PPI ScaneXPlus User manual

Multi-Channel Universal

Process Value Scanner with

Common High / Low Alarms

User Manual

Scane Plus

1. PANEL MOUNTING AND ELECTRICAL CONNECTIONS 1

2. FRONT PANEL LAYOUT 4

3. BASIC OPERATION 6

4. SET UP MODE : ACCESS AND OPERATION 9

5. CONFIGURATION PARAMETERS 11

6. ALARM CONFIGURATION PARAMETERS 18

7. ALARM SETTING PARAMETERS 19

APPENDIX-A : DC LINEAR SIGNAL INTERFACE 21

APPENDIX-B : BOTTOM / TOP CLIPPING 23

CONTENTS

User Manual

SCANEX PLUS

1

WARNING

MISHANDLING / NEGLIGENCE

CAN RESULT IN PERSONAL DEATH

OR SERIOUS INJURY.

PANEL MOUNTING AND ELECTRICAL CONNECTIONS

PANEL CUTOUT

PANEL MOUNTING

Follow the steps below for mounting the instrument on panel :

1. Prepare a cutout to the size shown in Figure 1.1.

2. Remove the Panel Mounting Clamp from the instrument Enclosure.

3. Insert the rear of the enclosure through the panel cutout from the front of the mounting panel.

4. Fix the mounting clamp pair such that it ensures secured mounting of the enclosure against the panel wall.

ELECTRICAL CONNECTIONS

Observe the followings while making electrical connections.

1. Run power supply cables separated from sensor (Thermocouple/RTD/mA/mV/V) cables. If the cables are run through

conduits, use separate conduits for power supply cable and sensor cables.

2. Use appropriate fuses and switches, wherever necessary, for driving the high voltage loads to protect the instrument from

any possible damage due to high voltage surges of extended duration or short-circuits on loads.

3. Switch-off the power supply while making / removing any connections.

The Figure 1.2(a) & Figure 1.2(b) show the terminals viewed from the rear side, with the scanner label upright, for 8 Channel &

16 Channel versions, respectively.

Panel Cutout

92 X 184 mm

-0, +0.5 mm

Figure 1.1

Figure 1.2(a) : 8 Channel

User Manual

SCANEX PLUS

Section 1

71 72 73 74 75 76 77 78

C NO C NO C NO C NO

RLY-1 RLY-2 RLY-3 RLY-4

Alarm Outputs

AI-1 AI-3 AI-5 AI-7

AI-4 AI-6 AI-8

12345678910 11 12 13 14 15 16

AI-2

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 67 68

+

-

RS485

OUT

69 70

L N

Supply

85~264VAC

33 34

+

-

RS485

IN

AI - X

RTD

TC

V/mV

mA

2

User Manual

SCANEX PLUS

AI - X

mV / V

T1 T2 T3 T4

T1 T2 T3 T4

INPUT CHANNELS

All input channels are identical from wiring connection viewpoint. For explanation purpose, the 4 terminals pertaining to each

channel have been marked as T1, T2 ,T3 & T4 in the following pages. The descriptions below apply to all the channels with no

deviations.

Thermocouple

Connect Thermocouple Positive (+) to terminal T2 and Negative (-) to terminal T3 as shown in

Figure 1.3. Use the correct type of Thermocouple extension lead wires or compensating cable for

the entire distance ensuring the correct polarity throughout. Avoid joints in the cable.

AI - X

TC

T1 T2 T3 T4

T1 T2 T3 T4

AI - X

RTD

T1 T2 T3 T4

T1 T2 T3 T4

DC Linear Voltage (mV / V)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mV / V

source. Connect common (-) to terminal T3 and the signal (+) to terminal T2, as shown in Figure

1.5.

RTD Pt100 (3-wire or 2-wire)

For 3-wire configuration, connect single leaded end of RTD bulb to terminal T2 and the double

leaded ends to terminals T3 and T4 (interchangeable) as shown in Figure 1.4. Use copper

conductor leads of very low resistance ensuring that all 3 leads are of the same gauge and length.

Avoid joints in the cable.

For 2-wire configuration, connect the 2 sensor wires to terminal T2 and T3 (interchangeable). Also

short terminals T3 & T4.

