Powtran PB6012 User manual

Foreword

Thank you for choosing POWTRAN Brake Unit.

This manual provides user the relevant precautions on model

no and specification, installation, wiring, function, routine

maintain, abnormal diagnosis and remove, and how to select

brake resistor etc. The manual can be used for system designer

reference.

In order to ensure correct installation and operation of the

frequency converter, please carefully read this manual before

installing it.

POWTRAN is committed to the continuous improvement of

the product performance, if any change of this information

without prior notice

Powtran

August,2014

Contents

Section I Safety Precautions ...............................................1

Section II Inspection............................................................4

Section III Installation.........................................................5

Section IV Function Parameter Description.....................8

Section V Single Unit Running...........................................9

Section VI Paralleled running ..........................................11

Section VII Fault Diagnosis and Solutions......................13

Section VIII Standard specification.................................14

Section IX Warranty .........................................................17

1

Section I Safety Precautions

Please read the manual before the installation, operation and inspection of

the product. For the safe operation, remind you to pay special attention to the

“Warning” and “Attention” in the manual.

*Attention:

The potential danger will lead to slight or medium life harm or

equipment damage. It could also warn the violate operation.

!Warning:

The potential danger could lead to life harm or private loss!

Statement: When the brake unit is used with other brand

frequency inverter together, our company is only undertake the

product quality problems of 3 packets of responsibility; If the

customer need other projects of joint liability guarantee, Please

cover insurance of the related domestic property insurance company

yourself, In order to obtain relatively good liability to pay

compensation.

*Attention:

*Attention:

●Do not use any brake unit and brake resistor lack of or with

damaged spares.

●Do not touch the internal spares for there are CMOS spares on the

control card of the brake unit. Otherwise it will damage the

spares.

●Please add the fan or other cooling equipment when multiple

brake units installed parallel in the one cabinet.

Section I Safety Precautions

2

*Attention:

*Attention:

* Attention:

!Warning:

●Ensure the right setting of brake unit and brake resistor.

●Do not make voltage resistance test on the brake unit, or it will lead

semiconductor spares damaged in the main circuit of the brake unit.

●Fix the srew when connecting, or the loose connection will lead fire

or creepage.

●Do not touch the brake unit, the internal spares and printing board

after the brake unit is connected, otherwise it will lead to electric

shock. There is high voltage direct current inside.

●Do not touch the heat sink of the brake unit and the brake resistors,

otherwise it will lead to scald or electric shock. There is high

temperature and heated spares inside after the brake unit is connected.

●The brake resistor should be with temperature and other protection.

Because the brake unit is defective when the brake resistor keeps

heated, it should have been isolated itself. Powtran will not take the

responsibility of such accident caused by no automatic isolation.

●The unit and brake resistor should be installed on the medium

with flame retardancy.

●Connection is allowed only when the power is switched off

and completely out of power.

●Only well-trained personnel are allowed to use this unit.

4

Section I Safety Precautions

3

!Warning:

!Warning:

!Warning:

!Warning:

●Ensure the correct connection before running.

●Ensure the right host and slave selection and voltage class before

running.

●Only when the charge light is off and ensure the charge voltage is

0 with the multimeter, the brake unit could be adjusted and

repaired.

●During the running, do not touch any spares inside.

●Please refer to the content in the manual when analyze and

manage the fault of the brake unit. Any modification to the brake

unit is not allowed otherwise the life harm and property loses will

not be burdened by Powtran.

●This product is the accessories of the inverter, if it is used

improperly which would not only do damage to itself but also to

the inverter. Please pay much attention to this.

4

Section II Inspection

Powtran Brake Unit has been tested and inspected before leaving the

manufacturer. Before unpacking the product, please check if the package is

damaged due to careless transportation, and if the specifications and type of the

product complies with the order. Please contact the supplier of Powtran

products if any problems are found.

Only the well-trained personnel are allowed to use this

unit, and such personnel must read through the parts of this

manual relating to the safety, installation, operation and

maintenance before using the unit. The safe operation of this

unit depends on correct transport, installation, operation and

maintenance.

5

Section III Installation

3-1.Conditions for Use

Hangging Brake unit should be installed inside the house where is

ventilative.

Ambient condition should accord with the followings:

(1).Environmental temperature -10℃to 50℃Above 40℃,the capacity will

decrease 3% by each 1℃.So it is not advisable to use inverter above 50℃

(2).Preventing electromagnetic interference, away from the interference so

urces

(3).Prevent dropping dust, powder, cotton fiber or fine metal powder from

entering it.

