Powtran PB200 Series User manual

Foreword

Thank you for choosing POWTRAN design and produce brake unit. This product made by

POWTRAN is based on years of experience in professional production and sale, and designed for

feed back the regenerative consumption of motor to the brake resistor when the motor decelerates,

enhances the brake capability of the inverter, ensures the motor to stop in a short time in the

setting time.

For any problem when using this product, please contact your local dealer authorized by this

company or directly contact this company, our professionals are happy to serve you.

The end-users should hold this manual, and keep it well for future maintenance & care, and

other application occasions. For any problem within the warranty period, please fill out the

warranty card and fax it to the our authorized dealer.

The contents of this manual are subject to change without prior notice. To obtain the latest

information, please visit our website.

For more product information, please visit: http://www.powtran.com.

Powtran

December,2018

Contents

Chapter 1 Inspection and safety precautions.................................................................................. 1

1-1. Inspection after unpacking............................................................................................. 1

1-1-1. Instructions on nameplate.................................................................................. 1

1-1-2. Model instruction...............................................................................................1

1-2. .Safety precautions......................................................................................................... 2

Chapter 2 Technical specifications and installation........................................................................3

2-1. Technical specifications................................................................................................. 3

2-2. Main circuit terminal screw specifications.....................................................................3

2-3. Installation......................................................................................................................4

2-4. Dimension and installation dimension........................................................................... 4

2-5. Wiring diagram.............................................................................................................. 6

Chapter 3 Operate keyboard...........................................................................................................8

3-1. Operate keyboard instruction......................................................................................... 8

3-2. Keyboard indicators instruction..................................................................................... 8

3-3. Operation panel button instruction.................................................................................8

3-4. Keyboard display alphabet and number correspondence table...................................... 9

3-5. Examples of parameter setting....................................................................................... 9

3-5-1. Description of Function code viewing and modifying method......................... 9

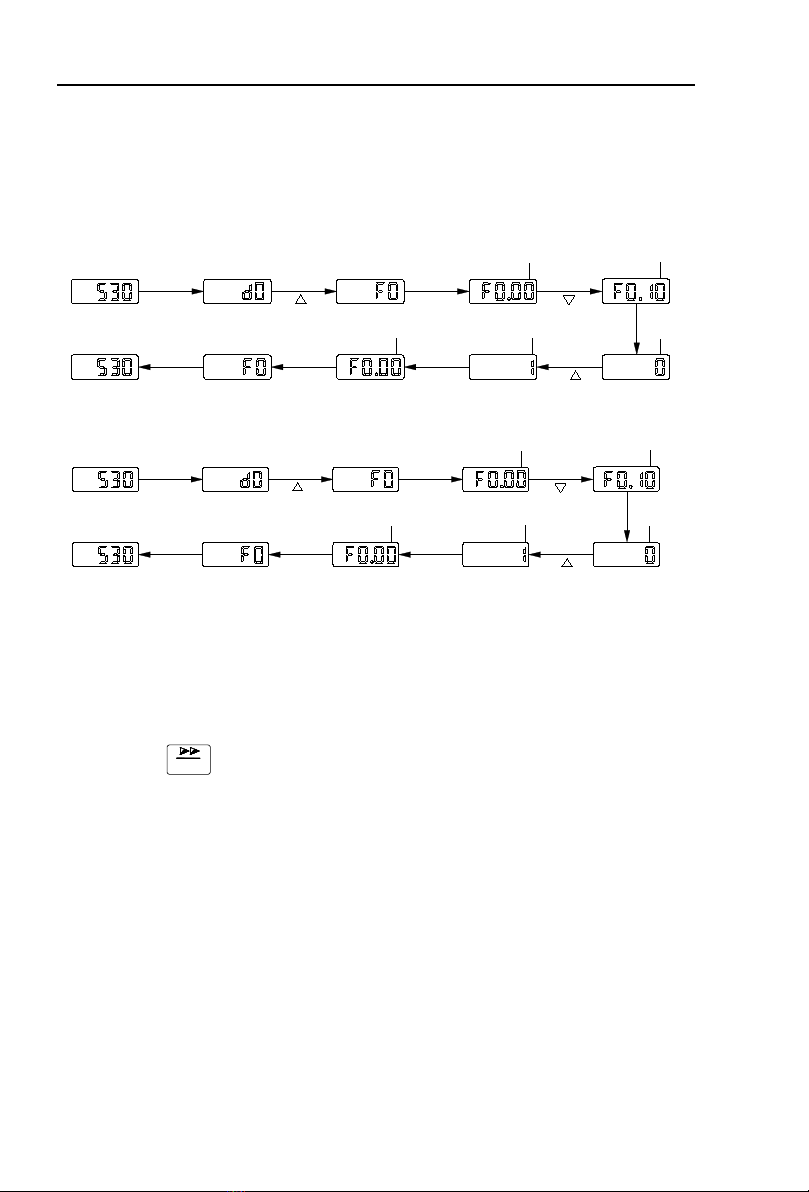

Figure 3-2: Operational flow chart................................................................................................. 9

3-5-2. Viewing method of state parameters................................................................10

Chapter 4 Function parameter description....................................................................................11

4-1. Menu group.................................................................................................................. 11

4-1-1.d0 Monitoring function group...........................................................................11

4-1-2.Basic functional group...................................................................................... 11

4-1-3. Fault query....................................................................................................... 12

Chapter 5 Brake unit and brake resistor....................................................................................... 14

5-1 Brake unit...................................................................................................................... 14

5-1-1. Brake voltage selection is based on below two conditions:.............................14

5-1-2. Brake resistor resistance selection................................................................... 14

5-1-3. Brake unit power selection...............................................................................14

5-1-4. Inverter input voltage level specification and selection reference...................15

Chapter 6 Abnormal diagnosis and treatment...............................................................................17

Chapter 7 Maintenance and repair................................................................................................18

7-1.Inspection and maintenance.......................................................................................... 18

7-2.Parts for regular replacement........................................................................................ 18

7-3.Storage...........................................................................................................................19

Chapter 8 Quality assurance.........................................................................................................20

Product information feedback..................................................................................................- 22 -

1

Chapter 1 Inspection and safety precautions

POWTRAN brake unit have been tested and inspected before leaving factory. After

purchasing, please check if its package is damaged due to careless transportation, and if the

specifications and model of the product are consistent with your order requirements. For any

problem, please contact your local authorized POWTRAN dealer or directly contact this company.