Figure 1.3

Figure 1.4

Figure 1.5

AI - X

mA

T1 T2 T3 T4

T1 T2 T3 T4

DC Linear Current (mA)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mA source.

Connect common (-) to terminal T3 and the signal (+) to terminal T2. Also short terminals T1 & T2.

Refer Figure 1.6.

Figure 1.6

71 72 73 74 75 76 77 78

C NO C NO C NO C NO

RLY-1 RLY-2 RLY-3 RLY-4

Alarm Outputs

AI-1 AI-3 AI-5 AI-7 AI-9 AI-11 AI-13 AI-15

AI-4 AI-6 AI-8 AI-10 AI-12 AI-14 AI-16

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

AI-2

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68

+

-

RS485

OUT

69 70

L N

Supply

85~264VAC

33 34

+

-

RS485

IN

AI - X

RTD

TC

V/mV

mA

Figure 1.2(b) : 16 Channel

3

User Manual

SCANEX PLUS

Figure 1.8

Line

Neutral

2 Pole

Isolating Switch

Fuse

Power Supply Terminals

69

70

L

N

As standard, the module is supplied with power connections suited for 85 to 264 VAC line supply. Use well-insulated copper

conductor wire of the size not smaller than 0.5mm² for power supply connections ensuring proper polarity as shown in Figure

1.8. The module is not provided with fuse and power switch. If necessary, mount them separately. Use a time lag fuse rated 1A

@ 240 VAC.

POWER SUPPLY

RELAY OUTPUTS

There are 4 Relay Outputs provided for common alarms. The relay connections are shown in Figure 1.7 below.

Figure 1.7

Potential-free Relay changeover contacts NO (Normally

Open) and C (Common) rated 10A/240VAC (resistive

load) are provided as Relay output.

AC

LOAD

Relay Output Terminals

NO

C

DC

4

Indicator Function

MANUAL

ALARMS

(1 to 16)

Glows ON when the Scanner is put in Manual Scan Mode.

Flashes if the corresponding channel is in Alarm condition.

Table 2.1

FRONT PANEL LAYOUT

The front panel comprises of digital readouts, LED indicators and membrane keys as shown in Figure 2.1 below.

READOUTS

The PV Readout is a 5 digit, 7-segment bright red LED display that displays the PV (Process Value). In Set-up Mode, the PV

Readout displays parameter values/options.

The Channel No. Readout is a 2 digit, 7-segment bright red LED display that shows the Channel No. for which the PV Readout

shows the PV. In Set-up Mode, the Channel No. Readout remains blank.

The Unit Readout is a 4 digit, 7-segment bright green LED display and usually displays the ‘Unit’ pertaining to the PV Readout.

In Set-up Mode, the Unit Readout displays parameter name (prompts).

INDICATORS

There is a single 3 mm red LED indicator that shows the Auto/Manual Scan Mode Status. A group of 16 red LEDs show the

Alarm Status for each of 16 channels. Refer table 2.1 below.

User Manual

SCANEX PLUS

Figure 2.1

Alarm Status

Indicators

ALARMS

Auto / Manual Key

Alarm Ack/View Key

ENTER Key

UP Key

DOWN Key

PAGE Key

Auto/Manual Scan

Mode Indicator

Channel No. Readout

Unit Readout

Scane Plus

MANUAL

PV Readout

Section 2

5

Press to enter / exit Set-up Mode

Press to decrease the parameter value. Pressing once

decreases the value by one count; holding the key pressed

speeds up the change.

PAGE

DOWN

Symbol Function

Press to store the set parameter value and to scroll to the next

parameter.

Press to Acknowledge any pending Alarm(s) and to View details

of the channels under Alarm.

Press to toggle between Auto and Manual Scan Mode. In Manual

Scan Mode, Use UP / DOWN keys to the desired channel.

Key

Press to increase the parameter value. Pressing once increases

the value by one count; holding the key pressed speeds up the

change.

UP

ENTER

Alarm

Ack/View

Auto /

Manual

User Manual

SCANEX PLUS

Table 2.2

KEYS

There are six tactile keys provided on the front panel for setting-up the parameter values and for other functions & commands.

The Table 2.2 below lists each key and the associated function.

6

POWER-UP

Upon switching on the power to the unit, all displays and indicators are lit on for approximately 3 seconds during which time the

Scanner runs a self initialization sequence.