(4).Prevent oil, salt and corrosive gas from entering it.

(5).Avoid vibration.

(6).Avoid high temperature and moisture and avoid being wetted due to raining,

with the humidity below 90%RH (not dewing).

(7).Prohibit the use in the dangerous environment where inflammable or

combustible or explosive gas, liquid or solid exists.

3-2.Sharp size

(A)PB6012/PB6014

8

Section III Installation

6

(B)PB6022/PB6024

(C) PB6032/PB6034

3-3.Main circuit specification:

Section III Installation

7

Connection diagram of Brake unit and Inverter

*NOTE:

(1) Cable length of the frequency converter and braking unit is less than

5 m

(2) Cable length of the Braking resistor (Rb) and brake unit is less than

10 m, and must use heat-resisting conductors

(3) P, N is the terminal "+""-" of the frequency inverter dc bus, P is the

positive terminal, e, N is a negative terminal "-"

(4) P, N line must be twisted together, Rb and Rb ' line must be twisted

together..

!Warning:Incorrect connection of the main circuit will lead the

damage to the brake unit and inverter.

8

Section IV Function Parameter Description

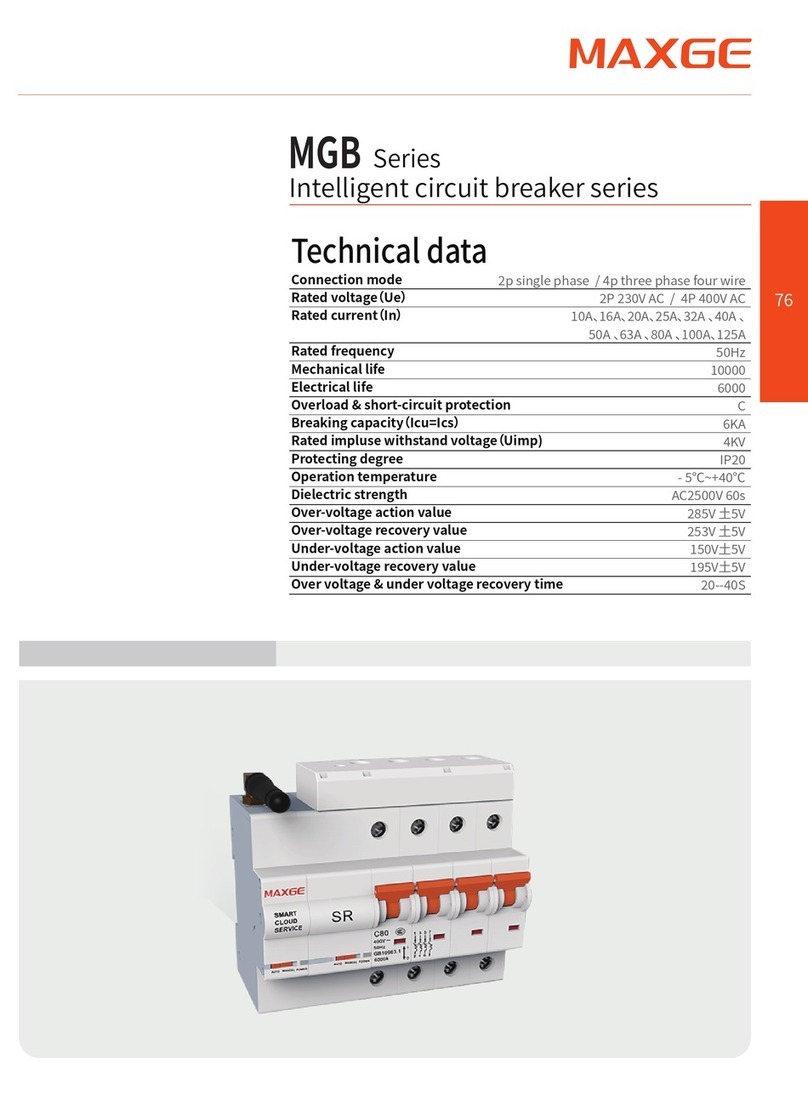

Parameter setting switch and control terminal

Note:Only PB6032,PB6034 have M,S slave and host selection,but other type

no. The voltage class is set OK during the factory setting.