1-1.Inspection after unpacking

※Check if that packing container contains this unit, one manual and one warranty card.

※Check the nameplate on the side of the frequency inverter to ensure that the product you

have received is right the one you ordered.

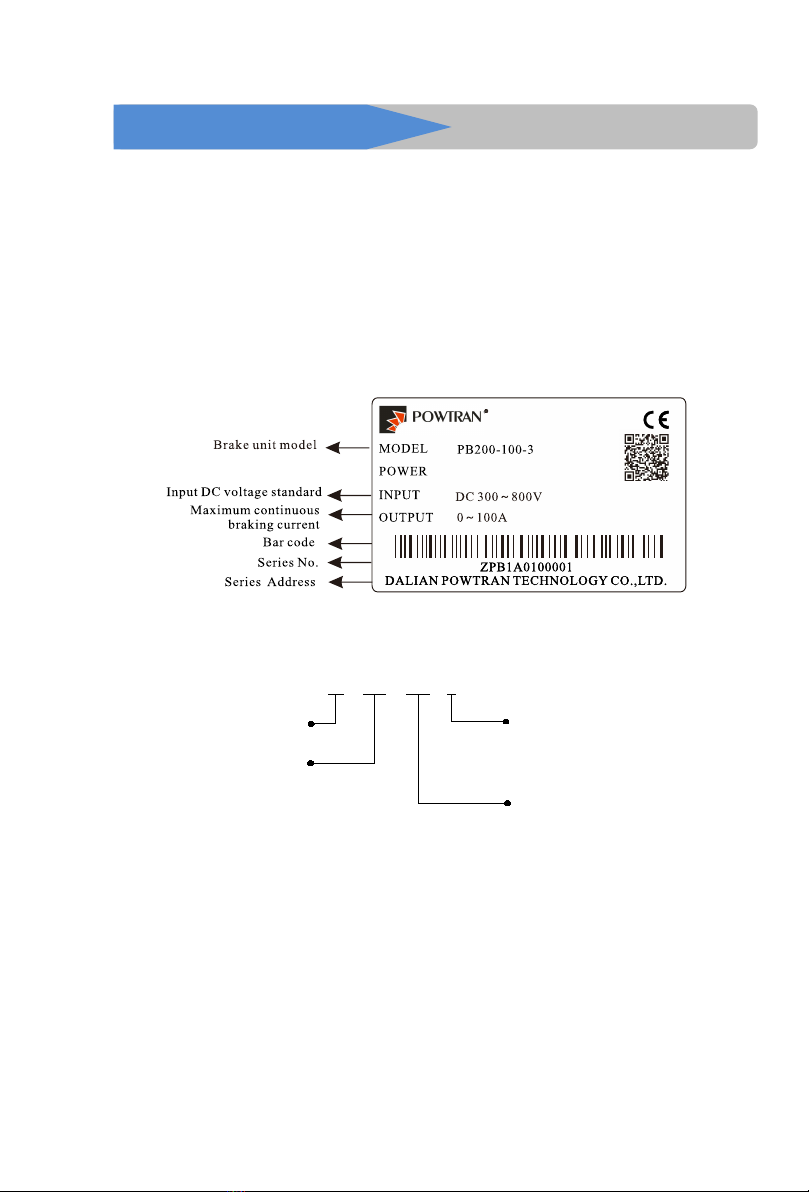

1-1-1.Instructions on nameplate

Figure 1-1:Nameplate description

1-1-2.Model instruction

Powtran Brake unit

PB 200 100 3

M axim um continuous

braking current

100:100A

040:40A

Series code:

PB200 series

Input voltage grade

2:220VAC

3:380VAC

4:480VAC

Figure 1-2:Model description

Chapter 1 Inspection and safety precautions

2

1-2..Safety precautions

Safety precautions in this manual are divided into the following two categories:

Danger: the dangers caused by failure to perform required operation, may result in

serious injury or even death;

Caution:the dangers caused by failure to perform required operation, may result in

moderate injury or minor injury, and equipment damage;

Process

Type

Dangerous

● Only well-trained personnel are allowed to use this unit.

● Fix the screw when connecting, or the loose connection will lead fire or creepage.

● Grounding terminal should be reliable grounding braking unit, or get an electric

shock risk.

●Do not touch the brake unit, the internal spares and printing board after the brake unit

is connected, otherwise it will lead to electric shock. There is high voltage direct

current inside.

●Don't let the cable damage from weight hanging and over load, or get an electric

shock risk.

●The unit and brake resistor should be installed on the medium with flame retardancy

(such as metal), away from combustible material, otherwise may cause fire

●Please check the wiring is correct before operation. Please confirm whether the input

DC voltage and brake unit voltage same level; Whether Input terminal (+, -) and

resistance terminal (RB1, RB2) connection position is correct; And check the

peripheral circuit of the connected to the drive for short circuit phenomenon, whether

the line is fastening, otherwise cause damage of drive.

●Please check whether master-slave choice and voltage grade Settings are correct.

●During the running, do not touch any spares inside.

●The repairs and maintenance task can be performed only when the inverter bus

voltage is lower than DC 36V, Power off more than ten minutes.Otherwise, the

residual charge from capacitor would cause personal injury!

Attention

● Do not use any brake unit and brake resistor lack of or with damaged spares.

●Do not touch the internal spares for there are CMOS spares on the control card of the

brake unit. Otherwise it will damage the spares.

●When many pieces brake units installed in parallel when used in the same case, please

install the fan or other cooling device.

●Ensure the right setting of brake unit and brake resistor.

●Do not make voltage resistance test on the brake unit, or it will lead semiconductor

spares damaged in the main circuit of the brake unit.

●Braking resistor should be temperature protection and other protection, if the brake

resistance keep hot which caused by the failure of the brake unit. fever, necessary to

isolate itself, does not automatically isolation caused any accident not be burdened

by Powtran.

