PPM CD30 Guide

P/N SM1222

Rev 6

Print Date 2/14/2018

6

CD30/35 MANUAL

&

START GUIDE

FOR USE ON

PPM ELECTROMAGNETIC EQUIPMENT

VF Advance

VF Premier

Mini VF

VFX

Magnatron

P/N SM1222

Rev 6

Print Date 2/14/2018

PPM Contact information:

AMERICAS EUROPE|MIDDLE EAST|AFRICA

PPM TECHNOLOGIES PPM TECHNOLOGIES EMEA Ltd.

500 E. Illinois St. Axis 40 Oxford Road

Ne berg, OR 97132 | USA Stokenchurch

(503) 538-3141 Buckinghamshire HP14 3SX

(800) 523-8123 toll free in the US +44 1494 682800

(503) 538-8575 fax +44 1494 682801 fax

Webpage: www.ppmtech.com

Printed in the USA

Manual Revision Log

REV # DATE CHANGE DESCRIPTION SECTIONS MODIFIED

BY

0 1/29/09 Original creation of quick start supplement for using the

CD30 on PPM EM equipment (VF, Magnatron, etc.) ALL NJD

1 3/1/09 Updated setup values, added –En note 4, 4.2 NJD

2 4/17/09 Clarified numerous sections, added QS addendum ALL NJD

3 7/28/09 Updated wiring diagram, added sections 1.3, 2.4 & 7x 2, 1.3, 2.4, 7x NJD

4 12/13/10 Added PPM Contact information Intro DER

5 8/8/12 Change section on how to hide service menus (C127) 3.2 (C127) CWJ

6 12/08/17 Revised sections for accelerometer use 2.2; 4.2; 4.3; QSA TNT

PPM Technologies reserves the right to alter at any time, without notice and without liability or other

obligations on its part, materials, equipment specifications, and models. PPM Technologies also reserves

the right to discontinue the manufacture of models, parts, and components thereof.

P/N SM1222

Rev 6

Print Date 2/14/2018

Table of Contents

1. Summary

1.1. Controller Specifications

1.2. Application

1.3. Safety Instructions

2. Wiring

2.1. Power (incoming to controller/outing to coil)

2.2. Feedback Sensor

2.3. System control wiring

2.3.1. Enable Unit

2.3.2. External Set Point (C038~ESP)

2.3.3. Status Relay (C040~r.b.)

2.3.4. 2

nd

Set Point (C038~2.)

2.4. Recommended Method for Installing a Frequency Controller

3. CD30/35 Important Menu Settings

3.1. Basic Display Navigation

3.2. C210, C143, C117, C127 (Save & Hide Settings)

3.3. C038 (Function Settings)

3.4. C040 (Service Settings)

4. Step by Step Setup Procedure

4.1. Wire CD30/35

4.2. Set CD30/35 Menu Settings for PPM equipment

4.3. Set Sensor Position using C051

4.4. Run Automatic Frequency Search (AFS)

4.5. Set Operating Characteristics (A, P)

4.6. Save User Settings & Hide Menus

5. Main Fault Messages

6. Troubleshooting

7. Special Applications

7.1. Master/Slave Control

7.2. Single Controller for Multiple Magnet Coils

CD30/35 Quick Start Addendum

P/N SM1222

Rev 6

Print Date 2/14/2018

1 – SUMMARY

The CD30 with software version “L” or higher is compatible with both Wright LT

conveyors and PPM VF & Magnatron conveyors. The main changes from the DMT include:

•The CD30/35 runs about half as quiet (10dbA less) as the DMT

•All settings are made by using the touch-panel and display (similar to a VFD touch-

panel) that is incorporated into the front panel of the CD30

•The CD30/35 does not come standard with a door potentiometer

•The CD30/35 does come with a local disconnect switch mounted onto the door

•The CD30/35 works as a replacement for both the DMT & MagII controllers, and will be

phased in PPM’s new standard controller for all applications for the above legacy

controllers.

1.1 – CONTROLLER SPECIFICATIONS

•Supply voltage: 115/230 v, +/-15%, 50/60 Hz

•Supply Power Draw: 3 to 4A

•Set Point: display, potentiometer 10kOhm, 0-10vdc, 0(4)-20mA

•Enable Input: contact, 24vdc

•Enable 2

nd

Setpoint: contact, 24vdc

•Status relay: change over contacts (max 250v, 2A)

•Fuse: 10A, Type B

•Operating Temperature: 0°C to 45°C

1.2 – APPLICATIONS

The CD30/35 has been tested & validated to work on the following equipment:

•VF Advance & Mini at 1200cpm (20hz) to 1450cpm (24.2hz)

•VF Premier & VFX at 750cpm (12.5hz) to 1200cpm (20hz)

•Magnatron at 1500cpm (25hz) to 2100cpm (35hz)

NOTE: CD30/35 will virtually work at any speed from 5hz to 60hz on all equipment, with or

without a feedback sensor. The above equipment speed ranges are just guidelines for our

typical equipment.

