to the module to confirm that it is as ordered

and compatible with the gas and electrical supplies on

site.

Read the entire document before commencing

installation.

2.1.2 Module Types

Modules are available for:

a) Use within an additional casing e.g. an air handling unit.

i.e no factory fitted burner /controls housing.

b) Internal use with a burner /controls housing.

c) For external use with a weatherproof burner/controls

housing.

Type a) and type b) can be for either B22 (combustion air

taken from the internal space) or C12/C32 (combustion air

taken from outside) flue configurations.

2.1.3 Module Fitment

Modules must be handled safely and lifted using the fitted

lifting brackets. These can be removed on installation if

necessary. The module should slide into the air handling

unit/duct section between top and bottom guide rails

sized to suit the module in question. It must be possible

to easily remove the module at a later date should this be

necessary.

There must be effective sealing between the module

burner/controls section so that there is no air leakage

from the main air flow path into the burner/controls

section.

Modules may be orientated so that the burner manifold(s)

is vertical or horizontal.

For external units please note:

The lowest edge of air inlets must be at least

500 mm above ground level. Access panels

and doors to be removed during normal

servicing shall be designed so that repeated removal and

replacement does not damage the insulation or impair the

waterproofing of the unit.

No opening (e.g. electrical wiring points) from the inside of

the appliance to the outside air shall permit the entry of a

16 mm diameter ball.

2.1.4 Combustion Air Inlet and Flue

Products Outlet

Combustion air inlet(s) and flue outlets must be

connected to each HEM unit so when the unit is installed,

their termination is at least 500mm from ground level.

