Pramac AT206 User manual

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 22

INDEX:

1 - General.....................................................................................................................................................................................................................23

1.1 - Introduction.........................................................................................................................................................................................................23

1.2 - General warning..................................................................................................................................................................................................23

1.3 - Symbols in the manual........................................................................................................................................................................................24

1.4 - Important tips ......................................................................................................................................................................................................25

1.5 - Cautions..............................................................................................................................................................................................................25

1.6 - Noise...................................................................................................................................................................................................................25

1.7 - Cautions levels....................................................................................................................................................................................................25

1.8 - Temporary Storage .............................................................................................................................................................................................25

1.9 - Transporting........................................................................................................................................................................................................26

1.10 - Overall size .......................................................................................................................................................................................................26

1.11 - Disposal............................................................................................................................................................................................................26

1.12 - Assistance center..............................................................................................................................................................................................26

1.13 - Repairs and spare parts....................................................................................................................................................................................26

1.15 - Ordering spare parts..........................................................................................................................................................................................26

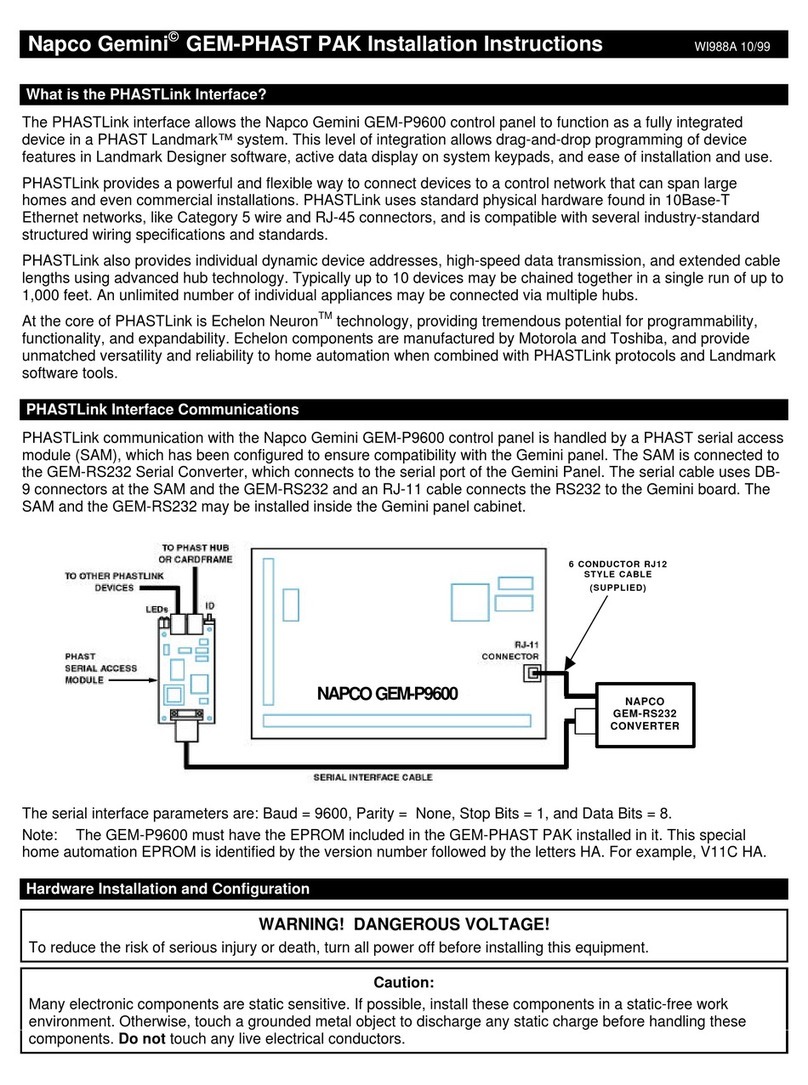

2- AT206 panel description ..........................................................................................................................................................................................27

2.1 – How is the package and what is included ...........................................................................................................................................................27

2.2 - Product external and internal view with description..............................................................................................................................................28

2.3 - Panel wall mounting instructions..........................................................................................................................................................................29

3 - First starting of the product, use and description.................................................................................................................................................30

3.1 - Operation to do during the first starting of the AT206 panel.................................................................................................................................30

3.2 - AT206 panel; LED indication decription...............................................................................................................................................................31

3.3 - AT206 panel; command buttons decription..........................................................................................................................................................31

3.4 - AT206 panel; function description........................................................................................................................................................................32

4 - AT206 connection and electrical drawings............................................................................................................................................................33

4.1 - Power connection................................................................................................................................................................................................33

4.2 - Panel electrical drawing.......................................................................................................................................................................................36

4.3 - Diesel engine auxiliary connection.......................................................................................................................................................................37

4.4 - Gasoline engine auxiliary connection ..................................................................................................................................................................38

5 - AT206 panel programmation instruction................................................................................................................................................................39

5.1 - Programmation menu access description............................................................................................................................................................39

5.2 - Parameters modification instructions...................................................................................................................................................................39

5.3 - User menu parameters........................................................................................................................................................................................39

5.4 - Advanced menu parameters................................................................................................................................................................................39

6 - General sales conditions and warranty................................................................................................................ Errore. Il segnalibro non è definito.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 23

1 - GENERAL

The Instruction for Use are integral part of the machine and must accompany it for all its useful life until its demolition.