MAIN DISPLAY MODE

After the self initialization sequence, the Scanner enters MAIN Display Mode. The PV Readout starts showing the measured

PV (Process value) with the corresponding channel number being shown on the Channel No. Readout. The MAIN Display

Mode is one that shall be used most often.

The Scanner may be configured to operate in either Auto or Manual Scan Mode. The Power-on default mode is ‘Auto Scan

Mode’. Use front panel key ‘A/M’ to toggle between the Auto and Manual Scan Mode.

Auto Scan Mode

In this mode, the Scanner shows the Process Value for each channel sequentially at a periodic interval, called ‘Scan Rate’.

The Scan Rate is user settable from 1 to 99 seconds. The channels are displayed in ascending (increasing) order with the last

channel automatically rolling over to the first channel. In Auto Scan Mode, the front indicator marked ‘MANUAL’ remains OFF.

Manual Scan Mode

In this mode, the Scanner keeps displaying the Process Value for the selected channel indefinitely. The user can switch to and

hold any desired channel by using UP/DOWN keys. In Manual Scan Mode, the front indicator marked ‘MANUAL’ is lit ON.

ALARM SYSTEM

There are up to 4 soft Alarms (AL-1 to AL-4) available for each channel.

Status Indication

There are 16 front panel Alarm Status LEDs, one for each channel. If any one or more set Alarm for a channel is active, the

corresponding front panel indicator flashes.

Relay Activation & Acknowledge

The 4 Relay Outputs (RLY-1 to RLY-4) are mapped with the 4 Alarms (AL-1 to AL-4) as explained below in Table 3.1.

User Manual

SCANEX PLUS

Section 3

BASIC OPERATION

Output Relay Activation

RLY-1 If Alarm-1 for any one or more channels is ON

If Alarm-2 for any one or more channels is ON

If Alarm-3 for any one or more channels is ON

If Alarm-4 for any one or more channels is ON

Associated Alarm

AL-1

RLY-2 AL-2

RLY-3 AL-3

RLY-4 AL-4

Table 3.1

The front panel Alarm Ack/View key is used to mute the Audio Alarm or to bring the system out of Trip Condition. The effect of

acknowledge function depends both on the Relay Logic (Direct / Reverse) and Latched / Un-Latched operation. Note that

Acknowledging the alarm only de-activates the relay output and does not remove the Alarm condition. Refer Table 3.2 for

effect of Acknowledge Key.

7

Relay Logic Effect of Acknowledge Key

Direct

(Alarm) Switches OFF the Alarm output

No effect

Switches OFF the Alarm output provided no Alarm condition is pending

Switches ON the Trip relay (brings out of tripping) provided no Alarm condition is

pending

Latched

No

Reverse

(Trip) No

Yes

Yes

Direct

(Alarm)

Reverse

(Trip)

Table 3.2

PV ERROR INDICATION

In case the PV falls below the Minimum Range or rises above the Maximum Range specified for the selected ‘Input Type’ or in

case the input sensor is open / broken; the PV Readout flashes the error messages listed in Table 3.3 below. The Figure 3.2

illustrates an open sensor condition for channel-14, for example.

Message PV Error Type

Over-range

(PV above Max. Range)

Under-range

(PV below Min. Range)

Open

(Sensor open / broken)

Table 3.3

Figure 3.2

ALARMS

Scane Plus

Manual

User Manual

SCANEX PLUS

Detail Alarm View

Pressing the Alarm Ack/View key also provides complete Alarm status information for the channels under alarm condition. The

information available is for view only. The Unit Readout indicates the ‘Channel Number’ under Alarm and the corresponding

‘Alarm Number(s)’ are indicated on the PV Readout. The UP/DOWN keys can be used to scroll through all the channels under

Alarm.

The example Figure 3.1 below illustrates the following case :

Channel-2 and Channel-12 are currently under Alarm condition. The active Alarms for Channel-2 are Alarm-1 and Alarm-4

while for Channel-12 it is only Alarm1.

