PRAWNTO MLG Series User manual

Prawnto Shrimp Machine Of Texas Co., Inc.

1

SHRIMP CUTTER

AND

DEVEINER

Models MLG SERIES

And MLG-BC

Prawnto Shrimp Machine Of Texas Co., Inc.

2

CONGRATULATIONS

You have just purchased one of the most exciting and serviceable machines you

have ever had in you operation. With proper care your PRAWNTO™ Shrimp

Machine will provide you years of quality service!

ATTENTION

Check your new PRAWNTO™ for freight damage immediately. If damage has

occurred, contact your United Parcel and report the nature of the damage. Also,

call us toll free at PRAWNTO SHRIMP MACHINE CO. OF TEXAS, INC. (From US –

1 800 426 7254, International – 001 903 527 4149) for a replacement machine.

WARRANTY

Prawnto Shrimp Machine Co. of Texas, Inc. Warrants the Prawnto™ Shrimp

Machine for one year against defects in parts and workmanship, including the electrical

motor, except for normal wear and tear of belts, rubber discs, roller and cutting blade

sharpness. Not withstanding the foregoing and except as to the electric motor, this

warranty is limited to a term of ninety days from date of purchase where the machine is

used for commercial processing of shrimp for its initial preparation for sale to retailers.

No warranty covers damage due to customer abuse or neglect. All warranty repair work

shall be performed at Prawnto Shrimp Machine Co. of Texas, Inc. with all shipping

costs to and from Prawnto™ to be paid by the purchaser. Proof and date of purchase

is a prerequisite to the effectiveness of any warranty. There are no warranties, which

Do not discard the original shipping

carton. The carrier will not honor a

claim without the ori

g

inal box.

Prawnto Shrimp Machine Of Texas Co., Inc.

3

extend beyond the description on the face hereof. Seller does not warrant

merchantability or fitness for a particular purpose.

OWNERS MANUAL CONTENT

WARRANTY................................................................................................................................................ 2

OWNERS MANUAL CONTENT............................................................................................................... 3

CHANGE CONTROL PAGE ..................................................................................................................... 4

PRAWNTO™ SHRIMP MACHINE.......................................................................................................... 5

AVAILABLE PRODUCTS.......................................................................................................................... 6

ACCESSORIES ............................................................................................................................................. 9

ADDITIONAL PRODUCTS ........................................................................................................................... 12

IMPORTANT SAFEGUARDS ................................................................................................................. 13

CLEANING PROCEDURES.................................................................................................................... 14

MLG SERIES............................................................................................................................................. 14

CLEANING PROCEDURES.................................................................................................................... 16

MLG-BC.................................................................................................................................................. 16

MAINTENANCE........................................................................................................................................ 19

PREVENTATIVE MAINTENANCE ................................................................................................................ 20

ALIGNMENT............................................................................................................................................. 21

MLG-SERIES............................................................................................................................................ 21

ALIGNMENT............................................................................................................................................. 23

MLG-BC.................................................................................................................................................. 23

TROUBLE SHOOTING............................................................................................................................ 28

MLG-SERIES............................................................................................................................................ 28

MLG-BC.................................................................................................................................................. 29

PARTS AND ACCESSORIES .................................................................................................................. 30

DIAGRAMS................................................................................................................................................ 31

PARTS LIST............................................................................................................................................... 38

NOTES ........................................................................................................................................................ 42

Prawnto Shrimp Machine Of Texas Co., Inc.

4

CHANGE CONTROL PAGE

Last Update Change

07/24/03 New updated version of Owners

Manual

5/13/06 MLG-BC machine and

components added to manual

Prawnto Shrimp Machine Of Texas Co., Inc.

5

PRAWNTO™ SHRIMP MACHINE

We manufacture the "PRAWNTO™shrimp cutter and deveiner - the most dependable

piece of equipment of its kind on the market today. Because it is powered by a ¼ h.p.

motor and constructed of aluminum and stainless steel, and high quality standards are

used in the manufacturing processes, we offer a 1-year warranty.