For every operation one must always apply to what is prescribed in the Instructions.

Follow scrupolously all indication reported in the Instructions

Prevent from making use of the machine operators not knowing the prescription based on the Instructions

Keep complete and legible Instructions in a place accessible to operators.

Hand over the manual to any other user or successive owner of the machine.

Verify if the registration number reproduced on the technical card of the acquired model agrees with that one cut with the label of the “Marking CE”

The Firm “PRAMAC s.r.l.” will not think he is responsible for difficulties, breaks, accidents etc. due to the no knowledge or at any rate to the no

application of the rules held in this manual.

The same is told for the execution of changes and variants or for the installation of accessory not previously authorized.

1.1 - Introduction

Dear Customer,

We would like to thank you for your attention and for purchasing a “PRAMAC” high-quality “Electric Panel.”

Our Technical Service and Spare Parts departments will do their utmost to help you should you need it.

To this regard, for all control and overhaul operations, please call “PRAMAC” who will provide you with specialized, prompt action.

If you have had parts replaced, ask and make sure that only genuine “PRAMAC” spare parts are used in order to assure you that the initial performance

and safety required by current standards are restored.

Use of non-genuine spare parts shall immediately forfeit all right to warranty and Technical Service by “PRAMAC”.

The special composition and design of this panel enables satisfying the most restrictive operator safety standards.

To use “PRAMAC Electric Panels” in the best way, below we give the most important rules to be followed.

1.2 - General warning

- This manual has been drawn up for the USER, the MAINTENANCE TECHNICIAN, the REPAIRS TECHNICIAN.

- Read this manual carefully since it server as a guide to the way the electric control board is designed to be used, to its technical features, to supply

the instructions for installation, assembly, regulation and use. It is also useful for personnel training, to indicate the maintenance operations, for

ordering spare parts and to give indications of the outstanding hazards.

- It is wise to remember that should any difficulty arise in its use, installation or whatever, our Technical Service is always at your disposal for any

explanations or action.

- The instruction manual should be considered as part of the equipment and must be "KEPT FOR FUTURE REFERENCE" as long as the equipment is

assembled.

- The manual must always be available for consultation near the electric control board and kept in a suitable manner (in protected, dry places, away

from direct sunlight, etc.).

- It should be borne in mind that some diagrams it contains have only the purpose of identifying the parts described and therefore might not correspond

to your machine.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 24

- After opening the package, check the entire unit in case of problems with this unit do not use it until you have consulted an the Retailer or

Manufacturer otherwise all warranty rights will be voided.

- This electric panel has only to be used for the purpose for which it was specifically designed. Any other use shall be considered improper and,

therefore, dangerous.

- Our products are made in conformity with current safety standards so it is recommended to use all these devices and take care that their use causes

no injury or damage.

- All operations concerning the installation of the control panel should be carried out by skilled personnel in conformity with present regulations.

- During work it is recommended to keep to the current personal safety rules in force in the country the product is destined for (clothing, work tools,

etc.).

- When the unit is working do not use the electric control board parts.

- Never for any reason modify any part of the electric panel (connections, holes, electrical or mechanical devices, etc.) unless duly authorized to do so

in writing by “PRAMAC”: the responsibility deriving from any such action shall fall on the person doing it since he then in fact becomes its

manufacturer.

- Before doing any cleaning or maintenance, de-energise and switch off the machine it is connected to.

-De-energise and disconnect the equipment in the event of breakdown or malfuncion. If any repairs is needed contact an Authorized Retailer only

and ask that only original spare parts are used. Failing to observe the above instructions may put the safety of the electric control board at risk

and the warranty will immediately decline.

-When installing the control panel comply with the IP protection seal indicated on the identification plate. If the IP protection seal is not indicated and

for different kinds of "IP" protections diverse contact one of our service centres or contact our technical office directly.

- Make sure that earthing complies with the standards in force in the country in which the appliance is used.

- Check that control panels that are installed on the machine are not subjected to vibrations that could damage the parts.

N.B.: The panel size depends on an ambient temperature of 35 degrees Centigrade.

- As a consequence, please make sure that these levels are complied with. As concerns atmospheric conditions, the prescriptions contained in the CEI

EN 60439-1 (6.1.2) have to be complied with.

- Check that the information on the control panel identification plate is compatible with appliance ratings such as voltage, current, frequency, etc.

- If the control panel can be locked, make sure that only authorised personnel can use the key to open the control panel.

- For the protection of inlet lines are not protected comply strictly with the regulations in force in the country in which the control panel is used.