●Please refer to the content in the manual when analyze and manage the fault of the

brake unit. Any modification to the brake unit is not allowed otherwise the life

harm and property loses will not be burdened by Powtran.

●This product is the accessories of the inverter, if it is used improperly which would

not only do damage to itself but also to the inverter. Please pay much attention to

this.

●Only the well-trained personnel are allowed to use this unit, and such personnel must

read through the parts of this manual relating to the safety, installation, operation and

maintenance before using the unit. The safe operation of this unit depends on correct

transport, installation, operation and maintenance.

Note: When brake unit work with powtran inverter,powtran will responsible for quality, If the

brake unit work for other project, Please make your own insurance related domestic property

insurance, in order to get better compensation from insurance company.

3

Chapter 2 Technical specifications and installation

2-1.Technical specifications

Brake unit model

Starting brake voltage (V)

Maximum continuous braking

current (A)

PB200-040-2

350

40

PB200-050-2

350

50

PB200-075-2

350

75

PB200-100-2

350

100

PB200-180-2

350

180

PB200-250-2

350

250

PB200-040-3

670

40

PB200-050-3

670

50

PB200-075-3

670

75

PB200-100-3

670

100

PB200-180-3

670

180

PB200-250-3

670

250

PB200-040-4

760

40

PB200-050-4

760

50

PB200-075-4

760

75

PB200-100-4

760

100

PB200-180-4

760

180

PB200-250-4

760

250

2-2.Main circuit terminal screw specifications

Brake unit model

Main circuit screw

specification

Tightening torque (Nm)

PB200-040-2

M5

2~2.5

PB200-050-2

M5

2~2.5

PB200-075-2

M5

2~2.5

PB200-100-2

M5

2~2.5

PB200-180-2

M8

9~11

PB200-250-2

M8

9~11

PB200-040-3

M5

2~2.5

PB200-050-3

M5

2~2.5

PB200-075-3

M5

2~2.5

PB200-100-3

M5

2~2.5

PB200-180-3

M8

9~11

PB200-250-3

M8

9~11

PB200-040-4

M5

2~2.5

Chapter 2 Technical specifications and installation

4

PB200-050-4

M5

2~2.5

PB200-075-4

M5

2~2.5

PB200-100-4

M5

2~2.5

PB200-180-4

M8

9~11

PB200-250-4

M8

9~11

2-3.Installation

2-3-1 Working environment

The breaking unit shall be installed in the room where it is well ventilated, the wall mounted

installation shall be adopted.

2-3-2Installation environment

1. Ambient temperature -10 ° C ~ 50 ° C. If exceeding 40 °C, derating at a rate of 3% derating

for every 1 °C. It is not recommended to use in an environment above 50 °C.

2. Prevent electromagnetic interference and keep away from interference sources.

3. Prevent the intrusion of dust, cotton wool and fine metal powder.

4. Prevent the intrusion of oil, salt and corrosive gases.

5. Avoid vibration.

6. Avoid high temperature and humidity and no rain dripping, humidity less than 90% RH (No

condensation).

7. It is forbidden to use under hazardous environmental conditions such as flammability,

flammability, explosive gas, liquid or solid.

