Bender cme420 User manual

Manual

EN

CME420

Multi-functional current relay, AC,

overcurrent/undercurrent/

window discriminator function

CME420_D00034_03_M_XXEN/08.2020

Table of Contents

3

CME420_D00034_03_M_XXEN/08.2020

1. Important information .................................................................................... 5

1.1 How to use this manual ................................................................................. 5

1.2 Technical support: service and support ................................................... 6

1.2.1 First level support ............................................................................................. 6

1.2.2 Repair service ..................................................................................................... 6

1.2.3 Field service ........................................................................................................ 7

1.3 Training courses ................................................................................................ 8

1.4 Delivery conditions .......................................................................................... 8

1.5 Inspection, transport and storage .............................................................. 8

1.6 Warranty and liability ...................................................................................... 9

1.7 Disposal ............................................................................................................ 10

2. Safety instructions ......................................................................................... 11

2.1 General safety instructions ........................................................................ 11

2.2 Work activities on electrical installations ............................................. 11

2.3 Intended use ................................................................................................... 12

2.4 Information about factory setting .......................................................... 12

3. Function ........................................................................................................... 13

3.1 Device features .............................................................................................. 13

3.2 Function ............................................................................................................ 13

3.2.1 Automatic self test ........................................................................................ 14

3.2.2 Manual self test .............................................................................................. 14

3.2.3 Malfunction ..................................................................................................... 14

3.2.4 Specify the number of reload cycles ...................................................... 15

3.2.5 Erasable history memory ............................................................................ 15

3.2.6 Assigning alarms to the alarm relays K/1K2 ........................................ 15

3.2.7 Residual current monitoring in window discriminator mode ...... 15

3.2.8 Time delays t, ton and toff ......................................................................... 16

Table of Contents

4CME420_D00034_03_M_XXEN/08.2020

3.2.9 Password protection (on, OFF) ................................................................. 16

3.2.10 Factory setting FAC ...................................................................................... 16

3.2.11 Display accuracy ............................................................................................ 16

4. Installation and connection ......................................................................... 17

5. Operation and setting .................................................................................. 19

5.1 Used display elements ................................................................................. 19

5.2 Function of the operating elements ...................................................... 20

5.3 Menu structure ............................................................................................... 21

5.4 Display in standard mode ......................................................................... 22

5.5 Display in menu mode ................................................................................ 23

5.5.1 Parameter query and setting: overview ................................................ 23

5.5.2 Switching over from overcurrent to undercurrent operation

or to window operation .............................................................................. 25

5.5.3 Response value setting for overcurrent: ............................................... 26

5.5.4 Setting the fault memory and operating principle of the alarm

relays .................................................................................................................. 27

5.5.5 Assigning alarm categories to the alarm relays ................................. 28

5.5.6 Setting the time delays ............................................................................... 30

5.5.7 Changing from overcurrent operation to window operation ...... 31

5.5.8 Setting the transformation ratio for external current

transformer ...................................................................................................... 32

5.5.9 Re-establishing the factory settings ....................................................... 34

5.5.10 History memory query ................................................................................. 34

5.6 Commissioning .............................................................................................. 35

5.7 Factory setting ............................................................................................... 35

5.8 Timing diagram: Current monitoring ..................................................... 36

6. Technical data ................................................................................................ 37

6.1 Data in tabular form ..................................................................................... 37

6.2 Standards, approvals and certifications ................................................ 40

6.3 Ordering information ................................................................................... 41

5

CME420_D00034_03_M_XXEN/08.2020

1. Important information

1.1 How to use this manual

Always keep this manual within easy reach for future reference.

To make it easier for you to understand and revisit certain sections in this man-

ual, we have used symbols to identify important instructions and information.

The meaning of these symbols is explained below:

This manual is intended for qualified personnel working in

electrical engineering and electronics!

This signal word indicates that there is a high risk of danger

that will result in electrocution or serious injury if not

avoided.

This signal word indicates a medium risk of danger that

can lead to death or serious injury if not avoided.

This signal word indicates a low level risk that can result in

minor or moderate injury or damage to property if not

avoided.

This symbol denotes information intended to assist the user

in making optimum use of the product.