- If the control panel is fitted with guards that need to be removed to wire up the control panel, make sure that they are refitted after the control panel

has been wired up. Make sure that the control panel is disconnected and locked out during these operations and that no parts carry residual current.

- Strictly follow the wiring diagram that accompanies the control panel.

- The manufacturer declines any responsability in to following cases:

a) misure of the machine or use by persons not trained for its operation.

b) incorrect installation.

c) operating faults machine is applied who to electric control board.

d) serious lack of due maintenance.

e) unauthorized modifications or servicing.

f) use of non-original or non-specific spare parts for the model.

g) total or pairtial failure to follow the instruction.

h) unforoseen events ect.

The instruction manual can never substitute a sufficiently experienced user.

The panels’ interruption power is 10 kA. For more powerful systems, please make sure that the right protection levels in the panel inlet lines are

supplied.

Warning: This booklet is not binding. “PRAMAC” reserves the right, without prejudice to the essential features of the model herein

described and illustrated, to make improvements and modifications to parts and accessories without moreover undertaking to update this

manual in time.

1.3 - Symbols in the manual

The symbols contained in this manual have the purpose of drawing the user’s attention in order to prevent trouble or danger both for persons and

objects or the equipment.

These symbols moreover have the purpose of drawing your attention in order to indicate correct use and obtain good operation from your electric panel.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 25

1.4 - Important tips

User tips on safety:

N.B. The information contained in this manual may be changed without notice.

Any damage caused in relation to the use of these instructions shall not be considered since they are only guidelines.

We remind you that failure to observe the instructions we give could cause injury or damage.

It is anyhow understood that current local regulations and/or laws must be observed.

1.5 - Cautions

Hazardous situations - safety for persons and objects.

USE ONLY WITH SAFE INSTALLATIONS

It is prohibited to fail to comply with, take away or put out of service the instructions, safety and supervision functions.

USE ONLY IN PERFECT TECHNICAL CONDITIONS

The electric panels must be used in perfect technical conditions. Any defects that may alter safety must immediately be eliminated.

Never install the electric panels close to sources of heat, in areas where there is a risk of explosion or fire hazard.

Where possible, repair the electric panels in a dry place far from water, protecting them against moisture.

1.6 - Noise

This appliance is in conformity with the provisions of EEC Directive 86/594 since the level of sound pressure is “irrelevant” (it is not perceptible by the

hearing of a human being) since its operation is given by the flow of energy passing through the control components and by the management of the

electric control panel.

1.7 - Cautions levels

Below we give the symbols used in the manual to draw the reader’s attention to the different levels of danger in the “Use and Maintenance” of the

electric panel.

DANGER!! Information or procedures that, unless carried out meticulously, cause death or serious injury.

CAUTION!! Information or procedures that, unless carried out meticulously, could cause death or serious injury.

PRUDENCE!! Information or procedures that, unless carried out meticulously, could cause slight injury or damage to the electric

panel.

WARNING Information or procedures that advise the operator on the optimum use of the electric panel to extend its service life

and prevent damage.

NOTE Important information and procedures.

1.8 - Temporary Storage

In the case of temporary storage of the electric panel, before final installation it is necessary to take some precautions so as not to damage the external

structure and internal electric and electronic devices.

Store the electric panel packed in a closed, covered place.

Position it in a stable manner with no risk of it accidentally falling.

- Position the electric panel in a place protected against atmospheric agents with a humidity level between 30 and 75% and a temperature between -

25°C and +55°C with short times not exceeding 24 h ours, up to +70°C.

- Stack the electric panels without stacking too many one on top of another.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 26

1.9 - Transporting

Transportation of the electric panel must be done so as not to jeopardize its structure.

On receiving the panel, inspect it for any damage suffered in transit and that the data given on the rating plate correspond to what you requested. Any

damage must be reported in writing to the carrier directly when the goods are received. Compensation for damage will be paid in accordance with

current legislation on carriage.

In the event of damage due to transportation or delivery of the wrong model, call the firm that carried out the service and “PRAMAC”.

Before removing the packing from the electric panel, carefully read the user warnings given in this handbook.

All the packing material of the electric panel must be disposed of in accordance with current regulations.

1.10 - Overall size

The size of the control panels is suited to meet customer requirements and their dimensions are therefore shown on the "Technical Data" identification

plate.

1.11 - Disposal

After use or in the case of demolition, the appliance must be disposed of according to the legislative provisions in force in the country it is destined for.

CAUTION!

In addition, it is wise to destroy the machine’s identification plate and any other documents.

1.12 - Assistance center

All maintenance work and technical service must be performed by “Specialized personnel” authorized by “PRAMAC” who will arrange for a technician

to step in after the customer’s call.

1.13 - Repairs and spare parts

For any further inconveniences, not mentioned in this booklet or any demages of the machine, we suggest you to go to the Retailer or Manufacturer

for the repair or possible replacement of any original spare parts.

When requesting spare parts, always:

- Quote serial number.

Identification abbreviation that is stamped onto the part.