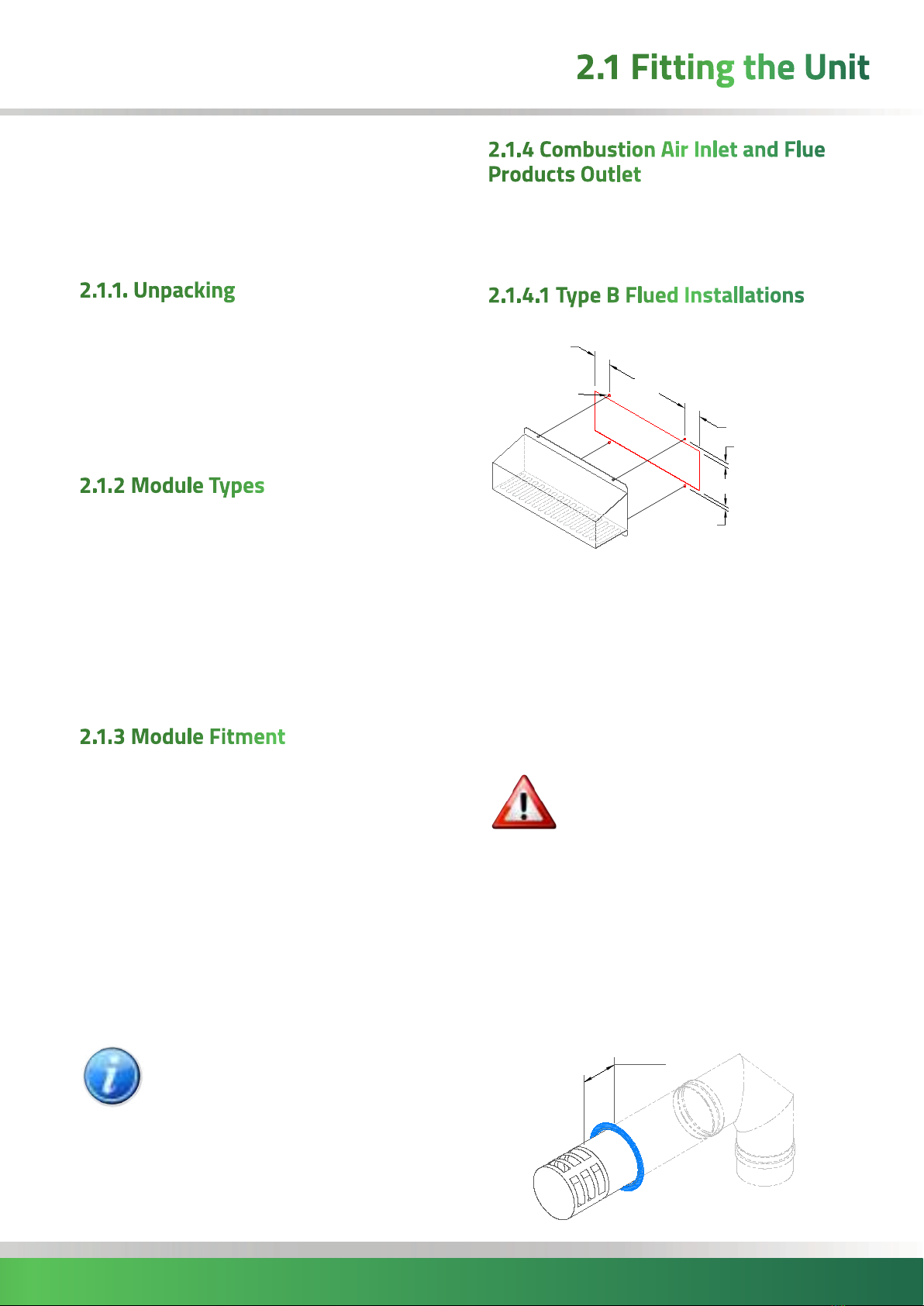

2.1.4.1 Type B Flued Installations

The combustion

air inlet

attachment

requires an

aperture to be

cut and four

pilot holes to

be drilled in the

front plate of

the controls

compartment

to the following

dimensions and must be installed on a level plane.

The combustion air inlet attachment can then be offered

up to the front plate and secured using self tapping

screws ensuring a positive seal to prevent any ingress of

water.

Alternatively an air inlet orifice having a free area of at

least 110 cm² (app 105 x 105mm) can be cut into the

burner enclosure panel to facilitate the combustion air.

Two air inlet attachments (or free area of

220cm²) are required on models SL75-15;

SL90-18; NVx & SL125; NVx & SL150; NVx &

SL175.

Three air inlet attachments (or free area of

330cm²) are required on models HEM SL200

A flue outlet terminal is required with every module and

is connected to the exhaust fan. Flue outlet terminals can

be either standard 450mm long terminals or Powrmatic

approved flue system. Flue terminals may be extended by

the use of a Powrmatic approved flue piece with sealing

ring or cut down to suit the particular application ensuring

the flue terminal projects from the front plate by at least

75mm

min 75mm

2.1 Fitting the Unit

220

96

12

12

40.5

40.5

4 HOLES Ø3

page no. 16 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

For horizontal type B flued installations a Combustion

Air Inlet and Flue Termination piece is supplied for each

module (two Combustion Air Inlets are supplied with

models HEMNVx 150 & 175). For Vertical type B flued

installations a Combustion Air Inlet and Flue Termination

piece is supplied for each module (two Combustion Air

Inlets are supplied with models HEMNVx 150 & 175).

The total calculated maximum permitted length of flue

system for sizes up to and including model 50 is 14m,

from model 60 to 125 is 16m. If an offset is required a set

Size A B C ØD

10-3 399 167 108 91

15-4 399 167 108 91

18-5 399 167 108 91

25-5 443 187 121.5 112

30-6 443 187 121.5 112

40-8 637 187 121.5 112

50-6 443 217 121.5 112

60-7 501 227 145.5 142

75-9 641 227 145.5 142

100-12 848 226 151.5 142

110-13 997 204 181 142

125-15 1137 204 181 142

150-18 1347 204 181 142

175-21 1554 204 181 142

A

B

HORIZONTAL FLUE POSITION

ØD HOLE FOR FLUE SEAL

C

A

B

HORIZONTAL FLUE POSITION

ØD HOLE FOR FLUE SEAL

C

HORIZONTAL FLUE POSITION

ØD HOLE FOR FLUE SEAL

A

BC

HORIZONTAL FLUE POSITION

ØD HOLE FOR FLUE SEAL

A

BC

Size A B C ØD

30-6 453.5 179 121.5 112

45-9 659 179 121.5 112

50-6 453.5 179 121.5 112

60-12 815 188 145.5 142

75-9 651 188 145.5 142

75-15 1172 188 145.5 142

90-18 1333 187 151.5 142

100-12 848 187 151.5 142

125-15 1135 35 180.5 142

150-18 1345 35 180.5 142

175-21 1552 35 180.5 142

200-24 1769 116 181 142

of 45° bends should be used being equivalent to 0.5m of flue

length. 90° bends may be used but each set will be equivalent

to 1.0m of flue length.

