ABB HD4/R User manual

Other ABB Circuit Breaker manuals

ABB

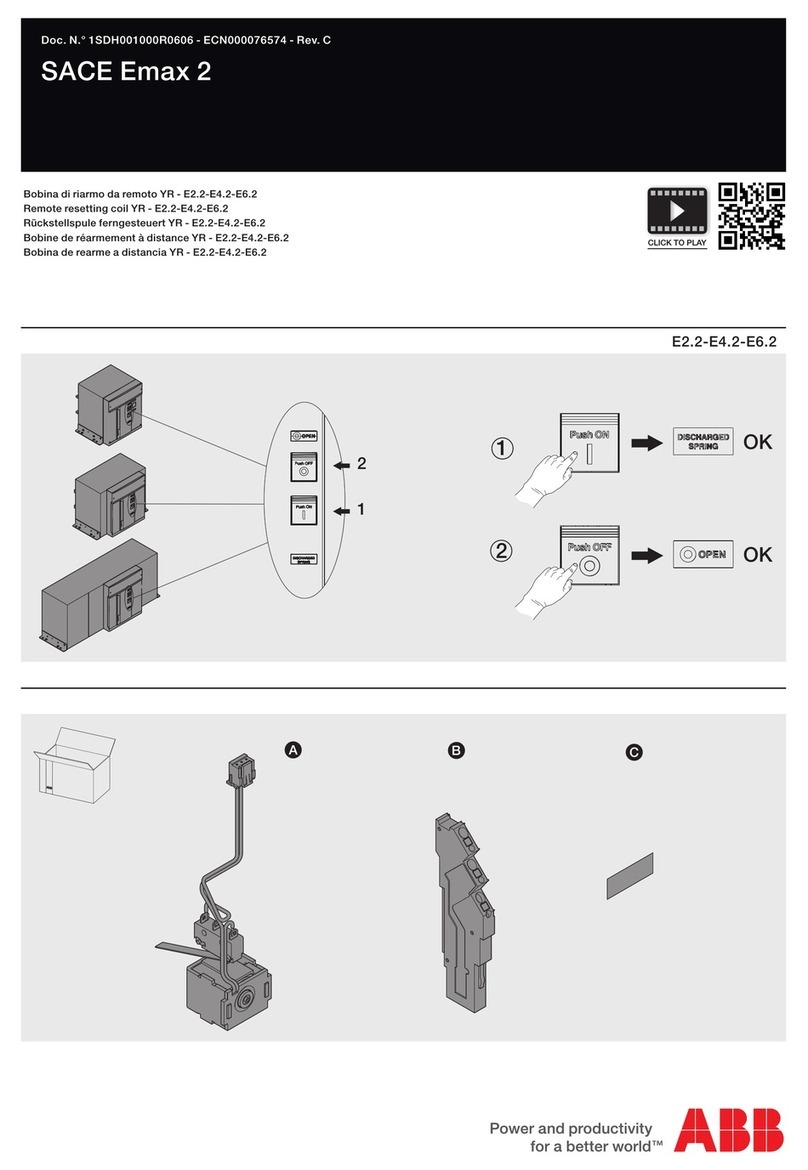

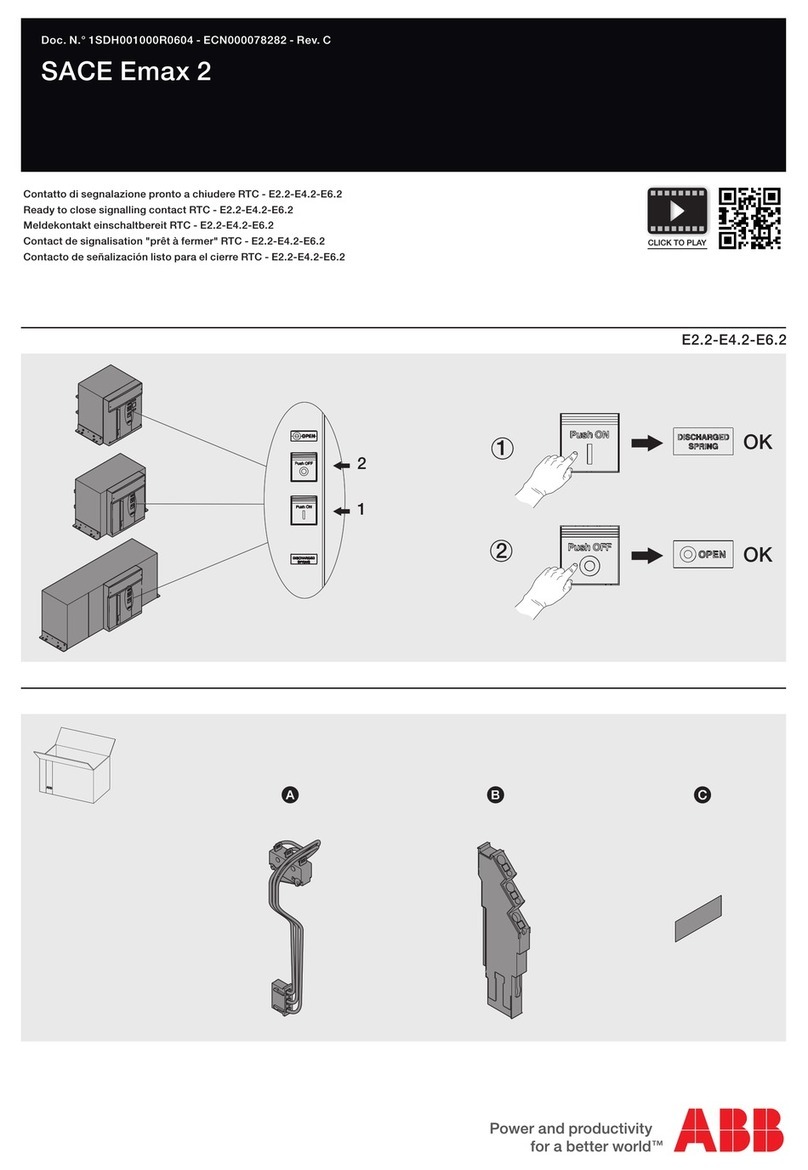

ABB SACE Emax 2 E2.2 User guide

ABB

ABB HD4/R Quick guide

ABB

ABB ADVAC Installation and operating instructions

ABB

ABB SACE Tmax XT5 User manual

ABB

ABB VD4X User manual

ABB

ABB SACE Emax 2 User manual

ABB

ABB SACE Emax 2 User manual

ABB

ABB Sace Emax UL Listed Manual

ABB

ABB SACE Tmax XT5 User manual

