Precision NPFC Series User manual

1

Lithium Iron Phosphate Battery

NPFC SERIES

(LiFePO4 Battery Module for Telecom)

Operation Manual

12

Contents

Notes | Safety and Warning

One | Product Information

Product Features

Main Application

Dimensions

Layout

Working Principle

Two | Technical Characteristic

Electric Performance

Discharge Performance

Charge Performance

Three | Operation

Perameter Settings

Operation Condition

Four | Storage and Installation

Storage

Installation

Five | Maintenance

General

Troubleshooting and Solutions

Annex1

Annex2

Annex3

Annex4

03

04

4

4

5

6

8

10

10

11

11

12

12

12

13

13

13

18

18

19

20

21

22

23

3 4

Safety and Warning

Chapter Notes

The NPFC series LiFePO4battery system installation, operation,

maintenance should follow important recommendations in this manual:

• The equipment shall be installed by the professional trained staff.

• Battery maintenance should be carried out by the experienced professionals and aware of the preventive measures

on the potential harm of the battery.

• Note: Be care of the risk of electric shock for large current in case of battery short circuit, pay attention to the

following points during operation

-Remove watches, rings or other metal objects

-Use tools with insulated handles

-Do not place tools or metal objects on the battery

• Do not direct access to the battery system to the mains grid power outlet.

• Do not put the battery system into re, do not use or storage the battery near to the high temperature source.

• Do not use liquid or other objects placed into the battery system.

• Do not open or cut the battery, not hit, throw or step on the battery.

• Using special communication between battery module and power plant to charge battery

• Be sure to subject to charge and discharge parameters setting in this manual.

• The output interface of the system is still voltage when grid power cut, avoid electric shock or short circuit when

operation.

• Please check if the box is damaged. If damaged, please immediately notify the supplier

• If you nd leaking liquid or white powder residue on product, prohibit operation.

Product Introduction

Chapter One

Product Features

NPFC series battery system is 48V system for communications back-

up type LiFePO4 (lithium iron phosphate) battery products, the system

uses the advanced LiFePO4 battery technology with the benefit of long

cycle life, small size, light weight, safety and environmental protection,

and has a strong environmental adaptability, it is idea for harsh outdoor

environments.

The system also integrates a smart battery management and monitoring

module, support for remote centralized monitoring and remote battery

management and maintenance, to meet the requirements

of unattended. Therefore, the NPFC system can fully meet the backup

power supply requirements of the access network equipment, mobile

communications equipment, transmission equipment, micro base stations

and microwave communication equipment.

Main Application

• Network Telecommunication Facilities

• OSP

• Terminal of FTTX

• Access network system

• Indoor distribution system

• Telecom BTS

• Integrated outdoor power cabinet

• UPS

• Internet data center (IDC)

• Solar energy

• Common Bonding Network (CBN) and or Isolated Bonding Network (IBN)

Warning

Read the

manual

Fire

forbidden

Circle used The product has

passed the UL

authentication

Do not put

batteries into

dustbin

Please take care of the following marks

Electricity

danger

Protecting

your eyes

With adults

custody

Watch

Short-circuits

5 6

Dimension

Fig.1-1 Structural Drawing of NPFC Series Batteries (48NPFC100 as example)

Fig.1-2 Battery Output Terminal

Table 1-1 Battery Model & Dimension of NPFC Series

Note:

1. Battery Model: Battery models listed in the datasheet are standard products. Narada can also supply customized design

in cell, BMS and dimensions for various application scenarios.

2. Terminal Torque: M4, 2~3 N•m ; M6, 7~8 N·m ; M8, 9~10 N·m;

Layout

Fig. 1-3 Layout of Front Panel for NPFC Series Batteries

(Received product may not have all parts above, this instruction is as an example)

Table 1-1 Battery Model & Dimension of NPFC Series

48NPFC10

48NPFC20

48NPFC50

48NPFC80 (3U)

48NPFC100 (5U 19”)

48NPFC100 (3U 23”)

48NPFC100 (3U 19”)

1

2

3

4

SOC

ALM

RUN

ADD Dip

switch

Indicators

for capacity

Indicators

for alarms

Indicator for

runing status

Address for

communication

Battery Model

Dimensions (mm)

Width

(No Ear)

6.4

11.5

28.5

37.5

44

48.0

38.5

442

442

442.5

442.5

442.5

522.5

442.5

44

88

132.5

132.5

222

132.5

133

243

243

390

400

400

420

400

M4

M4

M6

M6

M6

M6

M8

Typical

Weight

(kg)

Height Depth Φ

Battery

Output

Terminal

SOC is short for state of charge. There are four green

LED lights in front panel indicating SOC. Each SOC

LED light represents 25% of rated capacity. Detailed

information is shown in Annexed Table 1.1.

