PRECISION DIGITAL PD755 User manual

PRECISION DIGITAL CORPORATION

19 Strathmore Road • Natick MA 01760 USA

Tel (800) 343-1001 • Fax (508) 655-8990

www.predig.com

DIGITAL METERS

Large Display Temperature Meters

Instruction Manual

• Handles Thermocouple and RTD Inputs with Simplicity

• J, K, T, E, R and S Thermocouples

• 100 ΩPlatinum RTDs (0.00385 or 0.00392 curve)

• Large Display Readouts: 2.3", 1.0" and 0.8" High

• Display Resolution

Thermocouples: 1°, Type T T/C Displayed to 1°or 0.1°

RTDs Resolution: 1°or 0.1°, Field Selectable

• Displays °F or °C, Field Selectable

• No Calibration Necessary – Factory Calibrated

• Maximum/Minimum Temperature Display

• Input Offset Adjustment

• NEMA 4X and Explosion-Proof Enclosures

• 115 or 230 VAC Power, Field Selectable

• 24 VDC Powered Models, Optional

• 24 VDC Isolated Power Supply Standard on AC Models

• 4 Visual Alarm Points with Front Panel LED Status Indication

• 2 or 4 Relays and/or 4-20 mA Output Options

Large Display Temperature Meters Instruction Manual

2

Visit our website

http://www.predig.com

Large Display Temperature Meters Instruction Manual

3

Table of Contents

INTRODUCTION ----------------------------------------------------------------------- 7

Ordering Information ------------------------------------------------------------------------7

Model PD755 --------------------------------------------------------------------------------7

Model PD756 --------------------------------------------------------------------------------7

Model PD757 --------------------------------------------------------------------------------8

Accessories ----------------------------------------------------------------------------------8

Safety Notice -----------------------------------------------------------------------------------9

Specifications-------------------------------------------------------------------------------- 10

Basic Temperature Meter -------------------------------------------------------------- 10

Options -------------------------------------------------------------------------------------- 12

Display Functions and Messages----------------------------------------------------- 14

SETUP AND PROGRAMMING -------------------------------------------------- 15

Overview--------------------------------------------------------------------------------------- 15

Disassembling the Meter----------------------------------------------------------------- 16

Disassembling the PD755 -------------------------------------------------------------- 16

Disassembling the PD756 -------------------------------------------------------------- 16

Disassembling the PD757 -------------------------------------------------------------- 17

Reassembling the Meter ----------------------------------------------------------------- 18

Reassembling the PD755 -------------------------------------------------------------- 18

Reassembling the PD756 -------------------------------------------------------------- 18

Reassembling the PD757 -------------------------------------------------------------- 18

Jumper Configuration--------------------------------------------------------------------- 19

Input Selection and Lockout Jumpers (Main PCB)------------------------------- 19

Relay Acknowledge Enable (Display PCB) ---------------------------------------- 19

Fail-Safe Operation of Relays (Options PCB)------------------------------------- 19

Power Selection----------------------------------------------------------------------------- 20

Overview------------------------------------------------------------------------------------ 20

Changing from 115 to 230 VAC Power --------------------------------------------- 20

Labeling Meter for 115 VAC, 230 VAC or 24 VDC------------------------------- 21

Connections---------------------------------------------------------------------------------- 21

Overview------------------------------------------------------------------------------------ 21

Wiring Instructions------------------------------------------------------------------------ 22

Power Connections ---------------------------------------------------------------------- 23

Signal Connections----------------------------------------------------------------------- 24

Enter, Acknowledgement, and Hold Connections -------------------------------- 26

Optional Relays & 4-20 mA Output Terminals ------------------------------------ 27

Isolated 4-20 mA Output Transmitter Connections ------------------------------ 28

Large Display Temperature Meters Instruction Manual

4

Programming -------------------------------------------------------------------------------- 29

Overview------------------------------------------------------------------------------------ 29

Select Type of Input Signal T/C or RTD----------------------------------------- 29

ENTER Button Functionality ------------------------------------------------------- 30

ACK Button Functionality ----------------------------------------------------------- 30

Magnetic Reed Switch Functionality --------------------------------------------- 30

General Programming Description --------------------------------------------------- 31

Five Basic Digit/Display-Setting Instructions ----------------------------------- 31

Programming the Basic Meter--------------------------------------------------------- 32

Selecting Type of T/C or RTD (TYPE) -------------------------------------------- 33

Select °F or °C (f or C) ------------------------------------------------------------ 33

Alarm Setup and Set Points Programming----------------------------------------- 34

Overview -------------------------------------------------------------------------------- 34

Set Relays for Manual or Automatic Reset ------------------------------------- 34

Set Relays for Fail-Safe Operation ----------------------------------------------- 34

Setup for Latching or Non-Latching Relays (SetuP) ------------------------- 35

Alarm Set and Reset Points Programming ------------------------------------- 36

Programming Alarm Points Using Set Points (setpts) Menu ------------- 37

Alarm Set and Reset Programming Confirmation ---------------------------- 37

Isolated 4-20 mA Output Transmitter Option -------------------------------------- 38