There are two sizes of CD30/35 Controller, a 10A & a 15A controller. The controller required is

base on the rules below regarding the application & product density:

•Use the CD30 (10A controller) if:

oProduct density is 20lb/ft^3 or less

•Use the CD35 (15A controller) if:

oProduct density is greater than 20lb/ft^3, or

oThe conveyor is being fed by a hopper

P/N SM1222

Rev 6

Print Date 2/14/2018

1.3 – SAFETY CONSIDERATIONS

P/N SM1222

Rev 6

Print Date 2/14/2018

2 – WIRING

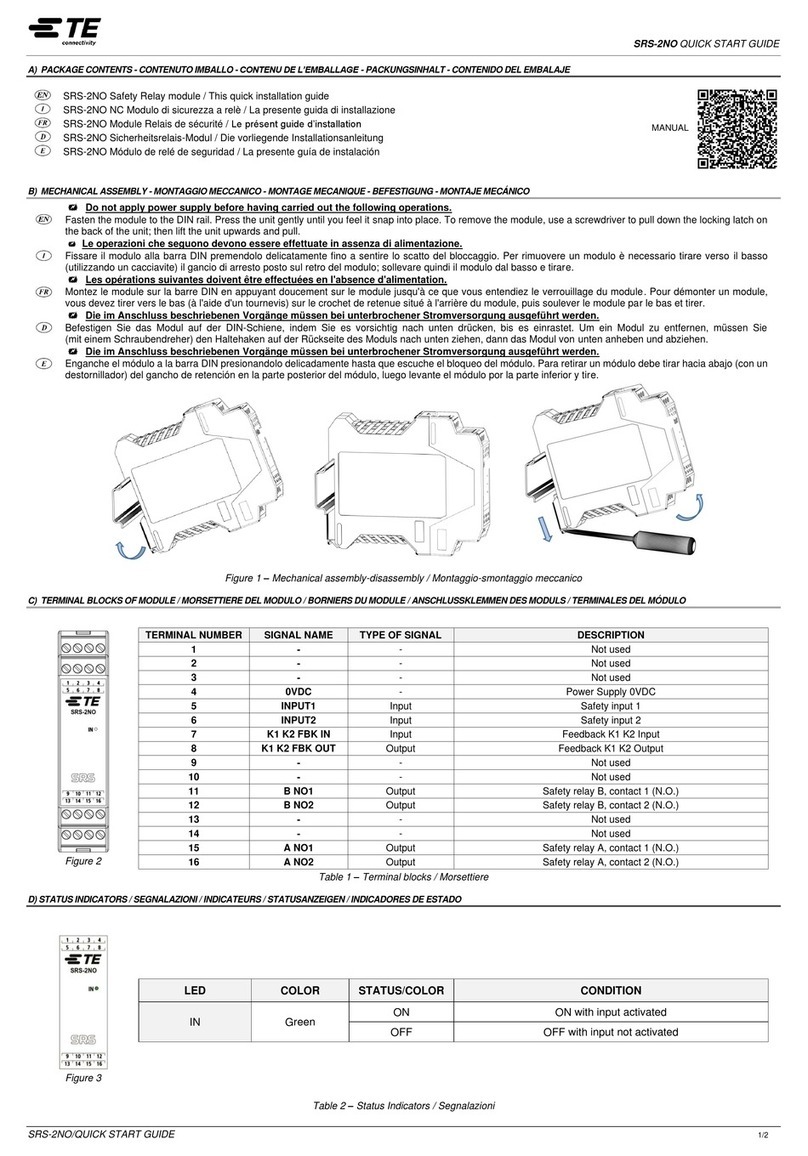

Use Diagram as reference for all connections in section 2

(Consult the CD30 manual for more detail)

P/N SM1222

Rev 6

Print Date 2/14/2018

2.1 – POWER (IN/OUT)

•Incoming Plant Power (230v, 1PH, 50/60hz)

oIf local disconnect is used (typically on the door of the CD30):

1

st

hot leg into terminal 35 (L)

2

nd

hot leg into terminal 36 (N)

Ground into terminal 38 (PE)

oIf not local disconnect is present (i.e. chassis mounted)