There is one red LED light in front panel indicating

alarms. Detailed information is shown in Annexed Table

1.3.

There is one green LED light in front panel indicating

running status. Detailed information is shown in

Annexed Table 1.2.

ADD is applicable to modules connected in parallel. ADD

consists of six binary bits. Detailed information is shown

in Annex 2.

No. Marks Functions Detailed Information

7 8

5

6

7

8

9

10

11

12

13

RS232

RS485

RESET

Dry

contact

Power

switch

Battery

Output

GND

Openable

Panel

(optional)

Side

mounting

communication

port

communication

port

Reset button

Dry contact

ON/OFF switch

Terminals for

battery output

Ground screw

Openable

Panel

Wall-hanging

installation

RS232 communication port just for software upgrade

now.

It is adopting RS485 series port communication pattern

to upload data. Contents of data transmit include

BMS parameters, battery running status, alarms, etc.

Communication of modules connected in parallel is

available through RS485.

Press RESET button when abnormity occurs to assure

stability of battery performance.

Failure Alarm: indicate BMS or battery fail including but

not limited to charge and discharge MOS fail, cell

voltage under 0.5V, NTC disconnect, and so on.

When turn-off, battery get into sleep mode, and cut-off

output, the alarm output also will be stopped.

Using terminals with four or two cores. Polarities are

+, -,+, - from left to right. The two ‘+’ and ‘-’ are equal

relatively. Detailed information is shown in Fig. 1-2.

Connect earth by flexible cable above GREEN

Sheathed, UL94-V0, gauge of the grounding wire should

be equal to or greater than the gauge of the battery

return wire.

Battery BMS can be removable and replace easily

through this.

The side mounting is used to wall-handing installation

battery. Also use the ear to handle the battery.