MAIN Display

Mode

Figure 3.1

Press UP / DOWN key

to view next / previous channel

in alarm condition

MAIN Display

Mode

Press ALARM

ACK/VIEW key

Press PAGE or ENTER

key to return to

Main Display Mode

Alarm View

Mode

Alarm View

Mode

8

User Manual

SCANEX PLUS

Table 3.4

Parameter Description Settings

(Default Value)

OPERATOR PAGE & PARAMETERS

The Operator page contains the parameters that are used most frequently and the commands that are required for day-to-day

operation. This page is not locked for editing by Master Lock. The Figure 3.2 below illustrates how to access Operator Page

(Page 0).

RESET COMMAND

This feature clears the current Min/Max values of all Channels and

starts afresh monitoring the channels for new highest and lowest

values.

For resetting, set the reset command to ‘Yes’.

View Only

(Default : NA)

MINIMUM PV

The minimum PV attained by the selected channel.

View Only

(Default : NA)

MAXIMUM PV

The maximum PV attained by the selected channel.

No

Yes

(Default : No)

1 to Actual no. of

Channels to Scan

(Default : 1)

CHANNEL NUMBER

Select the channel No. whose Min/Max PV is to be viewed.

This Parameter reappears cyclically after viewing Max/Min Values

for each selected channel number.

1 Sec. to 99 Sec.

(Default : 3 Sec.)

SCAN RATE

Applicable for Auto Scan Mode only. This parameter value sets the

time interval for which each channel is displayed. In other words,

the rate at which the channels are sequentially updated for

indication.

The Operator Page parameters are listed in Table 3.4 below.

Figure 3.2

Operator Page First Parameter

on Operator

Page

Press PAGE

key to enter

Set-up mode

Press ENTER

key to open

Operator Page

MAIN Display

Mode

9

SET UP MODE : ACCESS AND OPERATION

There are many user settings that determine how the instrument will function or operate. These setting are called Parameters.

For the convenience and ease of operation, the various parameters have been grouped separately depending upon the

functions they define. Each such group is called a PAGE. Each PAGE is assigned a unique number, called PAGE NUMBER,

for its access. The parameters contained in a PAGE are presented in a fixed sequence to the user for setting. The user can

access a desired PAGE by entering its PAGE NUMBER and can select and set the desired parameter values.

PARAMETER PROMPTS

Each parameter has an identifying tag, called the Parameter Prompt. While setting parameter values in a PAGE, the

parameter prompt is always displayed on the Unit Readout and its current value is displayed on the PV Readout.

ACCESSING A PAGE

Each PAGE is accessible only from the MAIN Display Mode. That is, from the current PAGE, the user must return to the MAIN

Display Mode before the other PAGE can be accessed.

Figure 4.1 illustrates access to the desired PAGE from MAIN Display Mode.

User Manual

SCANEX PLUS

Section 4

ADJUSTING PARAMETER VALUES

For accessing and adjusting the parameter, one must first open the PAGE containing the parameter.

Figure 4.2 illustrates how to access the desired parameter(s) and adjust the corresponding value(s). The illustration shows

accessing the parameter ‘Alarm Type’ for Alarm-1 of Channel-1 and changing its value from ‘None’ to ‘Process High’. Press

PAGE key to revert to MAIN Mode.

Figure 4.1

Default Page Page Number

Press PAGE

key to enter

Set-up mode

Use UP/DOWN

key to set

Page Number

Press ENTER

key to open

the Page

MAIN Display

Mode

Figure 4.2

Previous set

Alarm Type

Default Alarm

Number

Press & Release

ENTER Key

to select Channel-1

Use UP/DOWN

keys to set the

desired Value

First Parameter

on PAGE-10

Press & Release

ENTER Key

to select Alarm-1

First Parameter

on PAGE-10

10

PARAMETER LOCKING

For protecting the parameter values from unauthorized / accidental alterations, the parameter adjustments can be Locked.

The Operator Page is not affected by locking. The Figure 4.3 illustrates the steps for Locking.

For Un-Locking, repeat the sequence of steps shown in Figure 4.3 twice.

SETTING DEFAULT VALUES

The instrument is shipped from the factory with all the parameters set to their default values. Refer Figure 4.4 below for

regaining the factory default values.

User Manual

SCANEX PLUS

Figure 4.4

Default Page

Press PAGE

key to enter

Set-up Mode

Default Code

Use UP/DOWN

keys to set the

‘Default’ Code

Press ENTER key.