ABB

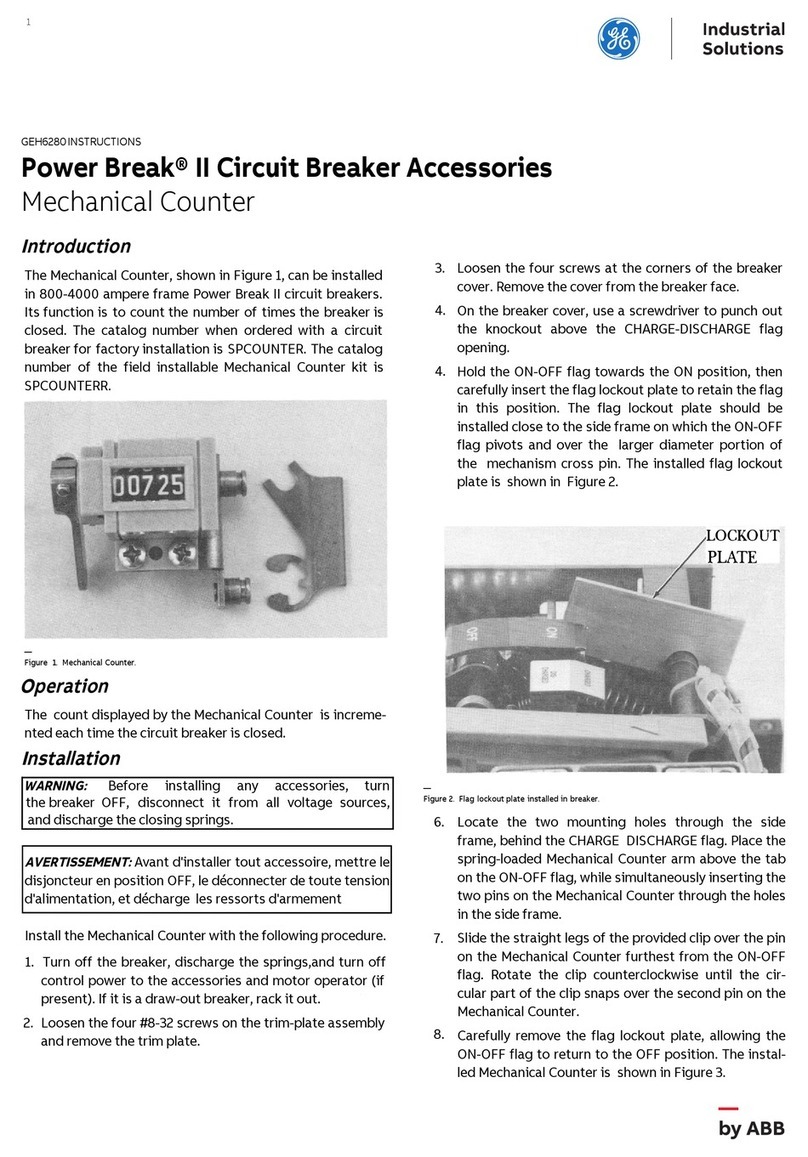

ABB GE Power Break II User manual

ABB

ABB SMISSLINE CLASSIC FS451 Service manual

ABB

ABB VD4 36 Quick guide

ABB

ABB VM1/A/P Quick guide

ABB

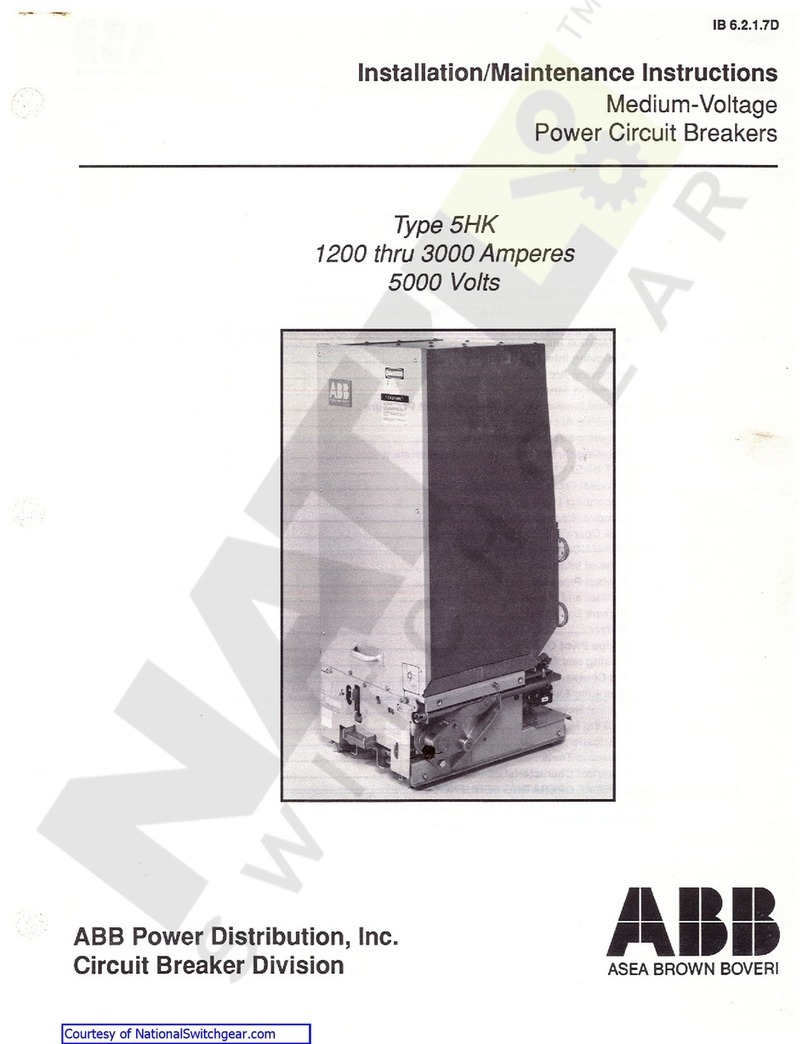

ABB 5HK Series Installation and operating instructions

ABB

ABB SACE Emax 2 User manual

ABB

ABB SACE Emax 2 E2.2 User manual

ABB

ABB Emax Series User manual

ABB

ABB VHK-R Installation and operating instructions

ABB

ABB H569-445 User manual

ABB

ABB R-MAG User manual

Popular Circuit Breaker manuals by other brands

Eaton

Eaton Power Defense PDG2 Instruction leaflet

Bticino

Bticino L4412CM2 quick start guide

Eaton

Eaton S-T0 Instruction leaflet

OEZ

OEZ 3VA9-RS-4VBH1 Installation, service and maintenance instructions

Siemens

Siemens PSR Instructions, Installation, Operation, Maintenance

Rockwell Automation

Rockwell Automation Allen-Bradley 140G-G manual