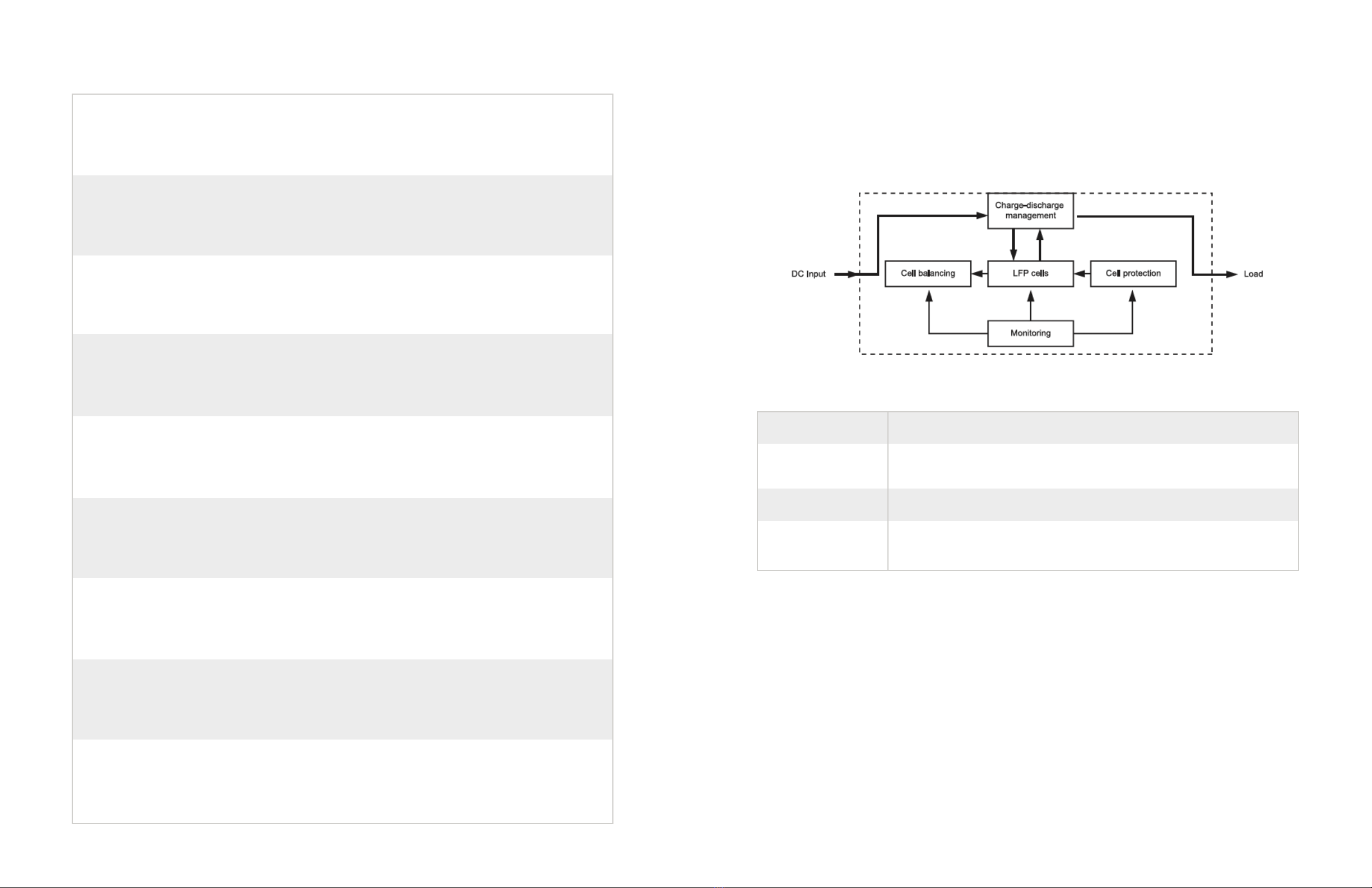

Working Principle

The NPFC battery system mainly includes Lithium battery pack, battery

protection, cell balancing unit, monitoring module and charge-discharge

management module for optional. Its schematic diagram shown in Figure 1-4

Fig.1-4 Schematic Diagram

NPFC battery working principle:

DC power input rectifier after filter, DC divided two circuits, one circuit

directly supply the load, another circuit charge lithium battery. When

grid power on, the system supplies the loads and charging inside lithium

batteries; When grid power failure, lithium inside system supply DC power

to the load, to ensure uninterrupted power supply as power system.

Battery Management System (BMS)

Smart BMS technology is adopted for battery modules of NPFC series to

assure smart automaticmanagement for batteries. Features of BMS are

shown as below:

LFP cells

Cell Protection

Cell balancing

Monitoring

Chemical power, energy storage and power supply components

Protect LFP cells against overcharge, over discharge, over current, over

temperature, short circuit

Equalization LFP cells for cells unbalanced

Suport centralized monitoring system (optional according to customer

requirements)

Table 1-1 Battery Model & Dimension of NPFC Series Continued

9 10

• There is a centralized monitoring unit in BMS. Functions such as remote measurement, remote

communication, remote controlling are available. Battery modules can be controlled remotely

by staffs in control center. NPFC series are in line with the requirements of the development of

modern communications technology.

• It is combined by technologies of power source and computer. Parameters and status of

rectifiers and AC/DC distributions can be detected and controlled.

• Excellent electromagnetic compatibility. BMS used for battery modules of NPFC series can

comply with the outdoor power plants during operation, no interfere with each other.

• BMS can provide protections against overcharge, over-discharge, over-temperature, over

current, short circuit, etc., to assure reliable safety and operation life.

• With patented cell balancing technology, BMS provide high efficiency for cell balancing and

prolong system operate life.

• Configuration flexibility, support parallel connection expansion

Technical Characteristic

Chapter Two

Note:

1 Battery Model Battery models listed in the datasheet are standard products.

2 Rated Voltage 48V = 3.20Vpc * 15pcs (Rated voltage of each LFP cell is 3.20Vpc)

3 Rated Capacity Five-hour rate capacity (0.2C to 40.5V at 25° C)

Electric Performance

48NPFC10

48NPFC20

48NPFC50

48NPFC80

48NPFC100-19”

48NPFC100-23”

Battery

Model

48

48

48

48

48

48

10

20

50

80

100

100

2

4

10

15

20

20

10

20

50

80

100

100

10

20

50

80

100

100

54.0

54.0

54.0

54.0

54.0

54.0

40.5 to 54.5

40.5 to 54.5

40.5 to 54.5

40.5 to 54.5

40.5 to 54.5

40.5 to 54.5

Rated

Voltage

(V)

Rated

Capacity

(Ah)

Voltage

Rage

(V)

Charge

Voltage

(V)

Charge Current (A)

Recomm Max.