For HEM150/175/200 units: use Ø130 flue

system for a total calculated length of up to 3M,

Ø150 for a total calculated length in excess of

3M up to 9M, Ø180 for a total calculated length

in excess of 10m up to 18M and Ø200 for in

excess of 18m up to 24M.

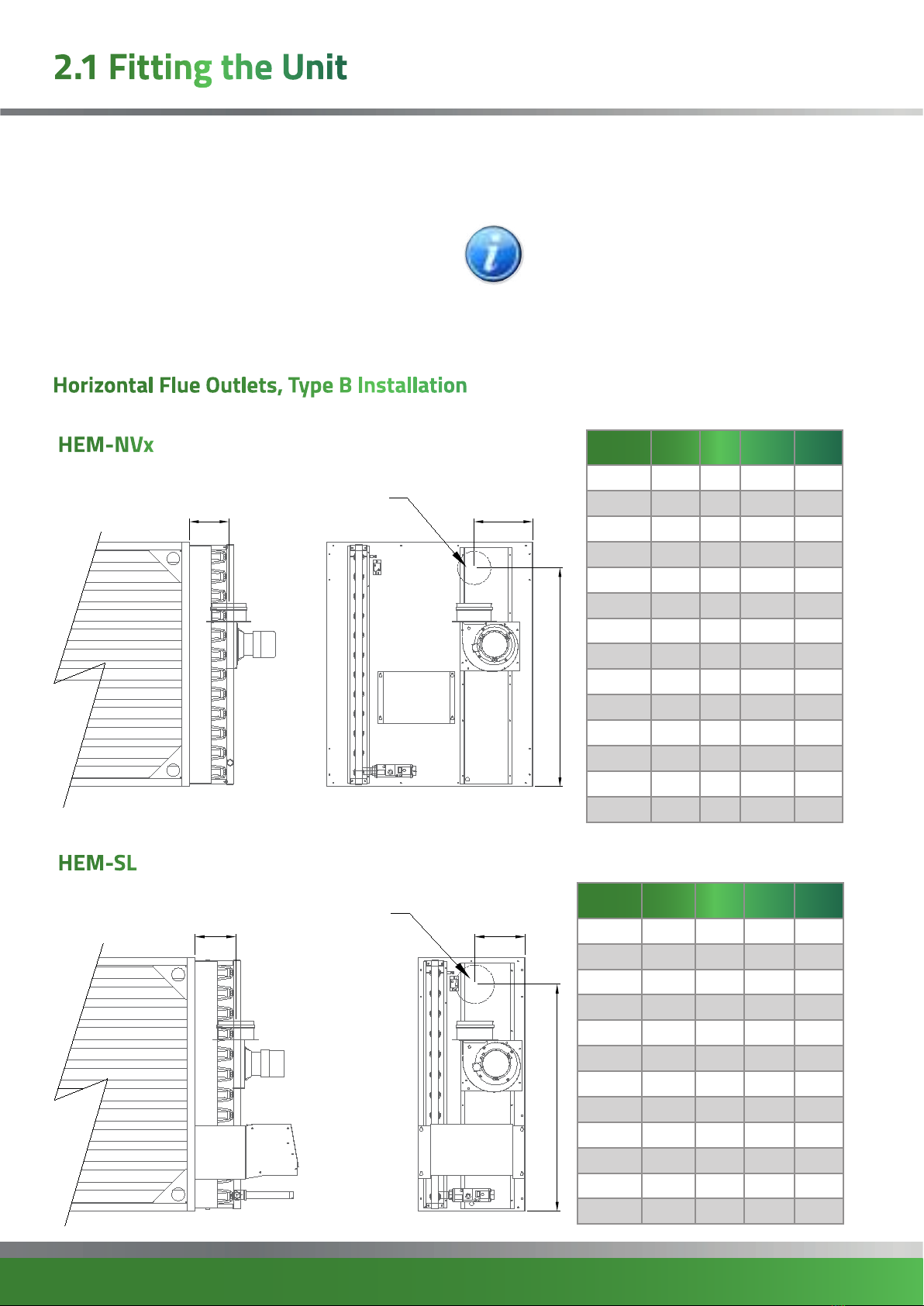

HEM-NVx

HEM-SL

2.1 Fitting the Unit

HorizontalFlueOutlets,TypeBInstallation

Exhaust flue outlet positions are shown in the following diagrams and tables.

