TEL TAVRIDA ELECTRIC VCB15 LD User manual

VCB

Vacuum Circuit Breaker

17.5kV, ...31.5kA, ...2000A

24kV, ...16kA, ...800A

User Guide

Contents

1. Product description..................................................................................................................................... 4

1.1 Abbreviations .................................................................................................................................... 5

1.2 Denitions......................................................................................................................................... 5

1.3 Main technical parameters................................................................................................................. 6

1.4 Disclaimers ........................................................................................................................................ 7

1.5 Precautions........................................................................................................................................ 7

1.6 Warranty ........................................................................................................................................... 7

2. Nameplates and seals................................................................................................................................. 8

3. Product handling......................................................................................................................................... 12

3.1 Transportation ................................................................................................................................... 13

3.2 Storage.............................................................................................................................................. 13

3.3 Unpacking and inspection.................................................................................................................. 13

3.4 Handling............................................................................................................................................ 23

4. Installation................................................................................................................................................... 24

4.1 Primary part....................................................................................................................................... 25

4.1.1 Preparation................................................................................................................................ 25

4.1.2 Installation of the ISM................................................................................................................ 25

4.1.3 Main terminal connections of LD ISM ........................................................................................ 27

4.1.4 Main terminal connections of HD ISM........................................................................................ 29

4.1.5 LD ISM interlocks....................................................................................................................... 33

4.1.6 HD ISM interlocks ...................................................................................................................... 36

4.1.7 Installation of HD ISM main contacts position indicator.............................................................. 39

4.1.8 Protective earthing..................................................................................................................... 40

4.2 Secondary part .................................................................................................................................. 42

4.2.1 Three-phase ISM secondary connections.................................................................................... 42

4.2.2 Single-phase ISM secondary connections ................................................................................... 43

4.2.3 CM secondary connections........................................................................................................ 44

4.2.4 Installation of the CM................................................................................................................ 45

4.2.5 Installation of secondary cables between ISM and CM ............................................................... 46

4.2.6 Auxiliary supply ......................................................................................................................... 48

4.2.7 CM indication............................................................................................................................ 49

4.2.8 CM relay contacts operation...................................................................................................... 50

5. Commissioning............................................................................................................................................ 51

6. Operation .................................................................................................................................................... 58

6.1 Switching .......................................................................................................................................... 59

6.1.1 Closing...................................................................................................................................... 59

6.1.2 Opening .................................................................................................................................... 60

6.1.3 Emergency opening................................................................................................................... 60

7. Maintenance and troubleshooting............................................................................................................ 62

7.1 Primary circuits .................................................................................................................................. 63

7.2 Secondary circuits.............................................................................................................................. 65

7.3 Troubleshooting................................................................................................................................. 65

8. Disposal ....................................................................................................................................................... 67

Appendix 1. Product range ............................................................................................................................ 69

Appendix 2. Overall drawings ....................................................................................................................... 72

Appendix 3. Secondary schemes ................................................................................................................... 86

1. Product description

5

1.1 Abbreviations

AC Actuator coil

AS Auxiliary switch

EMC Electromagnetic capability

CM Control Module

CO Close - Open operations cycle

Com Common point of contact

I/O Input / Output

ISM Indoor Switching Module

LED Light emitting diode

(P)MCB Protective miniature circuit breaker

PS Position switch

NA Not applicable

NC Normally closed contact

NO Normally open contact

PCD Pole center distance

USB Universal Serial Bus

VCB Vacuum Circuit Breaker

VI Vacuum interrupter

HD ISM Heavy duty ISM

LD ISM Light duty ISM

1.2 Denitions

Closing time

The closing time is the time period from the moment the close command is applied to the CM to the time when all

ISM poles make contact.

Opening time

The opening time is the time period from the moment the trip command is applied to the CM to the time when all

ISM poles are separated.

Break time

The break time is the time period from the moment the trip command is applied to the CM to the time when the

arcs in all phases are extinguished.

This Product Guide describes the Vacuum Circuit Breakers manufactured by Tavrida Electric.

Tavrida Electric circuit breakers are designed for rated voltages up to 24 kV.

Vacuum Circuit Breakers described in the current document can be used in various kinds of switchgear and RMUs

and are intended to perform switching operations in network rated and faulty modes.