8. The braking resistor cannot be installed close to the air inlet of the brake unit.

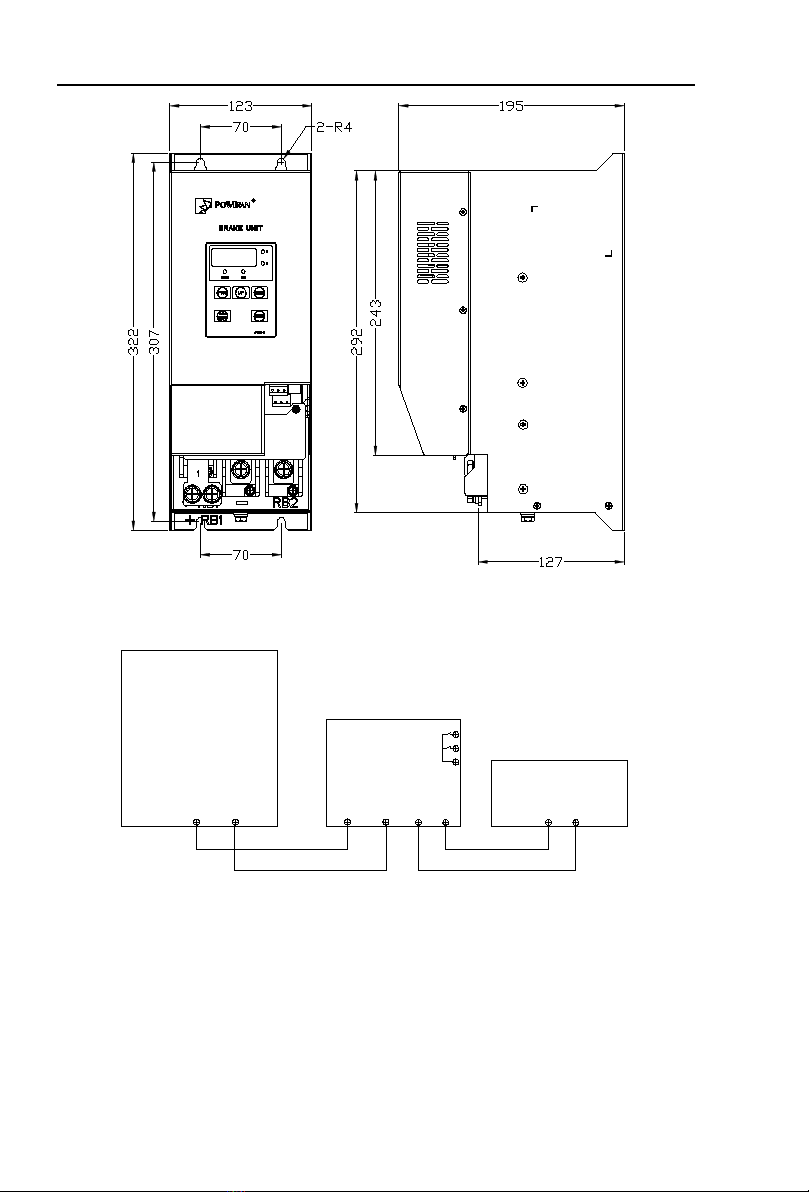

2-4.Dimension and installation dimension

Shell base

Shell cover

Fan

Wind into plate

Indicator light

Control keyboard

Figure 2-1:40-100A the braking unit sketch

Chapter 2 Technical specifications and installation

5

Fan

Case base

Case cover

Control keyboard

Indicator light

Air inlet board

Figure 2-2:180-250A the braking unit sketch

80

110

202

80 7

216

186

216

140

2-R3.5

Figure 2-3:40-100A Braking unit installation dimension

Chapter 2 Technical specifications and installation

6

Figure 2-4:180-250A Braking unit installation dimension

2-5.Wiring diagram

+-+-RB1 RB2

TA

TB

TC

Frequency

inverter

Brake unit

Brake resistor

Figure 2-5:Single brake unit wiring diagram

Chapter 2 Technical specifications and installation

7

Frequency

inverter

Brake unit

+-+-RB1 RB2 +-RB1 RB2

Brake resistor

Host Slave

COM PIO

COM PIO

(F0.06=0)

(F0.06=1)

TA

TB

TC

TA

TB

TC

Brake resistor

Brake unit

Figure 2-6:Figure multi-brake units parallel connection diagram

NOTE:

1. The connection cable of frequency inverter and brake unit shall be twisted with two lines,

the longest of which shall not exceed 5m

2. The distance of the connection between the brake resistor and brake unit should less than

10m, should use heat-resistant wires.

3. +/P+ is the positive end of DC BUS in the frequency inverter, -P- is the negative end.

4. Output relay TA/TB/TC,TA-TC normally open and TB-TC close. Relay drive

ability. :normally close 3A/AC 250V,normally open.5A/AC 250V.

5. Wrong connection of main circuit will cause damage of brake unit and frequency inverter.

6. Please do not touch the brake unit when it is working, to avoid scald.

2-5-1. Brake unit main circuit terminal and making circuit terminal

1、Main circuit terminal

RB1 RB2

(+)

(-)

Figure 2-5. Brake unit main circuit terminal

Terminal mark

Function instruction

(+)

Connect the positive terminal of the inverter DC BUS.

(-)

Connect the negative terminal of the inverter DC BUS.

RB1、RB2

External connect brake resistor terminal

PE

Brake unit ground terminal

2. Control circuit terminal

COM PIO

TA TB TC

Figure 2-6. Control circuit terminal

Terminal mark

Function instruction

COM

Brake unit control circuit ground.

PIO

Brake units work in parallel in input or output terminal, when multi brake

unit used in parallel, send control signal through the terminal that braking

unit can run simultaneously.

TA/TB/TC

Fault output terminals, when braking unit failure, send out fault alarm

signal. TA - TC for normally open and TB - TC closed

8

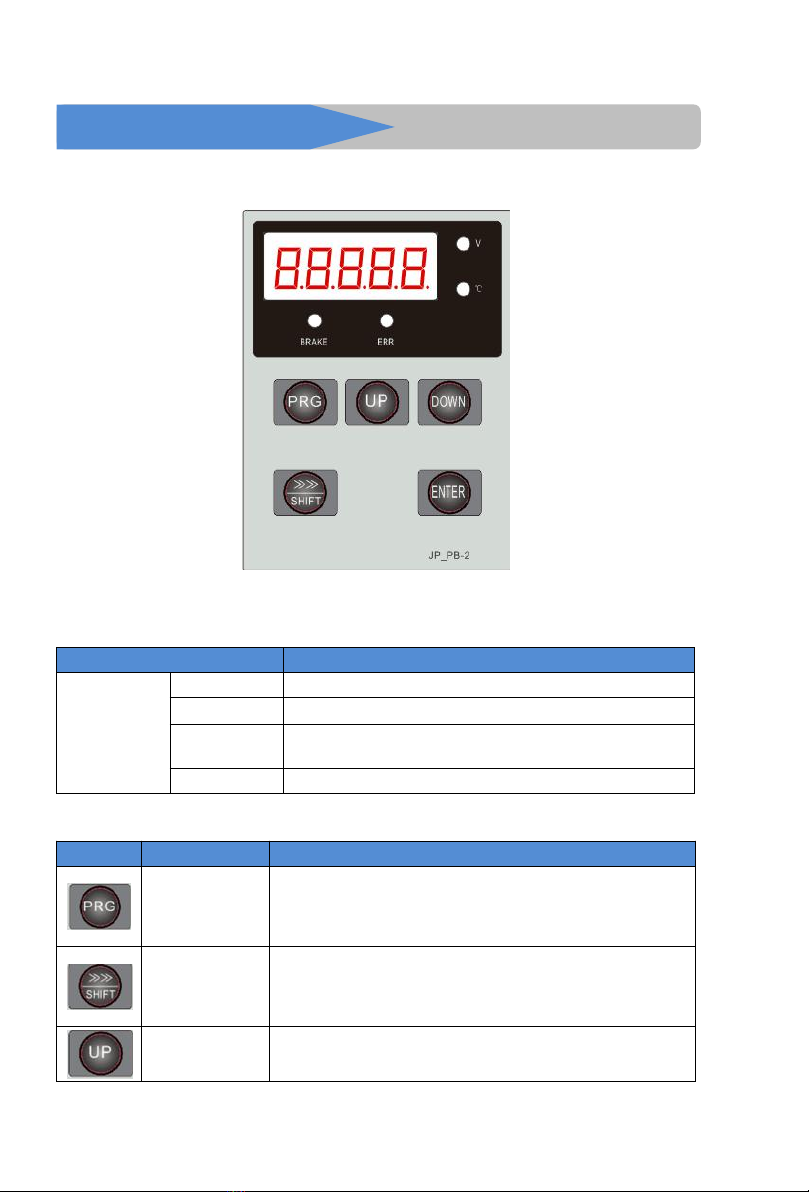

Chapter 3 Operate keyboard

3-1.Operate keyboard instruction

Figure 3-1:Operate keyboard display

3-2.Keyboard indicators instruction

Indicator mark

Name

Status light

V

Brake unit input voltage

℃

On :IGBT temperature

BRAKE

On :Brake unit on brake status .

