PR XRLED 400 BWS User manual

2

INDEX

1.

SAFETY AND WARNINGS…………………………………………………………………………………

3

2.

INSTRUCTIONS……………………………………………………………………………………………

4

3.

APPERANCE…………………………………………………………………………………………………

5

4.

INSTALLTION…………………………………………………………………………………………………

5

5.

SETUP AND TONFIGURATION……………………………………………………………………………

10

6.

OPERATION MENU…………………………………………………………………………………………

11

7.

DMX PROTOCOL ……………………………………………………………………………………………

13

8.

ERROR MESSAGES………………… ………………………………………………………………………

16

9.

TECHNICAL DATA…………………………………………………………………………………………

16

10.

CIRCUIT DIAGRAM …………………………………………………………………………………………

20

11.

COMPONENT ORDER CODES………………………………………………………………………………

21

APPENDIX……………………………………………………………………………………………………

22

ACCESSORIES

The following items are supplied with the projector and please check:

Name

Quantity

Unit

Remark

Safety cord

1

Pc

Clamp

2

Pc

Foldable clamp

2

Pc

Optional

User manual

1

Pc

Please note that as part of our ongoing commitment to continuous product development, specifications are subject to change

without notice. Whilst every care is taken in the preparation of the manual we reserve the right to change specifications in the

course of product improvement. The publishers cannot be held responsible for the accuracy of the information herein, or any

consequence arising from them.

Every unit is tested completely and packed properly by the manufacturer. Please make sure the packing and / or the unit are in

good condition before installation and use. Should there be any damage caused by transportation, consult your dealer and do not

use the unit. Any damage caused by improper use will not be assumed by the manufacturer and / or dealer

Any future technical change in the user manual won’t be with any notice.

Note: Products are calculated on the date of delivery by the company, the warranty for the whole product is one year starting

from the delivery date but the light source is not within the warranty

3

1. SAFETYAND WARNINGS

NOTE

Before a projector’s installation, power-on, operation and maintenance, please carefully read the

safety information hereinafter!

The following safety signs are used in the user manual.

Warning

User

Manual

Electrical

shock

Goggles

Protective

Gloves

Flames

High

Temperature

●● When unpacking , check if there is transportation damage before using the projector. Should there be

any damage causedby transportation,consultyourdealer and do not use it.

●● The manufacture is not responsible for loss caused by the user not following the manual or changing

the projector as he/shelikes

●● Pleasebe notedthatthedamage causedby changing theprojectorat willis notwarranted.

●● Do nothesitateto contactthe dealeror the manufacturerif any questionsor advice.

●● If a lamp is damagedor deforms becauseof heat, it shouldbe replaced.

● Theprojectoris for indoor use only,IP20.

● It cannot be used in humid and dusty areas. And it cannot contact water and other non-corrosive

liquids.

● The projector should be kept away from high temperature, fire, electrical surge, vibration and

strong light while being operated

● The projector is only intended for installation, operation and maintenance by qualified personnel.

And the operation must strictly follow the procedures in the manual

● No repairable parts in the projector and do not open covers for maintenance by yourself.

● Don’t look straightly into the light sources especially for epileptics, otherwise eyes will be burned.

● Do not connect a projector to any type of dimmer pack.

● If the lamp, lens and screen protective cover of the a projector have obvious damage, i.e., to the

extent that it hurts the performance like cracking or deformation. Please stop using it and replace

them with the original parts, otherwise its performance will be compromised.

● For the installation location of a projector, it shouldn’t be seen in the distance of less than 4 meters

for a long time.

● Before operation, please confirm that all covers (housing) are on and screws tightened. It’s

forbidden to use a projector while covers (housing)are off .

● Keep the lamp clean and do not touch it with bare hands.

● While operating it, wear protective items like eye goggles , gloves and etc.

● Anyelectricalconnectionmustbe carried out by a qualifiedperson .

● Beforeinstallation,pleaseconfirm the voltagesuppliedmatcheswhat is requiredfortheprojector

● Eachprojectormustbe properlyearthedandinstalledas per relatedelectricalstandards.