Scanner resets and restarts

with default parameter values

MAIN Display

Mode

MAIN Display

Mode

Figure 4.3

Default Page Locking Code

Press PAGE

key to enter

Set-up mode

Use UP/DOWN

keys to set the

‘Locking’ Code

Press ENTER key

to Lock & Return to

MAIN Mode

MAIN Display

Mode

MAIN Display

Mode

Desired Alarm

Type

Next Parameter

Press ENTER key

to store the value &

move to next Parameter

11

RESOLUTION

Set the process value indication resolution (decimal point). All the

resolution based parameters (Alarm setpoint, hysteresis etc.)

then follow this resolution setting.

Refer Table 5.2

(Default : 0.1)

Refer Table 5.2

(Default : Type K)

INPUT TYPE

Refer Table 5.2. Select the Input Type in accordance with the type

of sensor connected to the selected channel.

1 to Actual no. of

channels to scan

(Default : 1)

SELECT CHANNEL FOR CONFIGURATION

Refer Figure 5.1 (a) and 5.1 (b).

COMMON INPUT CONFIGURATIONS

In most applications the Scanner is used to monitor the process

value at different points within a closed space (Chamber, Cold

Room, etc). Thus the type of sensors and also the measurement

resolution and units used are Identical (Common) for all channels.

This parameter facilitates eliminating repetitive settings for

multiple channels in such cases.

Yes : The parameter values for Input type, Resolution and PV

Units are applied to all the channels.

No : The parameter values for Input type, Resolution and PV

Units need to be set independently for each channel.

SENSOR-BREAK PV STATUS

This parameter setting allows user to define the alarm behavior

under Sensor open condition.

UP : Any Alarm set as ‘Process High’ gets activated.

DOWN : Any Alarm set as ‘Process Low’ gets activated.

ACTUAL NUMBERS OF CHANNELS TO SCAN

The numbers of channels actually connected/used for monitoring.

This allows skipping unused channels for scanning. Note that only

consecutive channels, starting from channel-1, must be used.

PAGE 12 : CONFIGURATION PARAMETERS

The configuration parameters are listed in Table 5.1 below and are generally required to be set only at the time of installation.

Set these parameters appropriately based on the types of Thermocouple / Sensor connected and other application needs.

Parameter Description Settings

(Default Value)

Table 5.1

Up Scale

Down Scale

(Default : Up Scale)

1 to Max.

Available

(Default : 8 or 16)

No

Yes

(Default : Yes)

User Manual

SCANEX PLUS

Section 5

12

Parameter Description Settings

(Default Value)

PV UNITS

Select Temperature units in °C or °F for Thermocouple or Pt100

sensor.

For DC Linear input (mA/mV/V), Select appropriate Units from the

list in Table 5.3. Note however that the selected Units are for the

purpose of indication on Lower Readout only.

-1999.9 to 3000.0

(Default : 100.0)

DC RANGE LOW

(Applicable only for DC Linear Inputs)

The process value corresponding to the Signal Low value from the

transmitter. For more Description Refer Appendix-A.

-1999.9 to 3000.0

(Default : 0.0)

Refer Table 5.3

(Default : ºC)

User Manual

SCANEX PLUS

(Default : Disable)

Enable

Disable

BOTTOM CLIPPING ENABLE

(Applicable only for DC Linear Inputs)

Refer Appendix-B.

-1999.9 to Top Clipping

Default: 0.0

BOTTOM CLIPPING

(Applicable only for DC Linear Inputs)

Refer Appendix-B.

SIGNAL HIGH

(Applicable only for DC Linear Inputs)

The transmitter output signal value corresponding to Range High

process value. For more Description Refer Appendix-A.

SIGNAL LOW

(Applicable only for DC Linear Inputs)

The transmitter output signal value corresponding to Range Low

process value. For more Description Refer Appendix-A.

