PR XR230 BEAM User manual

2

INDEX

1. SAFETYAND WARNINGS ……………………………………………………………………………………… 3

2.

3.

INSTRUCTIONS……………………………………………………………………………………………………

APPEARANCE ……………………………………………………………………………………………………

4

5

4. INSTALLATION…………………………………………………………………………………………………… 5

5. SETUP AND CONFIGURATION…………………………………………………………………………………… 9

6. OPERATION MENU………………………………………………………………………………………………… 12

7. DMX PROTOCOL………………………………………………………………………………………………… 13

8. ERROR MESSAGES ……………………………………………………………………………………………… 16

9. TECHNICAL DATA………………………………………………………………………………………………… 16

10. CIRCUIT DIAGRAM AND PCB CONNECTIONS………………………………………………………………… 19

11. COMPONENT ORDER CODES…………………………………………………………………………………… 21

ACCESSORIES

The following items are supplied with the projector and please check:

Name

Quantity

Unit

Remark

Safety cord

1

Pc

Clamp

2

Pc

Foldable clamp

2

Pc

Optional

User manual

0

Pc

QR code

Please note that as part of our ongoing commitment to continuous product development, specifications are subject to change

without notice. Whilst every care is taken in the preparation of the manual we reserve the right to change specifications in the

course of product improvement. The publishers cannot be held responsible for the accuracy of the information herein, or any

consequence arising from them.

Every unit is tested completely and packed properly by the manufacturer. Please make sure the packing and / or the unit are in

good condition before installation and use. Should there be any damage caused by transportation, consult your dealer and do not

use the unit. Any damage caused by improper use will not be assumed by the manufacturer and / or dealer.

Any future technical change in the user manual won’t be with any notice.

Note: For the products made by Guangzhou PR lighting Ltd, the warranty for the whole product is one year starting from the

delivery date but the light source is not within the warranty

3

1. SAFETY AND WARNINGS

NOTE

Before a projector’s installation, power-on, operation and maintenance, please carefully read

the safety information hereinafter!

The following safety signs are used in the user manual.

Warning

User

Manual

Electrical

shock

Goggles

Protective

Gloves

Flames

High

Temperature

● When unpacking, check if there is transportation damage before using a projector. Should there be any damage

caused by transportation, consult your dealer and do not use it.

●The manufacturer is not responsible for any loss caused by the user not following the manual or changing a

projector as he/she likes.

●Please be noted that the damage caused by changing a projector at will is not warranted.

● Do not hesitate to contact the dealer or the manufacturer if any questions or advice.

● If a lamp is deformed by heat or damaged , please replace it with a new one.

● A projector with IP20 can only be used indoors.

●For a projector with IP20, keep it away from rain and moisture, excessive heat, humidity and dust. Do not allow

its contact with water or any other liquids.

●A projector should be kept away from high temperature, fire, electrical surge, vibration and strong light while

running.

●.Any maintenance and repair of a projector shouldn’t be carried out by a user and the user shouldn't open it for

any repair work.

●Don’t look straightly into the light sources especially for epileptics, otherwise eyes will be burned.

●Do not connect a projector to any type of dimmer pack.

●If the lamp, lens and screen protective cover of the a projector have obvious damage, i.e., to the extent that it

hurts the performance like cracking or deformation. Please stop using it and replace them with the original parts,

otherwise its performance will be compromised.

● For the installation location of a projector, it shouldn’t be seen in the distance of less than 4 meters for a long

time.

●Before operation, please confirm that all covers (housing) are on and screws tightened. It’s forbidden to use a

projector while covers (housing)are off .

●Keep the lamp clean and do not touch it with bare hands.

●While operating it, wear protective items like eye goggles , gloves and etc..

●Any electrical connection must be carried out by a qualified person .

●Before installation, please confirm the voltage supplied matches what is required for a projector.

●Each projector must be properly earthed and installed as per related electrical standards.

●Do not use power cord with its insulator damaged and connect the power cord with other cables.

●If a projector is not used or under cleaning,, please hold the plug and unplug it. Do not unplug it forcefully or by

pulling the power cable.

●All power cords must conform to related safety and regulations.