4-20 mA Output Programming (output) ---------------------------------------- 38

4-20 mA Output Programming Confirmation ----------------------------------- 38

Input Offset Adjustment (OFFSEt) ---------------------------------------------------- 39

Lockout Jumper --------------------------------------------------------------------------- 39

OPERATION -------------------------------------------------------------------------- 40

Overview--------------------------------------------------------------------------------------- 40

Basic Meter Operation -------------------------------------------------------------------- 41

Overview------------------------------------------------------------------------------------ 41

Maximum/Minimum Temperature Display------------------------------------------ 41

Relays Operation --------------------------------------------------------------------------- 42

Overview------------------------------------------------------------------------------------ 42

Relays Auto Initialization---------------------------------------------------------------- 42

Fail-Safe Operation ---------------------------------------------------------------------- 42

Front Panel LEDs------------------------------------------------------------------------- 43

Acknowledging Relays ------------------------------------------------------------------ 45

Switching Inductive Loads-------------------------------------------------------------- 46

4-20 mA Output Operation ------------------------------------------------------------- 46

RECALIBRATION (CALIB) -------------------------------------------------------- 47

Calibration Error (error) --------------------------------------------------------------- 47

Recommended Calibration Points ---------------------------------------------------- 48

Minimum Input Span--------------------------------------------------------------------- 48

Calibration Verification ------------------------------------------------------------------- 48

Large Display Temperature Meters Instruction Manual

5

INSTALLATION ---------------------------------------------------------------------- 49

Wall Mounting Instructions ------------------------------------------------------------- 49

PD755 Mounting -------------------------------------------------------------------------- 49

PD756 Mounting -------------------------------------------------------------------------- 49

PD757 Mounting -------------------------------------------------------------------------- 49

Panel Mounting Instructions------------------------------------------------------------ 50

PD755 Panel Mounting Instructions ------------------------------------------------- 50

PD757 Panel Mounting Instructions ------------------------------------------------- 51

Pipe Mounting Instructions for PD755 and PD756 ------------------------------ 53

Explosion-Proof Control Stations----------------------------------------------------- 55

OPTION CARD REMOVAL & INSTALLATION ----------------------------- 56

Option Card Installation in PD755 ---------------------------------------------------- 56

Option Card Installation in PD756 ---------------------------------------------------- 58

Option Card Installation in PD757 ---------------------------------------------------- 59

MODEL SENSITIVE ILLUSTRATIONS ---------------------------------------- 60

Removing the Display PCB ------------------------------------------------------------- 60

Locations of Connections and Jumpers-------------------------------------------- 61

Jumper Arrays and Status LEDs ------------------------------------------------------ 63

Front Panel Displays ---------------------------------------------------------------------- 65

Overall Dimensions ------------------------------------------------------------------------ 66

Wall Mounting Dimensions-------------------------------------------------------------- 67

PROGRAMMED PARAMETER SETTINGS ---------------------------------- 69

OTHER PRECISION DIGITAL PRODUCTS---------------------------------- 70

Large Display Temperature Meters Instruction Manual

6

List of Figures

Figure 1. Input Power Label ................................................................. 21

Figure 2. Input Power Connections for 756 and 757 .......................... 23

Figure 3. Four-Wire RTD Connections ................................................ 24

Figure 4. Three-Wire RTD Connections............................................... 24

Figure 5. Two-Wire RTD Connections ................................................. 25

Figure 6. Thermocouple Connections................................................. 25

Figure 7. External Control Connections.............................................. 26

Figure 8. Relay and 4-20 mA Output Terminals .................................. 27

Figure 9. Output Loop Powered by Meter ........................................... 28

Figure 10. Output Loop Powered from External Power Supply........... 28

Figure 11. JP1 Input Signal Selection Array. ......................................... 29

Figure 12. Reed Switch Operation.......................................................... 30

Figure 13. AC and DC Loads Protection ................................................ 46

Figure 14. Low Voltage DC Loads Protection ....................................... 46

Figure 15. PD755 Panel Mounting .......................................................... 50

Figure 16. PD757 Panel Mounting .......................................................... 51

Figure 17. PD757 Panel Mounting Cutout Dimensions......................... 51

Figure 18. 755 Pipe Mounting Assembly................................................ 53

Figure 19. 756 Pipe Mounting Assembly................................................ 53

Figure 20. Pipe Mounting Plate............................................................... 54

Figure 21. Explosion-proof Control Station........................................... 55

Figure 22. Removing the PD755 Display PCB ....................................... 56

Figure 23. PD755 Options PCB Standoffs Location.............................. 56

Figure 24. PD755 Options PCB Installation ........................................... 57

Figure 25. PD756 Option PCB Installation ............................................. 58

Figure 26. PD756 Option PCB Installed ................................................. 58

Figure 27. PD757 Option PCB Installation ............................................. 59

Figure 28. Removing the Display PCB on PD755 .................................. 60

Figure 29. Removing the Display PCB on PD756 .................................. 60

Figure 30. Removing the Display PCB on PD757 .................................. 61