Do not wait for the components to be worn out.

Replacing a component at the right moment means to improve the electric control board operation and at the same time avoid greater

damages.

1.15 - Ordering spare parts

The spare parts orders must be accompanied with following indications:

- Serial number of the board.

- Letter/code stamped on the component to be replaced.

Due to the different types of product, it is not possible to enclose drawings of spare parts. They need to be requested with the serial number of the board

and the code of each single component.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 27

2- AT206 PANEL DESCRIPTION

This product permit to control all the functions about a generator

•Engine command and protection module for diesel or gasoline generators

•Measurement system for main electric values

•Automatic control module for two different supply sources (Automatic Mains Failure)

•Automatic changeover switch from two different supply sources (Automatic Transfer Switch)

It’s builded to monitor monophase, triphase or triphase with neutral systems in alternate current; it permit to transfer the user’s load on generator when

the mains voltage is faulty.

2.1 – How is the package and what is included

The packing must be completely closed and it must be in good conditions.

In the package, there is the panel but there are also a pocket with a couple of connectors for auxiliary connections (a), a couple of fixing hooks (b), a

couple of spare fuses (c) and the instruction manual (d).

The identification plate data give all the informations about the product; you can found it on the package and on a side of the panel

WARNING: check if the product received is in accordance to the product ordered.

2.1.1 - Identification data plate

The technical plate is secured on the outside of the electric panel, it gives the main particulars and

certifies its conformity with the EEC machine directive 89/392 (attachment H). Therefore its CE

marking is valid only when mounted with machines made in accordance with the provisions of the

EEC machine directive 89/392 and subsequent amendments introduced 91/368 EEC, 83/44 EEC,

93/68 EEC.

Every time you need to carry out special maintenance, repairs or to request spare parts it is

necessary to call the Manufacturer or Dealer, always quote the serial number.

2.1.2 - Identification plate data specifics

In = Nominal current V = Maximum voltage used on main circuits

Imax.

= Maximum permitted current Vaux = Maximum voltage on auxiliary circuits (Warning!!! Depending on machine type

voltage may be direct current or alternating current. The cable of the auxiliary

circuit is red if the voltage is ac and brown if the voltage is dc

KA = Maximum current that is safe from

short circuits IP = The protection seal is IP 20 for both external and internal agents

Hz = Frequency Kg = Weight (only approximate and is subject to variation)

KVA

= Apparent power (calculated at a 0,8 m

cos) Dim = Sizes (refer to dimensions of the box and do not consider any components whose

installation might modify base dimensions). The measurements are expressed as

"heightxwidthxdepth".

KW = Active power Ser.n = Indicate the serial number required to identify the product. This number must

always be quoted in requests for spare parts.

HP = Horsepower Model = Indicates the code of the control panel that enables the type to be identified.

Targa dati tecniciIdentification data

plate

a

b

c

d

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 28

2.2 - Product external and internal view with description

ATTENTION: Change the fuses only with others of the

same type and with the same data current values

ATTENTION:

The panel in the picures is only an example and it’s one of the model in production; for this reason, the current transformers, the power

circuit and the contactors in the panel must be different from the components in the image.

Emergency button

ATTENTION!!! IN EMERGENCY SITUATION,

PRESS THIS BUTTON TO STOP IMMEDIATLY THE

GENERATOR

Control

board

Predisposition for

magnetothermic

switch or earth failure

relay.

Buzzer “B”

for acoustic

alarm

Input for

generator power

connection

Input for mains

power

connection

Output for load

power connection

Auxiliary

connector “

CN1”

F1 = F4A

F2 = F2A

F3 = F2A

Automatic battery

charger: when it’s

supplied, the red led is

on

Output terminals

for user’s power

connection

Generator

contactor

“TLG” and

power

connection

Mains contactor

“TLR”“ and power

connection

Earth

connection

fixing point

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 29

2.3 - Panel wall mounting instructions

WARNING: THE INSTALLATION OF THE PANEL MUST BE MADE ONLY BY SKILLED PEOPLE

For air flow reasons, it is necessary that

around the panel there is a free space of

about 10cm for all the perimeter

The panel must be fixed on the wall by

two fixing hook in equipment

.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 30

3 - FIRST STARTING OF THE PRODUCT, USE AND DESCRIPTION

3.1 - Operation to do during the first starting of the AT206 panel

When you supply for the first time the panel, the board is setted in RESET mode.

The non observance of the indications given about the first starting of the product, can cause faulty situations on the same product

Before the first starting of the panel, check that the indications on the “Identification data plate” (par. 2.1.1) are in accordance with the

characteristics of the present electrical system.

The programmation of Hour and Date are needed

3.1.1 - How programming the Date and time on the panel

To program the Date and time, follow the procedure descripted below:

-Press RESET button

-With the board in RESET position, press TEST button for 5 seconds; after that the enter in the menu is showed by the display with the first code of

the parameter “U.01 – Automatic test delay time”. To see all the parameters, please check the following table

-By continously pressing of MEAS button, reach parameter “U.11” showed on the display. This parameter is about the actual time.