●If a projector is not water and dust proof, while being operated it should not be under rains or in humidity to

4

avoid short circuit.

●Do not switch on and off a projector constantly in very short intervals, otherwise the light source’s and other

electrical parts’ life will be shortened .

●There are safety cord holes at the bottom of the base of a projector. In view of safety, please run the safety cord

supplied through the safety cord holes for safety support.

●Before any installation, maintenance and cleaning work, please ensure a projector is disconnected from power

mains.

●After stable operation under normal situation , its temperature is 80℃.

●While the lamp is stricken for the first time, there will be smoke and strange smell. It’s normal and does not

mean a projector has some defects.

●While it running, don’t touch the metal housing to avoid being burned!

●Do not mount a projector directly on inflammable surface.

●Do not project the beam straightly on combustible items and the minimum distance between a

projector

and illuminated items is 5m.

●A projector should be installed with good ventilation and the minimum distance between a projector and a wall

is 50cm. At the same time, please ensure the fans and air inlets and outlets are workable.

●Do not let the front lens under sunlight or other strong light sources at any angle, otherwise the danger of fire

can be caused by the focused beam by the lens inside a projector.

●The product meets The General Technical Requirements and Standards for Recycle and Use Of Expired

Appliance and Electronic Products.

●When the product meets disposal standards and needs to be disposed, a client needs to dispose and recycle it.

2. INSTRUCTIONS

●CLEANING AND MAINTENANCE

Keeping a projector is necessary and the dust, oil and smoke should not accumulate on or in it, otherwise its light output will be greatly

compromised. Regular cleaning will ensure light output at maximum and reliable running during its whole life span. It’s advised to use

soft cloth with good quality detergent. Under whatever circumstances, it should not use alcohol or other solvent.

For the accumulation of oil and smoke on the front lens, thus sharp decrease in light output, the front lens should be cleaned once every

week. Cooling fans cleaned once every month. Internal items inside the projector should be cleaned once every year using vacuum or

blower. Color filters, rotators and internal mirrors should be cleaned once every month.

Regular inspection of air filters and clean them before they fully blocked. Clean air filters at the bottom of the base. Please vacuum or

compressed air to clean and put them back after cleaning.

●Before any maintenance and cleaning, please ensure the project is off the power

●Only qualified person is allowed to do maintenance

●During maintenance and before maintenance, the projector must be off power.

●To avoid internal damage, sun light or other light mustn’t penetrate into the projector via front lens whether

it runs or not

●Do not use alcohol or other organic solvent to clean the housing to avoid damage.

●Do not use any solvent with chemical elements to clean color filters or hot mirror.

. Hot mirror should be cleaned every 3 days and coated with

5

●LUBRICATION

To ensure smooth movement of gobos and zoom and focus lens, it’s advised rotators’ bearings and 2 sliding bars for zoom and focus

lens be lubricated every 2 months. High quality and high temperature lubricant/grease is advised..

●TROUBLESHOOTING

PROBLEM ACTION

The projector doesn’t switch on

Check the fuse on the power socket.

Check the lamp.

The lamp is on but the projector doesn’t respond

to the controller

Make sure that the fixture’s start address is right

Replace or repair the XLR signal cable.

The projector functions intermittently

Make sure the fan is working well or fans and their shields are not blocked

Beam appears dim, Low in brightness

Make sure the lamp is within its lifespan

Remove dust or grease from the lenses.

The project image appears to have a halo

Carefully clean the lamp, optical lenses and other components.

Heavily Defective Beam

Check if lens are in good condition(not cracked)

Clean dust or grease on the lens.

3. APPEARANCE

4. INSTALLATION

A projector can be placed on the stage floor directly or mounted on a truss at any direction without impacting its performance. Please

use a safety cord, which can support 10 times the weight of the projector, while mounting it on the truss. The safety cord should be

used with magazine with a lock. Just as the figures below, please run the safety cord through the holes at the bottom of the base and

around the truss.

● RIGGING

1. Use M12 bolt to fix the clamp(1) into the omega holder (3), run the bolt through the holder’s holes

2. Push 2 quick-lock fasteners(4) into holes at the bottom of the base, fix them and tighten them clockwise

3.Run safety cord(2) through holes at the bottom of the base and around the truss(6)

Arm

Base

Body

6

Use fixing devices like spanner for safe installation.