● Do notusepower cordwith its insulator damagedandconnect the powercordwith other cables.

● If the projector is not used or under cleaning,, please hold the plug and unplug it. Do not unplug it forcefully

or by pullingthe powercable.

● All power cordsmust conform to relatedsafety and regulations

● While beingoperated, the projectorshouldnot be under rains or in humidity.

● Do not switch on and off the projector constantly in very short intervals, otherwise the light source’s and

4

other electrical parts’ life will be shortened

●There are safety cord holes at the bottom of the base of a projector. In view of safety, please run the

safety cord supplied through the safety cord holes for safety support.

●Before any installation, maintenance and cleaning work, please ensure a projector is disconnected

from power mains.

●After stableoperationunder normalsituation, its temperature is 80℃.

●While the lamp is stricken for the first time, there will be smoke and strange smell. It’s normal and

does not mean a projector has some defects.

●While it running, don’t touch the metal housing to avoid being burned!

●Do not mount a projector directly on inflammable surface.

●Do not project the beam straightly on combustible items and the minimum distance between a

projector and illuminated items is 8m.

●A projector should be installed with good ventilation and the minimum distance between a

projector and a wall is 50cm. At the same time, please ensure the fans and air inlets and outlets are

workable.

●Do not let the front lens under sunlight or other strong light sources at any angle, otherwise the

danger of fire can be caused by the focused beam by the lens inside a projector.

● The product meets The General Technical Requirements and Standards for Recycle and Use Of Expired

Appliance and ElectronicProducts

● Whentheproduct meetsdisposalstandardsandneedsto be disposed,a clientneedsto disposeandrecycleit.

2. INSTRUCTIONS

●

CLEANINGAND MAINTENANCE

Keeping a projector is necessary and the dust, oil and smoke should not accumulate on or in it, otherwise its light output will be greatly

compromised. Regular cleaning will ensure light output at maximum and reliable running during its whole life span. It’s advised to use

softcloth with goodqualitydetergent. Under whatevercircumstances, it shouldnot use alcoholor other solvent.

For the accumulation of oil and smoke on the front lens, thus sharp decreasein light output, the front lens should be cleaned once every

week. Cooling fans cleaned once every month. Internal items inside the projector should be cleaned once every year using vacuum or

blower. Colorfilters, rotators and internalmirrorsshould be cleanedonce every month.

Regular inspection of air filters and clean them before they fully blocked. Clean air filters at the bottom of the base. Please vacuum or

compressedair to cleanand put them backafter cleaning.

●Beforeany maintenanceandcleaning,please ensurethe projectis off thepower

●Only qualifiedperson is allowed to do maintenance

●During maintenanceand before maintenance,theprojectormustbe off power.

●To avoid internal damage, sun light or other light mustn’t penetrate into the projector via front lens whether it

runs ornot

●Do notusealcoholor otherorganic solventto clean thehousingto avoiddamage.

●Do notuseany solventwith chemical elementsto clean color filters or hot mirror.

. Hot mirror should be cleaned every 3 days and coated with

●

LUBRICATION

To ensure smooth movement of gobos and zoom and focus lens, it’s advised rotators’ bearings and 2 sliding bars for zoom and focus

lensbe lubricated every 2 months.High qualityand hightemperature lubricant/grease is advised..

5

●

TROUBLESHOOTING

PROBLEM

ACTION

The projector doesn’t switch on

Check thefuseon thepowersocket.

Check thelamp.

The lamp is on butthe projectordoesn’t respond

to thecontroller

Makesure that the fixture’sstart addressis right

Replace or repairtheXLR signalcable.

The projector functions intermittently

Makesurethefanisworkingwellorfansandtheirshieldsarenotblocked

Beam appears dim, Low in brightness

Makesurethelamp is withinitslifespan

Remove dust or greasefrom the lenses.

The project image appears to have a halo

Carefullyclean thelamp,opticallensesandother components.