Max.

Discharge

Current (A)

123

11 12

Operation

Chapter Three

Parameter Settings

Lead-acid batteries can be replaced by lithium battery of NPFC series if

power is matched. Table 3-1 is new parameter settings of power plant for

lithium battery.

Table 1-1 Battery Model & Dimension of NPFC Series

Note:

1.Equalization charge is requested to switch off for NPFC series batteries.

2.Rectifier parameter shall be set according to specific site requirement based on battery units used.

3.If the battery connected more than 2 in parallel, the max. charge current recommend 0.5C.

Operation Condition

Table 3-2 Requirements for Operation Environment

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Parameters

Float charge coltage

Equalization charge voltage

Standard charge current

Charge current limitation

Equalization charge interval

Equalization charge duration

Condition to equalization charge

Condition to float charge

Recovered LLVD voltage

LLVD

BLVD

Temperature compensation for float charge

Temperature compensation for equalization charge

Units

V

V

A

A

day

H

A

A

V

V

V

-mV/°C

-mV/°C

Defaults

54.0

NA or 54.1

0.2C

0.5C ~ 1.0C

NA

NA

NA

0.05C

50.0

47.0

43.2

NA

NA

Temperature Range (°C)

Recommended

Temperature(°C)

Humidity

Discharge

Charge

Storage

-25 ~ +75

-10 ~ +65

0 ~ +40

+15 ~ + 35

+15 ~ + 35

+15 ~ + 30

5% ~ 95%

Discharge

Charge

Storage

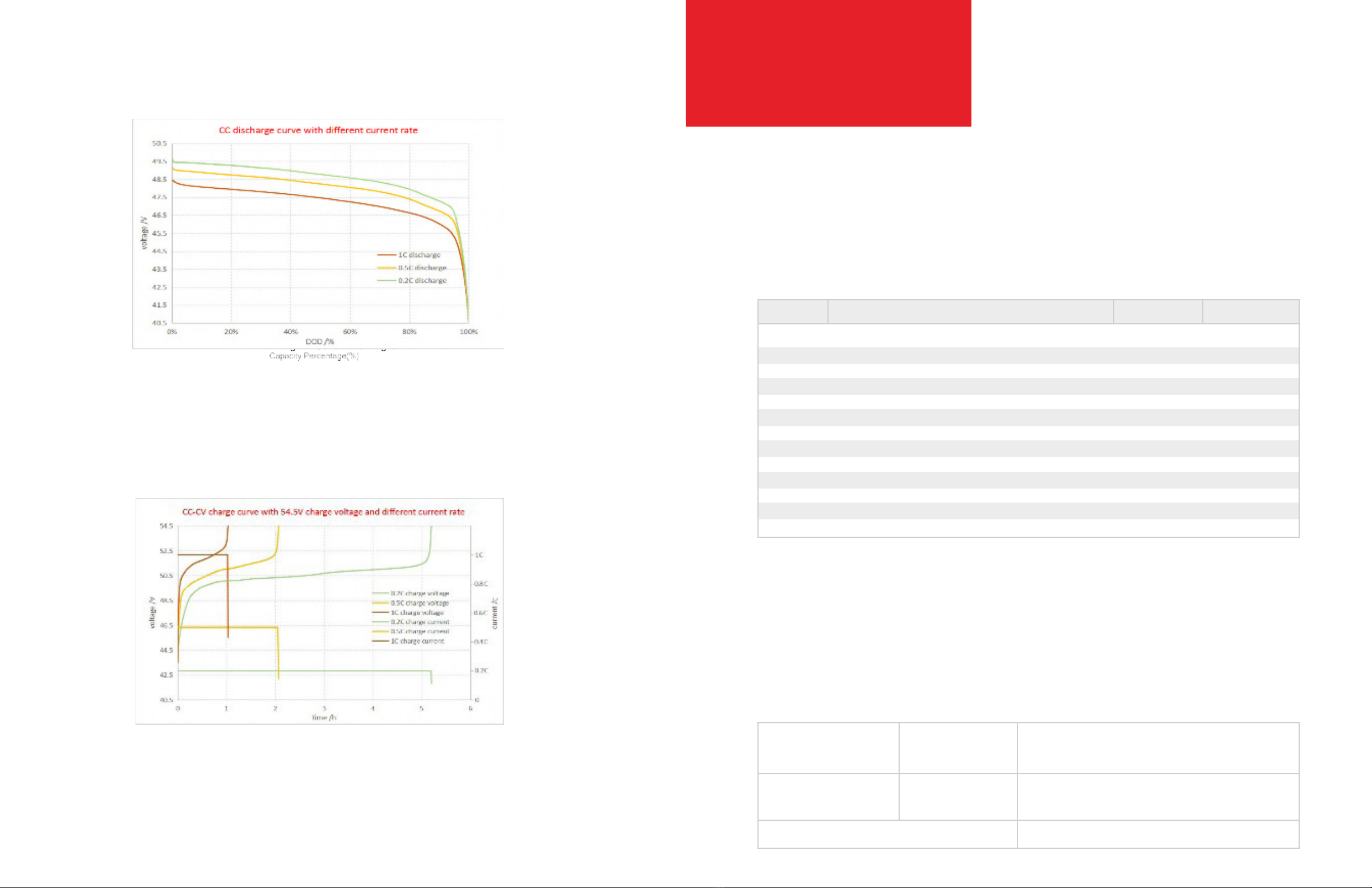

Discharge Performance

Fig.1-4 Schematic Diagram

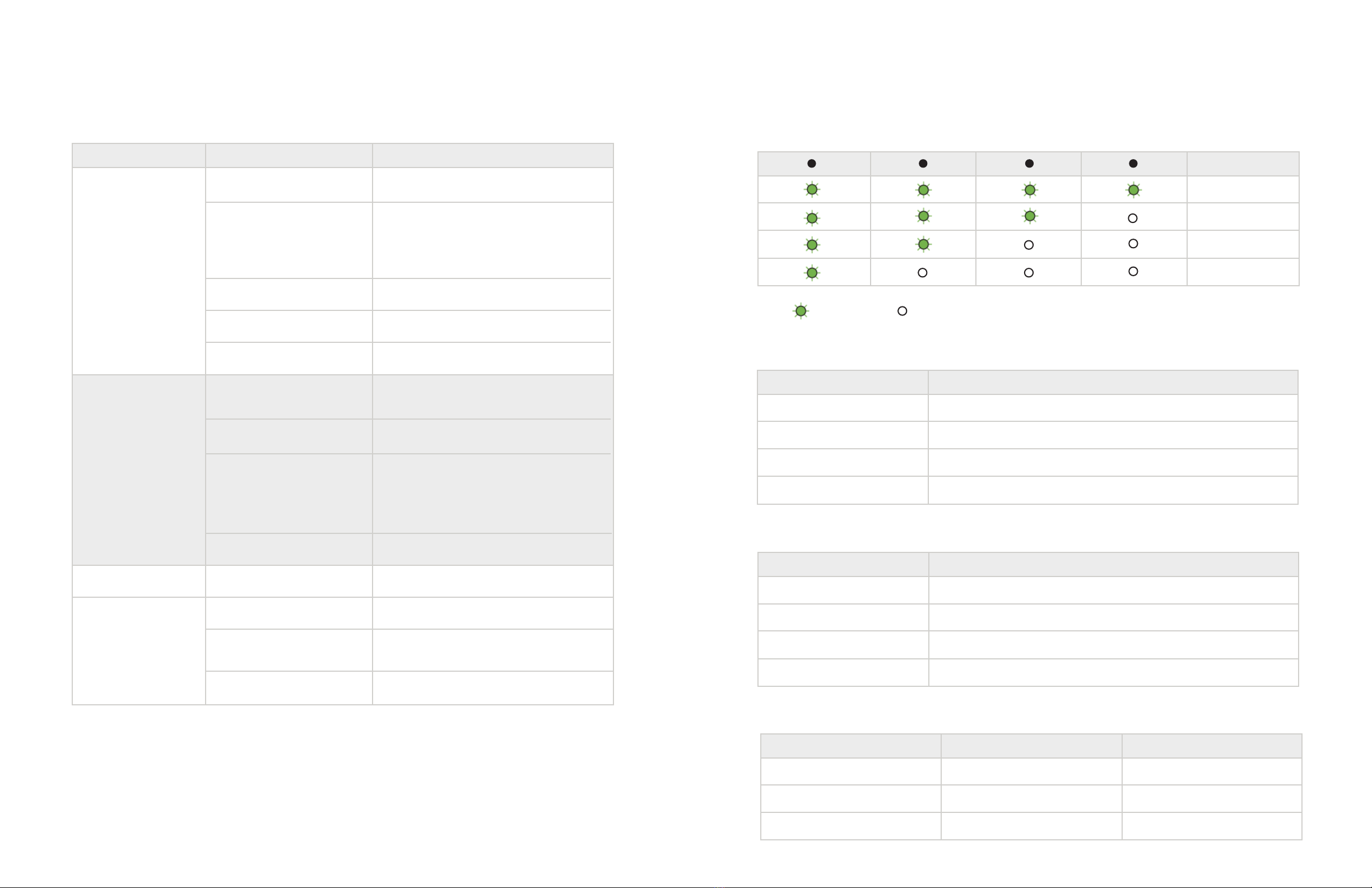

Charge Performance

Fig.1-4 Schematic Diagram

13 14

Storage and Installation

Chapter Four

Storage

• Storage temperature range: 0°C to 40°C.

• Storage battery should be at 50%-80%SOC.