Input Type Settings Default

0 to 20 mA 0.00 to Signal High 0.00

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

4.00 to Signal High

0.00 to Signal High

0.000 to Signal High

0.000 to Signal High

0.00 to Signal High

1.000 to Signal High

4.00

0.00

0.000

0.000

0.00

1.000

Input Type Settings Default

0 to 20 mA

4 to 20 mA

0 to 80 mV

0 to 1.25 V

0 to 5 V

0 to 10 V

1 to 5 V

Signal Low to 20.00 20.00

20.00

80.00

1.250

5.000

10.00

5.000

Signal Low to 20.00

Signal Low to 80.00

Signal Low to 1.250

Signal Low to 5.000

Signal Low to 10.00

Signal Low to 5.000

DC RANGE HIGH

(Applicable only for DC Linear Inputs)

The process value corresponding to the Signal High value from

the transmitter. For more Description Refer Appendix-A.

13

User Manual

SCANEX PLUS

Bottom Clipping to 3000.0

(Default : 100.0)

(Default : Disable)

Enable

Disable

TOP CLIPPING ENABLE

(Applicable only for DC Linear Inputs)

Refer Appendix-B.

TOP CLIPPING

(Applicable only for DC Linear Inputs)

Refer Appendix-B.

Parameter Description Settings

(Default Value)

Table 5.2

Resolution

Option What it means Range (Min. to Max. )

Type J Thermocouple

Type K Thermocouple

Type T Thermocouple

0.0 to +960.0°C / +32.0 to +1760.0°F

-200.0 to +1376.0°C / -328.0 to +2508.0°F

-200.0 to +387.0°C / -328.0 to +728.0°F

Type R Thermocouple

Type S Thermocouple

Type B Thermocouple

Type N Thermocouple

0.0 to +1771.0°C / +32.0 to +3219.0°F

1 °C/°F

or

0.1 °C/°F

3-wire, RTD Pt100

-199 to +600°C / -328 to +1112°F

-199.9 to +600.0°C / -328.0 to +1112.0°F

or

1 °C/°F

or

0.1 °C/°F

0.0 to +1314.0°C / +32.0 to +2397.0°F

0.0 to +1826.0°C / +32.0 to +3218.0°F

0.0 to +1768.0°C / +32.0 to +3214.0°F

Reserved for customer specific Thermocouple type not listed

above. The type shall be specified in accordance with the

ordered (optional on request) Thermocouple type.

-1999.9 to 3000.0

(Default : 0.0)

OFFSET

In many application, the measured PV at the input requires a

constant value to be added or subtracted to obtain a final process

value for removing sensor zero error or to compensate known

thermal gradient. This parameter is used to remove such errors.

Actual (Displayed) PV = Measured PV + Offset for PV.

14

User Manual

SCANEX PLUS

0 to 20mA DC current

4 to 20mA DC current

0 to 80mV DC voltage

Reserved

0 to 1.25V DC voltage

0 to 5.0V DC voltage

0 to 10.0V DC voltage

1 to 5.0V DC voltage

-19999 to 30000 units

1

0.1

0.01

0.001

units

Resolution

Option What it means Range (Min. to Max. )

°C

°F

Kelvin

Engineering Units

Percentage

Pascals

Mpascals

Kpascals

Bar

Milli bar

PSI

kg/sq cm

mm water gauge

Inches water gauge

mm mercury

Torr

Unit Readout Units

Table 5.3

15

User Manual

SCANEX PLUS

Liters per hour

Liters per minute

% Relative Humidity

% O2

% CO2

% Carbon Potential

volts

Amps

Milli amps

Milli Volts

Ohms

Parts per million

Revolutions per pinute

Milli seconds

Seconds

Unit Readout Units

Miles per hour

Milli grams

Grams

Kilo grams

Minutes

Hours

PH

%PH

16

Note : Press PAGE Key to Revert to Main Display Mode.

User Manual

SCANEX PLUS

Set Resolution common to all

Channels

Set Unit common to all

Channels

Select Channel for which

Offset value is to be set

Set Offset value for the

selected Channel

Figure 5.1(a)

Set Resolution common to all

Channels

Set Unit common to all

Channels

Set Signal Low

common to all Channels

Set Signal High

common to all Channels

Set DC Range Low

common to all channels

Set DC Range High

common to all channels

Choose

whether Bottom Clipping

to be enabled for

all Channel

Set the Bottom Clipping Value

common to all Channels

Select Channel for which

Offset value is to be set

Set Offset value for the

selected Channel

Select Input Type

All Channel Common = “YES”