-Press TEST button to see the value stored now.

-Press START button to increase this value or press STOP button to decrease this value

-When the value is correct, press RESET button to save the modification and return on the parameter code (the display shows U.11)

-By pressing MEAS button, go to paramter “U.12” showed on the display. This parameter is about the actual day.

-Press TEST button to see the value stored now.

-Press START button to increase this value or press STOP button to decrease this value

-Premere il pulsante START per aumentare tale valore o il pulsante STOP per diminuirlo

-When the value is correct, press RESET button to save the modification and return on the parameter code (the display shows U.12)

-Press RESET button than AUT button to exit from menu and return to the normal function mode.

Setup Descrizione Range Default

Gruppo 1 Test

U.01 Tempo intervallo test automatico 1 – 30gg / 1-4 settimane 3 gg

U.02 Durata test 1 – 30 min 15 min

U.03 Orario inizio test 00:00 – 23:59 10:00

U.04 Test con carico 0=carico 1=a vuoto 1

U.05 Orologio 0=no 1=si 0

U.06 settimanale / giorni 0=sett 1=giorni 0

U.07 giorno della settimana 1=lun 2=mar 3=mer ecc. 7

Gruppo2 Varie

U.08 Tempo chiusura relais sirena 0 – 60 sec 20 sec

U.09 Ritardo partenza motore da start EJP 0 – 99 min 25 min

U.10 Ritardo commutazione per EJP/T(1 filo) 0 – 30 min 5 min

Gruppo3 Prog. orologio

U.11 Orario 00:00 – 23:59 00:00

U.12 giorno della settimana 1=lun 2=mar 3=mer ecc. 7

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 31

3.2 - AT206 panel; LED indication decription

3.3 - AT206 panel; command buttons decription

If on, it indicates that one or

more alarms are active

(Par. 3.4

)

If on, it

indicates that

the mains

voltage is ok

If on, it indicates that

the generator voltage

is ok

If on, indicates that

the mains contactor

is closed (the mains

supply the load)

If on, indicates that the generator

contactor is closed (the generator

supply the load)

If on, it indicates that

the voltage measured

is about the mains

If on, it indicates that

the voltage measured

is about the

generator

If on, it

indicates that

the automatic

test is enable

(Par. 3.4)

If on, it indicates that

the board is in

MANUAL (Par. 3.4)

If on, it indicates that

the board is in

AUTOMATIC

(Par.

3.4)

If on, it indicates

that the board is in

RESET (Par. 3.4)

It permit to activate

the automatic test

(Par. 2.5)

Board in MANUAL

function (Par. 2.5)

It permit to change the

type of measurement

showed by the display

It permit to close

the mains

contactor (active

only in MANUAL

function; press it

with MAN button in

the same time)

It permit to close

the generator

contactor (active

only in MANUAL

function; press it

with MAN button in

the same time)

It permit to start the generator

(enable only in MANUAL

function)

It permit to stop the generator (enable only

in MANUAL function)

Board in

AUTOMATIC function

(Par. 2.5)

Board in RESET

(Par. 2.5)

Type of

measurement

showed by the

display

If flashing, it indicate that the

engine is running and the

alarms are not enable. If on,

it indicate that the engine is

running and the alarms are

enable.

4 digit multifunction

display to show

measurement,

function and

alarms status

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 32

3.4 - AT206 panel; function description

BOARD IN RESET

The generator can’t work. If the mains is ok, the mains contactor is closed. If the generator is running, when you change to this function mode the

engine is stopped immediatly and the eventual alarms are resetted. The alarm can’t be resetted if the cause of alarm still remain.

BOARD IN MANUAL

The generator can be started and stopped only manually by START and STOP buttons; also the changeover switch function work from mains to

generator and viceversa by MAINS and GEN buttons

BOARD IN AUTOMATIC

The generator start automatically when there is a mains failure and stop automatically when the mains is ok.

AUTOMATIC TEST

Is enable only if the board is in automatic function. If enable, make a complete starting procedure in accordance to the programmation setted. If the

mains is ok, this test is without changeover switch on the generator contactor; if during this test there is a mains failure, automatically the board close

the generator contactor to supply the load by the generator. The stop procedure begin only when the mains come back to correct values.

ALARMS

When there is an alarm, the display show an identification code about the problem: after about 2 seconds the display show also a descriptive text about

the alarm. By RESET button you can reset the alarms; if the alarm on the display doesn’t disappear, you have to remove the cause of the alarm.

3.4.1 – Procedure to setting tha automatic test

It’s strongly reccomended the enabling of the automatic test to prevent problems caused by a long inactivity of the generator

To enable the automatic test, please follow the instruction below:

-Press RESET button

-With the board in RESET position, press TEST button for 5 seconds; after that the enter in the menu is showed by the display with the first code of

the parameter “U.01 – Automatic test delay time”. To see all the parameters, please check the following table

-Press TEST button to see the value stored now, then press START button to increase this value or STOP button to decrease it. When the value is

correct, press RESET button to save the modification and return to the menu. This parameter specify the delay from one automatic test and the next

one. (about days and weeks setting, check parameter U.06). If you press ENTER insead of RESET button to exit from parameter to menu, you loose

the modification

-By pressing MEAS button, go to paramter “U.02” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change the duration time of the automatic test. When the value is correct, exit and save by RESET button.