1

st

hot leg into terminal 31 (L)

2

nd

hot leg into terminal 32 (N)

Ground into terminal 38 (PE)

•Outgoing power to coil (removable connector on bottom of CD30)

o1

st

hot leg into terminal 41 (A1)

o2

nd

hot leg into terminal 42 (A2)

oGround into terminal 43 (PE)

P/N SM1222

Rev 6

Print Date 2/14/2018

2.2 – FEEDBACK SENSOR

The CD30 is setup to operate with the standard DMT & Mag II sensor (Gordon p/n 06A578) as

well as PPM’s own accelerometer. It gets wired into the terminal strip on the CD30/35, so the

existing DMT connector on the end of the sensor wire must be cut off if replacing an existing

DMT or Mag II with a CD30/35.

Wiring connections for DMT/Mag II sensor:

•Black (ground) – terminal 1

•Red (+24v) – terminal 3

•White/grey (sensor) – terminal 12

•Black (large wire) (shield) – terminal 16

2.3 – SYSTEM CONTROL WIRING

2.3.1 – ENABLE UNIT

The Unit is enabled by closing contacts or by applying a 24v signal

•Input terminals for contacts: 5 & 6

•Input terminals for 24vdc: 4(-) & 5(+24v)

2.3.2 – EXTERNAL SET POINT (C038~E.S.P.)

NOTE: to enable external set point, set ESP = 1 (on menu C038)

•Potentiometer (10kOhm) input terminals: 7(-), 8(E), 10(+10v)

•0 to +10vdc input terminals: 7(-), 8(+0 to 10v)

•0(4) to 20mA input terminals: 7(-), 9(+0 to 20mA)

IMPORTANT – A minimum level for the output voltage can be selected when an external set

point is used (to adapt the set point to give a true minimum vibration of the feeder), this is

achieved by setting the internal set point “A” on the display. This must be done before

switching on the external set point source, through the controller. (Should there be no

requirement for a zero correction then “A” must be set to “0” before the external set point

function is selected).

2.3.3 – STATUS RELAY (C040~r.b.)

Internal relay contact on terminals 14 & 15

Wire into either a 100AC or 24DC relay

•When r.b.=0 (relay closes if output power is present)

•When r.b.=1 (relay closes if incoming (main plant power) power to the controller is

present & there are no error messages displayed)

2.3.4 – 2

ND

SET POINT (C038~2.)

2

nd

set point input terminals: 2 & 3

P/N SM1222

Rev 6

Print Date 2/14/2018

2.4 – RECOMMENDED METHOD FOR INSTALLING A FREQUENCY

CONTROLLER

P/N SM1222

Rev 6

Print Date 2/14/2018

3 – CD30 IMPORTANT MENU SETTINGS

(Consult the Wright CD30 manual for more detail)

3.1 – BASIC DISPLAY NAVIGATION

P/N SM1222

Rev 6

Print Date 2/14/2018

3.2 – C210, C143, C127, C117

•Hide Function menus (C117) – When set to 1 all parameter menus are not accessible,

only the set point can be changed

•Hide Service menus (C127) – When set to 1 service menu C040 is accessible.

•Set (C127) to zero to hide the service menu.

NOTE: C127 has a typo, when EnS=0 the service

menu (C040) is hidden.

P/N SM1222

Rev 6

Print Date 2/14/2018

3.3 – C038 Function Settings 3.4 – C040 Service Settings

3.

P/N SM1222

Rev 6

Print Date 2/14/2018

4 – STEP BY STEP SETUP PROCEDURE

When initially setting up a CD30, use the following steps.

NOTE: During initial setup if the controller’s on/off signal isn’t wired yet or is but isn’t being

sent, you must set –En = 1 (under menu C040) or place a jumper between contacts 5 & 6.

This will allow you to operate and run the controller without a run signal coming from a main

panel.

4.1 – WIRE CD30/35

Wire all connections to CD30/35, including:

