3

TABLE OF CONTENTS..............................................................................................................................3

INTRODUCTION........................................................................................................................................4

RECORDS .....................................................................................................................................................5

PRECISION WATER SYSTEMS WATER DISTILLER WARRANTY................................................6

IMPORTANT SAFETY PRECAUTIONS..................................................................................................7

PRECISION WATER SYSTEMS WATER DISTILLER OWNERS' SUMMARY...............................8

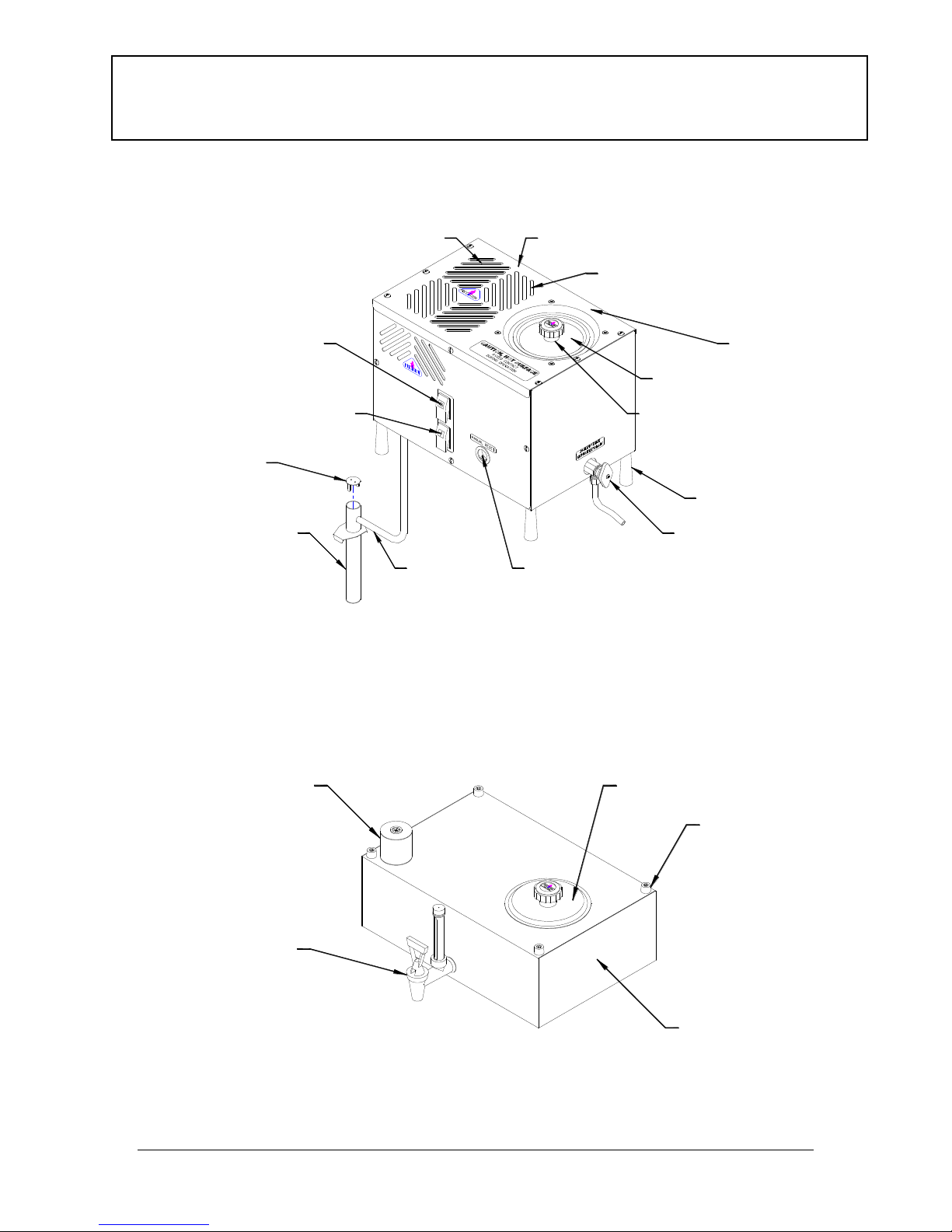

WATER DISTILLER AND OPTIONAL STORAGE TANK FEATURES ............................................9

10 FACTORS THAT WILL AFFECT YOU WATER DISTILLER PRODUCTION .........................10

UNDERSTANDING HOW PURE WATER IS PRODUCED.................................................................12

FINDING A GOOD INSTALLATION LOCATION...............................................................................13

UNPACKING YOUR WATER DISTILLER...........................................................................................13

WATER DISTILLER INSTALLATION TOOLS...................................................................................15

WATER DISTILLER LEG INSTALLATION ........................................................................................16

OPTIONAL STORAGE TANK ASSEMBLY..........................................................................................16

OPTIONAL STORAGE TANK TO DISTILLER HEAD ASSEMBLY................................................18

IMPURITIES DRAIN TUBE INSTALLATION......................................................................................19

BOILING TANK LID INSTALLATION .................................................................................................20

OPTIONAL STORAGE TANK LID REMOVAL AND INSTALLATION..........................................20

OPERATION...............................................................................................................................................21

CONTROLS -POWER,FAN,AND OVERHEAT RESET .....................................................................................21

BEFORE INITIAL WATER DISTILLER OPERATION.........................................................................................23

NORMAL OPERATION..................................................................................................................................23

MAINTENANCE AND CLEANING ........................................................................................................25

REGULAR INSPECTION AND CLEANING OF BOILING TANK..........................................................................25

CLEANING THE BOILING TANK USING CLEANER DESCALER .......................................................................26

REPLACING CHARCOAL IN POST CHARCOAL FILTER CANISTER (USED WITH 8-M).....................................27

REPLACING CHARCOAL IN CHARCOAL FILTER CANISTER (USED WITH 8-MST).........................................28

STERILIZATION............................................................................................................................................29

Liquid Sterilization of Optional Storage Tank ........................................................................................29

Steam Sterilization of Water Distiller Head............................................................................................30

Steam Sterilization of Water Distiller Head, Filter Canister and Optional Storage Tank......................32

Maintenance Schedule Table ..................................................................................................................33

Owner Maintenance Record Table..........................................................................................................33

TROUBLESHOOTING..............................................................................................................................34

ADDITIONAL OPTIONS..........................................................................................................................36

SPECIFICATIONS AND TECHNICAL INFORMATION....................................................................37

WIRING LIST AND SCHEMATICS..................................................................................................................38

INDEX..........................................................................................................................................................40

WARRANTY REGISTRATION CARD...................................................................................................41