-By pressing MEAS button, go to paramter “U.03” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change the starting time of the automatic test. When the value is correct, exit and save by RESET button.

-By pressing MEAS button, go to paramter “U.04” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change if you want the automatic test with changeover switch (set it to “0”) or without changeover switch (set it

to “1”). When the value is correct, exit and save by RESET button.

-By pressing MEAS button, go to paramter “U.05” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change if there is installed the “Clock” optional card (set it to “1”) or if is not installed (set it to “0”). When the

value is correct, exit and save by RESET button.

-By pressing MEAS button, go to paramter “U.06” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change if the delay from one automatic test and the next one must be in “days” or “weeks”; by this you can also

chose the day for starting the automatic test but the installation of the “Clock” optional board is needed. When the value is correct, exit and save by

RESET button.

-By pressing MEAS button, go to paramter “U.07” showed on the display. Press TEST button to see the value stored now, then by START button

(increase) or STOP button (decrease) change the automatic test starting day; available only if the “Clock” optional board is installed. When the value

is correct, exit and save by RESET button.

-At the end, press RESET then AUT button to exit from menu and to return to the normal operating mode.

When the automatic test parameters are setted, you have to enable this test; with the board in automatic mode, keep pressed TEST button fo 5

seconds, then the display shows “On” and the test led turn ON. From this moment the board starts the counting of the time to make the first test. This

test will begin after the set days in parameter “U.01”, at the set time in parameter “U.03” and for a set duration in parameter “U.02”. To disable the

automatic test, keep pressed TEST button for 5 seconds, then the display shows “Off” and the test led turn off.

ESEMPIO:

Setup Description Range Default

Group 1 Test

U.01 Automatic test interval time 1 – 30days / 1-4 week 3 days

U.02 Test duration 1 – 30 min 15 min

U.03 Test start time 00:00 – 23:59 10:00

U.04 Test with load 0=load 1=a vuoto 1

U.05 Clock 0=no 1=yes 0

U.06 weekly / days 0=week 1=days 0

U.07 day of the week 1=Mon 2=Tuesd 3=Wed. etc. 7

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 33

If you enable the automatic test (TEST button for 5 seconds) on Monday afternoon at 15.00, first test will start 3 days after (on Thursday) from 10.00 to

10.15. Second test will start on next Sunday (3 more days later) always from 10.00 to 10.15

4 - AT206 CONNECTION AND ELECTRICAL DRAWINGS

4.1 - Power connection

4.1.1 - Triphase connection

Il collegamento dei cavi ,e il serraggio dei morsetti ai contattori e alla morsettiera deve essere fatto in rispetto ai seguenti dati

Contattore(verificare il tipo

montato nel quadro)

Sezione minima e massima del

cavo flessibile collegato senza

terminali

Coppia minima e massima di serraggio dei terminali.Attenzione!!!

nel collegare i cavi di potenza fare attenzione a non rimuovere i

cavi ausiliari e di accertarsi che siano ben stretti assieme al cavo di

potenza

Tipo mm Nm Ibft

BF9T 1-6 1,5-1,8 1,1-1,5

BF12T 1-6 1,5-1,8 1,1-1,5

BF18T 1-6 1,5-1,8 1,1-1,5

BF26T 2,5-6 2,5-3 1,8-2,2

BF38T 2,5-16 2,5-3 1,8-2,2

BF40 2,5-16 2 2,24-2,88

BF50 4-50 4-5 2,95-3,69

BF65 4-50 4-5 2,95-3,69

BF80 6-50 4-5 2,95-3,69

CL04 2,5-16 1,4 1,02

Generator contactor

TG1.

Terminals sequence:

T1

-

T2

-

T3

-

T4

Generator input

Mains input

Load output

Mains contactor

TR1.

Terminals sequence:

T1

-

T2

-

T3

-

T4

Load connection

X0

.

Terminals sequence:

U

-

V

-

W

-

N

Generator phase 1: T1

Generator phase 2: T2

Generator phase 3: T3

Generator neutral: T4

Common earth connection

(Genarator, Mains, Load)

Mains phase 1: T1

Mains phase 2: T2

Mains phase 3: T3

Mains neutral: T4

Phase 1 load:

U

Phase 2 load: V

Phase 3 load:

W

Neutral load: N

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 34

WARNING !! If the installation of the product is not in accordance to the specifics descripted above, can cause problems in terms of

functionality and can also compromises warranty conditions. Then PRAMAC srl won’t be responsible for any direct or not direct damage

due to wrong installation.