•Incoming plant power

•Outgoing power to the conveyor coil

•The feedback sensor

•Along with any additional control wiring required for the application

NOTE: Reference section 3 for wiring specifics

4.2 – INITIAL CD30/35 MENU SETTINGS FOR PPM EQUIPMENT

Note: settings that say “n/a” don’t matter for initial setup

Menu C038

Menu C040

P

arameter

Setting

Parameter

Setting

I (current) 100 SIF (interface) 0

A (amplitude) n/a I (current) 100

P (power) n/a

L (low freq. limit) VFA & Mini = 15

VFP & VFX = 10

Mag II = 25

F (frequency) n/a

ESP (External set point) 0

2. (2nd set point) n/a

H (high freq. limit) VFA & Mini = 30

VFP & VFX = 20

Mag II = 35

ACC (loop control) 1

PA (proportional amplitude gain) 100

IA (integral amplitude gain) 100 F (actual freq.) n/a

AFC (auto freq. control) 1 AS (AFC threshold) 25

AFS (start freq. search) Squiggle up (soft start) 0

Squiggle down (soft stop) 0.1

-En (invert enable) 0

Efu (current regulation) 0

PI (prop current regulation) 20

II (Integral current regulation) 40

rb (status relay) 0

SPE 0

APS 1

P/N SM1222

Rev 6

Print Date 2/14/2018

4.3 – SET SENSOR POSITION

If using the older Gordon sensor (black in color), use menu C051 and adjust the sensor gap

until the reading C051=25

If using the newer PPM Accelerometer, no adjustment is needed and C051 can be ignored.

4.4 – RUN AUTOMATIC FREQUENCY SEARCH (AFS)

Before normal operation, the controller must perform an AFS to accurately find the resonant

frequency of the conveyor spring system. To do this, follow the following steps:

1. Turn the controller on so the conveyor is receiving a power signal

2. Adjust the stroke & power settings to:

a. Menu C038, A=0 (sets amplitude to 0)

b. Menu C038, P=10 (sets power to 10)

3. Double check the controller is setup to run in the natural frequency control mode by:

a. Menu C038, ACC=1 (closed-loop mode)

b. Menu C038, AFC=1 (automatic frequency control)

4. Menu C038, AFS, press up arrow (start frequency search)

The readout will show the frequency as the controller searches, when all three lines to the left

of the frequency stop blinking the controller has found the resonant frequency and will revert to

the normal run root menu.

NOTE: If the controller has a difficult time finding the resonant frequency, the following items

may help:

•Try increasing the set point (A) a small amount (by 5 or 10)

•If you know about what the resonant frequency is, try narrowing the frequency range

AFS can search (menu C040, parameters L & H)

•Reduce power limit (P)

Spacing between sensor and target 7/16” to 5/8"

P/N SM1222

Rev 6

Print Date 2/14/2018

4.5 – SET OPERATING CHARACTERISTICS (A & P)

For the feedback loop to operate correctly it must be set up for the vibratory feeder that it is

used with because every feeder has different response characteristics. Therefore, it is

important to adjust the output signal so that amplitude (A) setting of 100% corresponds to the

required maximum amplitude of the feeder. To do this, use the following steps:

1. In menu C038 set the (P) value to 10%, and the (A) value to 100%

2. Enable the controller so that the feeder is vibrating

3. Gradually increase the value of (P) until the required maximum amplitude of the feeder

is reached

NOTE: A “V” sticker on the side of the feeder tray can be used to give a visual guide if

another measuring system is not available.

4.6 – SAVE USER SETTINGS & HIDE MENUS

After setting up the controller, verify that is work to the customer’s satisfaction and that all

system controllers are working properly perform the following items:

1. Save User Settings (C143) – Go to C143 and push the up arrow to save all settings

under the user settings memory

2. Hide Function Menu (C117) – Go to C117 and set HdC=1 to hide the C038 function

menu

3. Hide Service Menu (C127) – Go to C127 and set EnS=0 to hide the C040 service menu

NOTE: With the above menus hidden, all the operator can do is adjust the amplitude (A) from

the root menu. If the customer more operator adjustment, the above menus can be left

unhidden. When they are hidden though there will be less chance of an untrained operator

causing a problem with the controller.

P/N SM1222

Rev 6

Print Date 2/14/2018

5 – FAULT MESSAGES

These messages show conditions that cause the controller to switch off!

To reset a fault either press the green button or go to C009, when at C009 press up arrow to

reset fault, or down arrow to reset fault and change set point (A=0)

P/N SM1222

Rev 6

Print Date 2/14/2018

6 – TROUBLESHOOTING

P/N SM1222

Rev 6

Print Date 2/14/2018

6 – TROUBLESHOOTING (continued)

P/N SM1222

Rev 6

Print Date 2/14/2018

6 – TROUBLESHOOTING (continued)

P/N SM1222

Rev 6

Print Date 2/14/2018

7 – SPECIAL APPLICATIONS

7.1 – MASTER/SLAVE CONTROL

For very large vibratory feeders with multiple magnet coils

7.2 – SINGLE CONTROLLER FOR MULTIPLE MAGNET COILS

This manual suits for next models

1

Table of contents