!Warning:Incorrect selection of the slave and host will lead

abnormal running and damage!

Description of control circuit terminal of the brake unit

Terminal

Specification

Note

Parameter

Setting

switch

1

Slave and host selection switch, when

M is ON, the brake unit is set to be

host brake unit

Factory

setting:O

N

2

Slave and host selection switch, when

S is ON, the brake unit is set to be

slave brake unit.

Factory

setting:O

FF

Control

M1/M2

Slave and host control terminal

S1/S2

Slave and host control terminal

TH1/TH2

OH protection switch(always close)

9

14

9

Section V Single Unit Running

Connection diagram of single brake unit and inverter

When 1 unit is used, please refer to the above diagram, connect the

inverter, brake unit and brake resistor and run it.

200V grade

Voltage

selection

the input power supply

voltage of the

frequency inverter

Brake starting voltage (PN

voltage)

220V

220VAC

365VDC±3%

400V grade

Voltage

selection

the input power supply

voltage of the

frequency inverter

Brake starting voltage (PN

voltage)

380V

380VAC~415VAC

690VDC±3%

* NOTE:

(1) if the grid voltage 20% higher than the normal voltage supply, please set the

larger voltage.

12

Section V Single Unit running

10

(2) please confirm starting braking voltage macth the device .

!Warning: in the CHARGE indicating lamp before fully

extinguished (there is voltage between PN) not allowed to adjust

the settings!

16

9

14

11

Section VI Paralleled running

Diagram of the connection of paralleled running brake unit and inverter

(Only PB6032,PB6034 with this function)

If 2 or more over brake units are paralleled, please refer to the above

diagram and connect the inverters, multiple brake units and brake resistors.

6-1、Host and slave select of function setting

(1) The factory setting of the brake unit is set to be the host (M), do not

modify the factory setting if only one brake unit is used.

(2) When 2 or more over brake units are paralleled, the control terminal

(S) is used. Please refer to the “Host and slave control connection”.

6-2、Host and slave control connection

(1) The brake unit has host/slave switch. Set the brake unit 1 to be “M”,

the brake unit 2 and 3 to be “S”

(2) Connect separately M1, M2 of the brake unit 1 with S1, S2 of the

brake unit 2;

Connect separately M1, M2 of the brake unit 2 with S1, S2 of the

Section VI Paralleled running

12

brake unit 3. Etc.

*Note:

Double wind the M1, M2 and S1, S2, and please make it as short as you

can; the maximum paralleled brake units is only 10.

16

13

Section VII Fault Diagnosis and Solutions

NO.

Fault state

Reason

Processing

method

1

The brake

resistor

heated badly

when it

brakes.

Main circuit power IGBT of

the unit short circuit

Change brake

unit

Incorrect selection of the brake

unit voltage

Choose suit

voltage brake

unit

Brake unit faulted

Change brake

unit

2

Inverter OU

Lack of braking of the brake

resistor

check the brake

condition

Not suited brake unit voltage

braking unit

voltage too high

Brake unit faulted

Change brake

unit

3

relay action

over heat

protection

Heat sink temperature over

80℃

Braking rate is

too high, forced

air cooling

*NOTE:

The electric net voltage is too high, please select the high voltage

setting.

!Warning:Open the P and N, ensure there is no voltage

between PN when use and inspect the unit! This unit

control circuit is not isolated circuit.

14

Section VIII Standard specification

8-1、Model specification:

200V level(200/220/240V)

Type

Sharp size

Allowed max. brake current (65℃)*

PB6012

A

40A

PB6022

B

70A

PB6032

B

140A

400V level(380/415V)

Type

Sharp size

Allowed max. brake current (65℃)*

PB6014

A

40A

PB6024

B

70A

PB6034

B

140A

*NOTE:

The allowed maximum current of the power spares IGBT inside the brake

unit with the certain temperature.

8-2、Model designation:

e.g.:

6: Design Series No.

01/02/03: Capacity No.

2: 200V 4:400V

PB: Powtran Brake Unit

Section VIII Standard Specification

15

8-3、200V specification and selection reference:

Capacity no.