page no. 17 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

2.1.4.2 Type C Flued Installations

IMPORTANT:

Not applicable for models 150, 175 & 200

For Type C flued installations, a concentric flue system

should be used of the appropriate orientation.

The total calculated maximum permitted length of flue

system for sizes up to and including model 50 is 14m,

from model 60 to 125 is 16m. Concentric flue terminals are

equivalent to 5m of flue length. If an offset is required two

sets of 45° bends should be used each set being equivalent to

0.5m of flue length. 90° bends may be used but each set will

be equivalent to 1.0m of flue length.

Exhaust flue outlet positions are shown in the previous

diagrams and tables.

Air inlet holes should be cut to the dimensions in the

following table to accept the silicone seals supplied.

(where ØD is the actual cut size in the casing/sheet metal).

Type C Flue and air inlet cut hole sizes and centres

distances. (refer to table below)

HEMNVx HEMSL A CRS ØD

10-3 n/a 120 91

15-4 n/a 120 91

18-5 n/a 120 91

25-5 n/a 142 112

30-6 30-6 142 112

40-8 n/a 142 112

n/a 45-9 142 112

50-6 50-6 142 112

60-7 n/a 220 142

n/a 60-12 220 142

75-9 75-9 220 142

n/a 75-15 220 142

n/a 90-18 220 142

100-12 100-12 220 142

110-13 n/a 220 142

125-15 125-15 220 142

2.1 Fitting the Unit

The silicone seals supplied are not water tight

and should not be used in external vertical

applications. A suitable water tight seal or

sealant must be used in these instances

Silicone

Seals

A CRS

2.1.5GasInstallation

The whole of the gas installation, including the meter,

should be inspected and tested for soundness and purged

in accordance with the recommendations of IM/16:1988.

Simulated enclosure

A CRS

ØD

ØD

page no. 18 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

2.1.8FlueSystem

Only flue systems supplied through Powrmatic Ltd may be

used with HEM modules. The flue outlet socket must be

connected via the provided flue system to outside air.

The maximum permitted length of flue system is shown in

duties on page 6 and 7. If an offset is required, two sets of

45° bends should be used each set being equivalent to 0.5m

of flue length. 90° bends may be used but each set will be

equivalent to 1.0m of flue length.

All outer joints must be finished with the provided locking

bands. A smear of silicon grease to the inside of sockets

will assist in fitting components together.

All flue and combustion air ducts must be supported

independently of the air heater.

The flue or flue/combustion air terminal must not be

installed so as to be less than:

300mm below an opening e.g. window, air brick etc.

200mm below eaves or gutter.

300mm from an internal or external corner.

1200mm from a surface facing the terminal.

1500mm vertically from another terminal on the same wall.

300mm horizontally from another terminal on the same wall.

The flue must terminate in a freely exposed position and be

sited to prevent the products of combustion entering any

opening in a building in such concentration as to be

prejudicial to health or a nuisance.

Twin Wall Flue can also be used

2.1.9CondensateDrainage

If, given the application and usage of the module, it is

considered that condensate will be formed at times then

the condensate drain pipe at the base of the unit must be

fitted with an external trap, equivalent to that shown below,

the outlet of which must be run to a local drain point. The

trap can be a proprietary item or fabricated using standard

domestic 32mm waste water fittings in which case ensure

that the dimensions shown are adhered to.

The trap must be filled with water after installation and

before the heater is commissioned. The trap and associated

pipe work must be protected from freezing. If drainage

under gravity is not possible a condensate pump should be

used and installed following the manufacturers instructions.