What exactly does the PRAWNTO™do?

It cuts the shrimp down the back to any depth while destroying most of the sand vein.

The shell is then easily removed by "pinching" or pulling it off from the underside. The

tail can be removed or left on for any presentation required.

What about cutting different sizes of shrimp?

Here is the beauty of the Prawnto... It's self-adjusting for different sizes. With our NEW

patented roller system only the depth knob is necessary for different depths of cut.

Can the PRAWNTO™butterfly?

Yes. The cut will be deep in the front to fan the shrimp for better presentation while

stopping at the tail section for efficient breading or skewering. Round cut and western

cuts are also possible with the Prawnto™.

Prawnto Shrimp Machine Of Texas Co., Inc.

6

How fast is the Prawnto™?

U-12 300 lbs.

16-20 200 lbs.

26-30 128 lbs.

36-50 84 lbs.

50-60 65 lbs.

90-110 36 lbs.

What are the size ranges the PRAWNTO™can handle?

U10 down to 90/115 count green headless product. Head-on shrimp can also be run

through the Prawnto.

Will there be any damage or miss-cut shrimp?

NO. With proper, simple maintenance and cleaning, the cutting blade will always cut

down the center of the shrimp's back each and every time.

AVAILABLE PRODUCTS

The Prawnto™ Shrimp Machine is available in three models:

Prawnto™ Shrimp Machine MLG-3

Specifications:

Dimensions: W-11 ½", L-17 ¼",

Hgt.-10 ½"

Shipping Weight: 32 Pounds

Electrical: 115V, 60 C.P.S. ¼ H.P.,, 5.1

amp

Also 220V, 50 & 60 C.P.S., 2.7 amp

Listings:

An inexperienced operator can cut

shrimp at the rate of 4,000 shrimp

per hour. That rate translates into

the following pounds per hour:

An experienced operator can cut

shrimp at the rate of 6000 shrimp

per hour. That rate translates into

the following pounds per hour

U-12 500 lbs.

16-20 330 lbs.

26-30 214 lbs.

36-50 140 lbs.

50-60 109 lbs.

90-110 60 lbs.

Prawnto Shrimp Machine Of Texas Co., Inc.

7

MLG-3 (fig 1.1)

Prawnto™ Shrimp Machine MLG-2K

MLG-2K (Fig 1.2)

Prawnto™ Shrimp Machine MLG-4

MLG-4 (shown without cover) (fig 1.3)

Specifications:

Dimensions: W-11 ½", L-17 ¼", Hgt.-

10 ½"

Shipping Weight: 31 Pounds

Electrical: 115V, 60 C.P.S. ¼ H.P.,,

5.1 amp

Also 220V, 50 & 60 C.P.S., 2.7 amp

Listings:

Specifications:

Dimensions: W-11 ½", L-17 ¼",

Hgt.-10 ½"

Shipping Weight: 34

Electrical: 115V, 60 C.P.S. ¼ H.P.,,

5 amp

Internal Cooling Fan for continuous

operation

Also 220V, 50 & 60 C.P.S., 2.7 amp

Listings:

Prawnto Shrimp Machine Of Texas Co., Inc.

8

Introducing

Prawnto Belly-Cut Shrimp Machine MLG-BC

Prawnto continues to be the innovative leader in shrimp preparation with the

introduction of the NEW Prawnto Belly-Cut Shrimp Machine MLG-BC. Built on the

same chassis as the Prawnto Shrimp Machine MLG Series the MLG-BC allows you

to cut and de-vein the shrimp along the belly following the natural curve of the shrimp’s

body.

Like the MLG Series the MLG-BC is adjustable for various depths of cut and is

designed for ease of use, and is easily maintained.

The Prawnto Belly-Cut Shrimp Machine MLG-BC along with the traditional Prawnto

Shrimp Machine MLG Series allows you to provide more variety of shrimp products for

your customers.