Note:

1. the distance between the foot

of the base and the front lens

cover(the head facing

downward)

2. the

distance between

mounting truss and the front

lens cover( the head facing

downward)

3. The maximum diameter of

the rotating head ( minimum

spacing between fixtures)

7

WARNING:

●The projector MUST be lifted or carried by the HANDLES instead of clamps.

●.For safety the safety cord should afford 10 times the Projector’s weight.

It must use secondary safety accessory like appropriate net. The structures of the secondary accessory must ensure that while

malfunction happens, the installed parts won’t fall to the ground.

While rigging, mounting or maintaining, the projector mustn’t be placed in the areas listed hereinafter: the bridge, high work areas

or other dangerous areas.

The operator of the projector or its related safety items must be accepted by safety experts before first launching or re-running after

any replacements or repairing.

The operator must ensure a test before acceptance every 4 years and the related safety measures and installation accepted by

experts.

The operator must ensure the related safety measures and its installation must be approved by the technicians every year. The

projector may be installed in places under which people may walk by or sit. Important! Installations in high places requires wide

experience, including but not limited to load limit calculation, the installing materials needed and regular inspection of installing

materials and the projectors. If lacking the qualifications, please don’t try installation by yourself, but seek help from professionals

using designated lifting gears. Abnormal installation may cause body harm or property damages.

The projectors must be installed in places where people can’t reach. If they are removed from ceiling or high places, professional

truss must be used. It is forbidden to let any projector move freely in a room after installation.

Note: Device falling down can cause heavy body harm! If you have any questions about its safety, don’t install any projector!

Before installation, please ensure mounting areas can endure 10 times the weight of a project at least.

●POWER CONNECTION

Connect the power cord as follows:

L (live) =brown

E (earth) =yellow/green

N (neutral) =blue

Before power connection, please ensure the power supplied must match what the nameplate says. It is recommended that each

projector be connected with power separately so that they may be individually switched on and off.

●The earth wire(yellow/green) must be connected to the ground. And electrical connection

must be in accordance with the standards concerned.

●If any questions about the electrical installation, do not continue but consult a qualified

electrician.

●DMX CONTROL CONNECTION

Connection between controller and projector and between one projector and another must be made with a twin-screened cable, with each

wire having at least a 0.5mm in diameter. Connection to and from the projector is via cannon 5 pin (which are included with the projector)

or 5 pin XLR plugs and sockets. The XLR's are connected as shown in the figure above.

4N/C

N/C

5

PIN FUNCTION

GND

1

3DATA+

DATA-

2

DMX 512

DMX IN

DMX OUT

1

2

3

4

55

4

3

2

1

8

Note: care should be taken to ensure that none of the pins touch the metallic body of the plug or each other. XLR plugs and sockets mustn’t

be connected in any way other than mentioned in the above figure. The XR330BWS accepts digital control signals in protocol DMX512

(1990).

Connect the controller’s DMX output to the first fixture’s DMX input, and connect the first fixture’s DMX output to the second fixture’s

DMX input and connect the rest fixtures in the same way. Eventually connect the last fixture’s DMX output to a DMX terminator as shown

in the figure below.

●DMX TERMINATOR

In the Controller mode, at the last fixture in the chain, the DMX output has to be connected with a DMX terminator. This prevents electrical

noise from disturbing and corrupting the DMX control signals.

The DMX terminator is simply an XLR connector with a 120Ω(ohm) resistor connected across pins 2 and 3, which is then plugged into

the output socket on the last projector in the chain. The connections are illustrated below.

●ADJUSTMENT/INSTALLATION/REPLACEMENT OF A LAMP

The procedures for the replacement/adjustment of a lamp

1. Select LAMP OFF under the menu after a fixture is on mains power. Then shut it off from the mains power

2. Loosen 8 screws of the plastic cover

3. Loosen 4 screws of the fan frame, unplug the fan and remove the module

4. Push the upper lamp clipping plate making the spring contract, at the same time push the lamp towards the opposite direction

till it is off the plate. At last remove the lamp obliquely.