The breakers are comprised of following main components:

• Indoor Switching Module (ISM) - The air insulated ISM incorporates Tavrida Electric vacuum interrupters with mon-

stable magnetic actuators and solid dielectric insulating materials. No SF-6 or oil insulation is used in the ISM;

•

• Control Module (CM) - The CM is a microprocessor based controller that provides ISM operation, protection

and data logging functions;

•

• Kits - The kits of components are used to provide circuit breaker application properties.

This guide contains information on switching operations, required check-ups and maintenance, as well as service

and disposal procedures. The purpose of the document is to provide necessary product information for users

providing installation, commissioning and utilizing installed equipment.

6

1.3 Main technical parameters

Main technical data and circuit breaker technical parameters are presented in the tables below.

Table 1 - Main technical parameters

Type VCB15_LD VCB15_Shell VCB25_LD

Rated voltage (Ur) ≤ 12 kV ≤ 17.5 kV ≤ 24 kV

Rated normal current (Ir) ≤ 800 A ≤ 1250 A 1)

≤ 2000 A ≤ 800 A

Rated power frequency withstand voltage (Ud) 28 (42) 2) kV 38 (42) kV 2) 50 kV

Rated lightning impulse withstand voltage (peak) (Up) 75 kV 95 kV 3) 125 kV

Rated short-circuit breaking current (Isc) ≤ 20 kA 4) ≤ 31.5 kA 4) ≤ 16 kA 4)

Rated peak withstand current (Ip) ≤ 50 kA ≤ 82 kA ≤ 40 kA

Rated short-time withstand current (Ik) ≤ 20 kA ≤ 31.5 kA ≤ 16 kA

Rated duration of short circuit (tk) 4 s

Rated frequency (fr) 50/60 Hz

Rated operating sequence O-0.3s-CO-10s-CO-10s-CO 5)

Standards IEC 62271-100

GB 1984- 2003

IEC 62271-100

GB 1984- 2003 IEC 62271-100

Weight (depending on Pole centre distance) for three-phase ISM 34-36 kg 51-55 kg 36-38 kg

Weight for single phase ISM 13 kg 14 kg

CM supply voltage

Rated range of supply voltage of CM_16_1(60_x_x) 24V to 60V DC

Rated range of supply voltage of CM_16_1(220_x_x) 110V to 220V AC/DC

Power consumption of CM

Charging the close and trip capacitors of CM_16_1(60_x_x) ≤ 25 W

Charging the close and trip capacitors of CM_16_1(220_x_x) ≤ 42 W AC 6)

≤ 37 W DC

Permanent power consumption (standby) of CM_16_1(60_x_x) ≤ 5 W

Permanent power consumption (standby) of CM_16_1(220_x_x) ≤ 7 W AC 7)

≤ 5 W DC

Inrush current of of CM_16_1(60_x_x) with discharged capacitors ≤ 120 A

Inrush current of of CM_16_1(220_x_x) with discharged capacitors ≤ 18 A

Inrush time constant of CM_16_1(60_x_x) with discharged capacitors ≤ 0.5 ms

Inrush time constant of CM_16_1(220_x_x) with discharged capacitors ≤ 4 ms

Altitude above sea level 1000 m 8)

Relative humidity in 24 hours ≤ 95 %

Relative humidity over 1 month ≤ 90 %

Temperature range -25 °C ... +55 °C

1) For VCB ISM15_Shell with Low upper terminal – up to 1250 A, with High upper terminal – up to 2000 A.

2) The information in brackets refers to the national Chinese standards GB1984-2003 and installation altitude of maximum 1000 m.

3) Parameter valid only when ISM is used with insulation masks. For details see dimensional drawings and accessory information.

4) At 40% d.c. component.

5) The number of sequential Close-Trip operations with interval 10 seconds should not exceed 10. The number of Close-Trip operations should not

exceed 60 per hour. Sequence of 10s Close-Trip operations can be repeated only after 260 s pause.

6) At Cos j >0.66.

7) At Cos j >0.33.

8) Up to an installation altitude of 1000 m above sea level. Above 1000m, the external insulation measurement of the ISM must be increased by

the atmospheric correction factor Ka according to IEC 62271-1 compared to the insulation measurement at sea level. The maximum allowed

altitude is 2000 m above sea level.

7

1.4 Disclaimers

Tavrida Electric will not accept any claims for damages caused by improper transport, storage as well as

unpacking. Transport damage must be reported in writing to the supplier as soon as it is discovered.