For DC Input Type

For Thermocouple/RTD

Input Type

No

Choose

whether Top Clipping

to be enabled for

all Channel

Set the Top Clipping Value

common to all Channels

Yes

Yes

A

A

B

B

No B

17

Figure 5.1(b)

Set Resolution for the

Selected Channel

Set Unit for the Selected

Channel

Set Signal Low

for the Selected Channel

Set Signal High

for the Selected Channel

Set DC Range Low

for the Selected Channel

Set DC Range High

for the Selected Channel

Choose

whether Bottom Clipping

to be enabled for

Selected Channel

Set the Bottom Clipping Value

for the Selected Channel Select Channel for which

Offset value is to be set

Set Offset value for the

selected Channel

Select Input Type

All Channel Common = “NO”

For DC Input Type For Thermocouple/RTD

Input Type

Set the Top Clipping Value for

the Selected Channel

Yes

Yes

User Manual

SCANEX PLUS

Choose

whether Top Clipping

to be enabled for

Selected Channel

Select Channel

D

D

Set Resolution for the

Selected Channel

Set Unit for the Selected

Channel

Select Channel for which

Offset value is to be set

Set Offset value for the

selected Channel

D

No

A

A

B

B

No C

C

18

RELAY LATCH

No : The Relay switches ON or OFF with Alarm activation or de-

activation.

Yes : The Relay Output switches (ON for Normal Logic / Off for

Reverse logic) upon Alarm activation. However, Alarm de-

activation does not affect the Relay status. The Relay

status can only be regained by pressing acknowledge key

provided the Alarm has de-activated.

RELAY LOGIC

Normal : The Relay remains ON under Alarm condition; OFF

otherwise. Useful for activating Audio (like hooter) or

Visual (like lamp) gadget.

Reverse : The Relay remains OFF under Alarm condition; ON

otherwise. Useful for Tripping the system under

monitoring.

1 to No. of

Alarms per channel

(Default : NA)

SELECT OUTPUT RELAY NUMBER

The Scanner features 4 Relay Outputs (RLY-1 to RLY-4) that are

mapped to AL-1 to AL-4 of each channel. The relay outputs can be

used for either activating Audio/Visual gadgets (Normal Logic) or

for Tripping the system being monitored (Reverse Logic). Further

the output can be programmed to either switch ON/OFF with

Alarm switching (Relay Latch = No) or remain Latched until

acknowledged (Relay Latch = Yes).

This parameter allows to select 1 out of 4 Relays for ‘Logic’ and

‘Latch’ parameter setting.

1 to 4

(Default : 4)

NUMBER OF ALARMS PER CHANNEL

The instrument is provided with 4 independently settable soft

Alarms per channel. However, the actual number of Alarms

required per channel may vary from application to application.

This parameter allows selecting the exact number of Alarms

required per channel (Maximum 4).

Normal

Reverse

(Default : Normal)

The parameters presented on this page allow configuring the number of Alarms per channel, the Alarm output function (Audio /

Visual or Tripping) and Alarm latching.

PAGE 11 : ALARM CONFIGURATION PARAMETERS

Parameter Description Settings

(Default Value)

Table 6.1

No

Yes

(Default : No)