5. The installation of the lamp is like its removal

9

6. After the lamp is in the right position, install the fan module, fix it using screws, plug the fan with fan wires, check if the lamp

wires are plugged properly and strike the lamp at last.

7. After lamp on, focus a gobo well. If the light spot is not centered, use flat screwdriver to adjust the lamp’s adjusting screws

8. After lamp adjustment, set LAMP OFF under menu. Shut the fixture off the main power and fix the plastic cover to complete

it.

5. SETUPAND CONFIGURATION

●FRONT PANEL OPERATION

DMX ADDRESS CODE SETTINGS: Set the DMX address(划强调线部分需要与灯具实际英文菜单比对)

CHANNEL MODE: Set DMX channel mode. The numbers stipulated in the menu options mean DMX Channel Number.

RESET: Reset motors

MOTOR POWER:If ON selected, all motors are off power, otherwise all motors will be re-powered and reset. The submenu

is used to re-power and reset motors after re-plugged without mains power being shut off.

PAN TILT : Reset Pan and Tilt motors

………..

RUN:Set running mode

Functions for all submenus are as follows (Note: AUTO mode differs in functions between different products)

DMX :Running via DMX 512 controller

AUTO(Factory test) : Running via programs set by the factory and for factory test

USER : running via programs made by the user. Edit scenes via SELF PROGRAM under RUN SETTINGS

LAMP : Turn on or turn off the lamp. After the value changed, it takes about 3s to execute it. The operation can be canceled via getting the

value back to the original within 3s. After the lamp-off, it must wait between 1 and 2 minutes to re-strike the lamp. If the lamp is

re- stricken within 2minutes, the lamp won’t be on. After 2 minutes lapse, the lamp will be on automatically.

If ON selected, after mains power on, the system will try to strike the lamp.

MANUAL :Set DMX channel values manually

CHANNEL 1 : Set its DMX value

CHANNEL 2: Set its DMX value

CHANNEL 3: Set its DMX value

………..

RUNNING SETTINGS : Set running parameters

MASTER/SLAVE MODE : Set master/slave mode

PAN/TILT SETTINGS :

X REVERSE : If “Y” selected, reverse the rotating direction of the pan motor, otherwise the default.

Y REVERSE : If “Y” selected, reverse the rotating direction of the pan motor, otherwise the default.

X SETTINGS:

STA RT FROM 0-254

FINISH AT 0-255

Y SETTINGS:

STA RT FROM 0-254

FINISH AT 0-255

LINEAR COLOR: If “Y” selected, color wheel moves linearly

10

DIMMER CURVE: Options for dimmer curves( specially for LED fixtures)

SELF PROGRAM:

STEPS

DMX 512 signal detected, it runs in this way.

POWER ON : If there is no DMX signal during the initialization of the fixture, the above-mentioned mode will be executed.

Otherwise, keep the last position before power-off last time.

Middle: the values of all DMX channels at 0 excluding Pan and Tilt at middle point

Auto(Factory test/gobos/colors): runs programs set by the factory

User:runs programs edited by a user

RUN TIME: If DMX signal loss, it will execute it at any time

Keep:Keep last frame of DMX value

Shutter off:Shutters close.

DISPLAY SETTING: Set LCD display

AUTO IGNITION: If “NO” selected, after reset the lamp won’t be on, otherwise it will be on automatically.

ADVANCED SETTINGS:

ADJ: factory testing function and it needs password.

LANGUAGE: Set the system’s language

HIBERNATION: Set the status of the motors after lamp-off. “Hibernation” means shutting all motors from power but those two for

Pan and Tilt( Motors for Pan and Tilt won’t be shut off from power and can run normally)

WAITING FOR SIGNALS Set the time without any DMX signal before it goes into HIBERNATION mode

LIGHT CLOSED Set the time after light closed before it goes into HIBERNATION mode

THRESHOLD FOR LIGHT CLOSED: Set the threshold for closed light, i.e., if the value of the Dimmer channel is lower than it,

it is regarded as light closed.