Figure 31. PD755 Connectors and Jumper Location ............................ 61

Figure 32. PD756 Connectors and Jumper Location ............................ 62

Figure 33. PD757 Connectors and Jumper Location ............................ 62

Figure 34. PD755 Jumper Arrays and Status LED Identification ......... 63

Figure 35. PD756 Jumper Arrays and Status LED Identification ......... 63

Figure 36. PD757 Jumper Arrays and Status LED Identification ......... 64

Figure 37. PD755 Front Panel Display.................................................... 65

Figure 38. PD756 Front Panel Display.................................................... 65

Figure 39. PD757 Front Panel Display.................................................... 65

Figure 40. PD755 Overall Dimensions.................................................... 66

Figure 41. PD756 Overall Dimensions.................................................... 66

Figure 42. PD757 Overall Dimensions.................................................... 67

Figure 43. PD755 Wall Mounting Dimensions ....................................... 67

Figure 44. PD755 Wall Mounting Screw Installation ............................. 67

Figure 45. PD756 Wall Mounting Dimensions ....................................... 68

Figure 46. PD757 Wall Mounting Dimensions ....................................... 68

Large Display Temperature Meters Instruction Manual

7

INTRODUCTION

The Large Display Temperature Meters are housed in rugged, NEMA 4X

or explosion-proof enclosures. These meters handle temperature display

and alarm applications with simplicity, accuracy, and reliability. They

accept the common thermocouples J, K, T, E, R, and S or 100 Ω

platinum RTDs. Options include up to 4 relays for alarms as well as an

isolated 4-20 mA transmitter output. An isolated 24 VDC power supply is

available as standard feature on AC powered models to power the

transmitter output.