2.1 Fitting the Unit

2.1.6ElectricalConnections

Only a suitably qualified operative can complete the

electrical installation and must observe the rules in force.

All electrical connections are made to the screw terminals

in the control section and should be in accordance with

the terminal markings and the wiring diagram for the

module.

Module(s) must be earthed.

A lockout indicator light and reset button are fitted in

the control panel. If required these functions can be

duplicated remotely from the module.

2.1.7 Main Air Fan

The module(s) does not include the main air moving fan.

Direction of airflow may be either R-L or L-R for vertically

orientated modules or from top to bottom or bottom to

top for horizontally orientated units.

2.1.7.1 Main Fan Interlock Proving

Switch

The main fan must be interlocked to the module

by a pressure switch or sail switch or equivalent

so that if the main air flow fails for any reason

the module(s) is shut down.

2.1.7.2MinimumAirflowRequirement

The minimum airflows specified in section 1.2 must not

be reduced.

2.1.7.3 Maximum Airflows

The airflow across the module(s) should be kept at a level

that ensures condensation in the tubes will not occur with

the remainder of the air flow passing through a bypass

section to be mixed with the heated air downstream of

the module(s).

Please contact the Powrmatic office to obtain the

appropriate bypass dimensions to suit the specific heater.

2.1.7.4 Main Fan Over-run

The main fan controls must ensure that when

the module is tuned off, i.e. the heat demand is

satisfied, the main fan continues to run for 3-4

minutes to dissipate the residual heat from the module.