The present User Guide contains information necessary for the installation, commissioning and operation. It is

absolutely necessary for the proper use of the Vacuum Circuit Breakers to read the User Guide carefully before

starting and to adhere to the instructions and the relevant regulations. Tavrida Electric will not accept any claims

for damages caused by improper usage of the Vacuum Circuit Breakers. In case of special congurations please

contact Tavrida Electric prior of usage of the Vacuum Circuit Breakers.

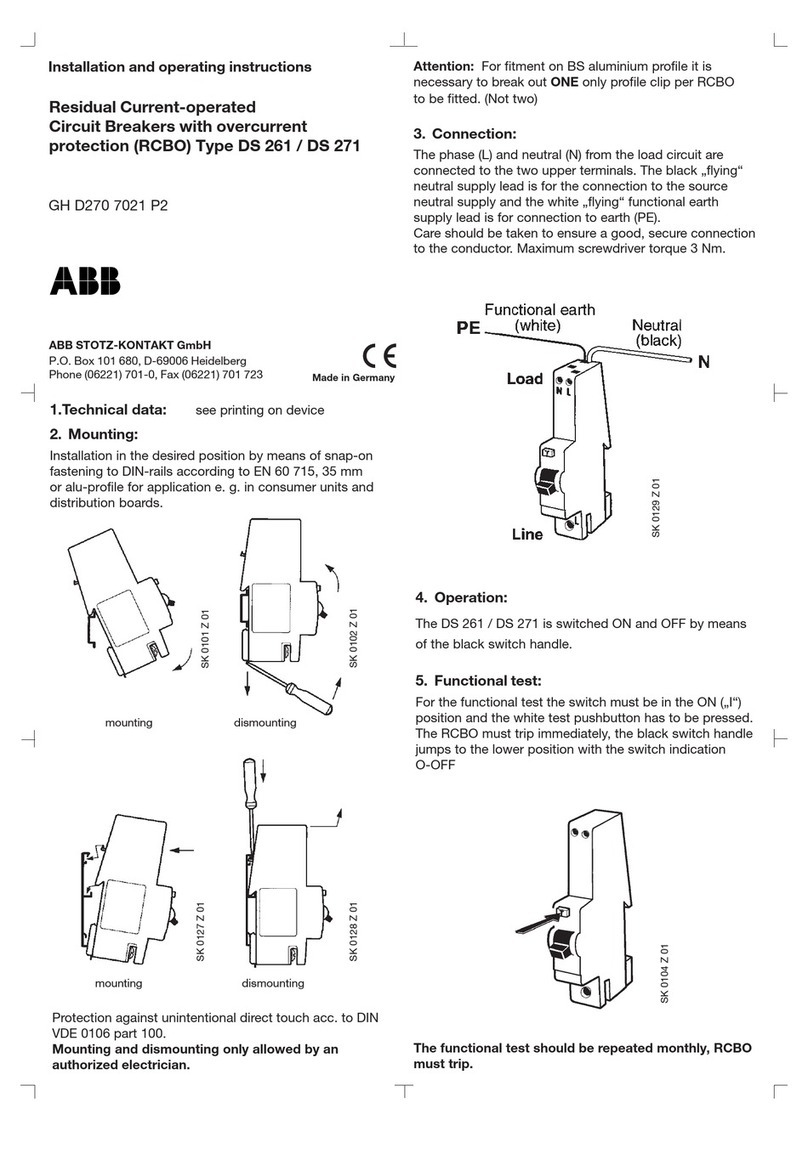

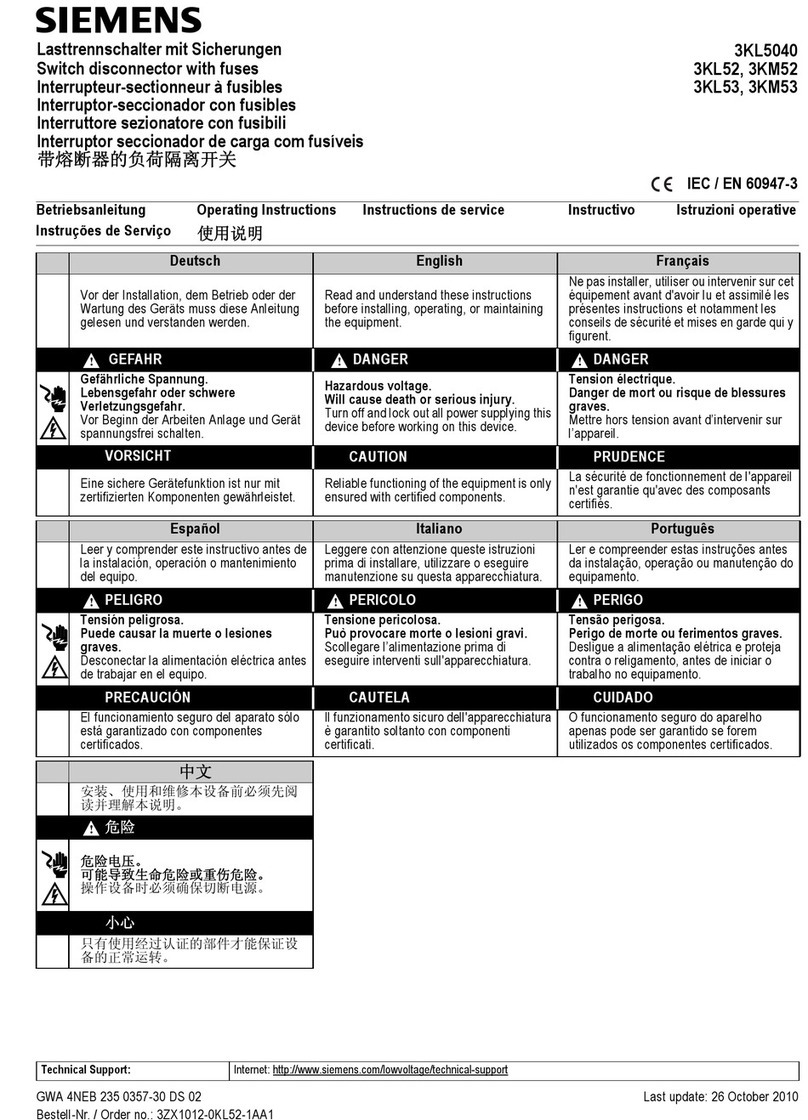

1.5 Precautions

• Check whether the installation position (distances, spatial separation, and the surroundings) is suitable for the

switching devices.

• Installation, operation and maintenance shall only be carried out by trained and experienced personnel who

are familiar with the equipment and the electrical safety requirements.

• During installation, commissioning, operation and maintenance of the equipment the relevant legal regu-

lations (such as DIN/VDE/IEC), accident prevention regulations and the connecting conditions of the electric

utilities shall be followed.

• Take note that during operation of the Vacuum Circuit Breakers certain parts are subject to dangerous voltage.

Mechanical parts, also remote-controlled, can move quickly. Failure to comply may result in death, severe per-

sonal injury or damage to equipment.

• Pay attention to the hazard statements located throughout this User Guide.

• The operating conditions of the vacuum circuit breakers shall comply with the technical data specied in this

User Guide.

• Personnel installing, operating and maintaining the equipment shall be familiar with this User Guide and its

contents.

1.6 Warranty