Ordering Information

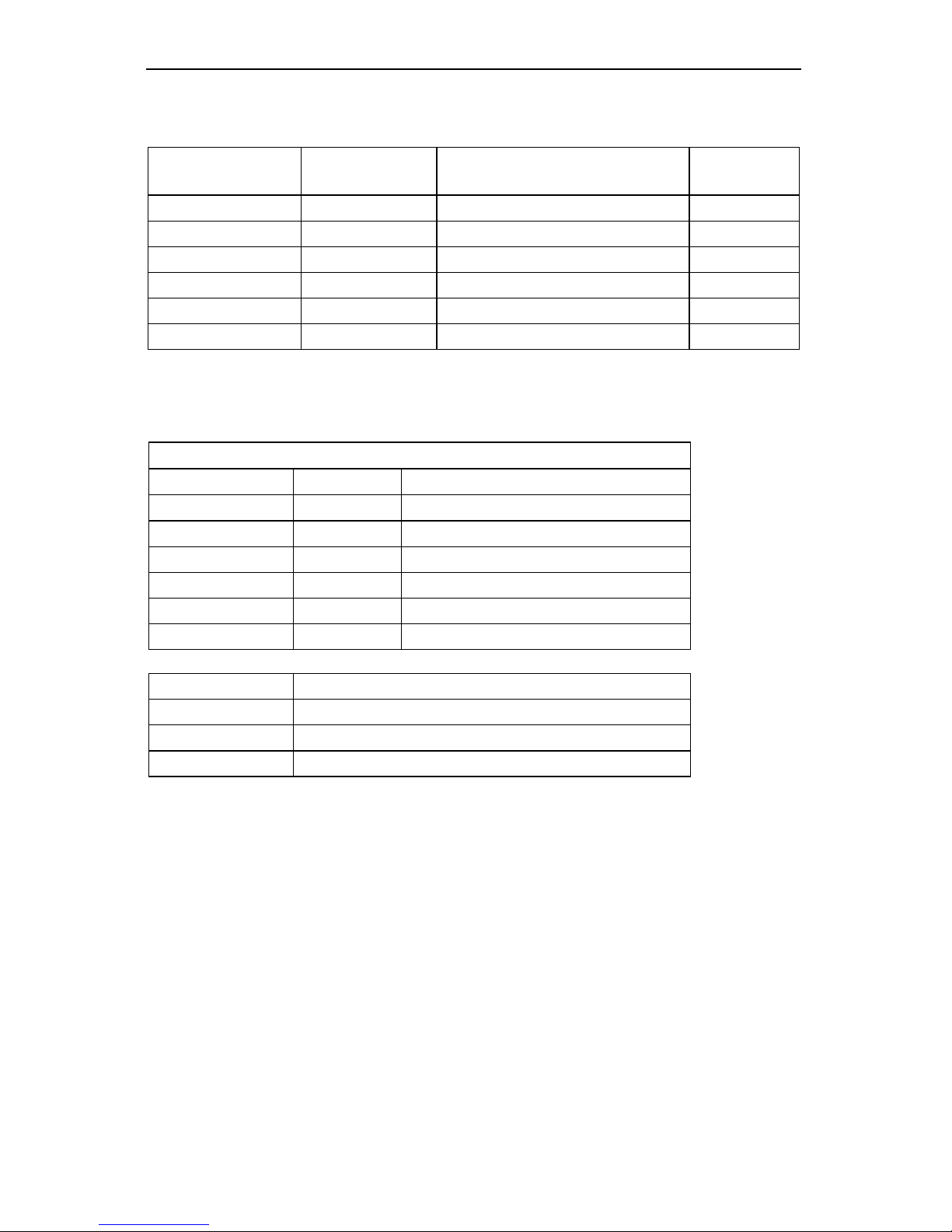

Model PD755

115/230 VAC

MODEL

24 VDC

MODEL

DESCRIPTION Option

Card*

PD755-N PD755-2-N No Options

PD755-44 PD755-2-44 2 Relays PD474

PD755-45 PD755-2-45 4-20 mA Output PD475

PD755-46 PD755-2-46 2 Relays + 4-20 mA Output PD476

PD755-47 PD755-2-47 4 Relays PD477

PD755-48 PD755-2-48 4 Relays + 4-20 mA Output PD478

Model PD756

115/230 VAC

MODEL

24 VDC

MODEL

DESCRIPTION Option

Card*

PD756-N PD756-2-N No Options

PD756-44 PD756-2-44 2 Relays PD474

PD756-45 PD756-2-45 4-20 mA Output PD475

PD756-46 PD756-2-46 2 Relays + 4-20 mA Output PD476

PD756-47 PD756-2-47 4 Relays PD477

PD756-48 PD756-2-48 4 Relays + 4-20 mA Output PD478

*Option Cards (When Ordered Separately)