DANGER

WARNING

CAUTION

Important information

6CME420_D00034_03_M_XXEN/08.2020

1.2 Technical support: service and support

For commissioning and troubleshooting Bender offers you:

1.2.1 First level support

Technical support by phone or e-mail for all Bender products

Questions concerning specific customer applications

Commissioning

Troubleshooting

Telephone: +49 6401 807-760*

Fax: +49 6401 807-259

In Germany only: 0700BenderHelp (Tel. and Fax)

E-mail: [email protected]

1.2.2 Repair service

Repair, calibration, update and replacement service for Bender products

Repairing, calibrating, testing and analysing Bender products

Hardware and software update for Bender devices

Delivery of replacement devices in the event of faulty or incorrectly

delivered Bender devices

Extended guarantee for Bender devices, which includes an in-house

repair service or replacement devices at no extra cost

Telephone: +49 6401 807-780** (technical issues)

+49 6401 807-784**, -785** (sales)

Fax: +49 6401 807-789

E-mail: [email protected]

Please send the devices for repair to the following address:

Bender GmbH, Repair-Service,

Londorfer Str. 65,

35305 Grünberg

Important information

7

CME420_D00034_03_M_XXEN/08.2020

1.2.3 Field service

On-site service for all Bender products

Commissioning, configuring, maintenance, troubleshooting of Bender

products

Analysis of the electrical installation in the building (power quality test,

EMC test, thermography)

Training courses for customers

Telephone: +49 6401 807-752**, -762 **(technical issues)

+49 6401 807-753** (sales)

Fax: +49 6401 807-759

E-mail: fieldservice@bender.de

Internet: www.bender.de

*Available from 7.00 a.m. to 8.00 p.m. 365 days a year (CET/UTC+1)

**Mo-Thu 7.00 a.m. - 8.00 p.m., Fr 7.00 a.m. - 13.00 p.m

Important information

8CME420_D00034_03_M_XXEN/08.2020

1.3 Training courses

Bender is happy to provide training regarding the use of test equipment.

The dates of training courses and workshops can be found on the Internet at

www.bender.de -> Know-how -> Seminars.

1.4 Delivery conditions

Bender sale and delivery conditions apply.

For software products the "Softwareklausel zur Überlassung von Standard-

Software als Teil von Lieferungen, Ergänzung und Änderung der Allgemeinen

Lieferbedingungen für Erzeugnisse und Leistungen der Elektroindustrie"

(software clause in respect of the licensing of standard software as part of de-

liveries, modifications and changes to general delivery conditions for prod-

ucts and services in the electrical industry) set out by the ZVEI (Zentralverband

Elektrotechnik- und Elektronikindustrie e. V.) (German Electrical and Electron-

ic Manufacturer's Association) also applies.

Sale and delivery conditions can be obtained from Bender in printed or elec-

tronic format.

1.5 Inspection, transport and storage

Inspect the dispatch and equipment packaging for damage, and compare the

contents of the package with the delivery documents. In the event of damage

in transit, please contact Bender immediately.

The devices must only be stored in areas where they are protected from dust,

damp, and spray and dripping water, and in which the specified storage tem-

peratures can be ensured.

Important information

9

CME420_D00034_03_M_XXEN/08.2020

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to

property are excluded if they can be attributed to one or more of the follow-

ing causes:

Improper use of the device.

Incorrect mounting, commissioning, operation and maintenance of the

device.

Failure to observe the instructions in this operating manual regarding

transport, commissioning, operation and maintenance of the device.

Unauthorised changes to the device made by parties other than the

manufacturer.

Non-observance of technical data.

Repairs carried out incorrectly and the use of replacement parts or

accessories not approved by the manufacturer.

Catastrophes caused by external influences and force majeure.

Mounting and installation with device combinations not recom-

mended by the manufacturer.

This operating manual, especially the safety instructions,

must be observed by all personnel working on the device. Furthermore,

the rules and regulations that apply for accident prevention at the place of use

must be observed.

Important information

10 CME420_D00034_03_M_XXEN/08.2020

1.7 Disposal

Abide by the national regulations and laws governing the disposal of this de-

vice. Ask your supplier if you are not sure how to dispose of the old equip-

ment.