Unless otherwise stated in the contract, the warranty period is stated in Standard warranty policy. If agreed to

otherwise, the contract conditions apply. No warranty is given in the case of …

a) … the warranty period having run out during the period of storage with the customer;

b) … the operating conditions, ambient conditions, transport and storage conditions have not been adhered to

according to the application description or the Installation and Operating Instructions;

c) … an unauthorized manipulation of the device has been carried out, such as opening the housing or

damaging the seal;

d) … the device has not been properly installed, such as incorrect connection of supply voltage of auxiliary

circuits.

2. Nameplates and seals

9

Figure 1

ISM label

Figure 2

Serial number plate

The serial number plate contains information about ISM type and serial number.

The label contains brief information about ISM technical parameters.

There are warranty seal labels on each side of the ISM metal frame.

1 2

1. Label

2. Serial number plate

3. Seal

a) LD ISM labeling b) HD ISM labeling

Figure 3

Warranty seal

3

Label, seal and serial number plate arrangement is shown below

Figure 4

Serial number plate, label and seal arrangement

1. Manufacturer

2. Rated voltage Ur

3. Rated power frequency withstand voltage Vd

4. Rated impulse withstand voltage Up

5. Applicable standards

6. Rated duration of short circuit tk

7. Rated short-circuit current Isc

8. Rated current Ir

9. Pole center distance p

10. Weight W

11. Year of manufacturing

12. Rated operating sequence

1

2

3

4

5

6 7 8

9

10

11

12

The Vacuum Circuit Breakers itself does not have nameplates or seals but main components (ISM, CM and

manual generators) it is comprised of have them.