• Recharge charge before using to recover capacity loss of self-discharge during storage and transport.

• Recharge battery during long-term storage for self-discharge. Recharge program as follow table:

• Storage battery over 40°C or under 0°C will reduce battery life,

• Storage battery in dry and low temperature, well ventilated place

• Battery performance degradation after long-term storage, please shorten shelf time as possible as you can.

Installation

Unboxing & Inspection

• Please study this manual before installation.

• Please inspect the package before unboxing, if any destroy with appearance, contact with the supplier as soon as

possible.

• This device shall be installed and operated by professionals.

Preparation for Installation

• Batteries shall not be placed in direct sunshine or close to heat source.

• Batteries shall be installed in place with good ventilation to assure enough heat dissipation.

• Batteries shall be placed in are with clean ambient and low humidity.

• Heavy weight shall not be placed on any cable.

• Following are the tools possibly but not limited be use for installation:

Storage Temperature

0°C-30°C

30°C-40°C

Recharge interval

Every 6 months

Every 3 months

Single Module Recharge Procedure

1) Charge with 0.2C to 100%SOC

2) Discharge with 0.2C to 0%SOC

3) Charge with 0.2C per module for 4 hours

Tool items (possibly but not limited)

Installation of Battery Modules

1. Installation and fixation

Battery modules of NPFC series are applicable to installation in cabinets

and wall-hanging.

• Cabinet installation

Insert battery module into cabinet, and fix two handles of battery module with cabinet rack

using 4pcs M6 screws.

• Wall-hanging installation