Heavily Defective Beam

Check if lens are in good condition(not cracked)

Cleandust or grease on the lens.

3. APPEARANCE

4. INSTALLATION

A projector can be placed on the stage floor directly or mounted on a truss at any direction without impacting its performance. Please

use a safety cord, which can support 10 times the weight of the projector, while mounting it on the truss. The safety cord should be

used with magazine with a lock. Just as the figures below, please run the safety cord through the holes at the bottom of the base and

around thetruss.

●

RIGGING

1.

UseM12 bolt to fixthe clamp(1)intothe omega holder (3), run the bolt through the holder’s holes

2.

Push2 quick-lockfasteners(4)into holesat the bottomof thebase, fix themandtightenthem clockwise

3.Runsafety cord(2)through holes at thebottom of the base and around the truss(6)

Head

Arm

Base

6

The bracket of BASE:

Use the spanner supplied with a projector to help installation.

WARNING:

●TheprojectorMUST be lifted or carriedby theHANDLESinstead of clamps.

●.Forsafetythesafety cordshould afford10 times the Projector’s weight.

It must use secondary safety accessory like appropriate net. The structures of the secondary accessory must ensure that while

malfunction happens, the installed parts won’t fall to the ground.

While rigging, mounting or maintaining, the projector mustn’t be placed in the areas listed hereinafter: the bridge, high work

areas or other dangerous areas.

7

The operator of the projector or its related safety items must be accepted by safety experts before first launching or re-running

after any replacementsor repairing.

The operator must ensure a test before acceptance every 4 years and the related safety measures and installation accepted by

experts.

The operator must ensure the related safety measures and its installation must be approved by the technicians every year. The

projector may be installed in places under which people may walk by or sit. Important! Installations in high places requires

wide experience, including but not limited to load limit calculation, the installing materials needed and regular inspection of

installing materials and the projectors. If lacking the qualifications, please don’t try installation by yourself, but seek help from

professionals using designated lifting gears. Abnormal installation may cause body harm or property damages.

The projectors must be installed in places where people can’t reach. If they are removed from ceiling or high places,

professional truss must be used. It is forbidden to let any projector move freely in a room after installation.

Note: Device falling down can cause heavy body harm! If you have any questions about its safety, don’t install any projector!

Before installation, please ensure mounting areas can endure 10 times the weight of a project at least.

●

POWER CONNECTION

Connect the power cord as follows:

L(live) =brown

E (earth)

=yellow/green N

(neutral) =blue

Before power connection, please ensure the power supplied must match what the nameplate says. It is recommended that each

projector be connected with power separately so that they may be individually switched on and off.

●

The earth wire(yellow/green) must be connected to the ground.And electrical

connection must be in accordance with the standards concerned.

●

If any questions about the electrical installation, do not continue but consult a qualified

electrician.

●

DMXCONTROLCONNECTION

Connection between controller and projector and between one projector and another must be made with a twin-screened cable, with

each wire having at least a 0.5mm in diameter. Connection to and from the projector is via cannon 5 pin (which are included with the

projector) or 5 pin XLR plugs and sockets. TheXLR'sare connected as shown in the figureabove.

Note: care should be taken to ensure that none of the pins touch the metallic body of the plug or each other. XLR plugs and sockets

mustn’t be connected in any way other than mentioned in the above figure. The fixture accepts digital control signals in protocol

DMX512 (1990).

Connect the controller’s DMX output to the first fixture’s DMX input, and connect the first fixture’s DMX output to the second

fixture’s DMX input and connectthe rest fixtures in the same way. Eventuallyconnect the last fixture’sDMX output to a DMXterminator

as shown in the figurebelow.

8

●

DMXTERMINATOR

In theController mode,at the last fixturein thechain, the DMX output has to be connectedwith a DMX terminator.Thisprevents

electrical noisefromdisturbingandcorruptingthe DMXcontrol signals.

The DMX terminator is simply an XLR connector with a 120(ohm) resistor connected across pins 2 and 3, which is then plugged into

the output socket on the last projector in the chain. The connections are illustrated below.