ISM nameplates and seals

Each ISM has the following plate and labels:

• Label

• Serial number plate

• Seals

13 2

10

CM nameplates and seals

Each CM has the following labels :

• Designation label

• Serial number label

• Seals

Figure 5

Designation label

Figure 6

Serial number label

Figure 7

Serial number and designation label arrangement

1

2

1. Serial number label

2. Designation label

3. Warranty seal

3

3

11

Figure 8

Designation label

Figure 9

Serial number label

Manual generator nameplates

Each manual generator has the following labels :

• Designation label

• Serial number label

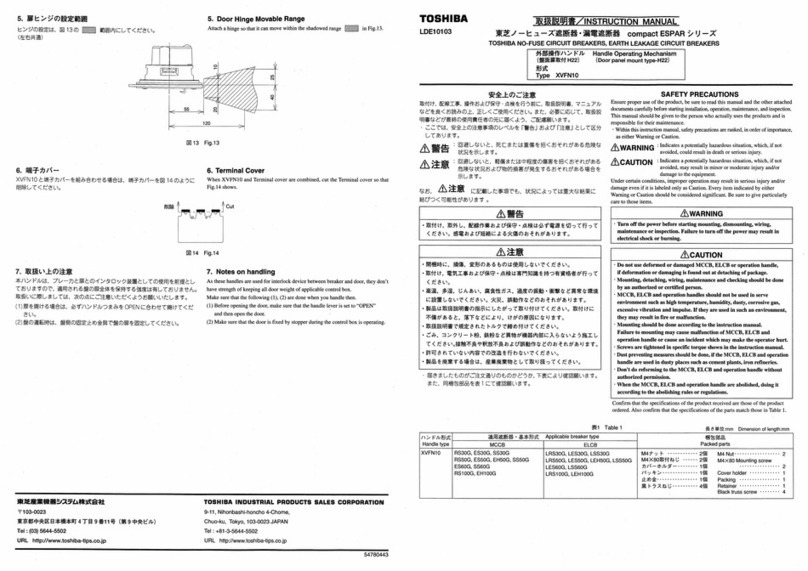

3. Product handling

13

3.1 Transportation

The VCBs are transported in the original packing only. Any kind of transport and combinations thereof are ap-

plicable. Transportation shall be provided in waterproof compartments. If air transport is used all products shall

be transported inside heated, pressurized compartments. The packed goods shall be handled in accordance with

the handling symbols. Loading procedures for VCB packaging shall be carried out only with use of fork lifts,

hoists or cranes. If possible the packaged VCB shall be placed on a pallet. During transportation the VCB must

not be subjected to sharp impacts or dropped.

3.2 Storage

If immediate installation is not possible, the VCB shall be stored in the original packing under the following

conditions:

• the ISM is switched off;

• dessicant must be placed in the packaging;

• storage must be dry, well ventilated and the room temperature should be between - 25°C and + 55°C.

Average humidity measured over 1 year period shall not exceed 75% at 50ºC. If several VCBs are stacked a ma-

ximum of two vertical layers are permitted

In case the storage term exceeds one year from the production date it is recommended to perform the procedu-

re of CM‘s electrolytic capacitor conditioning:

• apply power to the CM for 20 seconds;

• switch off the power supply and wait for 60 seconds;

• repeat the above actions 2 times;

• apply power to the CM continuously for 8 hours.

This procedure shall be performed annually during storage of the CM.

Figure 10

Lifting of ISM15_LD_1, ISM15_LD_3, ISM25_LD_1,

ISM25_LD_2, ISM15_LD_3

Figure 11

Lifting of ISM15_Shell_2

3.3 Unpacking and inspection

VCB unpacking and check

Before unpacking, check the carton for damage. Removal of the products from the original packaging must

be carried out with care and in accordance with lifting procedures. Every VCB component shall be checked for

completeness against the packing list included within the routine test certicate supplied with the CM and ISM.

These shall also be veried against the BOM list on the VCB packing list for VCB components and kits.

Unloading procedures for ISM shall be carried out only with use of hoists or cranes. Lifting gear must not be at-

tached to the support insulators; methods of lifting the ISM out of the carton shown below and must be strictly

followed.