Wall-hanging installation also can be adopted, fix two handles of battery module with triangle

rack on the wall using 4pcs M6 screws.

Preferred

Forbidden (Except for 48NPFC10, 48NPFC20, 48NPFC100-19)

Alternate

15 16

2. Ground connection

Connect earth by flexible cable above GREEN Sheathed, UL94-V0, gauge

of the grounding wire should be equal to or greater than the gauge of the

battery return wire, .no less than 6AWG, connection through 2-hole 0.75in

center spacing, on right side of cabinet back.

3. Battery output connection

• Connect ‘+’ of battery output with positive copper bar of power plant, and ‘-’ with negative

copper bar or power switch.

• If multi battery modules will be connected in parallel, please take note of follows:

• Color for cable between ‘+’ and positive bar is suggested as RED, and cable between ‘-’ and

negative as BLACK.

• The picture of paralleling connection for NPFC Series Batteries see Fig. 4-2. There is a tray

under each battery to support the battery.

Fig. 4-1 Ground connection for NPFC Series Batteries

1. The battery modules connected no more than 8 in parallel.

2. The minimum spacing between batteries is 10mm.

3. Connect ‘+’ of battery output of each battery module with positive copper bar of power

plant, and ‘-’ with negative copper bar of power plant or power switch separately.

4. Length of cable between battery module and power plant shall be less than 2.0m. To

make sure similar voltage drop of cable for each battery, length of all positive and

negative cables should be the same.

4. Power on for battery module

• When installation is accomplished, battery module is in dormant state. Once power on for

the power plant and battery module, battery will go into normal running status, and discharge

charge can be available.