Large Display Temperature Meters Instruction Manual

8

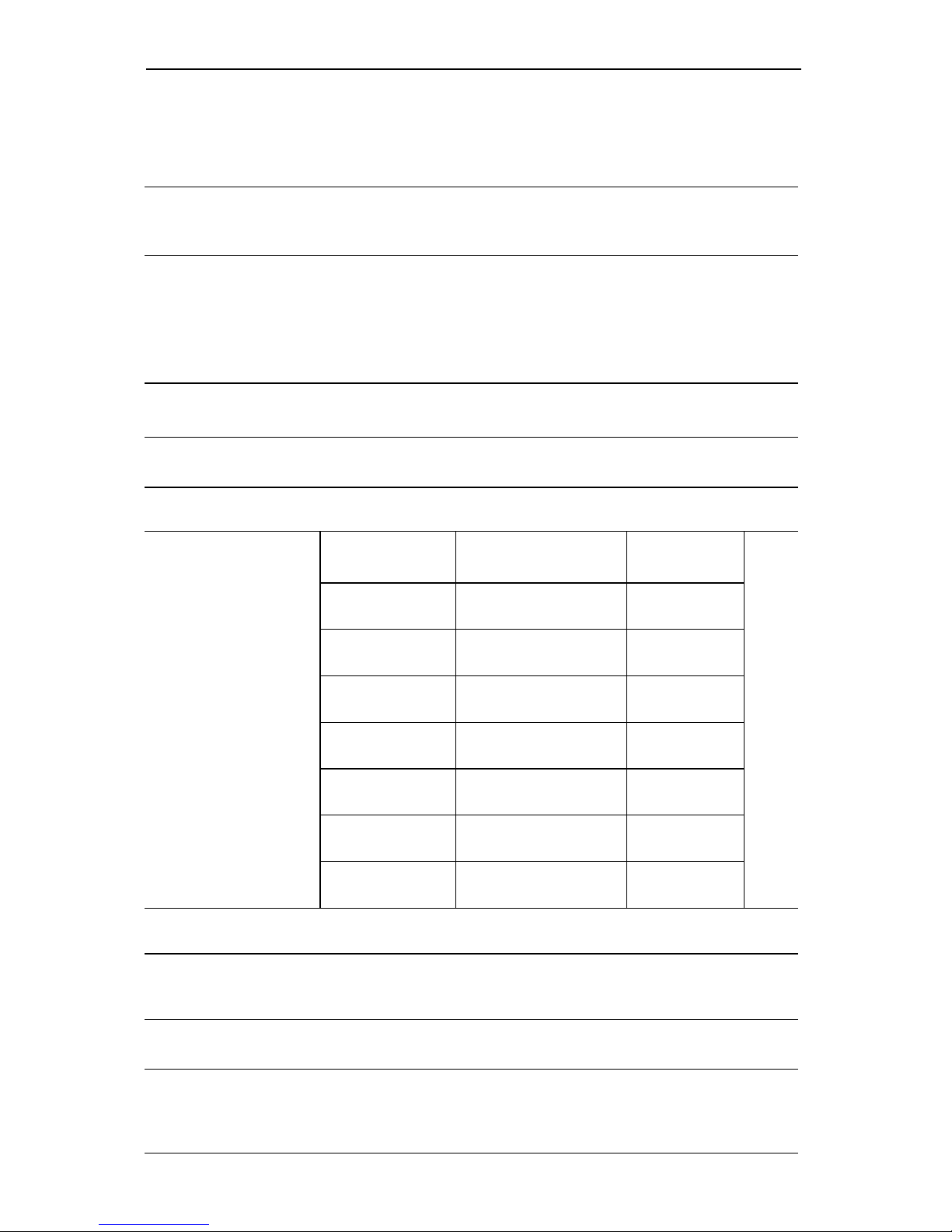

Model PD757

115/230 VAC

MODEL

24 VDC

MODEL

DESCRIPTION Option

Card*

PD757-N PD757-2-N No Options

PD757-34 PD757-2-34 2 Relays PD374

PD757-35 PD757-2-35 4-20 mA Output PD375

PD757-36 PD757-2-36 2 Relays + 4-20 mA Output PD376

PD757-37 PD757-2-37 4 Relays PD377

PD757-38 PD757-2-38 4 Relays + 4-20 mA Output PD378

*Option Cards (When Ordered Separately)

Accessories

Control Stations

Model Switches Labels

PDA2451-E 1 ENTER

PDA2451-A 1 ACK

PDA2451-R 1 RESET

PDA2452-EA 2 ENTER and ACK

PDA2452-ER 2 ENTER and RESET

PDA2453-EAR 3 ENTER, ACK, and RESET

PDA-MAG Magnet Assembly for PD656 & PD756

PDA6504 Panel Mounting Kit for PD757**

PDA6554 Panel Mounting Kit for PD755**

PDA6545 2" Pipe Mounting Kit for PD755 and PD756

** These panel mounting kits are not intended to provide waterproof protection to

the panel.

Large Display Temperature Meters Instruction Manual

9

Safety Notice

!

CAUTION: Read complete

instructions prior to installation and

operation of the meter.

WARNING: Risk of electric shock.

!

Observe all safety regulations. Electrical wiring should be performed in

accordance with all applicable national, state, and local codes to

prevent damage to the meter and ensure personnel safety.

!

It is recommended to use this meter in a fail-safe system that

accommodates the possibility of meter failure or power failure.

WARNING

Hazardous voltages exist within enclosure. Installation and service should

be performed only by trained service personnel.

AVERTISSEMENT

Les pièces à l'intérieur du boîtier portent des tensions dangereuses. Seules

des personnes qualifiées et bien entrainées devraient entreprondre

l'ótalonnage et la maintenance.

Disclaimer

The information contained in this document is subject to change without notice.

Precision Digital makes no representations or warranties with respect to the

contents hereof, and specifically disclaims any implied warranties of

merchantability or fitness for a particular purpose.

Large Display Temperature Meters Instruction Manual

10

Specifications

Except where noted all specifications apply to operation at +25°C.

Basic Temperature Meter

INPUTS Field selectable: type J, K, T, E, R, or S thermocouples with 1°

resolution; type T to 0.1°; 100 Ωplatinum RTD (0.00385 or

0.00392 curve) to 1°or 0.1°resolution.

DISPLAY 4½ digit, high efficiency red LED, automatic lead zero blanking,

F or C displayed to indicate Fahrenheit or Celsius.

Digit Size:

PD755– 1.0" (25.4 mm) high

PD756– 0.8" (20.3 mm) high

PD757– 2.3" (58.0 mm) high

COLD JUNCTION

REFERENCE

Automatic, fixed, no user calibration needed.

INPUT

IMPEDANCE

Greater than 100 kΩ

LOCKOUT Jumper JP2, located on Main PCB, restricts modification of set

values.

ACCURACY Input

Type Range Accuracy

Type J T/C –328°to 1382°F

–200°to 750°C

±2°F

±1°C

Type K T/C –328°to 2498°F

–200°to 1330°C

±2°F

±1°C

Type T T/C –330.0°to 760.0°F

–200.0°to 404.0°C

±2°F

±1°C

Type E T/C –328°to 1832°F

–200°to 1000°C

±2°F

±1°C

Type R T/C 32°to 3213°F

0°to 1767°C

±5°F

±3°C

Type S T/C 40°to 3214°F

4°to 1768°C

±6°F

±3°C

100 ΩRTD –328.0°to 1382.0°F

–200.0°to 750.0°C

±0.7°F

±0.4°C

RECALIBRATION All ranges are calibrated at the factory. Recalibration is

recommended at least every 12 months.

INPUT OFFSET Programmable to ±100% FS display. This parameter allows the

user to apply an offset value to the input temperature being

displayed.

SENSOR BREAK

DETECTION

Open sensor circuit indicated by display flashing OPEn. All relays

and alarm status LEDs go to alarm state.

MAX/MIN

TEMPERATURE

DISPLAY

The maximum and minimum temperature reached by the process

is stored in memory until cleared (reset) by the user or until power

to the meter is turned off. Max/min values are displayed via the

ENTER button and HI t, LO t menu functions, respectively.

Large Display Temperature Meters Instruction Manual

11

ALARM POINTS Four, any combination of high or low alarms. Latching or non-

latching.

ALARM POINT

DEADBAND

0-100% of full scale, user selectable

ALARM STATUS

INDICATION

Front panel LED

NON-VOLATILE

MEMORY

All programming values are stored in non-volatile memory for a

minimum of ten years if power is lost.