Specifications:

Dimensions: W-11 ½", L-17 ¼", Hgt.-10 ½"

Shipping Weight: 34

Electrical: 115V, 60 C.P.S. ¼ H.P.,, 5 amp

Internal Cooling Fan for continuous operation

Prawnto Shrimp Machine Of Texas Co., Inc.

9

MLG-BC (Fig 1.4)

Accessories

The following Prawnto Accessories when used with the Prawnto Shrimp Machine

MLG Series and the NEW Prawnto Belly-Cut Shrimp Machine MLG-BC allow for

quicker and more efficient shrimp production.

Prawnto Shrimp Machine Of Texas Co., Inc.

10

Speed Pan Model 600

MLG-3 With Speed Pan Model 600

(fig 1.5)

Processing Table Model 900

Designed with built-in funnel for

faster operation if Model 900

processing station is not used.

Fits any model Prawnto ever

sold.

Prawnto Shrimp Machine Of Texas Co., Inc.

11

(fig 1.6)

Processing Table Model 900

(Tub not included)

Welded 300 series stainless

steel, NSF listed with 5" casters,

two locking. Ergonomically

correct for speed and comfort

while allowing for the fastest

speed of operation. It is a self-

contained processing station

that can be used anywhere

there is a power plug.

No assembly required

Prawnto Shrimp Machine Of Texas Co., Inc.

12

Additional Products

EZ Shucker Model EZ-100

Model EZ-100 (Fig 1.8)

The EZ Shucker quickly and easily opens oysters and other bivalves, including clams,

scallops and mussels.

The EZ Shucker is safe and easy. The knife is protected by a lexan blade guard and

is easily controlled by the machine handle. The blade never points at the hand while

the knife is moved with a natural patented shucking motion.

The EX Shucker is crafted from high-quality stainless steel and commercial grade

plastics. There is a 90-day guarantee on all parts, material and labor.

Specifications:

Height 19”

Width 12”

Length 12”

Ship Weight 13 lbs

Prawnto Shrimp Machine Of Texas Co., Inc.

13

The EZ-Shucker easily separates clusters of oysters into singles so you can save up to

50% off premium prices for select grades and still purchase top quality products.

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions

should always be followed.

Use the following important safeguards whenever using your PRAWNTO SHRIMP

CUTTER:

∗Read all instructions

∗For commercial use only

∗To protect against risk of electrical shock do not immerse

base in water or other liquid.

∗Unplug from outlet when not in use, before putting on or

taking off part and before cleaning.

∗Avoid contacting moving parts. Never put fingers or utensils

into feed or discharge areas. Never take round cutting guard

off when motor is running and never operate without safety

guard secured.

∗Do not operate any appliance with a damaged cord or plug

or after the appliance malfunctions, or is dropped or

damaged in any manner. Return appliance to the nearest

authorized service facility for examination, repair or electrical

or mechanical adjustment.

∗The use of attachments not recommended or sold by the

appliance manufacturer may cause fire, electrical shock or

injury.

∗Do not let cord hang over edge of table or counter or touch

hot surfaces.

Prawnto Shrimp Machine Of Texas Co., Inc.

14

∗Always operate Prawnto Shrimp Machine with all covers

and guards in place.

∗To avoid injury, always have Prawnto Shrimp Machine in

place before starting.