4.1.2 - Monophase connection

Generator neutral:

to use maximum contactor

power, poles T3 and T4

must be connected

togheter; T3+T4=Neutral.

By this connection the

max current of the

contactor is Ith x 1,6

Generator phase:

to use maximum contactor

power, poles T1 and T2

must be connected

togheter; T1+T2=phase.

By this connection the

max current of the

contactor is Ith x 1,6

Mains phase:

to use maximum contactor

power, poles T1 and T2

must be connected

togheter: T1+T2=phase.

By this connection the

max current of the

contactor is Ith x 1,6

Mains neutral:

to use maximum contactor power,

poles T3 and T4 must be connected

togheter: T3+T4=Neutral. By this

connection the max current of the

contactor is Ith x 1,6

Generator contactor

TG1.

Terminals sequence:

T1

-

T2

-

T3

-

T4

Mains contactor

TR1.

Terminals sequence:

T1

-

T2

-

T3

-

T4

Load connection

X0

.

Terminals sequence:

U

-

V

-

W

-

N

Load phase:

to use maximum terminals

power, poles U and V must

be connected togheter;

U+V=Phase.

Load neutral:

to use maximum terminals

power, poles W and N must

be connected togheter:

W+N=Neutral.

Generator input

Mains input

Load output

Common earth connection

(Genarator, Mains, Load)

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 35

Cables connection and contactors terminals serration must be in accordance to the following specifics

Contactor type (check the type

installed in the panel.

Minimum and maximum section

of flexible wire connected

without termination

Contactors terminals min and max tightening torque.

Warning!!! Don’t move auxiliary wires when you connect the power

cables and check that are connected togheter both power and

auxiliary wires.

Tipo mm Nm Ibft

BF9T 1-6 1,5-1,8 1,1-1,5

BF12T 1-6 1,5-1,8 1,1-1,5

BF18T 1-6 1,5-1,8 1,1-1,5

BF26T 2,5-6 2,5-3 1,8-2,2

BF38T 2,5-16 2,5-3 1,8-2,2

BF40 2,5-16 2 2,24-2,88

BF50 4-50 4-5 2,95-3,69

BF65 4-50 4-5 2,95-3,69

BF80 6-50 4-5 2,95-3,69

CL04 2,5-16 1,4 1,02

WARNING !! If the installation of the product is not in accordance to the specifics descripted above, can cause problems in terms of

functionality and can also compromises warranty conditions. Then PRAMAC srl won’t be responsible for any direct or not direct damage

due to wrong installation.

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 36

4.2 - Panel electrical drawing

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 37

4.3 - Diesel engine auxiliary connection

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 38

4.4 - Gasoline engine auxiliary connection

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 39

5 - AT206 PANEL PROGRAMMATION INSTRUCTION

5.1 - Programmation menu access description

With the board in RESET position, press TEST button for 5 seconds; after that, the entrance in the menu is showed by the display with the first code of

the parameter “U.01”.

This procedure permit to enter only in the “User menu”; the description of the parameters is at par 5.3.

To have access to complete menu (advanced menu), you need a different password; please contact the dealer or the manufacturer. The complete

description of all the parameters is in the par 5.4

5.2 - Parameters modification instructions

TEST button permit to see the value of the parameter

START button permit to increase the value

STOP button permit to decrease the value

RESET button save the value of the parameter and exit from it

MEAS button permit to change (increase) the number of the parameter in a menu

MAN button permit to change (increase) the number of the menu

To exit from programmation, press RESET than AUT buttons

5.3 - User menu parameters

5.4 - Advanced menu parameters

Setup Description Range Default

Group 1 Panel nominal data

P1.01 Nominal frequence 50Hz= 0 60Hz=1 0

.02 TA report (2000 =10000/5) 1…2000 1

.03 System 0=220M 1=220T

2=380T 0

Group 2 Engine start-up

P2.01 500 rpm signal from alternator or gen. (started engine) 1=altmm 0=gen

2=altes 2

.02 Started engine alternator voltage threshold 3-30V 10

.03 Started engine generator voltage threshold 20-500V 60

Setup Description Range Default

Group 1 Test

U.01 Automatic test interval time 1 – 30days / 1-4 week 3 days / 1 week

U.02 Test duration 1 – 30 min 10 min

U.03 Test start time 00:00 – 23:59 10:00

U.04 Test with load 0=load 1=a vuoto 1

U.05 Clock 0=no 1=yes 0

U.06 weekly / days 0=week 1=days 0

U.07 day of the week 1=Mon 2=Tuesd 3=Wed. etc.