• Parameter settings for lithium battery modules in power plant are shown in Table 3-1.

5. RS232/RS485 communication connection

• If there is only one battery module in operation, communication between battery module and

computer can available through RS485.

• If there are more than one battery modules in operation, parallel communication can be

available using RS485.

• The last battery in each rack has an empty RS485 port, its need to be connected with a cable

with RJ45 terminals to avoid interference with communication. The other end of the cable

should covered with insulating tape Its also can insert a 120Ω terminators.

• RS232 communication port just for software upgrade.

• Communication protocols for RS485 are shown in Annex 3.

• Dry contact should be connected when battery connected in electric circuit.

Fig. 4-2 Layout of paralleling connection for NPFC Series Batteries

17 18

6. Discharge with dummy load

• Dummy load cannot be larger maximum discharge current of each battery model according to

the datasheet, and BLVD is larger than 43.2V.

• Voltage drop on cable between battery module and power plant shall be less than 0.5V. Method

of calculation for cross sectional area of cable is shown as below.

A=ΣI×L/(K×∆U)

In the above formula, A is across sectional area of wire (mm2), ΣI is the total current (A), L is

length of cable, ∆U is the permit voltage drop on cable (V), and K is electrical conductivity of

wire. For example, for copper, K = 57.

Fig. 4-3 How to handle the empty RS485 port for NPFC Series Batteries

Maintenance

Chapter Five

General

Proper maintenance will prolong the life of a battery and will aid in

assuring that it can satisfy its design requirements. A good battery

maintenance program will serve as a valuable aid in determining the

need for battery replacement. The users must consider their application

and reliability needs if maintenance procedures, other than those

recommended in this document, are used. Battery maintenance should

be performed by personnel knowledgeable of batteries and the safety

precautions involved.

NPFC series lithium batteries can be used at an altitude of less than 5000

meters. If the altitude more than 5000 meters, it will affect the battery

performance and life due to the decrease of air pressure and temperature.

• The battery shall be recharged every three months if in long time storage

• Please clean the dust by the dust collector when dust is accumulated on vent

• Please use clean and dry cloth/fabric to clean up the cabinet, if need further cleaning, please

use neutral cleanser. Alcohol or ammonia synthesis is forbidden.

• Carrying shall be handled gently, prevent from severe compact

• Prevent battery from splashing liquid

• Suggest inspect the tighten of output screw every two years

19 20

Troubleshooting and Solutions

Table 5-1 Troubleshooting and Solutions

Different flash status of LED indicators represents corresponding running

status or alarms. Detailed information is shown Annex 1.

Note: The improvement of product and technology, and the possible of battery specification and

appearance changes, Narada hold the right of final explanation!

Troubles

Battery cannot

discharge

Battery cannot

charge

All LED indicators on

Communication

failure

Troubleshooting

Protection against under-voltage

Protection against over-

temperature or undertemperature

(cell temperature is lower than

-20°C or higher than 70°C)

Battery output is short circuit

Protection against over current

System failure

Battery is fully charged. Normal

chargemanagement

Protection against over voltage

Protection against over-

temperature or undertemperature

(cell temperature is lower than

-10°C or higher than 70°C)