Dull : Brake unit on standby status

ERR

Off :Fault indicator light

3-3.Operation panel button instruction

Mark

Name

Function

Parameter setting /

ESC key

* Enter the first level menu parameters changes state.

* Exit function data modify.

* Exit from submenu or function item menu to status display

menu

Shift key

* Under the standby display interface and brake display interface,

display parameters can be selected circularly. When modify a

parameter, customer can select the modification bit of the

parameter

Increasing key

*Date and function increasing key.

Chapter 3 Operate keyboard

9

Descending key

* Date and function descending key.

Confirm key

*Step by step into the menu screen, set parameter confirmation.

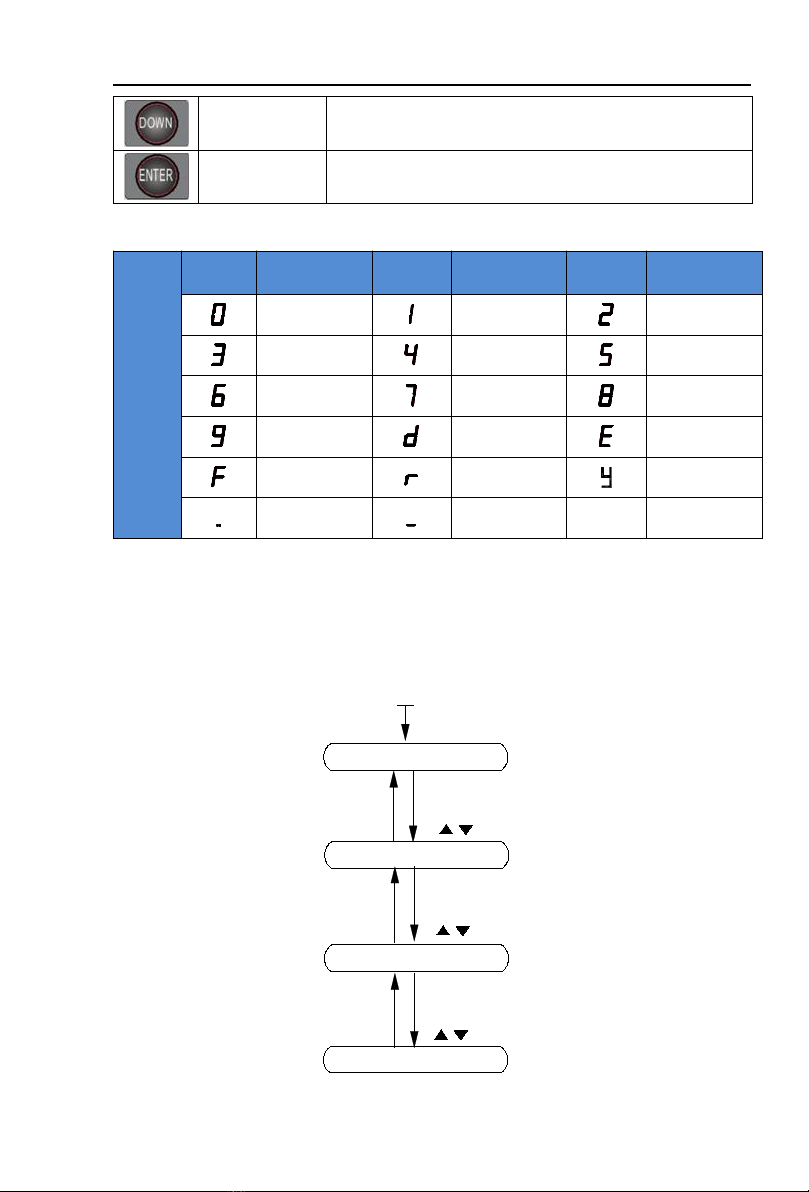

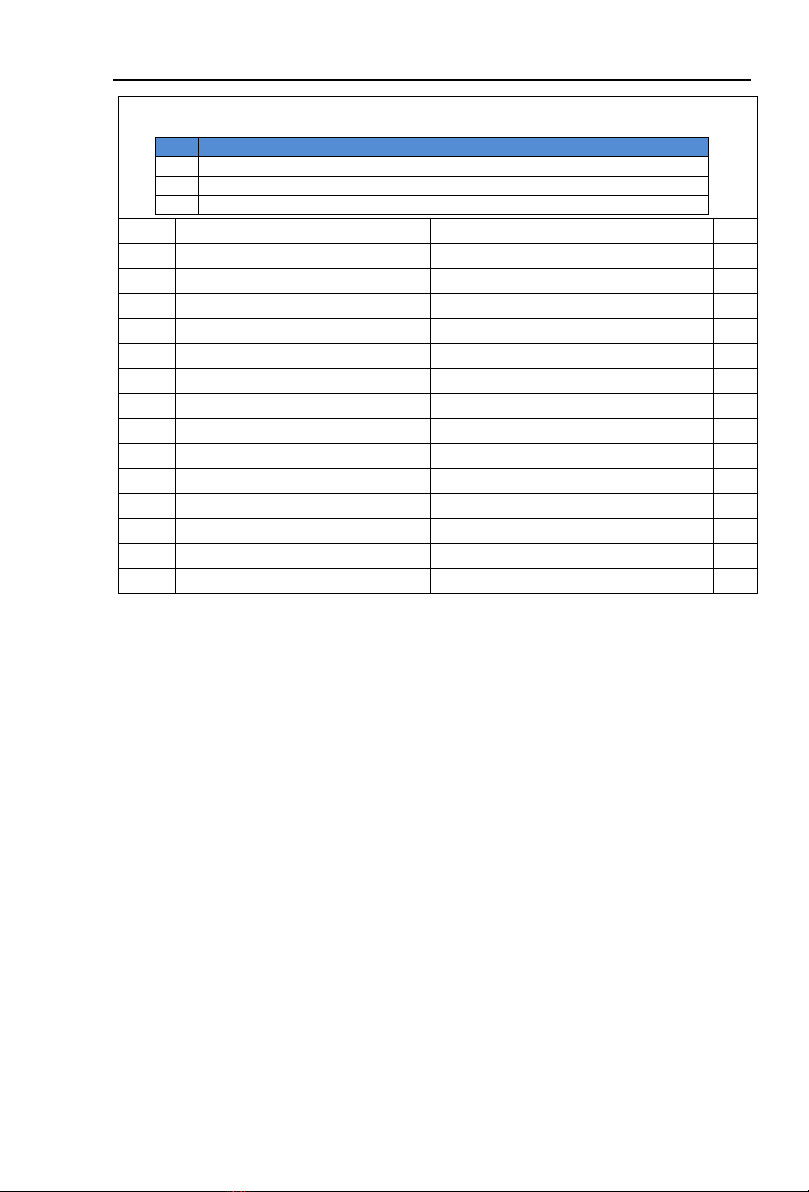

3-4.Keyboard display alphabet and number correspondence table

Digital

display

area

Display

Alphabet

Correspondence

Alphabet

Display

Alphabet

Correspondence

Alphabet

Display

Alphabet

Correspondence

Alphabet

0

1

2

3

4

5

6

7

8

9

d

E

F

r

y

.

-

3-5.Examples of parameter setting

3-5-1.Description of Function code viewing and modifying method

PB200 operation panel adopts three-level menu structure to set parameters and other

operations. The three-level menus are: function parameter group (first-level menu) function code

(second-level menu) function code setting value (third-level menu). The operation flow is shown in

the figure.

Standby parameter show

PRG

Change parameter

group

PRG

First-level menu display

ENTER

Change parameter

function choice

PRG

ENTER

Change function

parameter value

PRG

ENTER

Power on

Second-level display

Third-level display

Figure 3-2: Operational flow chart

Chapter 3 Operate keyboard

10

Description: In the operation of three-level menu, you can press PRG or ENTER to return to

the second-level menu. The difference between the two is: Press ENTER key to save the set

parameters and return to the secondary menu, and automatically transfer to the next function code;

Pressing the PRG key directly returns to the secondary menu, without storing parameters, and

returns to the current function code.

Example 1: The starting voltage of braking is modified to 380V, assuming that the input

voltage of the braking unit is 530VDC.

Change F0.00 from 670V to 660V

Press

Flash

Press

PRG

Press

ENTER

Press

ENTER

Press

ENTER

Press

PRG

Press

Press

Flash

Flash

Flash

Flash

Press

ENTER

Example 2. Restore factory parameters

Press

Flash

Press

PRG

Press

ENTER

Press

ENTER

Press

ENTER

Press

ENTER

Press

PRG

Press

Press

Flash

Flash

Flash

Flash

In the third menu state, if the parameter has no flicker bits, it means that the function code can

not be modified. The possible reasons are as follows:

1) The function code is an unmodifiable parameter. For example, the actual detection

parameters, operation record parameters and so on.

2) The function code can not be modified in the running state, and can not be modified until

the downtime.

3-5-2.Viewing method of state parameters

During shutdown or operation, the temperature and brake unit input voltage can be separated

by the shift key.

SHIFT

11

Chapter 4 Function parameter description

4-1. Menu group

Attention:

"★": In the braking state, the setting value of this parameter can not be changed;

"●": The actual detection value can not be changed;