21

3

120

DMX TERMINATOR

CONNECTION

Connect a 120 (OHM) resistor

across pins 2 and 3 in an XLR plug

and insert into the DMX out socket

on the last unit in the chain.

PIN 3

PIN 2

GOBO REPLACEMENT

1.

Disconnect the projectorwith mains powerand letit cool

2.

After loosening 4 1/4 fasteners of the head cover,remove it

3.

Gentlypull the gobo holder(3)fromrotating gobo wheel upward.

4.

Use appropriate tool like flat screwdriver of small size to remove spring lock(1). Do not use bare hand to touch pattern side of

the gobo.

5.

Remove the old gobo(2) and insert new one with the smooth side facing light source. At the edge of the Gleelite gobo, there

is small positioning point(8), which must overlap with gobo holder’s positioning point(4). Insert spring lock and fix the gobo

inside the goboholder.

6.

Insert the gobo holder into the rotating gobo wheel via locking pins (6 and 7) and ensure positioning point (4) overlaps

extruding point in the shape of tooth at the edge of the rotating wheel(5). Important! After inserting rotators into the wheel, the

neighboring rotators must be positioned based on same rules, which means positioning point(4) must overlap extruding point(5)

at the edge of the wheel. With 2 markings (4) and (5), when the wheel is at proper position where the rotators can be inserted,

the rotators can be placedone by one.

7.

Beforepoweron,pleaseinstalltheheadcover.

8.

Use menuto fine tune replaced gobos( Service->Calibration->Standard effect->R. Gobo Indexing1…R Gobo Indexing(6)

Note:The magnet(9) in the gobo holderis of thesame function as thepositioningpoint(4).

9

DANGER!

BEOFORE GOBO REPLACEMENT, IT MUST BE OFFPOWER!

10

5. SETUPAND CONFIGURATION

●

FRONTPANELOPERATION

To browse through or view a projector’s function settings, push any key to activate the screen after power-on.. After screen

unlocked, push both key and to enter into menus. Each main menu has its sub-menus with different special functions, for

detailspleasesee the 5th point hereinafterOPERATIONMENU.

1、Under menu page for functionsettings,push ▲or▼to select function desired.

2、During menu operation▶key is to escape,OK key means ENTER,push OK key to save settings or enter into

submenus,push

▲or▼key to change values(plus or minus). Push▶key to go back to uppermenu.If not, the screenwill go

backto initial displayautomatically.

●DMXSTARTADDRESS

Push any key to enter into options interface.

If multipleprojectors are controlled by DMX controller, each projector must have its own DMX address to receive DMX signals from the

controller and respond to them. The projector has 2 DMX modes. There are short mode and standard mode. For example standard mode

has 27 channels, so set the No. 1 projector’s address 001, No. 2 projector’s address 028, No. 3 projector’s address 055, No. 4 projector’s

address82 andso on.

Turn on a projector and push any key to enter into options interface

SelectCHANNELMODE iconandpushENTERkey OK . Select DMXADRESS in 2nd levelmenuto set start address

PushkeyUP ▲or DOWN▼to set value desired.

PushENTERkey OK to confirmit.

Push ESCAPEkey▶to enterintoupper levelmenus.

●STAND-ALONEMODE

Without connecting a projector with a controller via XLR cable, after preset memories under the master mode enabled, it

will run in Stand-Alone mode.

●MASTER/SLAVEMODE

(1)

Edit the scene desired

Twowaysto edit scene

a.

Editmanually

Disconnect a projector from XLR cable and enter into scene editing via control panel.A scene has 20 steps and select any step via its

sequence No.. Enter into channel control to edit its data. After disconnected from a DMX controller, a projector will respond to data

editedsimultaneously.

b.

Editwithhelpof a DMXcontroller

Use a DMX controller to control a projector. After the projector is controlled properly in positions, select the sequence No. of step to

be saved and click to store DMX values.

Current DMX data will be automatically saved to its scene’s data and the sequence NO. added 1. And so on, it can save 20-step scene.