The directive on waste electrical and electronic equipment (WEEE directive)

and the directive on the restriction of certain hazardous substances in electri-

cal and electronic equipment (RoHS directive) apply in the European Commu-

nity. In Germany, these policies are implemented through the "Electrical and

Electronic Equipment Act" (ElektroG). According to this, the following applies:

Electrical and electronic equipment are not part of household waste.

Batteries and accumulators are not part of household waste and must

be disposed of in accordance with the regulations.

Old electrical and electronic equipment from users other than private

households which was introduced to the market after 13 August 2005

must be taken back by the manufacturer and disposed of properly.

For more information on the disposal of Bender devices, refer to our

homepage at www.bender.de -> Service & support.

11

CME420_D00034_03_M_XXEN/08.2020

2. Safety instructions

2.1 General safety instructions

Part of the device documentation in addition to this manual is the enclosed

"Safety instructions for Bender products".

2.2 Work activities on electrical installations

If the device is used outside the Federal Republic of Germany, the applicable

local standards and regulations must be complied with. The European stand-

ard EN 50110 can be used as a guide.

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

DANGER

Safety instructions

12 CME420_D00034_03_M_XXEN/08.2020

2.3 Intended use

The current monitor is designed to monitor the threshold values of AC cur-

rents for overcurrent and undercurrent conditions. In case of direct measure-

ment, currents up to 16 A (screw-type terminals) resp. 12 A (push-wire

terminals) can be continuously monitored. For indirect measurement by me-

ans of a current transformer, a transformation ratio factor up to 2000 can be

set. The device allows pure overcurrent and pure undercurrent operation, as

well as window operation between two adjustable response values. The de-

vice is factory set to overcurrent operation.

In order to meet the requirements of the applicable standards, customised pa-

rameter settings must be made on the equipment in order to adapt it to local

equipment and operating conditions. Please heed the limits of the range of

application indicated in the technical data.

Any use other than that described in this manual is regarded as improper.

2.4 Information about factory setting

The page 35 provides a summary of all factory settings.

If you want to reset the current monitor to factory settings refer to page 34.

13

CME420_D00034_03_M_XXEN/08.2020

3. Function

3.1 Device features

Undercurrent or overcurrent monitoring in AC systems, < I or > I and

current monitoring with window discriminator function

Indirect current monitoring by means of a current transformer,

suitable for transformation ratio factor 1…2000

Adjustable switching hysteresis

r.m.s. value measurement AC

Continuous self monitoring

Starting delay, response delay and delay on release

Measured value display via multi-functional LC display

Alarm indication via LEDs (AL1, AL2) and changeover contacts (K1, K2)

N/C operation or N/O operation selectable

Fault memory behaviour selectable

Password protection against unauthorized parameter changing

Sealable transparent cover

Two-module enclosure (36 mm)

With push-wire terminals: two terminals per connection

3.2 Function

Once the supply voltage is applied, the starting delay "t" is activated. Measu-

red values changing during this time do not influence the switching state of

the alarm relays.

The devices provide two separately adjustable measuring channels (overcur-

rent/undercurrent). When the measured value exceeds (ALARM 1) resp. drops

below (ALARM 2) the adjusted threshold value, the time of the response de-

lays "ton 1/2" begins. After the expiry of the response delay, the alarm relays

switch and the alarm LEDs light. If the measured value falls below or exceeds

the adjusted delay on release (response value plus hysteresis) after the alarm

Function

14 CME420_D00034_03_M_XXEN/08.2020

relays have switched, the delay on release starts "toff". After the expiry of "toff“,

the alarm relays switch back to their initial position. With activated fault me-

mory, the alarm relays do not change their actual state until the reset button

R is pressed.

3.2.1 Automatic self test

The device automatically carries out a self test after connecting to the system

to be monitored and later every 24 hours. During the self test internal functio-

nal faults or connection faults will be determined and will appear in form of an

error code on the display. The alarm relays are not checked during this test.

3.2.2 Manual self test

After pressing the internal test button for > 1.5 s, aself test is performed by the

device. During this test, internal malfunctions will be determined and appear

in form of an error code on the display. The alarm relays are not checked du-

ring this test.