"☆": It can be changed when it is in downtime or running state.

Group d is the monitoring function parameter, Group F is the basic function parameter, Group

Y1 is the fault history query.

4-1-1.d0 Monitoring function group

Paramet

er Code

Parameter name

Paramet

er name

d0.00

Braking unit input voltage / Inverter bus voltage

V

Braking unit input voltage

d0.01

Module temperature

℃

Detection value of radiator temperature of inverter module

d0.02

Software version

-

Display current brake unit software version number

4-1-2.Basic functional group

Code

Parameter name

Setting range

Factory

setting

Cha

nge

F0.00

Braking start voltage

300V~2500V

Model

confirmed

☆

This parameter is used to set the starting braking voltage of the braking unit.

220V voltage level, default braking voltage is 350V;

380V voltage level, default braking voltage is 670V;

480V voltage level, default braking voltage is 760V;

F0.01

Braking hysteresis voltage

0V~100V

20V

☆

This parameter is used to set the hysteresis voltage during braking.

Generally when setting braking start voltage and braking stop voltage, there must be a

hysteresis loop. Such as settings F0.00=670V,F0.01=20V,when the bus voltage d0.00 is higher

than F0.00, start braking. When the bus voltage d0.00 is lower than (F0.00-F0.01), stop braking.

When the original state is in braking state, and the value of d0.00 is within F0.00 ~ (F0.00-

F0.01), the braking state is maintained.

F0.02

Default brake voltage selection

0~2

1

★

This parameter is used to set the default braking voltage for different voltage levels.

When setting to 0, corresponding to 220V voltage level, the default braking voltage is 350V;

When setting to 1, corresponding to 380V voltage level, the default braking voltage is 670V;

When setting to 2, corresponding to 480V voltage level, the default braking voltage is 760V;

F0.03

Braking rate

0%~100%

100%

☆

This parameter is used to select the braking rate.

When braking rate is set to 100%, it shows that the braking is fully open, at this time the

braking effect is the best, with the fastest voltage drop, but the brake resistor temperature rises

quickly.

When the braking rate is set to 0%, it shows that the braking is turned off, at this time even

if it reaches the braking condition, the braking does not work.

Chapter 4 Function parameter description

12

F0.04

Voltage modulation factor

0%~200%

100%

☆

This parameter can be used to adjust the d0.00 bus voltage detection value.

That is d0.00=DC BUS input voltage =d0.00*F0.04.

F0.05

Relay output function selection

0~4

0

☆

Relay function instructions below:

Setting

value

Function

Description

0

No output

The relay outputs no action.

1

In Braking

In braking state, the relay outputs ON signal.

2

Braking feedback fault

(IGBT short circuit)

In braking process, it feedback IGBT short-circuit fault, the

relay output ON signal.

3

Over-temperature alarm

When the module temperature exceeds 85℃, the over-

temperature alarm signal is generated, the relay outputs ON

signal.

4

Fault output

When brake feedback fault or over-temperature fault

occurs, the relay output ON signal.

F0.06

Master and slave selection

Slave

0

1

★

aster

1

This parameter is used for the parallel function, setting the braking unit as master or slave. If

you do not use the parallel function, the system single-set default unit host.