(2)

Select use mode from scene menu.There are 2 modesforselection:singleand recycle. If not used,it can be closed.

11

6. OPERATION MENU

Main Menu

Level 1

Level 2

Level 3

Press the button

DMX Address

code Settings

Address:

001

001-512

Channel Mode:

22CH/28CH

Reset

Motor Power

On/off

Reset All

On/off

Pan Tilt

On/off

Color

On/off

Gobo

On/off

Beam Path

On/off

Run

DMX/User/Auto

Manual

Pan

0-255

Tilt

0-255

P/T Speed

0-255

Strobe

0-255

Dim

0-255

Color

0-255

Gobo

0-255

GoboWheel

0-255

Rot Gobo

0-255

Prisml

0-255

Rot Prisml

0-255

Fire Arm

0-255

Fire Wheel Rot

0-255

Frost

0-255

Zoom

0-255

Focus

0-255

C

0-255

M

0-255

Y

0-255

CTO

0-255

Run Settings

Pan/Tilt Settings

Manual Pan/Tilt

On/off

X Reverse

N/Y

Y Reverse

N/Y

Speeed Chn

Yes/No

12

DimCurve

Linear/Square/Square

Root/S-Curve/Log

If No DMX

Power On

Middle/Auto/User/No Effect

Run Time

Shutter Off/Keep

Silent Mode

OFF/ON

Advanced Settings

Adj

Input PSW

****

LCD Display

Sleep

30sec/2min/10min/No

Flip

No/Yes

Auto Lock

N/Y

Language

English/Chinese

Ignore Err

Raster Waveform

No/Yes

Adj Recover

Input PSW

****

Info

DMX Value

Error

LED

Usage Times

****hr

Clear Times

****

Test Mode

Fan Test

Pan/Tilt

13

7. DMX PROTOCOL

DMX channel

Value

Function

Short Mode

22CH

Standard

28CH

1

1

Pan

0-255

0-100%

2

Pan Fine

0-255

0-100%

2

3

Tilt

0-255

0-100%

4

Tilt Fine

0-255

0-100%

3

5

Pan and Tilt speed

0-255

Fast ->Slow

4

6

Strobe

0-3

Close

4-103

Strobe: Slow->Fast

104-107

Open

108-207

Pulse strobe: Slow->Fast

208-212

Open

213-225

Strobe at random: slow speed

226-238

Strobe at random: medium speed

239-251

Strobe at random: fast speed

252-255

Open

5

7

Dimmer

0-255

0-100%

8

Dimmer Fine

0-255

0-100%

6

9

C

0-255

0-100%

7

10

M

0-255

0-100%

8

11

Y

0-255

0-100%

9

12

CTO

0-255

0-100%

10

13

CMY macro

0-3

No function

4-255

CMY to-and-fro movement

11

14

Colors

0-7

Open

8-15

Open+Color1

16-23

Color1

24-31

Color1+Color2

32-39

Color2

40-47

Color2+Color3

48-55

Color3

56-63

Color3+Color4

64-71

Color4

14

72-79

Color4+Color5

80-87

Color5

88-95

Color5+Color6

96-103

Color6

104-111

Color6+Color7

112-119

Color7

120-127

Color7+Open

128-190

Clockwise rotation: Fast->Slow

191-192

Stop

193-255

Anti-clockwise rotation: slow->fast

12

15

Fixed gobo wheel

0-5

Open

6-15

GOBO1

16-25

GOBO2

26-35

GOBO3

36-45

GOBO4

46-55

GOBO5

56-65

GOBO6

66-75

GOBO7

76-92

GOBO1 SHAKE: Slow->Fast

93-109

GOBO2 SHAKE: Slow->Fast

110-126

GOBO3 SHAKE: Slow->Fast

127-143

GOBO4 SHAKE: Slow->Fast

144-160

GOBO5 SHAKE: Slow->Fast

161-177

GOBO6 SHAKE: Slow->Fast

178-199

GOBO7 SHAKE: Slow->Fast

200-201

Open

202-227

Clockwise rotation: Fast->Slow

228-229

Stop

230-255

Anti-clockwise rotation: slow->fast