NORMAL MODE

REJECTION

64 dB at 50/60 Hz

POWER AC Power:115 VAC or 230 VAC ±10%, 50/60 Hz, 12 VA

DC Power: 22-28 VDC, 12 watts maximum

ENVIRONMENTAL Operating temperature range: 0 to +65°C

Storage temperature range: -40 to +85°C

Relative humidity: 0 to 90% non-condensing

CONNECTIONS Removable screw terminal blocks accept 22 to 12 AWG wire.

ENCLOSURE

PD755 Impact-resistant glass filled polycarbonate, NEMA 4X, modified

specifically for PDC; two holes for ½" conduit provided at base.

PD756 Explosion-proof sand-cast aluminum – 0.3% max. copper content,

NEMA 3, 4, 7, 9. For use in hazardous locations Class I Groups C

& D, Class II Groups E, F & G (suitable for Division 1 and

Division 2). Two ¾" NPT holes provided at opposite sides. Up to

four holes can be provided for an additional charge.

PD757 Die cast aluminum, NEMA 4X, modified specifically for PDC; four

holes for ½" conduit provided at base, 3 plugs provided.

MOUNTING

PD755 Enclosure contains four holes for wall mounting. Panel mounting

and pipe mounting kits available.

PD756 Enclosure contains four 7/16" holes for wall-mounting, pipe

mounting kit available.

PD757 Enclosure contains four ¼" holes for wall-mounting. Panel

mounting kit available.

OVERALL DIMENSIONS

PD755 6.7" x 5.5" x 3.7" (170 mm x 140 mm x 95 mm)

PD756 8.0" x 8.0" x 5.7" (203 mm x 203 mm x 145 mm)

PD757 4.9" x 14.3" x 3.2" ( 125 mm x 362 mm x 81 mm)

WEIGHT

PD755 3.8 lbs (1.73 kg)

PD756 14.6 lbs (6.6 kg)

PD757 7.0 lbs (3.2 kg)

WARRANTY 1 year parts and labor

EXTENDED

WARRANTY

Warranty may be extended an additional 12 months by returning the

Product Registration Form within 2 months from date of purchase. Go to

www.predig.com for online registration.

Large Display Temperature Meters Instruction Manual

12

Options

Relays

RATING 2 or 4 SPDT (form C); rated 2 Amp @ 30 VDC or 2 Amp @ 250

VAC resistive load; 1/14 HP @ 125 / 250 VAC for inductive loads.

RESET User select via JP5 jumper array and SetuP menu.

Automatic reset only.

Manual reset only, at any time.

Automatic plus manual reset at any time.

Manual reset only after alarm condition has been corrected.

Automatic reset: Relays will automatically reset when the input

passes the reset point.

Manual reset: It can be performed via user supplied external

contact closure at terminals AK and CM or front panel ACK

button. Manual reset resets all manually resetable relays.

BUILT-IN

SUPPRESSION

A built-in suppressor (snubber) to prolong the life of the relays

protects each relay contact. The suppressor provides a degree

of protection against electrical noise caused by inductive loads.

Suppressor value, .01 µF/470 Ω, 250 VAC.

DEADBAND 0-100% of full scale, user selectable.

FAIL-SAFE

OPERATION

Relay coils are energized in non-alarm condition. In case of

power failure, relays will go to alarm state. Fail-safe operation

may be disabled, by removing jumper J5 located on the Options

PCB.

SENSOR BREAK

DETECTION

Open sensor circuit indicated by display flashing OPEn. All relays

and alarm status LEDs go to alarm state.

AUTO

INITIALIZATION

When power is applied to the meter, the relays always reflect the

state of the input to the meter.

Large Display Temperature Meters Instruction Manual

13

Isolated 4-20 mA Transmitter Output

CALIBRATION

RANGE

The transmitter output can be calibrated so that a 4 mA output is

produced for any number displayed on the meter. The 20 mA

output may correspond to any number displayed on the meter

(larger or smaller). However, best results are obtained with a

500-count difference between 4 and 20 mA displays.

The output will be linear (example: 4 mA = 0°, 20 mA = 1000°,

output is 6 mA at 125°.)

ACCURACY ±0.1% F.S., ±.004 mA @ 25°C

NO EQUIPMENT

NEEDED

The 4-20 mA output from the Temperature Meter is calibrated

via the ENTER button without the use of a calibrator.

OUTPUT LOOP-

POWER

24 VDC ± 5% @ 20 mA, regulated. Maximum loop resistance is

1200 Ω. Isolated from input signal.

ISOLATION 500 VDC or peak AC, input-to-output or input/output-to-power

line.

EXTERNAL

LOOP-POWER

SUPPLY

35 VDC maximum

OUTPUT LOOP

RESISTANCE

Power supply Minimum loop

resistance

Maximum loop

resistance

24 VDC

10 Ω600 Ω

35 VDC (external) 600 Ω1000 Ω

Large Display Temperature Meters Instruction Manual

14

Display Functions and Messages

The meter displays various functions and messages during operation and

programming. The following table shows the various displayed functions and

messages with their description.