CLEANING PROCEDURES

MLG Series

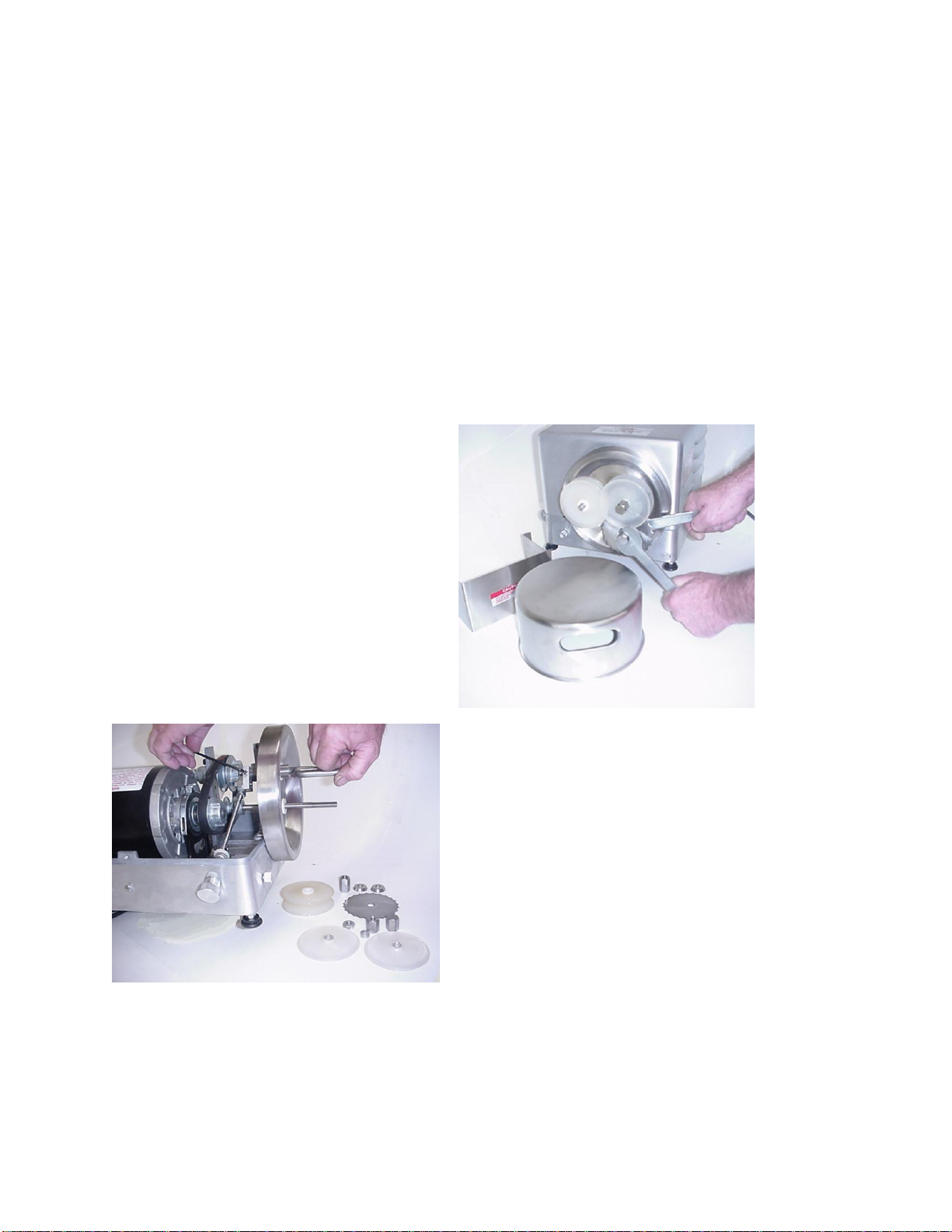

(fig 2.1)

(Fig 2.2)

1. Be sure to unplug the machine

before cleaning.

2. Daily – Remove the safety guard

#211 by loosening the two thumb

screws securing it. Remove the

round cutting guard #208. With

the two 5/8” wrenches provided in

your tool kit, remove the blade

#310S and the set of two rubber

discs #313, and the nuts and

washers securing those parts.

(see figure 2.1)

3. With step 2 accomplished;

remove the motor cover #206

by loosening the Phillips screw

on each side. Next, remove

the short shaft #504 by pulling

it out from the front splash area

after loosening the set screw

securing it. (see figure 2.2)

Prawnto Shrimp Machine Of Texas Co., Inc.