13

16

Rotating GOBO wheel

0-5

Open

6-15

GOBO1

16-25

GOBO2

26-35

GOBO3

36-45

GOBO4

46-55

GOBO5

56-65

GOBO6

66-75

GOBO7

76-92

GOBO1 SHAKE: Slow->Fast

93-109

GOBO2 SHAKE: Slow->Fast

110-126

GOBO3 SHAKE: Slow->Fast

127-143

GOBO4 SHAKE: Slow->Fast

144-160

GOBO5 SHAKE: Slow->Fast

161-177

GOBO6 SHAKE: Slow->Fast

178-199

GOBO7 SHAKE: Slow->Fast

200-201

Open

202-227

Clockwise rotation: Fast->Slow

228-229

Stop

15

230-255

Anti-clockwise rotation: slow->fast

14

17

GOBO Rotation

0-127

Positioning:0-360°

128-191

Clockwise rotation: Fast->Slow

192-255

Anti-clockwise rotation: slow->fast

18

GOBO Rotation fine

0-255

0-100%

15

19

4 facet prism

0-127

No Function

128-255

Prism in

16

20

4 facet prism rotation

0-127

0-360°

128-190

Clockwise rotation: Fast->Slow

191-192

Stop

192-255

Anti-clockwise rotation: slow->fast

17

21

Effect wheel

0-127

No Function

128-255

Effect wheel in

18

22

Effect wheel rotation

0-3

No Function

4-129

Clockwise rotation: Fast->Slow

130-255

Anti-clockwise rotation: slow->fast

19

23

Frost

0-255

0-100%

20

24

Zoom

0-255

0-100%

25

Zoom Fine

0-255

0-100%

21

26

Focus

0-255

0-100%

27

Focus Fine

0-255

0-100%

22

28

Functional channel

0-199

No Function

200-209

Pan & Tilt reset

210-219

Head reset

220-229

All reset

230-255

No Function

16

8.ERROR MESSAGE

Name

Type

Correction

Pan

Optical sensor error: Pan

Check if wiring, optical sensor and motors are normal

Tilt

Optical sensor error: Tilt

Check if wiring, optical sensor and motors are normal

Pan & Tilt driver board

Communication error: module1

Check if wiring, hall sensor and motors are normal

Motor driver board

Communication error: module2

Check if wiring, hall sensor and motors are normal

Focus

Hall error: Focus

Check if wiring, hall sensor and motors are normal

Zoom

Hall error: Zoom

Check if wiring, hall sensor and motors are normal

Effect wheel

Hall error: Effect wheel

Check if wiring, hall sensor and motors are normal

Color wheel

Hall error: Color wheel

Check if wiring, hall sensor and motors are normal

Fixed gobo wheel

Hall error: Fixed gobo wheel

Check if wiring, hall sensor and motors are normal

Rotating gobo wheel

Hall error: Rotating gobo wheel

Check if wiring, hall sensor and motors are normal

GOBO Rotation

Hall error:GOBO Rotation

Check if wiring, hall sensor and motors are normal

9. TECHNICALDATA

ELECTRIC PARAMETERS

Input voltage : 120V~240VAC,50/60Hz

Input power : 600W @ 220V

Current at Maximum : 4.5A @ 120V

Power factor: PF>0.9

THE SPECIFICATIONS OF THE LIGHT SOURCE

LED : 500W White LED Engine

Colortemperature :7800K±200K

CRI : >72 (Standard)

CRI : >90 (Optional)

LED life expectancy: 40000Hrs L70

*It may change based on various factors, for example like the type of usage and environment condition*