Display Parameter Description/Comments

9999F Out of range Indicates the input signal exceeds the full-scale

range of the meter.

CALIb Calibration Calibrates meter using a calibrated signal source.

CLEAr Clear Clears (resets) maximum or minimum temperatures

reached by the process.

DIA9 Diagnostic Displays parameter settings one at a time for

diagnostic purposes. Setting can not be changed

under this function.

Error Error Indicates calibration was not successful.

F or C °F or °C Type of scale to be used Fahrenheit or Celsius.

HI t High temperature Displays maximum temperature reached by the

process since last cleared (reset).

InPt 1 Input 1 Sets low input calibration (low input signal must be

applied to the meter).

InPt 2 Input 2 Sets high input calibration (high input signal must

be applied to the meter).

LO t Low temperature Displays minimum temperature reached by the

process since last cleared (reset).

LatCk Latch Sets alarm set points for latching or non-latching

relay operation.

OFFSET Input offset Adds or subtracts a programmed offset value to the

input.

Open Open Indicates open sensor circuit.

outPut Output Sets the optional 4-20 mA output values.

Set 1 Set point 1 Sets operation for Set point 1.

Set 2 Set point 2 Sets operation for Set point 2.

Set 3 Set point 3 Sets operation for Set point 3.

Set 4 Set point 4 Sets operation for Set point 4.

SetPtS Set points Sets alarm set and reset point values.

Setup Setup Sets operation of set points for latching or non-

latching mode.

Type Type Sets type of thermocouple or RTD to be used as

the input. Jumper JP1 must be configured

accordingly.

Large Display Temperature Meters Instruction Manual

15

SETUP AND PROGRAMMING

Overview

To setup and program the Digital Temperature Meter, it is necessary to

disassemble the Display PCB. See disassembling instructions in the next pages.

Setting up and programming the Digital Temperature Meter involves four basic

steps:

1. Jumper Configuration (Page 19)

a. Input selection and lockout jumpers

b. Relay acknowledge enable

c. Fail-safe operation of relays

2. Power Selection (Page 20)

a. Changing to 230 VAC power if needed. 115 VAC is factory default on

AC powered models.

b. Labeling meter for power input: 115 VAC or 230 VAC (24 VDC powered

models are labeled as such at the factory).

3. Connections (Page 21)

a. Power connections

b. Signal connections

c. Enter, acknowledgement, and hold reading

d. Relays connections

e. 4-20 mA output connections

4. Programming (Page 29)

a. Basic meter

b. Alarm setup and set points

c. 4-20 mA output

d. Lockout jumper

Programmed Parameter Settings

To simplify programming, write down the desired programming values prior to

attempting to program the meter. The Programmed Parameter Settings form,

located on page 69, provides a convenient method to record the user settings; it

also provides the factory setting for most of the programmable parameters.

Large Display Temperature Meters Instruction Manual

16

Disassembling the Meter

To perform the steps described above, it is necessary to partially disassemble the

meter. Main PCB may remain attached to enclosure’s base even during conduit

hub installation if proper precautions are taken.

Disassembling the PD755

1. Loosen the four screws that hold enclosure’s cover and remove the cover.

2. Remove the four mounting screws holding the Display PCB (see Figure 28,

page 60).

3. Move Display PCB out of the way. Ribbon cable to Display PCB may be

removed during meter installation. Do not remove standoffs from Main

PCB. Main PCB is secured to enclosure’s base with four mounting screws.

4. Change voltage selection as required; this is described on page 20. Set

configuration jumpers; connect power and signal wires.

5. Reassemble Display PCB prior to applying power.

6. Program meter prior to installing enclosure’s cover.

7. Install lockout jumper to prevent accidental changes to programmed settings.

Disassembling the PD756

!

When servicing the PD756 in a hazardous area, all appropriate

hazardous area procedures must be followed.

1. Remove enclosure’s cover.

2. Loosen the two mounting screws on the right side of the Display PCB (see

Figure 29 on page 60). It is not necessary to remove the faceplate.

3. Remove the two mounting screws on the left side of the Display PCB.

4. Slide the Display PCB out from under the screws. Ribbon cable to Display

PCB may be removed during meter installation. Do not remove standoffs

from Main PCB. Main PCB is secured to enclosure’s base with four

mounting screws.

5. Change voltage selection as required, described on page 20. Set

configuration jumpers; connect power and signal wires.

6. Reassemble the Display PCB prior to applying power.

7. To program meter using front panel buttons leave cover off until meter

programming is complete.

8. Install lockout jumper to prevent accidental changes to programmed settings.

Large Display Temperature Meters Instruction Manual

17

Disassembling the PD757

1. Loosen the four screws that hold the enclosure’s cover in place and remove

cover.

2. Loosen the top three mounting screws holding the Display PCB (see Figure

30, page 61).

3. Remove the bottom three mounting screws.

4. Slide Display PCB out from under the top three screws. Ribbon cable to

Display PCB may be removed during meter installation. Do not remove

standoffs from Main PCB. Main PCB is secured to enclosure’s base with

four mounting screws.