HP(kW)

Brake Unit

Brake resistor(150% brake

torque)

Type

Qty(pc)

Type

Qty(pc)

7.5(5.5)

PB6012

1

30Ω/520W

1

10(7.5)

1

20Ω/780W

1

15(11)

1

13.6Ω/2400W

1

20(15)

1

10Ω/3000W

1

25(18.5)

PB6022

1

8Ω/4800W

1

30(22)

1

6.8Ω/4800W

1

40(30)

1

5Ω/6000W

1

50(37)

1

5Ω/6000W

1

60(45)

PB6032

1

3.4Ω/9600W

1

75(55)

1

3.4Ω/9600W

1

100(75)

PB6032

2

5Ω/6000W

2

125(93)

PB6032

3

5Ω/6000W

3

150(110)

3

5Ω/6000W

3

8-4、400V specification and selection reference:

Capacity no.

HP(kW)

Brake Unit

Brake resistor(150% brake

torque)

Type

Qty(pc)

Type

Qty(pc)

7.5(5.5)

PB6014

1

75Ω/780W

1

10(7.5)

1

50Ω/1040W

1

15(11)

1

50Ω/1040W

1

20(15)

1

40Ω/1560W

1

25(18.5)

1

32Ω/4800W

1

30(22)

1

27.2Ω/4800W

1

40(30)

PB6024

1

20Ω/6000W

1

50(37)

1

16Ω/9600W

1

60(45)

1

13.6Ω/9600W

1

75(55)

1

10Ω/12000W

1

100(75)

PB6034

1

6.8Ω/12000W

1

125(93)

1

6.8Ω/12000W

1

Section VIII Standard Specification

16

150(110)

1

6.8Ω/12000W

1

175(132)

PB6034

2

6.8Ω/12000W

2

200(160)

2

6.8Ω/12000W

2

250(187)

PB6034

3

6.8Ω/12000W

3

300(220)

3

6.8Ω/12000W

3

8-5、Brake resistor selection:

(1) The best braking resistance with no sense of resistance, in order to

reduce the inductance.

(2) Braking resistor grounded is strictly prohibited, otherwise it will lead

the serious damage to the unit and inverter

(3) Selection of the brake resistor capacity is for reference, it depends on

the load intertia, brake frequency, etc characteristic. Please inquire

Powtran when you have questions

*NOTE:

(1) Parallel braking unit can improve the braking capability.

(2) Braking ability of 2 sets brake unit parallel is 2 times for single one.

Example: PB6032= PB6022×2 = PB6012×4.

17

Section IX Warranty

The product quality shall comply with the following provisions:

1. Warranty terms

1-1. The product from the user the date of purchase, the warranty period

of 12 months (limited to domestic market).

1-2. Export products and non-standard products warranty period is 12

months or according to the agreement of warranty execution.

1-3. The product from the user the purchase date, guarantee to return,

replacement, repair service, within one month after the date of shipment.

1-4. The product from the user the date of purchase, replacement, repair

within three months after the date of shipment.

1-5. The product from the user the purchase date, enjoy lifelong

compensable service.

2. Exceptions clause

If belongs to the quality problems caused by following reasons products,

not within the warranty.

2-1. The user is not in accordance with the "products manual" is used

method of operation caused the failure.

2-2. Users without permission to repair or alteration caused by product

failure.

2-3. Users beyond the standard specifications require the use of the

inverter caused by product failure.

2-4. Users to buy and then fell loss or damage caused by improper

handling.

2-5. Because the user use environment device caused by aging lead to

product failure.

2-6. Due to the fault cause of earthquake, fire, lightning, wind or water

disaster, abnormal voltage irresistible natural disasters.

2-7. Damaged during shipping (Note: the transport mode specified by

the customer, the company to assist to handle cargo transfer procedures).

3. The following conditions, manufacturers have the right not to be

warranty

3-1. No product nameplate or product nameplate blurred beyond

recognition.

3-2. Not according to the purchase contract agreement to pay the

money.

3-3. For installation, wiring, operation, maintenance and other users can

not describe the objective reality to the company's technical service center.

4. In return, replacement, repair service, shall be returned the company,

confirmed the attribution of responsibility, can be returned or repair

This manual suits for next models

5

Table of contents

Other Powtran Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

Siemens

Siemens NXPLUS C Installation and operating instructions

Delixi

Delixi NAVIGATOR DZ47L Series user manual

TEL

TEL TAVRIDA ELECTRIC VCB15 LD user guide

ABB

ABB HD4/R Installation and operating instructions

CHNT Power

CHNT Power Smart Meter CPS1000 user manual

Eaton

Eaton Cutler-Hammer Digitrip RMS 810 instructions