While the test button T is pressed and held down, all device-related display

elements appear on the display.

3.2.3 Malfunction

In the event of an internal malfunction, all three LEDs flash. An error code ap-

pears on the display (E.02…E.32).

If the fault continues to exist, please contact the Bender Service.

Error code Meaning Action

E.02 Fault occured

during manual

self test

Check device connection. After eliminating

the fault, the error code will be automati-

cally deleted.

E.03…E.32 Carry out a reset. Reset the device to fac-

tory setting. After eliminating the fault, the

error code will be automatically deleted.

Function

15

CME420_D00034_03_M_XXEN/08.2020

3.2.4 Specify the number of reload cycles

If faults occur only temporarily, but recurrently, in the system being monito-

red, with deactivated fault memory M, the alarm relays would switch synchro-

nously to the error status.

RL in the out menu can be used to limit the number of these changeover pro-

cesses. As soon as the specified number of processes is exceeded, the fault

memory will come on and an activated alarm remains stored.

3.2.5 Erasable history memory

The first alarm value that occurs will be entered in this memory. The memory

can be cleared via the menu HiS.

3.2.6 Assigning alarms to the alarm relays K1/K2

Different alarm categories can be assigned to the alarm relays K1/K2 via the

menu "out".

3.2.7 Residual current monitoring in window discriminator

mode

Change the measuring principle by selecting the window mode (SEt / In). In

the window discriminator mode, the threshold values I1 and I2 represent the

upper and the lower value. If the measured value is not within this area, an

alarm is initiated by the device (see page 31).

Function

16 CME420_D00034_03_M_XXEN/08.2020

3.2.8 Time delays t, ton and toff

The times t, ton and toff described below delay the output of alarms via LEDs

and relays.

Starting delay t

After connection to the supply voltage US, the alarm indication is delayed by

the preset time t(0…300 s).

Response delay ton1/2

If the current value exceeds or falls below the threshold value, the current mo-

nitor does not initiate an alarm before the response time tan has elapsed.

A set response delay ton1/2 (0…300 s) adds up to the device-related operating

time tae and delays alarm signalling (total delay time tan = tae + ton).

If the fault does not continue to exist before the time of the response delay has

elapsed, an alarm will not be indicated.

Release delay toff

When no alarm exists after deactivating the fault memory, the alarm LEDs will

go out and the alarm relays switch back to their initial position. After acti-

vating the release delay (0…300 s), the alarm state is continuously maintained

for the selected period.

3.2.9 Password protection (on, OFF)

With activated password protection (on), settings can only be carried out

when the correct password (0…999) has been entered.

3.2.10 Factory setting FAC

After activating the factory setting, all settings previously changed are reset to

delivery status.

3.2.11 Display accuracy

The display accuracy of the measured current values depends on the set res-

ponse values. When an alarm response value I2 of 10 A has been selected, cur-

rents smaller than 350 mA are displayed as < 0.3 A.

