Precision PX1 V2016 Quick start guide

1|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision

®

ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

ModelPX1V2016

ExtractionSystem

OperationalManual

ForHazardousEnvironments

2|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision

®

ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

ModelPX1V2016

OperationalManual

CongratulationsonthepurchaseofyournewPrecision

®

ExtractionSolutions,

ModelPX1V2016extractionsystem!Youarewellonyourwaytoabetterexperiencein

professionalextraction.

Pleasereadandunderstandthisoperationalmanualthoroughlypriortousingyour

newextractor.AlsovisitourYouTubechannelforvideotutorialsonthePX1systemand

otherPrecision

®

ExtractionSolutionsproducts.Remember,safetyfirst!

IffurtherassistanceisneededpleasecontactPrecision

®

ExtractionSolutions

technicalsupportdirectlyat855-420-0020.

Important:PreliminaryMatters

YOUWILLNEEDTOORDERADESSICANT.WERECOMMEND3AAND4A

MOLECULARSIEVE8/12DESSICANTFROMDELTAABORBANTS.25LBSOFEACH

BLENDEDAT50/50ISIDEALWHENINSERTEDINTOYOURMACHINE.PURCHASETHIS

FROMDELTAABSORBANTS(www.deltaadsorbents.com).

YOUWILLNEEDTOORDERAHEATTRANSFERFLUIDFORYOURCHILLER.

DYNALENEHC-50(-50C)ISRECOMMENDEDFORTHEDFR-50CHILLER.DYNALENEMV

(-100C)ISRECOMMENDEDTHEDFR-80CHILLER.YOUMAYPURCHASETHESEONLINE

FROMDYNALENECORPORATION(www.dynalene.com).YOUWILLNEEDTOHAVE10

GALLONSONHAND.

IMPORTANT:IFYOUHAVEAPRECISION

®

EXTRACTIONSOLUTIONS

TECHNICIANINSTALLINGYOUREQUIPMENT,THEYWILLNOTSCHEDULEUNTIL

THESETWOITEMSAREONSITE.

3|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision

®

ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

ModelPX1OperationalManual

INDEX

ChapterTitle

Page

PrefaceWarnin

g

-

Safet

y

First!

4

1

2

3

Components

GettingStarted

PressureTesting

6

7

8

4Char

g

in

g

/Fillin

g

theSolventVessel

10

5Preparin

g

toOperate

12

6Runnin

g

theExtractor

14

7VentDownandPourOff

16

8PeriodicMaintenance

17

AppendixA

AppendixB

AppendixC

Facilit

y

Requirements

AssemblyRequirements

WarrantyCard

19

21

24

4|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision

®

ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

WARNING-SAFETYFIRST!

Thisequipmentistobeoperatedonlybyproperlytrainedindividualswithathorough

understandingofitsproperoperationandtherisksinvolvedwiththeuseoflight

hydrocarbonsolvent.

THEOWNERANDOPERATOROFTHISEQUIPMENTUNDERSTAND:THEUSEOF

LIGHTHYDROCARBONEQUIPMENTISINHERENTLYDANGEROUSANDTHEUSE

ANDMISUSEOFTHISEQUIPMENTCANRESULTINSEVEREINJURY,INCLUDING

BUTNOTLIMITEDTODEATHANDDISABILITY,ANDSUBSTANTIALPROPERTY

DAMAGE.

Theoperatormusttakeeverypossibleprecautiontoinsurethesafetyoftheoperator,

andotherpersonsandproperty,byfollowingsafetyprecautions.

DANGER

DANGER

WARNING

WARNING

ThisequipmentcontainsLiquefiedPetroleumGases(“LPG”).Overfillin

g

tanksorvesselsmaycauseaviolentruptureresultinginsevereinjuryor

evendeath.Asaminimum,useascaletocontinuouslymonitorrecovery

tankweight.Whilethesystemisprotectedwithpressurereliefvalves,care

shouldbetakentoensureoverfillingdoesnotoccur.

Flammablegasunderpressure–leakingLPGcancauseafireorexplosion

ifignited.

AllhosesmaycontainliquidLPGunderpressure.ContactwithLPGmay

causefrostbiteorotherrelatedinjuries.Wearproperpersonalprotective

equipmentsuchassafetygogglesandgloves.Whendisconnectingany

hose,pleaseuseextremecaution.