System failure

System failure

Fault of communication cable

Halt of System communication

management

System failure

Single Module Recharge Procedure

Charge battery

Regulate cell temperature in the range of -20°C

to 70°C for discharge

Relieve short circuit and charge battery

Remove some unimportant load and charge battery

Shutdown system and call maintenance service

Do not need to solve

Do not need to solve

Regulate cell temperature in the range of 0°C to

55°C for charge

Shutdown system and call maintenance service

Shutdown system and call maintenance service

Inspect communication cable

Press RESET button

Shutdown system

Call for maintenance service

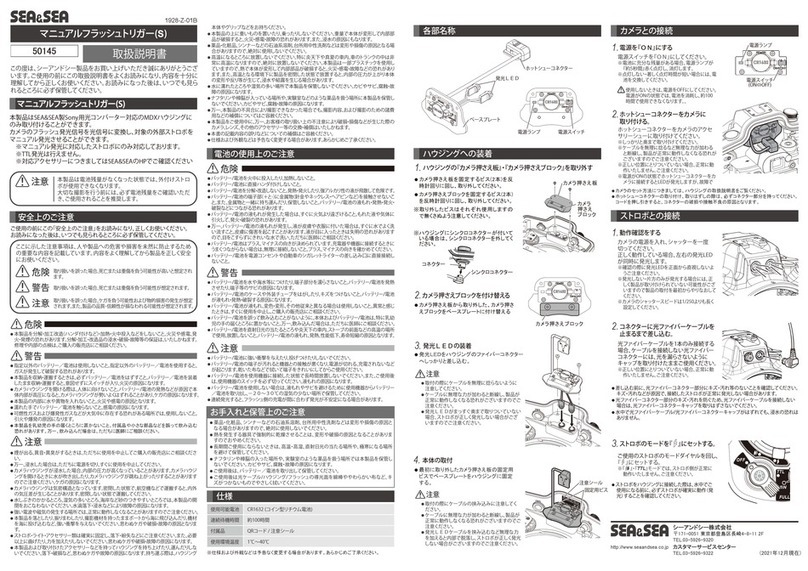

Annex 1-Instructions for LED Flash

Annex Table 1.1 – SOC LED Indicators Description

Note: mean light on, mean light off

Annex Table 1.2 – RUN Indicators Description

Annex Table 1.3 – ALM Indicators Description

Annex Table 1.4 – Flash Instruction of LED Indicators

SOC

75% ~ 100%

50% ~ 75%

25% ~ 50%

0% ~ 25%

Running Status of Battery

Activation state, but neither charge nor discharge

Charging state

Discharging state

Dormant state

Alarm Information of Battery

Minor Alarm(Various Alarm Status)

Fail(Various fail)

Major Alarm(Various protection status)

Normal, no alarm

Flash Status

Flash 1

Flash 2

Continue light

Extinguish

Flash Status

Extinguish

Flash 2

Flash 3

Extinguish

Flash Status

Flash 1

Flash 2

Flash 3

ON

0.25s

0.5s

0.5s

OFF

3.75s

0.5s

1.5s

21 22

Annex 2 – Instructions for ADD Dip Switch

ADD Dip Switch is applicable to modules connected in parallel. ADD

consists of four binary bits

Annexed Table 2.1 – Instruction for Addresses of Communication

Annexed Table 2.2 – Instruction of ADD for Parallel Communication

Note: Counting of ADD must begin from 0001, without interruption, or parallel communication cannot

be available

Instructions for ADD Dialing

1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Module No.

Default ADD

PACK 1

PACK 2

PACK 3

PACK 4

PACK 5

PACK 6

PACK 7

PACK 8

Binary Code

0000

0001

0010

0011

0100

0101

0110

0111

1000

2

OFF

OFF

ON

ON

ON

OFF

ON

ON

OFF

3

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

Default

0000

PACK 1

0001

PACK 5

0101

PACK 2

0010

PACK 6

0110

PACK 3

0011

PACK 7

0111

PACK 4

0100

PACK 8

1000

Annex 3 – Communication Protocol for

RS232 and RS485

There is one RS232 port in front panel for software upgrade, and one

RS485 port in front panel for communication between battery and PC, also

for communication between battery modules connected in parallel.

Annex Table 3.1 – RJ11 Pins Assignment (RS232)

Annex Table 3.2 – RJ45 Pins Assignment (RS485)

Sketch

Sketch

RJ45 Pins

1

2

3

4,5,6,7,8

RJ11 Pins

1

2

3

4

Definition

GND

RS485_A

RS485_B

No connection

Definition

GND

Pack receipt, computer delivery

Pack delivery, computer receipt

No connection

2 RXD Receive data - From battery to computer

3 TXD Deliver data - From computer to battery

5 GND – Signal ground

23

Annex 4 – Operation of Openable Panel

The front panel of the battery can be opened and closed to facilitate BMS

maintenance. When opening the front panel, the two bolts at the bottom of

the battery need to be removed first, then turn the three bolts on the front

panel to open it.

Fig. 5 Positions of the bolts that to open the front panel

This manual suits for next models

5

Table of contents

Popular Camera Accessories manuals by other brands

Sea & Sea

Sea & Sea 50145 instruction manual

Blackmagicdesign

Blackmagicdesign Design 3G-SDI Arduino Shield Installation and operation manual

Sea & Sea

Sea & Sea DX-3000G instruction manual

Foxtech

Foxtech FH230 TIR manual

OutBack Power

OutBack Power EnergyCell TT Series quick start guide

pro master

pro master GH26 manual