17

CME420_D00034_03_M_XXEN/08.2020

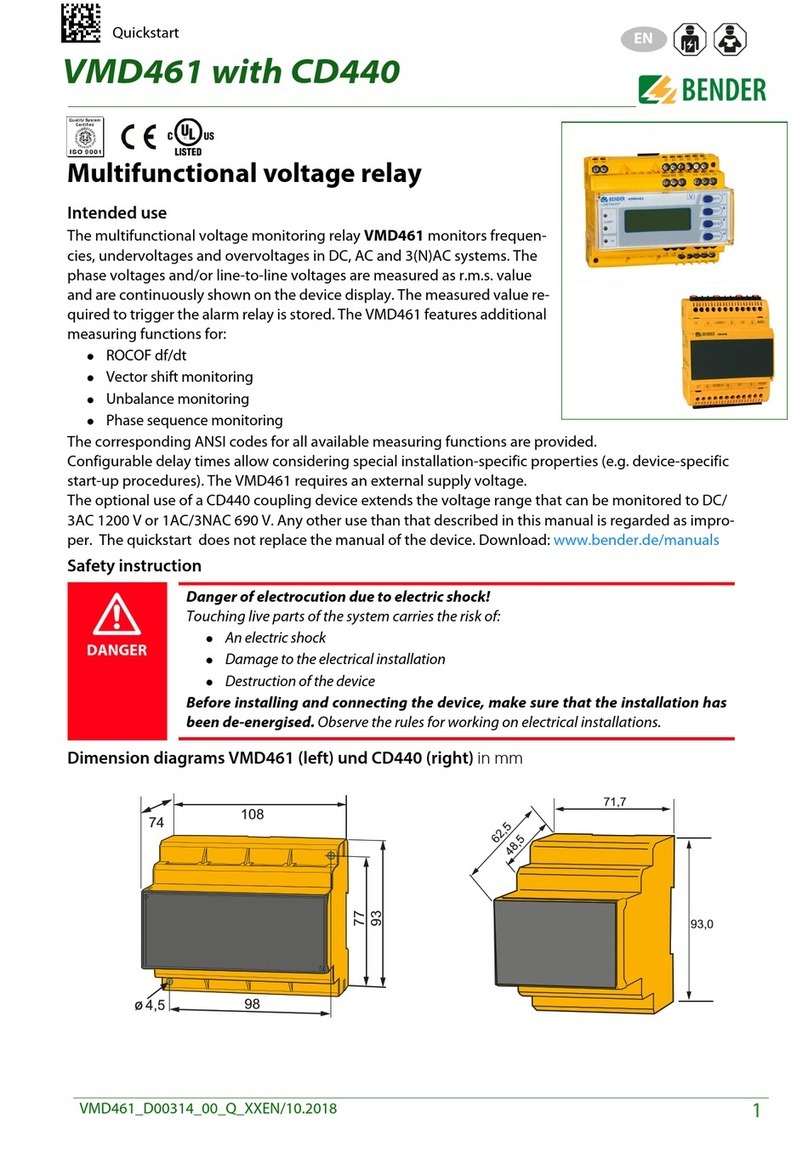

4. Installation and connection

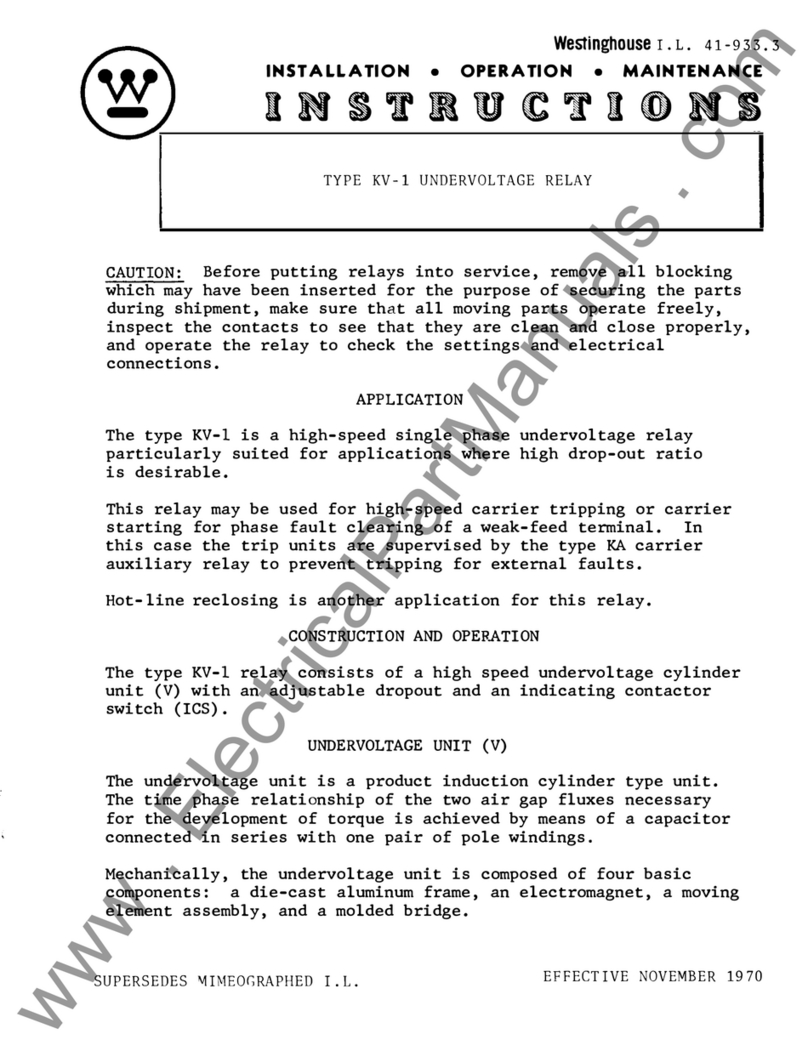

Dimension diagram and drawing for screw fixing

Only qualified personnel are permitted to carry out the

work necessary to install, commission and run a device or

system.

Risk of electrocution due to electric shock!

Touching live parts of the system carries the risk of:

An electric shock

Damage to the electrical installation

Destruction of the device

Before installing and connecting the device, make sure

that the installation has been de-energised. Observe the

rules for working on electrical installations.

DANGER

90 mm

45

67,5

36 mm

31,1

47,5

70,5

100 mm

116 mm

Zubehör/

Accessory

Installation and connection

18 CME420_D00034_03_M_XXEN/08.2020

The front plate cover is easy to open at the lower part identified by an arrow.

1. DIN rail mounting:

Snap the rear mounting clip of the device into place in such a way that

a safe and tight fit is ensured.

Screw fixing:

Use a tool to move the rear mounting clips (a second mounting clip

required, see ordering information) to a position that it projects over

the enclosure. Then fix the device using two M4 screws.

2. Wiring

Connect the device according the wiring diagram.

Terminal Connections

A1, A2 Connection to supply voltage Us

k, l Connection to the conductor to be monitored: directly

or by means of a current transformer

11, 12, 14 Alarm relay K1

21, 22, 24 Alarm relay K2

U

s

A1

~/

~/+

6A 6A

IT-System

A2

kl

11 1412

21 2422

A2A1

lk

L1

N

lk

L1

N

19

CME420_D00034_03_M_XXEN/08.2020

5. Operation and setting

5.1 Used display elements

A detailed description of the meaning of the display elements is given in the