page no. 19 of 44

HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

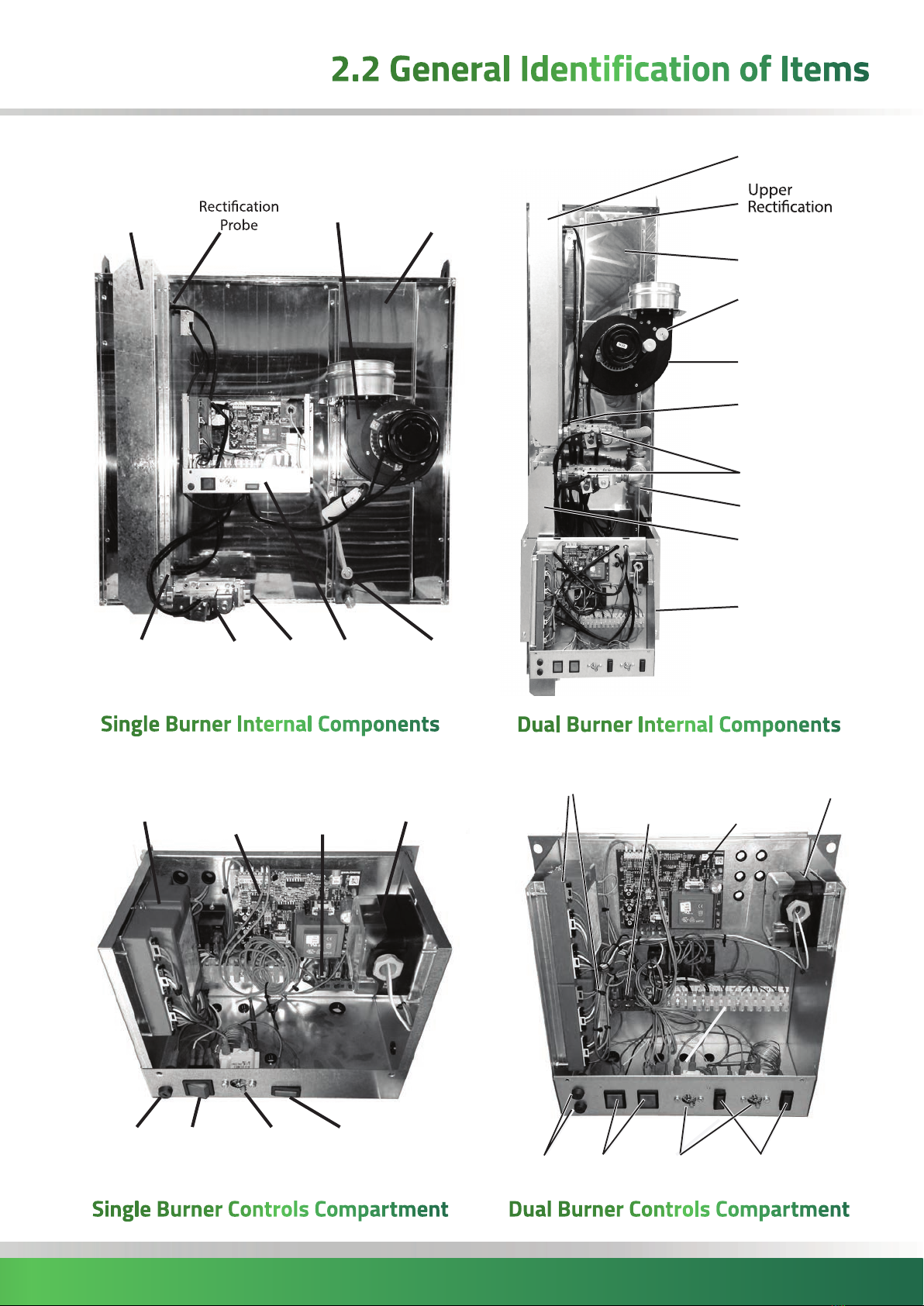

Dual Burner Controls Compartment

Exhaust

Header Box

Upper

Burner Set

Lower

Burner Set

Exhaust Fan

Exhaust Fan Flow

Sensing Point

Gas Valves

Gas Inlet

Controls

Panel

Upper Spark

Ignition Probe

Probe

Limit

Thermostat

Sequence

Controllers Exhaust Fan

APS

Incoming

Electrical

Connection

Point

Limit

Indicators

Lockout

Indicators

Fuses

Burner Set

(behind Heat Shield)

Exhaust Fan Exhaust

Header Box

Spark Ignition

Probe

Gas Valv

Inlet

Control

Panel

Exhaust Fan

Flow Sensing

Point

Sequence

Controller

Exhaust Fan

APS

Limit

Thermostat

Limit

Indicator

Lockout

Indicator

Fuse

eGas

SingleBurnerControlsCompartment

SingleBurnerInternalComponents DualBurnerInternalComponents

2.2GeneralIdentificationofItems

Incoming

Electrical

Connection

Point

Modulating

Interface

Board

(where tted)

Modulating

Interface

Board

(where tted)

page no. 20 of 44 HEMNVx & HEMSL Range Users, Installation & Servicing Instructions Doc Ref M103 issue 3.6 Mar 2020.

Warning: THIS APPLIANCE MUST BE

EARTHED.

Warning: Lockout reset is by a switched

Neutral to the controls in the heater.

Warning: Wiring external to the unit must be

carried out by an appropriately qualified

person to current IEE regulations for

Electrical Installations and any local regulations which

apply. Wiring should be completed in flexible conduit.

The local electrical supply must be run to a point adjacent

to the heater and be suitably terminated to provide an

isolation point that will prevent remote activation of the

unit during servicing.

The local electrical supply conditions must be compatible

with the electrical data given on the appliance data plate.

Wiring should be completed in flexible conduit.

Heaters are for use with 230V, 1N, 50Hz supplies.

The method of connection to the main electricity supply

must:-

- facilitate the complete electrical isolation of the

heater(s) via a suitable fused isolator that will prevent

remote activation of the heater during servicing (see

section 1.2 for ratings).

- be in a readily accessible position adjacent to the

heater(s).

- serve only the heater(s).

- have a contact separation of at least 3mm in all poles.

See section 2.5 or the accompanying wiring diagram for

the heater electrical connections.

Reference must be made to Section 2.4.5 to ascertain

the electrical loading of the unit(s) being installed so that

cables of adequate cross-sectional area are used for

the electrical installation. The length of the conductors

between the cord anchorage and the terminals must be

such that the current carrying conductors become taut

before the earth conductor if the cable or cord slips out

of the cord anchorage. All external controls must be of an

approved type.