15

(Fig 2.3)

(Fig 2.4)

4. With the above parts removed

clean them in hot soapy water or

place in the dishwasher. Then

sanitized them.

5. Clean the splash area and food

zone with hot soapy water,

sanitize, then allow to air dry in a

clean protected area .

6. Replace the cutting parts,

aligning the blade and rubber

discs as shown in the

maintenance section of this

manual. Replace the round

cutting guard #208 and re-

secure the safety guard #211

with the thumbscrews. (See

figure 2.4)

7. Store machine in a clean,

protected place for further use.

Prawnto Shrimp Machine Of Texas Co., Inc.

16

CLEANING PROCEDURES

MLG-BC

Prawnto Shrimp Machine Of Texas Co., Inc.

17

(fig 3.1)

(Fig 3.2)

(Fig 3.3)

1. Be sure to unplug the machine

before cleaning.

2. Daily – Remove the safety guard

#211 by loosening the two thumb

screws securing it. Remove the

round cutting guard #208. With

the two 5/8” wrenches provided in

your tool kit, remove the blade

#310BC and the set of two rubber

discs #313, and the nuts and

washers securing those parts.

(see figure 3.1) 4. With step 2 accomplished;

Next, remove the shrimp guide

#101 by loosening and

removing the nut #510 and

backup nut #499BC. (see

figure 3.2)

6. With the above parts removed

clean them in hot soapy water or

place in the dishwasher. Then

sanitized them.

7. Clean the splash area and food

zone with hot soapy water,

sanitize, then allow to air dry in a

clean protected area .

Prawnto Shrimp Machine Of Texas Co., Inc.

18

(Fig 3.4)

8. Replace the cutting parts,

aligning the blade, rubber discs

and shrimp guide #1001 as

shown in the maintenance

section of this manual.

Replace the round cutting

guard #208 and re-secure the

safety guard #211 with the

thumbscrews. (See figure 3.4)

9. Store machine in a clean,

protected place for further use.

Prawnto Shrimp Machine Of Texas Co., Inc.

19

MAINTENANCE

™

The Plastic Guide Roller should be oiled DAILY with use.

Also oil the Plastic Guide Roller in the event of roller chatter

or squealing.

Prawnto Oil™ is recommended to increase the life of the cutting mechanism. Refer to

figure 4.1 and 4.2 below for oiling locations.

MLG Series (Fig 4.1) MLG-BC (Fig 4.2)

Regardless of the number of spacer washers between the

rubber discs, the blade should align to the center of the

discs.

For the alignment procedures follow directions in the Alignment section.

Prawnto Shrimp Machine Of Texas Co., Inc.

20

Preventative Maintenance

In the event of unusual noise it is recommended that the cover be

removed after the machine has been unplugged at the power source,

and these checks be made periodically:

9Feeder disks oiled

9Pulleys tight on the shaft

(Set screws tight)

9Shaft collars snug to the nylon washers and to shaft

(No in or out movement)

9Belt tension snug but not too tight

(About ¾” sag when pressure is applied between the motor pulley and top shaft

pulley)

Prawnto Shrimp Machine Co. of Texas, Inc. stocks all parts

and accessories for the Prawnto Shrimp Cutter. See the

section on Parts in this manual for information on ordering

parts and accessories

MLG Series (Fig 5.1) MLG-BC (Fig 5.2)

Other manuals for MLG Series

1

This manual suits for next models

4

Table of contents

Popular Commercial Food Equipment manuals by other brands

Blodgett

Blodgett BLT-E Series Installation operation & maintenance

Henny Penny

Henny Penny FlexFusion FPG-615 Operator's manual

Henny Penny

Henny Penny LOV LVE-102 Operator's manual

Polar Electro

Polar Electro G603 instruction manual

Cleveland

Cleveland AWC1 Specifications

IET Labs

IET Labs KVD-700 Series Operation manual