※Technical Data

Square drive……………………………………………………………………………………1/2”(13mm)

Free speed………………………………………………………………………………………7,000rpm

Max torque……………………………………………………………………………………..230ft/lb(310N.m)

Avg.air consumption…………………………………………………………………………..4cfm(114l/min)

Operating pressure……………………………………………………………………………...90psi(6.3bar)

Air inlet size…………………………………………………………………………………….1/4”

Weight…………………………………………………………………………………………...5.40Lbs(2.5kgs)

A weighted sound pressure level……………………………………………………………….84.4dB(A)

Sound power level………………………………………………………………………………95.4dB(A)

Vibration in the handle………………………………………………………….…….………..2.6m/s2

※Important Safety Rules

1. Follow all workshop safety rules, regulations, and conditions when using wrench.

2. Do not wear watches, rings bracelets or loose clothing when using air tools.

3. WARNING! Disconnect from air supply before changing accessories or servicing.

4. Maintain the wrench in good condition and replace any damaged or worn parts. Use genuine parts only.

Non-authorised parts may be dangerous.

5. WARNING! Check correct air pressure is maintained and not exceeded. We recommend 90psi.

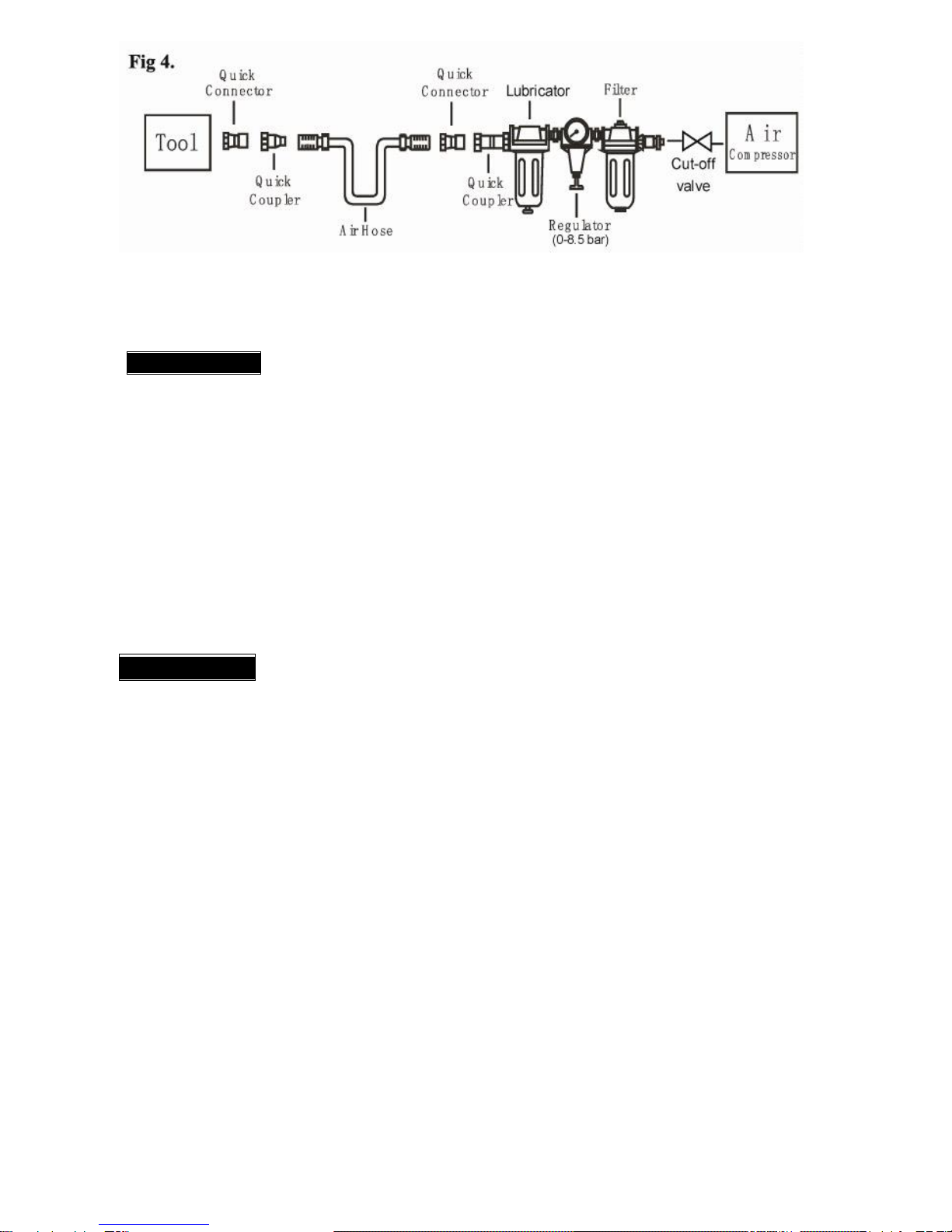

6. Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that all

connections are secure.