F0.07

Temperature hysteresis value

0~50

3

☆

This parameter is used to set the hysteresis value of the temperature. The default temperature

alarm value for the brake unit is 85 ℃. If the temperature hysteresis value is set to 3 ℃, when

there is not over temperature fault, if only the temperature exceeds 85 ℃, it alrms. If over

temperature fault occurs, the alarm is canceled only when the temperature drops below 82 ℃.

F0.08

Total power-on time

0~50000h

-

●

Display the total power-on time of braking unit since it is out of factory.

F0.09

Total running time

0~50000h

-

●

F0.10

Parameter

initialization

No operation

0

0

★

The parameters restored to factory value

1

Clear record information

2

1: Restore to the factory setting (F0.10 = 1), most of the brake unit parameters are restored to

factory setting, except default braking voltage level (F0.02), fault record information, total power-

on time, total running time.

2: Clear the record information (F0.10 = 2) Clear the fault record information, total power-on

time, total running time of the braking unit.

4-1-3. Fault query

Code

Parameter name

Setting range

Factory

setting

Cha

nge

y1.00

Type of the first fault

0~2

-

●

y1.01

Type of the second fault

0~2

-

●

y1.02

Type of the third(at last) fault

0~2

-

●

Record the type of the last three faults of PB200, 0 for no fault. Please refer to the related

Chapter 4 Function parameter description

13

instructions for the possible causes and solutions for each fault code.

Failure type table:

No.

Failure type

0

No fault

1

Braking feedback fault (IGBT short circuit)

2

Over temperature fault

y1.03

Bus voltage of the third fault

Bus voltage of the last fault

●

y1.04

Temperature of the third fault

Temperature of the last fault

●

y1.05

Braking rate of the third fault

Braking rate of the last fault

●

y1.06

Power on time of the third fault

Power on time of the last fault

●

y1.07

Running time of the third fault

Running time of the last fault

●

y1.08

Bus voltage of the second fault

Bus voltage of the previous fault

●

y1.09

Temperature of the second fault

Temperature of the previous fault

●

y1.10

Braking rate of the second fault

Braking rate of the previous fault

●

y1.11

Power on time of the second fault

Power on time of the previous fault

●

y1.12

Running time of the second fault

Running time of the previous fault

●

y1.13

Bus voltage of the first fault

Bus voltage before the previous fault

●

y1.14

Temperature of the first fault

Temperature before the previous fault

●

y1.15

Braking rate of the first fault

Braking rate before the previous fault

●

y1.16

Power on time of the first fault

Power on time before the previous fault

●

y1.17

Running time of the first fault

Running time before the previous fault

●

14

Chapter 5 Brake unit and brake resistor

5-1 Brake unit

5-1-1.Brake voltage selection is based on below two conditions:

(1) According to the input voltage level of inverter , choose the brake unit with relative

voltage level

(2) According to the required braking power when inverter is braking , choose the brake

unit with relative power .

The principle of brake unit power selection is that the power of brake unit is greater than the

braking power . in the case where the braking power is not specified , please estimate according to

below ways :

Pb=P*Td*K

In this formula:Pb-----braking power;

P----- motor power

K----- mechanical energy conversion efficiency,the general value is 0.7

Td---- ratio of brake torque to motor rated torque

Td values vary in different systems , as shown in the following table.

Common

applications

Elevator lift

crane

Uncoiler and

recoiling

Large inertia equipment

that requires quick

stopping

Ordinary

inertial load

Td value

100%

120%

120%

80%

5-1-2.Brake resistor resistance selection

When it is braking, the regenerative energy of the motor is almost consumed on the brake

resistor ,according to the formula:

U*U/R=Pb

In the formula:U----- braking voltage in stable braking system

(vary in different systems , for 220VAC system usually choose 380v; for 380VAC system

usually choose 700V, for 480VAC system usually choose 800V)

Note: when the value of R is less than the minimum resistance of each voltage level, multiple

brake units are required.

5-1-3.Brake unit power selection

In theory , the power of brake resistance is same as the braking power , but considering

derating is 70%. according to formula:

0.7*Pr=Pb*ED

In the formula:Pr-----brake unit power

ED----- braking frequency , the proportion of braking process in the whole working process

Common application

ED value

Uncoiler and recoiling

20%~30%

Accidental braking load

5%

Elevator

20%~30%

Lifting machinery , centrifuge

50%~60%

Injection molding machine

5%~10%

General occasion

10%

In the above table, the recommended braking unit and braking resistor resistance can meet

various inverters with ED=0~100%. And the power of the braking resistor depends on the

application conditions.

Chapter 5 Brake unit and brake resistor

15

5-1-4.Inverter input voltage level specification and selection reference

1. This table is the selection reference of 220V inverter, according to the brake unit DC

operating point 350V, braking frequency ED = 10%, and braking torque 100%.

Inverter

power (kW)

Brake unit

Brake resistor (100% brake torque)

Specification

Quantity (pcs)

Specification

Quantity

(pcs)

15

PB200-040-2

1

≥9Ω/2kW

1

18.5

PB200-040-2

1

≥9Ω/2kW

1

22

PB200-050-2

1

≥7Ω/3kW

1

30

PB200-075-2

1

≥5Ω/3kW

1

37

PB200-075-2

1

≥5Ω/4kW

1

45

PB200-100-2

1

≥4Ω/5kW

1

55

PB200-100-2

1

≥4Ω/6kW

1

75

PB200-180-2

1

≥2Ω/8kW

1

93

PB200-180-2

1

≥2Ω/10kW

1

110

PB200-180-2

2

≥2Ω/7kW

2

132

PB200-180-2

2

≥2Ω/8kW

2

160

PB200-100-2

2

≥2Ω/9kW

2

2.This table is the selection reference of 380V inverter, according to the brake unit DC

operating point 670V, braking frequency ED = 10%, and braking torque 100%.