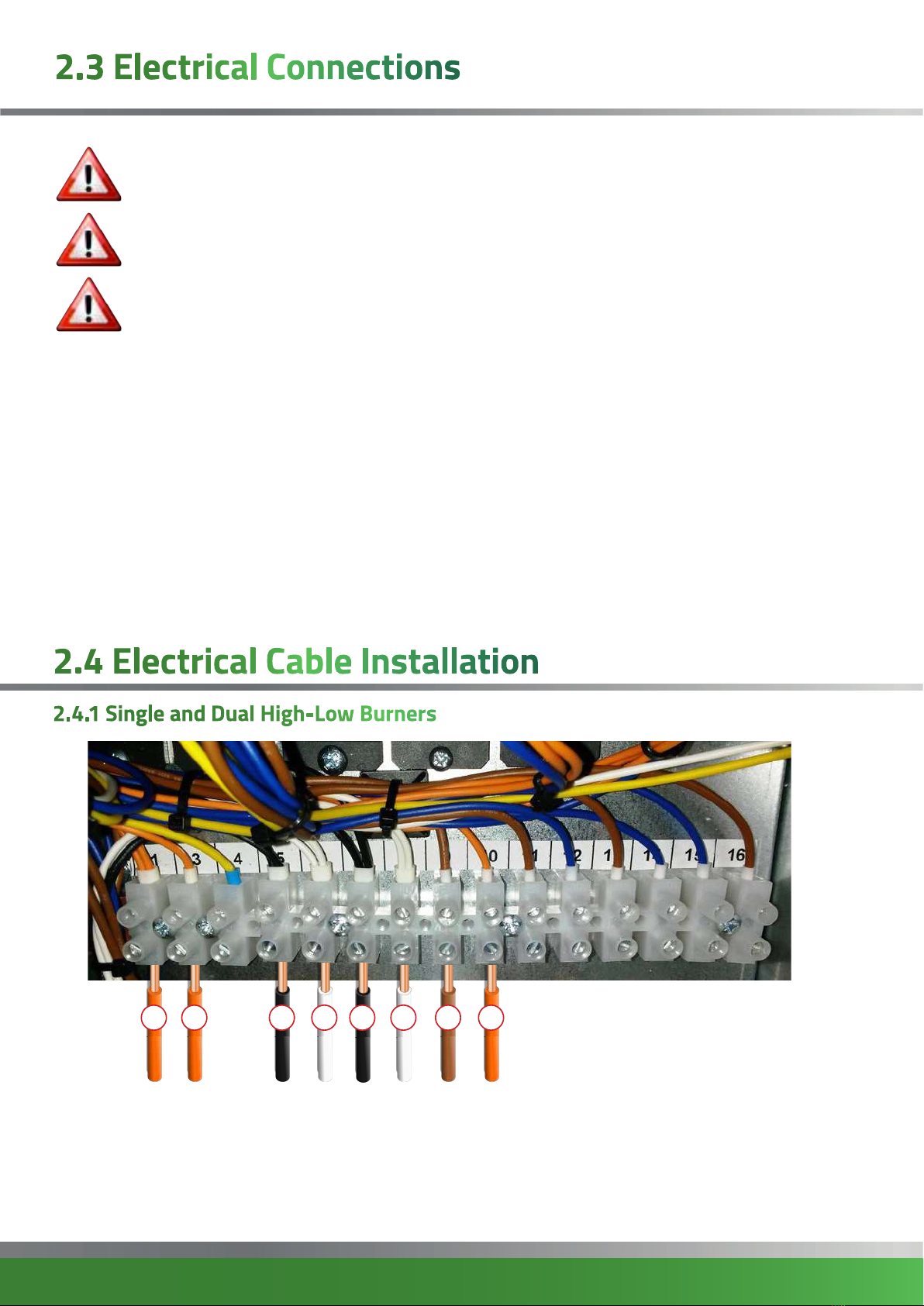

2.4.1 Single and Dual High-Low Burners

* where used

Heat LOW Demand

230V Input

Lockout 1 Indication

230V Output

Lockout 1 Reset

Neutral Input

Main fan

Proving Switch

(suppled by others)

*Heat HIGH Demand

230V Input

*Lockout 2 Indication

230V Output

*Lockout 2 Reset

Neutral Input

t1 t10

t8 t9

t3 t5 t6 t7

2.3ElectricalConnections

2.4ElectricalCableInstallation

This manual suits for next models

27

Table of contents