INFO

DMX VALUE Shows the value received via DMX signal

DMX CHANNEL Select the DMX channel for view

VALUE shows DMX value of selected channel

ERROR shows error information(If there is any error in the menu, a exclamatory mark will appear on the top-light of the screen)

RAM shows if the RAM works properly. Otherwise, it won’t record ,read menu, lamp time and the data for user program will lose

RAM ERROR internal memory allotment of the chip fails. If it occurs, please contact the factory

BUS COMMUNICATION If any error, all motors won’t run normally. If it appears, please check the wires between the PCBs are

connected well or not

LAMP Communication with the lamp striking board, if any error, the main chip can’t decide if the lamp is turned off or on normally,

which can cause some function failures.

LAMP STRIKING BOARD Communication with lamp striking board

X RESET if it fails, check if optical coupler or motor works normally

Y RESET if it fails, check if optical coupler or motor works normally

COLOR WHEEL RESET Color wheel reset fails

FIXED GOBO WHEEL RESET Fixed gobo wheel reset fails

FAN FAILURE Blowers fail and the lamp will be turned off automatically some time after the failure

LAMP shows lamp running time

TOTAL TIME shows the total hours of the lamp since last lamp hour reset

RESET HOURS reset total lamp hours to zero

TEST MODE ONLY for product test or temporary use

PROUDCT CODE product’s internal code, reference only for production or maintenance or repair

Description of the 1st page of the screen

11

1- Current DMX address in large font

2- Customer’s logo

3- FPS of DMX signal

4- Current DMX channel mode and the numbers mean the number of DMX channels

5- Fan speeds( it will appear or not based on actual product)

6- Current mode( Master/slave)

7- Current running mode(DMX512,auto,user)

8- Error info. If any info in red with “X”, there are errors found during self test(push DOWN key for more details)

9- Temperature or other info( actual info based on actual product)

10-SN (lock and deadline status)

●STAND-ALONE MODE

Operate the projector without connecting with a controller, enable the master mode through the operation panel, the

projector will run in Stand-Alone mode automatically.

DMX address can be set at any number within 512.

●MASTER/SLAVE MODE

Many projectors can run synchronously in the Master/Slave mode by linking them with each other. First,

connect the first fixture’s DMX output to the second fixture’s DMX input using XLR-XLR control cable and then connect the second

fixture’s DMX output to the third fixture’s DMX input, and so on until all projector are connected in this way. Eventually connect the last

fixture’s DMX output to a DMX terminator. Set 1st projector as the master and others are Slaves. It’s advised that the

maximum quantity of projectors in a DMX chain is less than 32.

Start Addresses of all Slaves are 001; Operation mode of the Master can be set any mode for a Master’ and Slaves’ operation mode can be

set accordingly.

After Powered on, the group will run in Master/Slave Mode

12

6. OPERATION MENU

Level 1 Level 2 Level 3 Press the

button

DMX Address

code Settings

Address:

001 001-512

Channel Mode: 16Ch/20CH

Reset

Motor Power On/off

Reset all On/off

Pan Tilt On/off

Dim On/off

Color On/off

Gobo On/off

Beam Path On/off

Run DMX/User/Auto

Lamp On/off

Manual

Color 0-255

Strobe 0-255

Dim 0-255

Gobo 0-255

Prism 0-255

Prism Rot 0-255

Frost 0-255

Foucs 0-255

Pan 0-255

Pan Fine 0-255

Tilt 0-255

Tilt Fine 0-255

P/T Speed 0-255

Functinl 0-255

Run Settings

Pan/Tilt Settings

Manual

Pan/Tilt On/off

X Reverse N/Y

Y Reverse N/Y

Speeed Chn Yes/N o

If No DMX Power On Middle/On

13

7. DMX PROTOCOL

Level 1 Level 2 Level 3 Press the

button

DMX Address

code Settings

Address:

001 001-512

Channel Mode: 16Ch/20CH

Effect/User/

Auto

Run Time Shtter

Off/Keep

Auto Ignition On/off

Advanced Settings Adj ****

Language English/Chinese

Ignore Raster Waveform Yes /N o

Adj Recover ****

Info DMX Value

Error

Lamp Usage Times ****hr

Clear Times ****

Test Mode Fan Test

Pan/Tilt

Product Code

******

DMX Chart OF PR-2204

Short

mode

Standard

mode

Value Function

1 1

Color

000-128

Linear Color

129-133

Open

134-137

Color1

138-141

Color2

142-145

Color3

146-149

Color4

150-153

Color5

154-157

Color6

158-161

Color7

162-165

Color8

166-169

Color9

170-173

Color10

14

174-177

Color11

178-181

Color12

182-185

Color13

186-193

Color14

194-225

Clockwise rotation from fast to slow

226-255

Anti-clockwise rotation from slow to fast

2

2

Strobe

000-003

Close

004-103

Strobe from slow to fast

104-107

Open

108-207

Pulse strobe from slow to fast

208-212

Open

213-225

Slow Random strobe

226-238

Medium Random strobe

239-251

Fast Random Strobe

252-255

Open

3 3

Dimmer

000-255

Linear Dimmer 0-100%

4

4

Fixed gobo wheel

000-004

Open

005-009

GOBO1

010-014

GOBO2

015-019

GOBO3

020-024

GOBO4

025-029

GOBO5

030-034

GOBO6

035-039

GOBO7

040-044

GOBO8

045-049

GOBO9

050-054

GOBO10

055-059

GOBO11

060-064

GOBO12

065-069

GOBO13

070-074

GOBO14

075-079

GOBO15

080-084

GOBO16

085-089

GOBO17

090-094

GOBO1 SHAKE: Slow->Fast

095-099

GOBO2 SHAKE: Slow->Fast

100-104

GOBO3 SHAKE: Slow->Fast

105-109

GOBO4 SHAKE: Slow->Fast

110-114

GOBO5 SHAKE: Slow->Fast

115-119

GOBO6 SHAKE: Slow->Fast

15

120-124

GOBO7 SHAKE: Slow->Fast

125-129

GOBO8 SHAKE: Slow->Fast

130-134

GOBO9 SHAKE: Slow->Fast

135-139

GOBO10 SHAKE: Slow->Fast

140-144

GOBO11 SHAKE: Slow->Fast

145-149

GOBO12 SHAKE: Slow->Fast

150-154

GOBO13 SHAKE: Slow->Fast

155-159

GOBO14 SHAKE: Slow->Fast

160-164

GOBO15 SHAKE: Slow->Fast

165-169

GOBO16 SHAKE: Slow->Fast

170-174

GOBO17 SHAKE: Slow->Fast

175-214

Clockwise rotation: Fast->Slow

215-255

Anti-clockwise rotation: slow->fast

5 5

Prism

000-032

Open

033-255

Prism in

6 6

Prism rotation

000-127

Prism indexing 0-360

°

128-190

Clock wise rotation from fast to slow

191-192

Stop

193-255

Anti-clockwise rotation from slow to fast

7 7 Color Wheel in 16 bit

000-255

0-100%

8 8

Frost

000-255

0-100%

9 9

Focus

000-255

0-100%

10 10

Pan

000-255

0-100%

11 11

Pan in 16 bit

000-255

0-100%

12 12

Tilt

000-255

0-100%

13 13

Tilt in 16 bit

000-255

0-100%

14 14

Pan and Tilt Speed

000-255

Speed from fast to slow

15 15

Reset

000-099

No

100-109

Pan and Tilt reset

110-119

Head reset

120-127

No

128-130

Total Reset

131-255

No

16

8. ERROR MESSAGE

Name Type Correction

Pan

Optical sensor error: Pan

Check if wiring, optical sensor and motors are normal

Tilt

Optical sensor error: Tilt