User Manual

SCANEX PLUS

Section 6

Table of contents

Popular Scanner manuals by other brands

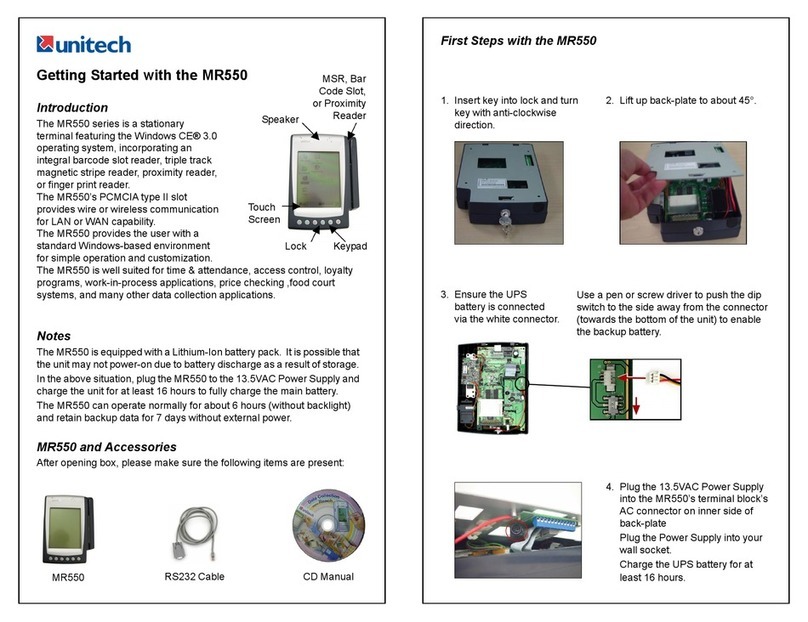

Unitech

Unitech MR550 Getting started guide

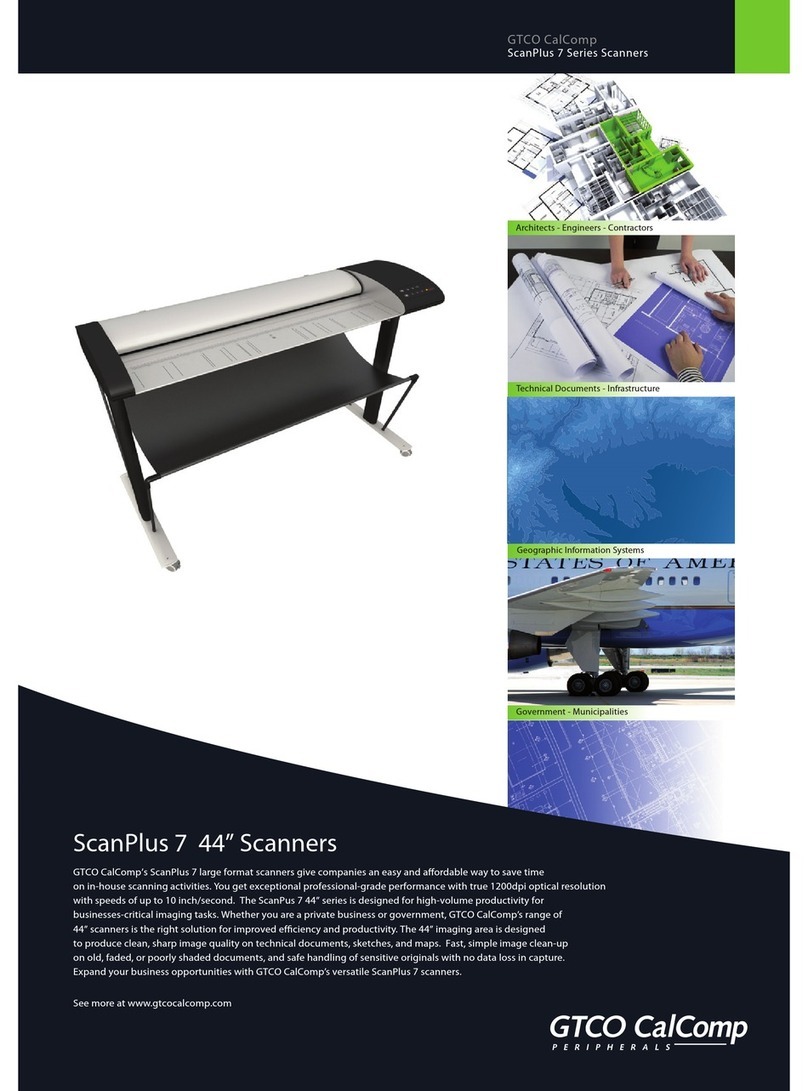

GTCO CalComp

GTCO CalComp ScanPlus 7 ATF1824C Brochure & specs

Smartoptics

Smartoptics Vinyl Series operating manual

JB Systems Light

JB Systems Light Winner II Operation manual

Hanatech

Hanatech DCN PRO & SCAN user manual

Shining 3D

Shining 3D EinScan HX user manual

rs scan

rs scan iQube mini E100 Installation and user guide

3D Histech

3D Histech Pannoramic SCAN II user guide

Silvercrest

Silvercrest SND 3600 A2 operating instructions

Silvercrest

Silvercrest SND 3600 A2 operating instructions

Image Access

Image Access WideTEK 24F Setup instructions

Fujitsu

Fujitsu fi-5530C - Document Scanner Getting started