14

VCB packaging and delivery set

The VCB are placed in cardboard boxes (Figure 14):

• handling symbols label for transport and storage of the delivery unit (Figure 12);

• labels for manufacturers and product information (Figure 15);

• label for logistics data (Figure 13).

The delivery sets of VCB on the level of main components are presented in Appendix 1

3 421

1. This side up

2. Fragile

3. Protect from rain

4.

Max. weight on the delivery unit

Figure 12

Label 1 Handling symbols

Figure 13

Label 2 Logistics data

Figure 14

Carton box

Figure 15

Label 3 for manufacturers‘ and product information

70

Mark: TEG-C-000111

Place of delivery:

Consignee:Address

Address

Address

Address

Address

Phone:

Contact person

P/O Number: Customer reference

Article: Article description

Serial Number:

TAVRIDA ELECTRIC GmbH, Im Leimen 14, 88069 Tettnang/Tannau, Germany, Phone: 0049-7542-946785-1

VCB has in its package:

1. Indoor Switching Module (ISM);

2. Control Module (CM);

3. Additional kits and/or components (if applicable);

4. Routine test certicate of VCB.

All items should be checked visually for:

• mechanical damage, scratches, discoloration, corrosion;

• damage to the seals (Figure 3, Figure 7).

Any transport damage must be reported immediately to the carrier in writing.

Damages shall be photographically documented.

Consignee:

15

CM packaging and delivery set

As part of the VCB the CM are delivered inside of the VCB package. If the CM are delivered as spare part of the

VCB they are packed in cardboard boxes.

1

2

4

3

6

Figure 16

CM packaging

5

1. Manufacturer

2. Product name

3. Type of device

4. Serial number

5. Product code

6. Handling symbols

Figure 17

CM packaging labels

The CM shall have undamaged warranty seals (its placement on the CM is shown in Figure 7). The CM designa-

tion and serial number shall comply with data in the VCB packing list and the CM routine test certicate (appea-

rance of the CM designation label and serial number label are shown in Figure 5 and Figure 6, their placement

on the CM - in Figure 7).

The ISM shall have undamaged warranty seals (appearance of seal is shown in Figure 3, its placement on the

ISM (there are two warranty seals on each side of the ISM metal frame) - in Figure 4). The ISM designation and

serial number shall comply with data in the VCB packing list and the ISM routine test certicate (appearance of

serial number plate plate is shown in Figure 2, its placement on ISM - in Figure 4).

16

Figure 18

CM delivery set

b) screwdriver

Unit_Screwdriver_1

c) brackets

Det_Holder_84

a) CM

Each CM is supplied with the following components:

b) screwdriver

Unit_Screwdriver_1

a) ISM

ISM packaging and delivery set

As part of the VCB the ISM are delivered inside of the VCB package. If the ISM are delivered as spare part of the

VCB they are packed in cardboard boxes like the VCB. Each LD ISM is supplied with the following components:

Figure 19

LD ISM delivery set

17

a) ISM b) position indicator

Unit_PosInd_1

c) screwdriver

Unit_Screwdriver_1

Gasket

Det_Gasket_38 Plastic insulator

Det_PlastIns_48

Rubber insulator

Det_RubberIns_19

Plastic insulator

Det_PlastIns_49

The kit includes for each pole of the ISM:

Figure 20

HD ISM delivery set

Figure 21

CBkit_Ins_3 delivery set

Each HD ISM is supplied with the following components:

CBkit_Ins_3 delivery set

24 kV variants of VCB25_LD1_16F and VCB25_LD3_16F include CBkit_Ins_3. As part of a VCB CBkit_Ins_3

is placed inside the VCB package. If the kit is delivered separately as a spare part of the VCB it is packed in a

plastic bag.

18

CBkit_Shell15_1 delivery sets

17.5kV variants of VCB15_Shell15_16F include CBkit_Shell15_1 for at bus bar connection to ISM terminals. As

part of a VCB CBkit_Shell15 is placed inside the VCB package. If the kit is delivered separately as a spare part of the

VCB it is packed in a plastic bag.