Inverter

power (kW)

Brake unit

Brake resistor (100% brake torque)

Specification

Quantity (pcs)

Specification

Quantity

(pcs)

18.5

PB200-040-3

1

≥17Ω/2kW

1

22

PB200-040-3

1

≥17Ω/3kW

1

30

PB200-040-3

1

≥17Ω/3kW

1

37

PB200-040-3

1

≥17Ω/4kW

1

45

PB200-050-3

1

≥14Ω/5kW

1

55

PB200-075-3

1

≥9Ω/6kW

1

75

PB200-100-3

1

≥7Ω/8kW

1

93

PB200-100-3

1

≥7Ω/10kW

1

110

PB200-180-3

1

≥4Ω/12kW

1

132

PB200-180-3

1

≥4Ω/15kW

1

160

PB200-180-3

1

≥4Ω/18kW

1

187

PB200-100-3

2

≥7Ω/10kW

2

200

PB200-100-3

2

≥7Ω/11kW

2

220

PB200-180-3

2

≥4Ω/12kW

2

250

PB200-180-3

2

≥4Ω/13kW

2

280

PB200-180-3

2

≥4Ω/15kW

2

315

PB200-180-3

2

≥4Ω/17kW

2

355

PB200-180-3

3

≥4Ω/13kW

3

400

PB200-180-3

3

≥4Ω/14kW

3

Chapter 5 Brake unit and brake resistor

16

3.This table is the selection reference of 480V inverter, according to the brake unit DC

operating point 760V, braking frequency ED = 10%, and braking torque 100%.

Inverter

power (kW)

Brake unit

Brake resistor (100% brake torque)

Specification

Quantity (pcs)

Specification

Quantity (pcs)

18.5

PB200-040-4

1

≥19Ω/2kW

1

22

PB200-040-4

1

≥19Ω/3kW

1

30

PB200-040-4

1

≥19Ω/3kW

1

37

PB200-040-4

1

≥19Ω/4kW

1

45

PB200-050-4

1

≥16Ω/5kW

1

55

PB200-075-4

1

≥11Ω/6kW

1

75

PB200-075-4

1

≥11Ω/8kW

1

93

PB200-100-4

1

≥8Ω/10kW

1

110

PB200-100-4

1

≥8Ω/12kW

1

132

PB200-180-4

1

≥5Ω/14kW

1

160

PB200-180-4

1

≥5Ω/18kW

1

187

PB200-180-4

1

≥5Ω/20kW

1

200

PB200-180-4

1

≥5Ω/22kW

1

220

PB200-100-4

2

≥8Ω/12kW

2

250

PB200-180-4

2

≥5Ω/14kW

2

280

PB200-180-4

2

≥5Ω/15kW

2

315

PB200-180-4

2

≥5Ω/17kW

2

355

PB200-180-4

2

≥5Ω/19kW

2

400

PB200-180-4

2

≥5Ω/21kW

2

Table of contents

Other Powtran Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

Siemens

Siemens NXPLUS C Installation and operating instructions

Delixi

Delixi NAVIGATOR DZ47L Series user manual

TEL

TEL TAVRIDA ELECTRIC VCB15 LD user guide

ABB

ABB HD4/R Installation and operating instructions

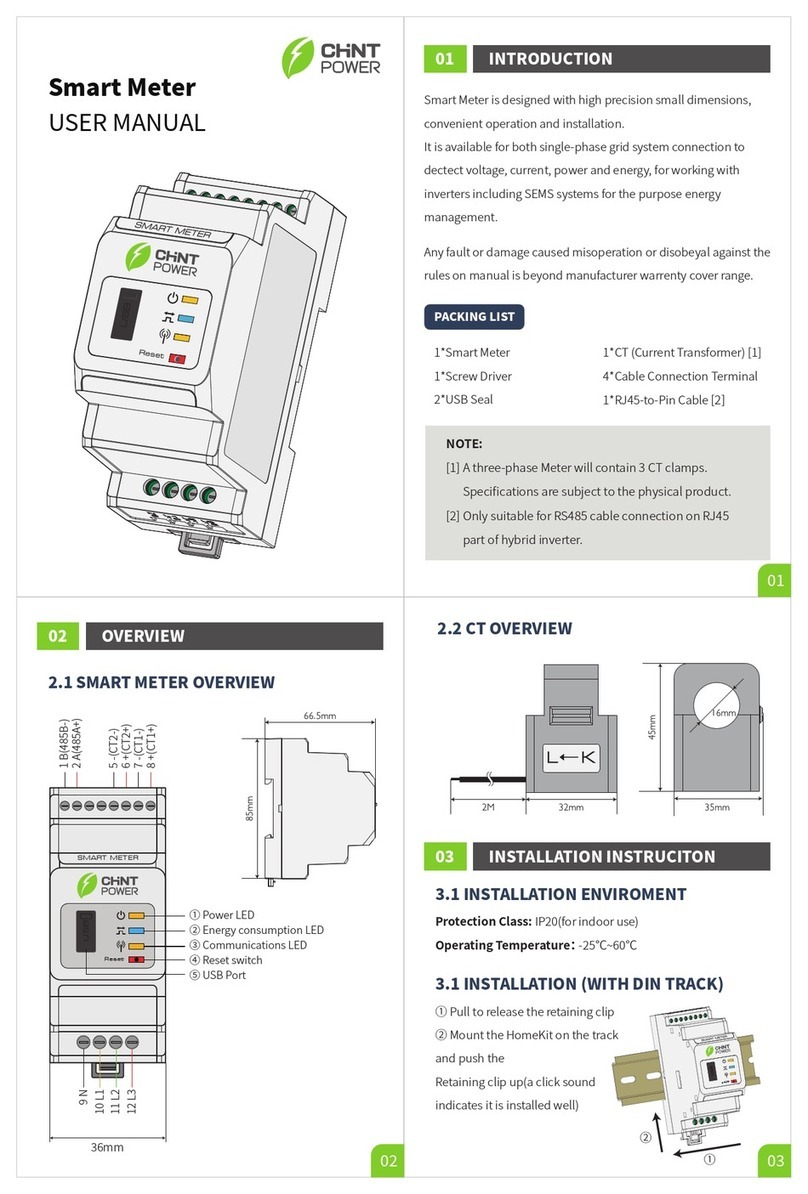

CHNT Power

CHNT Power Smart Meter CPS1000 user manual

Eaton

Eaton Cutler-Hammer Digitrip RMS 810 instructions