COLORS

1Color wheel: 7colors + Open

CMY+CTO

17

CMY

C M

Y CTO

FIXED GOBO WHEEL/EFFECTWHEEL

1 fixedgobowheel:7gobos+open, gobodiameter=6.5mm,itsthickness=0.5mm

1

2

3

4

5

6

7

1 fireeffectwheel

ROTATING GOBO WHEEL

1 rotating gobo wheel: 7 gobos +open Gobo diameter Ф19.5mm, 4mm thick

1

2

3

4

5

6

7

18

PRISM/FROST

1 4-facet prism

1 Frost

FOCUS

DMX linear focus

DIMMER /STROBE

Strobe at variable speeds

0-100% linear dimmer

HEAD MOVEMENT

Pan 540º, Tilt 270º with 16 bit control

BEAMANGLE

Beam: 5°~45°

Spot :11°~46°

Wash: 8°~ 48°

CONTROL

Projectorand lamp information readable,externalDMX value receivedand thermal sensor built-in forerrorandmalfunction

analysis Presetmemory

Unintentional head move to cause power-off, quiet fans for cooling

International standard DMX 512 protocol, 5-pin interface 22channelsin short mode and 28channels in standard mode

OPTIONALWIRELESS CONTROLMODULE/RDM MODULE

Compliantwith USITTDMX-512(1986and 1990)and512-AFullDMX for fidelity and DMX framingintegrity

Auto-detecting DMX framing size and speed

<5ms DMX delay

Frequency range: 2402-2480 MHz

HOUSING

High temperature ABS and aluminum , IP20

OPERATION TEMPERATURE

Ambient temperature at maximum:45°C

Ambient temperature at minimum:-5°C

NET WEIGHT:

21.5Kg

SIZES:

19

LIGHT OUTPUT

20

10. CIRCUIT DIAGRAM

This manual suits for next models

1

Table of contents

Other PR Light Fixture manuals

Popular Light Fixture manuals by other brands

dtec

dtec Denta/Dentaplus owner's manual

Sensio

Sensio TRIOTONE SE21100 installation instructions

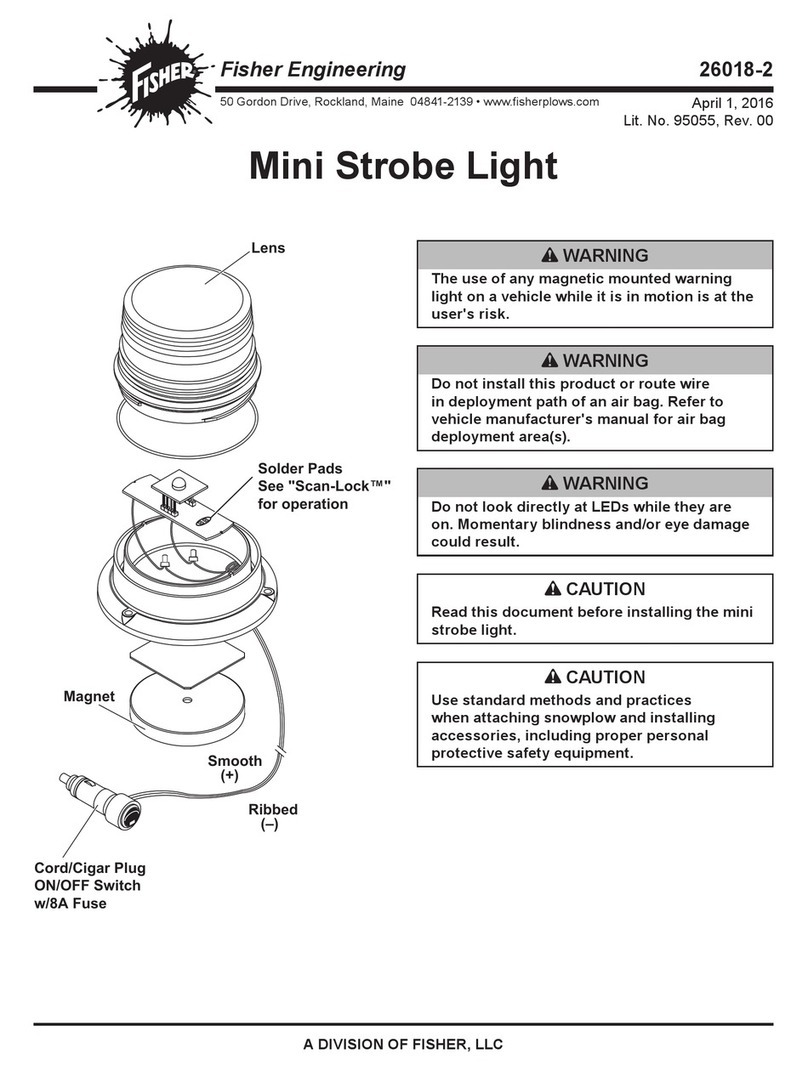

Fisher

Fisher Mini Strobe Light quick start guide

Martin Professional

Martin Professional Wizard Extreme user manual

Tungsram

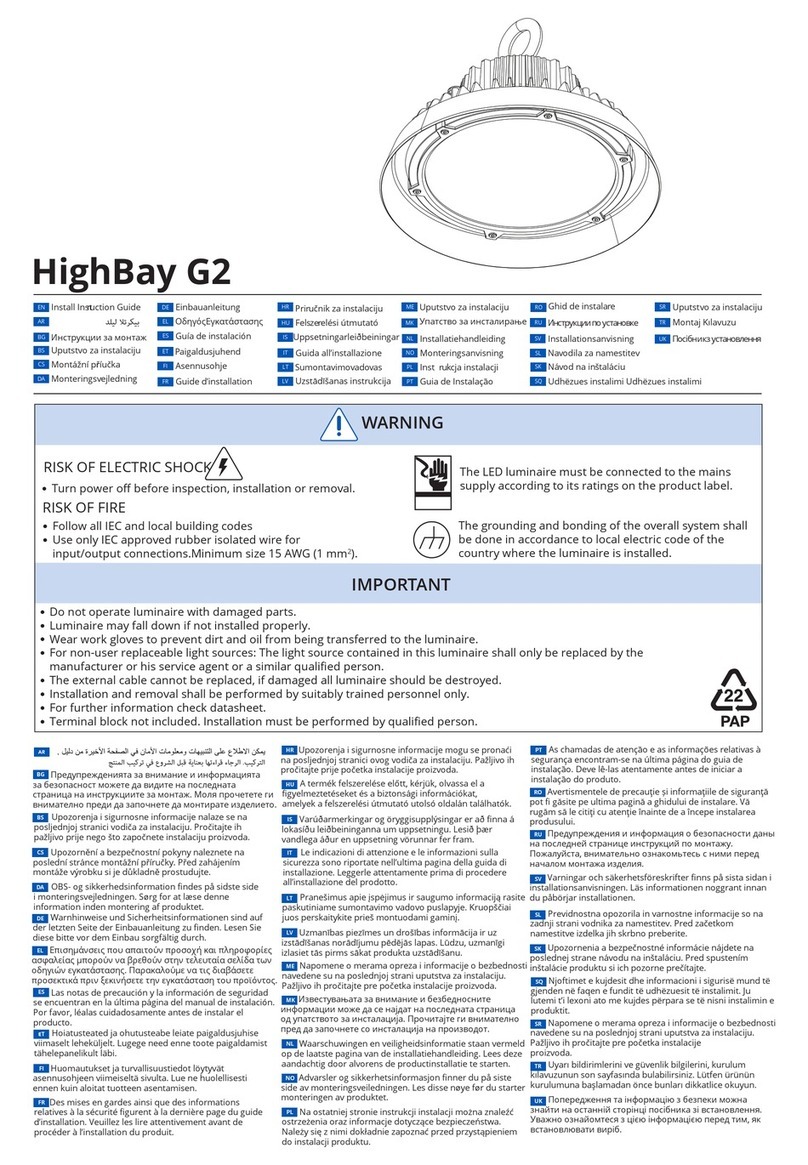

Tungsram HighBay G2 Install Instruction Guide

Coemar

Coemar ISPOT 575 EB instruction manual