5. Change voltage selection as required, described on page 20. Set

configuration jumpers; connect power and signal wires.

6. Reassemble Display PCB prior to applying power.

7. To program meter using front panel buttons leave top cover off until meter

programming is complete.

8. Install lockout jumper to prevent accidental changes to programmed settings.

Large Display Temperature Meters Instruction Manual

18

Reassembling the Meter

After the wiring and jumper selections have been made, reassemble the Display

PCB.

Reassembling the PD755

1. Place the Display PCB on top of the four standoffs. Make sure the ribbon

cable is connected to the connector on the Display PCB.

2. Replace the four mounting screws (see Figure 28 on page 60).

3. Install enclosure’s cover matching enclosure base and cover tabs.

4. Fasten the four screws that hold the enclosure cover in place.

Reassembling the PD756

1. Slide the Display PCB under the two screws on the right side of the Display.

PCB (see Figure 29 on page 60).

2. Replace the two mounting screws on the left side of the Display PCB.

3. Tighten the two mounting screws on the right side of the Display PCB

4. To program the meter using the front panel buttons leave cover off until

meter programming is complete.

5. Replace the enclosure cover.

Reassembling the PD757

1. Slide the Display PCB under the top three screws (see Figure 30, page 61).

2. Replace the bottom three mounting screws.

3. Tighten the top three mounting screws.

4. Align the enclosure cover so the alarm numbers on the cover are on the left

side of the meter and aligned with the alarm status LEDs.

5. To program the meter using the front panel buttons leave top cover off until

meter programming is complete.

6. Replace the enclosure cover and tighten the four screws that hold it in place.

Large Display Temperature Meters Instruction Manual

19

Jumper Configuration

Before programming the Digital Temperature Meter, it is necessary to configure

three jumper arrays. The jumper arrays are used for setting type of input signal

(thermocouple or RTD), lockout programmed settings, enable relay

acknowledgement (ACK), and setting relay fail-safe operation.

Input Selection and Lockout Jumpers (Main PCB)

Figure 31 on page 61 for PD755

Figure 32 on page 62 for PD756

Figure 33 on page 62 for PD757

Jumper JP1 Position Function

RTD RTD Input

TC Thermocouple Input

Jumper JP2 Position Function

LOCK Sets a lock on programming

functions

Relay Acknowledge Enable (Display PCB)

Figure 34 on page 63 for PD755

Figure 35 on page 63 for PD756

Figure 36 on page 64 for PD757

Jumper

JP5 Position

Function

1 Enable relay 1 manual reset

2 Enable relay 2 manual reset

3 Enable relay 3 manual reset

4 Enable relay 4 manual reset

Fail-Safe Operation of Relays (Options PCB)

Figure 24 on page 57 for PD755

Figure 25 on page 58 for PD756

Figure 27 on page 59 for PD757

Jumper

J5 Position

Function

On Apply fail-safe function to all relays

Off Disable fail-safe function to all relays

Large Display Temperature Meters Instruction Manual

20

Power Selection

Overview

Power Selection involves the following:

1. Changing to 230 VAC power if needed. 115 VAC is factory default on AC

powered models.

2. Labeling the meter as to how it will be powered: 115 VAC or 230 VAC.

Meters powered from 24 VDC are labeled as such at the factory.

Note: Meters ordered to operate from 24 VDC do not require any special

setup; this option is not field selectable.

Installation and configuration must be undertaken by qualified servicing

personnel.

!

When servicing the PD756 in a hazardous area, all appropriate

hazardous area procedures must be followed.

!

All AC powered meters are shipped from the factory set for 115 VAC

power. Do not apply 230 VAC without first setting up the Digital

Temperature Meter to accept this voltage. Otherwise it will cause

damage to the meter and endanger personnel.

!

Disconnect power prior to performing the following procedures.

All three meters are field selectable for either 115 VAC or 230 VAC

power. Changing the voltage selection involves the removal of the front

cover and the Display PCB, then selecting 115V or 230V on switch S1

located on the Main PCB.

!

Observe polarity for DC powered meters. Applying voltage with reverse

polarity may damage the meter.

Do not apply an AC voltage to DC powered meters. Applying an AC

voltage to DC powered meters will result in damage to the meter and

endanger personnel.

Changing from 115 to 230 VAC Power

To access the 115/230 VAC switch it is necessary to remove the housing cover

and the Display PCB, see Disassembling the Meter, page 16.

Once the Display PCB has been removed, switch S1 is visible. It is the large

black component with a red slide switch on the top, located next to the

transformer. For an illustration see:

Figure 31 on page 61 for PD755

Figure 32 on page 62 for PD756

Figure 33 on page 62 for PD757

For 115 VAC operation, the switch shows 115V; for 230 VAC it shows 230V.

Several setup steps are required and connections made while Display PCB is

removed, so it should not be reinstalled just yet. However, to avoid electric shock,

install Display PCB prior to applying power.

Other manuals for PD755

1

This manual suits for next models

2

Table of contents

Other PRECISION DIGITAL Test Equipment manuals