7

Group2 Various

U.08 Siren relay closing time 0 – 60 sec 20 sec

U.09 Engine departure delay from EJP start 0 – 99 min 25 min

U.10 Switching delay for EJP/T(1 wire) 0 – 30 min 5 min

Group3 Clock setting

U.08 Time 00:00 – 23:59 00:00

U.09 day of the week 1=Mon 2=Tuesd 3=Wed etc. 7

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 40

.04 Starting with power failure On=1 Off=0 1

.05 Preheating time 1-60 sec 30

.06 Number of starting attempts 1-10 5

.07 Duration of starting attempts 1-30sec 5

.08 Pause time within starting attempts 1-20sec 10

.09 Not active

.10 Alarm enabling delay at starting (oil/V/freq.) 1-60sec 10

.11 Air time 0-10 sec 5

.12 Air switch-off threshold 30-200V 100

Group 3 Motor stop

P3.01 Stop times (electromagnet closing time) 1-30sec 15

.02 Decelerated funct. time 1-60 sec 30

.03 Cooling time 1 – 300sec 120

Group 4 Protections

P4.01 Minimum frequency (50 Hz) 80 – 100 % 90%

.02 Maximum frequency (overspeed) (50 Hz) 100 – 120% 110%

.03 Maximum frequency al. tripping delay 0-15 sec 5 sec

.04 Battery minimum frequency 7-12V 9

.05 Battery maximum frequency 13 – 17V 15V

.06 Load maximum current 10 – 2550 50A

.07 Maximum current delay 0 – 600sec 10

.08 Tripping delay of “500rpm failure” (strap breaking) 0 –10 sec 5

.09 “Mechanical failure” tripping delay 0 - 10 sec 5

Group 5 Various Range Default

P5.01 Generator and network contactor closing delay 0,1 –5 sec 1

P5.02 Remote start input function 0=nor 1=ejp

2=ejpt 3=scr 0

P5.03 Re-commutation lock on network in case of alarm during EJP

/EJPT / SCR 1 = on

0 = off 0

P5.04 Counter value 0 – 999.999 0

Group 6 Programmable outputs

P6.01 Progr. Relay (terminal 63)

air 0

glow plugs 1

alarm 2

air

P6.02 Progr. relay (terminal 53 - 54)

alarm 0

decelerator 1

electromagnet 2

alarm

P6.03 Progr. relay (terminal 62)

siren 0

alarm 1

siren

Cod.Doc.AT206 PRAMAC - installator guide - IT,EN.doc Pagina 41

Group 7 Network parameters

P7.01 Mains voltage minimum threshold 160 – 230Vac 195Vac

.02 Mains voltage maximum threshold 253 – 345Vac 299Vac

.03 Mains voltage time out of the limits 1 – 9999 sec 5 sec

.04 Mains voltage return time within the limits 01– 9999 sec 10 sec

Group 8 Group parameters

P8.01 Group voltage minimum threshold 160 – 230Vac 195Vac

.02 Group voltage maximum threshold 253 – 345Vac 299Vac

.03 Group voltage delay out of the limits 1 – 9999 sec

5 sec

.04 Group voltage time within the limits 1 – 9999 sec 20 sec

Note : Range P7.01, P7.02, P8.01 E P8.02 are in reference to 400V if P1.03 =2

Alarms

Setup Description Range Default

0=no 1=yes

A1 Engine overtemperature yes/no yes

A1.01 Stop without cooling yes/no yes

A1.02 Stop with cooling yes/no no

A1.03 Siren relay yes/no yes

A1.04 Alarm relay (if enabled see P6.02) yes/no yes

A1.05 Not active yes/no yes

A2 Oil low pressure yes/no yes

A2.01 Stop without cooling yes/no yes

A2.02 Stop with cooling yes/no no

A2.03 Siren relay yes/no yes

A2.04 Alarm relay (if enabled) yes/no yes

A2.05 Not active yes/no yes

A3 Avaria meccanica yes/no yes

A3.01 Stop without cooling yes/no yes

A3.02 Stop with cooling yes/no no

A3.03 Siren relay yes/no yes

A3.04 Alarm relay (if enabled) yes/no yes

A3.05 Not active yes/no yes

A4 500 rpm failure (strap breaking) yes/no yes

A4.01 Stop without cooling yes/no yes

A4.02 Stop with cooling yes/no no

A4.03 Siren relay yes/no yes

A4.04 Alarm relay (if enabled) yes/no yes

A4.05 Not active yes/no yes

A5 Overspeed (maximum frequency) yes/no yes

A5.01 Stop without cooling yes/no yes

A5.02 Stop with cooling yes/no no

A5.03 Siren relay yes/no yes

A5.04 Alarm relay (if enabled) yes/no yes

A5.05 Not active yes/no yes

A6 Minimum frequency yes/no yes

A6.01 Stop without cooling yes/no yes

A6.02 Stop with cooling yes/no no

A6.03 Siren relay yes/no yes

A6.04 Alarm relay (if enabled) yes/no yes

Table of contents

Popular Control Panel manuals by other brands

Bevco

Bevco IECAX480V125A Installation, operation and service manual

Notifier

Notifier AFP-300 Programming manual

DMP Electronics

DMP Electronics XR150 series quick start guide

VTS Medical Systems

VTS Medical Systems HMI WING HY manual

Sole Diesel

Sole Diesel SCO 11 Operator's manual

Frick

Frick QUANTUM maintenance