PZE X4V8

Operating Manual PZE X4V8

1003204-EN-07 8

Function description

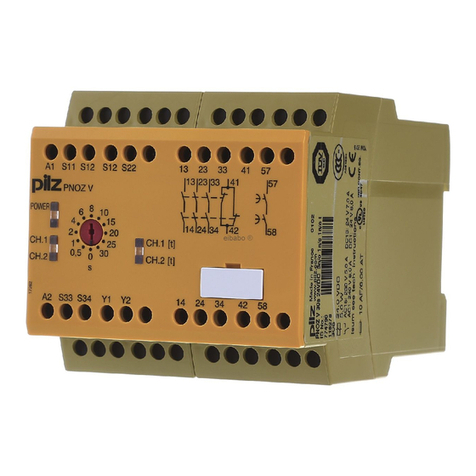

The contact expansion module PZE X4V8 is an add-on device with selectable delay-on de-

energisation, and it is used to expand a safety circuit. The contact expansion module is

driven by a base unit (e. g. emergency stop relay).

}Functional procedure once the input circuit is closed (e.g. safety contacts on the base

unit are closed):

– The supply voltage is present at input (A1) of the contact expansion module.

– The safety contacts 17-18, 27-28, 37-38 and 47-48 close.

– The LEDs "CH.1" and "CH.2" are lit.

}Functional procedure once the input circuit is opened (e.g. safety contacts on the base

unit are opened):

– The supply voltage is not present at input (A1) of the contact expansion module.

– The LEDs "CH.1" and "CH.2" go out.

– Safety contacts 17-18, 27-28, 37-38 and 47-48 are opened redundantly once the

delay time has elapsed.

NOTICE

At the latest the safety contacts open after the set delay time tv + 50% of the

set value, even in the case of a component failure.

Installation

}The unit should be installed in a control cabinet with a protection type of at least IP54.

}Use the notch on the rear of the unit to attach it to a DIN rail.

}Ensure the unit is mounted securely on a vertical DIN rail (35 mm) by using a fixing ele-

ment (e.g. retaining bracket or an end angle).

Wiring

Please note:

}Information given in the "Technical details [ 12]" must be followed.

}Outputs 17-18, 27-28, 37-38 and 47-48 are delay-on de-energisation safety contacts.

}To prevent contact welding, a fuse should be connected before the output contacts (see

Technical details [ 12]).

}Calculation of the max. cable runs lmax in the input circuit:

Rlmax = max. overall cable resistance (see Technical details [ 12])

Rl/km = cable resistance/km

}Use copper wire that can withstand 60/75°C.

}Sufficient fuse protection must be provided on all output contacts with capacitive and in-

ductive loads.