Check if wiring, optical sensor and motors are normal

Pan & Tilt driver board

Communication error: module1

Check if wiring, hall sensor and motors are normal

Motor driver board

Communication error: module2

Check if wiring, hall sensor and motors are normal

Focus

Hall error: Focus

Check if wiring, hall sensor and motors are normal

Color wheel

Hall error: Color wheel

Check if wiring, hall sensor and motors are normal

Fixed gobo wheel

Hall error: Fixed gobo wheel

Check if wiring, hall sensor and motors are normal

Lamp striking

Lamp striking error

Check if wiring and igniter are normal and if the voltage of

the igniter is normal

9. TECHNICAL DATA

ELECTRIC PARAMETERS

Input voltage100V~240V AC,50/60Hz

Input power 350W@230V

Power factor PF>0.90

THE SPECIFICATIONS OF THE LIGHT SOURCE

Lamp Osram 7R

Color temperature 8000K

rated life 2000hrs

COLORS

1color wheel: 14colors+ Open

16 16

Lamp Control

000-064

No

065-068

Lamp off

069-178

No

179-181

Lamp on

182-255

No

17

Pan and Tilt speed

000-255

From fast to slow

18

Color Wheel Speed

000-255

From fast to slow

19

Focus Speed

000-255

From fast to slow

20

Fixed Gobo Wheel Speed

000-255

From fast to slow

17

FIXED GOBO WHEEL

1 fixed gobo wheel: 17gobos+open

PRISM/FROST

1 16-facet prism, bi-directional rotation from slow to fast , both can be overlapped

FOCUS

DMX linear focus

DIMMER /STROBE

Strobe at variable speeds(15 F.P.S at maximum)

0-100% linear dimmer

HEAD MOVEMENT

Pan 540º, Tilt 270º with 16 bit control

BEAM ANGLE

2.5°

CONTROL

International standard DMX 512 protocol, 5-pin interface

16channels in short mode and 20channels in standard mode

18

HOUSING

High temperature and anti-UV ABS and aluminum , IP20

NET WEIGHT

17.5Kg

OPERATION TEMPERATURE

Ambient temperature at maximum:45°C

SIZES

LIGHT OUTPUT

19

10. CIRCUITDIAGRAM

20

PCB CONNECTIONS

12-channle motor driverboard

12-channel motor driver board

1 Pan motor 14 Hall for color wheel

2

Tilt motor

15

Hall for focus

3

Fixed gobo wheel motor

16

Hall for Tilt

4

Color wheel motor

17

Magnet sensor for Tilt

5

Prism motor

18

Magnet sensor for Pan

6 Prism rotation motor 19 Voltage input 12V 36V

7

Frost motor

8

Focus motor1

9

Focus motor 2

10

Strobe motor 1

11

Strobe motor 2

12

Signal input

13

Hall for fixed gobo wheel

This manual suits for next models

1

Table of contents

Other PR Floodlight manuals

Popular Floodlight manuals by other brands

Lithonia Lighting

Lithonia Lighting TFX3 installation instructions

Maxi Led

Maxi Led NightSearcher Solaris Pro user manual

Ryobi

Ryobi R18ALW Original instructions

Ledj

Ledj PERFORMER 54 RGBW user manual

Showline

Showline SL ParBlazer 100 UV Installation & user manual

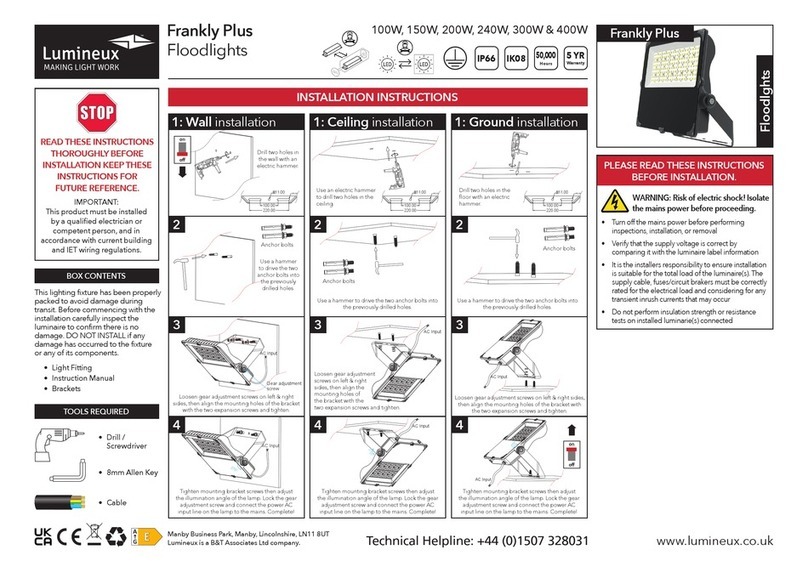

Lumineux

Lumineux Frankly Plus installation instructions