The kit CBkit_Shell15_1(310) for ISM15_Shell_2(210_H) and ISM15_Shell_2(275_H) includes:

6

1. Screw StandDet_Screw_DIN912(M16_100_Fe88-Zn)

2. Screw StandDet_Screw_DIN912(M16_110_Fe88-Zn)

3. Terminal CBdet_Terminal_1

4. Washer StandDet_Washer_DIN125-1A(17_Fe-Zn)

5. Washer CBcomp_Washer_1

6. Plastic insulation CBdet_PlastIns_2(310_50_H)

7. Plastic insulation CBdet_PlastIns_1(50)

7

2

1

3

4

5

The kit CBkit_Shell15_1(205) for ISM15_Shell_2(150_L) and ISM15_Shell_2(210_L) includes:

6

1. Screw StandDet_Screw_DIN912(M16_100_Fe88-Zn)

2. Screw StandDet_Screw_DIN912(M16_110_Fe88-Zn)

3. Terminal CBdet_Terminal_1

4. Washer StandDet_Washer_DIN125-1A(17_Fe-Zn)

5. Washer CBcomp_Washer_1

6. Plastic insulation CBdet_PlastIns_2(205_50_L)

7. Plastic insulation CBdet_PlastIns_1(50)

7

2

1

3

4

5

Figure 22

CBkit_Shell15_1(205) delivery set

Figure 23

CBkit_Shell15_1(310) delivery set

Two variants of bolts are included in CBkit_Shell15_1:

• StandDet_Screw_DIN912(M16_100_Fe88-Zn) - for case of single bus bar connection (10 mm thickness);

• StandDet_Screw_DIN912(M16_110_Fe88-Zn) - for case of double bus bar connection (20 mm thickness).

19

CBkit_LD15_2 and CBkit_LD15_3 delivery sets

VCB15_LD6_16RD includes the plastic parts kit CBkit_LD15_2 for LMT Retrot Draw-out type VCB or

CBkit_LD15_3 for AG16 Retrot Draw-out type VCB. As part of a VCB CBkit_LD15_2 and CBkit_LD15_3 are

placed inside the VCB package. If the kits are delivered separately as a spare part of the VCB it is packed in a

plastic bag.

Figure 24

CBkit_LD15_2 delivery set

Figure 25

CBkit_LD15_3 delivery set

1. Indicator CBdet_Indicator_1

2. Rubber ring Det_RubberRing_7(68)

3. Plastic insulation CBdet_PlastIns_5

4. Plastic button CBdet_PlastBut_1

5. Plastic washer CBdet_PlastWasher_1

6. Plastic washer CBdet_PlastWasher_2

7. Lever CBunit_Lever_1

8. Guide CBdet_Guide_1

1. Indicator CBdet_Indicator_1

2. Lever CBunit_Lever_1

3. Plastic insulation CBdet_PlastIns_4

4. Plastic insulation CBdet_PlastIns_3(1)

5. Plastic insulation CBdet_PlastIns_3(2)

6. Plastic insulation CBdet_PlastIns_3(3)

7. Rubber ring Det_RubberRing_12

8. Guide CBdet_Guide_1

7. Lever CBunit_Lever_1

2

1

3

45678

1

2

3

4 5

678

9

20

Figure 26

CBkit_Interlock_1 delivery set

1. Holder Det_Holder_22

2. Holder Det_Holder_20

3. Bolt StandDet_Bolt_DIN933(M6_20_Fe88-Zn)

4. Bolt StandDet_Bolt_DIN933(M8_40_Fe88-Zn)

5. Shaft CBdet_Shaft_1

6. Stopper CBdet_Stopper_1

1

2

3

5

6

ISM15_LD_3 and ISM25_LD_3 are already equipped with the CBkit_Interlock_1 pre-installed.

4

CBkit_Interlock_1 packaging and delivery set

CBkit_Interlock_1 can be used for VCB15_LD1_16F and VCB25_LD1_16F as an interface for various manual trip

/ indication / lockout accessories. The kit is packed in a plastic bag.

The kit includes:

VCB accessories unpacking and check

21

CBunit_ ManGen_1 and CBunit_ ManGen_2 packaging and delivery set

CBunit_ManGen is used to charge the CM_16_1 in cases where the main auxiliary power supply is not available.

It is packed in a cardboard box.

Figure 27

CBunit_ ManGen_1 and CBunit_ ManGen_2 packing

1

34

2

1. Manufacturer

2. Type of device

3. Product name

4. Product code

5. Handling symbols

6. Serial number

Figure 28

CBunit_ ManGen_1 package labeling

5

6

Figure 29

CBunit_ ManGen_1 and CBunit_ ManGen_2 delivery set

This manual suits for next models

2

Table of contents