7. Only use impact sockets which are specifically designed for use with an impact wrench.

8. Wear approved safety eye/face shield, ear defenders, and hand protection.

9. WARNING! Due to the possible presence of asbestos dust from brake linings, when working around vehicle

brake systems we recommend you wear suitable respiratory protection.

10. Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

11. Keep children and non essential persons away from the working area.

12. DO NOT use the wrench for a task it is not designed to perform.

13. DO NOT use wrench if damaged or thought to be faulty.

14. DO NOT use wrench unless you have been instructed in its use by a qualified person.

15. DO NOT carry the wrench by the air hose at yourself or others.

16. DO NOT direct air from the air hose at yourself or others.

17. When not in use disconnect from air supply and store in a safe, dry, childproof location.

※Operating Instruction

Description

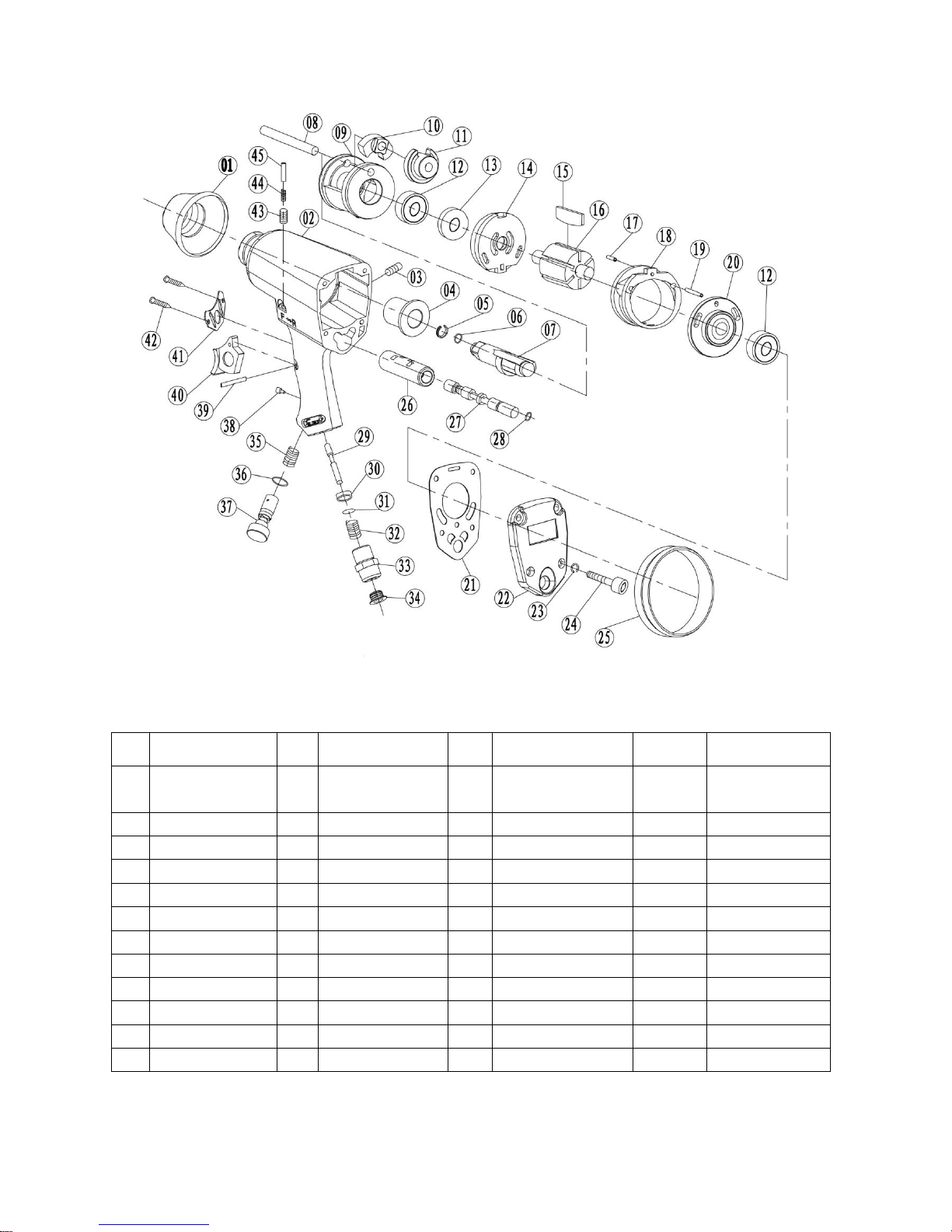

Die cast aluminum body,Reversible,Rubber scuff guards on nose and back,Built –in –air regulator varies speed &

power,Side exhaust, designed for removing and installing nuts and bolts. Also ideal for tire changing and general

assembling work and other workshop applications.