table below.

Used display elements Element Function

RL Reload function with memory = off

(L = I.)

nTransformation ratio factor for

external current transformer

<I

>I

Undercurrent

Overcurrent

r1, 1

r2, 2

Alarm relay K1,

Alarm relay K2

I Hys,

%

Response value hysteresis in %

ton1,

ton2,

t,

toff

Response delay ton1 (K1),

Response delay ton2 (K2)

Starting delay t,

Delay on release toff for K1, K2

MFault memory active

Operating mode of the relays K1, K2

Password protection active

Operation and setting

20 CME420_D00034_03_M_XXEN/08.2020

5.2 Function of the operating elements

Device front Element Function

ON Power On LED, green

AL1,

AL2

LED Alarm 1 lights (yellow):

Response value 1 reached

LED Alarm 2 lights (yellow): Res-

ponse value 2 reached

1,6 A,

M

I = 1.6 A flow via

the terminals k and l,

Fault memory active

T, Test button (> 1.5 s):

Indication of the display elements,

starting a self test;

Up key (< 1.5 s):

Menu items/values

R, Reset button (> 1.5 s):

Deleting the fault memory;

Down key (< 1.5 s):

Menu items/values

MENU, MENU key (> 1.5 s):

Starting the menu mode;

Enter key (< 1.5 s):

Confirm menu item, submenu item

and value.

Enter key (> 1.5 s):

Back to the next higher menu level.

ON AL1 AL2

TMENUR

Other manuals for cme420

2

This manual suits for next models

2

Table of contents

Other Bender Relay manuals

Bender

Bender LINETRAXX VMD461 User manual

Bender

Bender cme420 Manual

Bender

Bender RCM470LY User manual

Bender

Bender EDS440 Instruction manual

Bender

Bender CMD420 User manual

Bender

Bender cme420 User manual

Bender

Bender EDS44 L-CN Series User manual

Bender

Bender IOM441-S User manual

Bender

Bender IOM441-S User manual

Bender

Bender LINETRAXX VMD258 User manual