AvoidbreathingLPGvapors.Breathinghighconcentrationlevelsmay

causeheartarrhythmia,lossofconsciousness,orevencausesuffocation.

Exposuremayirritateeyes,nose,throatandskin.Pleaseread

manufacturer’sMaterialSafetyDataSheetforfurthersafetyinformation

onLPG.

5|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Makecertainallsafet

y

devicesarefunctionin

g

properl

y

beforeoperatin

g

equipment.

Improperuse/assemblyormodificationstotheunitmayresultinserious

injuryordeath.

Non-odorizedLPGdoesnothaveascent,thereforeanalarming

hydrocarbondetectormustbeusedatalltimes.

TheVacuumpumpisonlytobeusedtoevacuatethesystemofAIRand

isneverintendedtobeusedwithLPG.Itisimportanttoevacuatethe

systemofoxygenpriortotheintroductionofLPG.

Thefacilitymustprovideadequateventilation/exhaustasdeterminedby

theEngineerofRecordinordertomaintainthelocalatmospherebelow

25%oftheLowerFlammabilityLimit(“LFL”).

LPGisheavierthanairandcansettleinlowplaces.

DONOTallowchildrentotamperorplaywiththeequipment.

DONOTuseorstoreequipmentorcontainerswheretheycouldbe

exposedtohightemperatures.Reliefvalvescanopenallowingalarge

amountofflammablegastoescape.DONOTartificiallyheatequipment

orcontainersabove125°F.

ThisequipmentisNOTequippedwithanoverfillpreventiondevice.

Allsystemcontainersmustbedepressurizedpriortoopening.

ITISTHEUSER’SSOLERESPONSIBILITYTOUSE,TRANSPORTANDSTORETHE

EQUIPMENTINASAFEMANNER.USERASSUMESALLRISKASSOCIATEDWITHTHE

USEOFTHISEQUIPMENT.

USERAGREESTHEEQUIPMENTISONLYTOBEUTILIZEDFORLAWFULPURPOSES.

6|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER1

Components

7|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER2

GettingStarted

PlacementofSystem.Placethesystem:

i)inaproperlyventilatedareaeitheroutdoorsorinaventilatedlaboratory

environmentthathasbeenapprovedbyyourlocalfiremarshal

ii)onalevelsurface

MountingofComponents.Ensurethat:

i)allvesselsaresecurelymountedtothemountingrack

ii)themountingrackunionsareproperlytightened

iii)thecomponentsarelevel

iv)allwheelsonthemountingrackarelocked

Chiller/HeaterOptions.Forhazardous(ClassI,Division1andClassI,

Division2locations)environments,bothaliquidheatsourceandcooling

sourcewillneedtobeplumbedintothehazardousarea.Thisisgenerally

donebyusingaheaterandchiller,andplacingtheminanareadetermined

tobefitbyyourlocalbuildingdepartment.Ifrequired,youmayhaveto

utilizeULlistedequipmentforthistask,andsubmitabuildingplantoyour

municipality.YoushouldspeaktoyourPrecision®ExtractionSolutions

technicalrepresentativetoensurethatyourcoolingandheatingoptionsare

adequateforseamlessoperationofthePX1systeminapassive

configuration.ThePX1V2016extractionsystemcomespreconfiguredwith

heatingandcoolingunitssuitableforthispurpose.

SolventRequirements.ThePX1V2016extractionsystemisdesignedtobe

usedwitheithera100%butane,100%propane,oranyblendthereof.

8|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER3

PressureTesting

PressureTesting/PreparingtheEquipmenttoOperate

YourPX1unitcomesfactorytestedandinspectedforsustainedpressureholding

capabilities.However,shippingandmovingoftheunitmaycreatepressureleaks,aswell

drasticchangeintemperature.Itistheoperator'sresponsibilitytocheckforpressurefor

leakspriortooperation.

Tocheckthesystemforleaks,pleaseattachallthecomponentsandhose

assembliesperthedrawinginthismanual.Ifpressuretestingtheentiresystemnew,the

solventvesselistobeincluded.Iftestingthesystemafterthesolventtankhasbeenfilled,

pleasekeepallvalvesonthesolventvesselCLOSED.AllothervalvesshouldremainOPEN.

Attacha3/8"JIChosetothecollectionvessel,andwithallthevalvesopenonthe

system,bringthesystempressureto150PSIusingcompressedairviaanaircompressor.

EnsuretheventdownnipplesonthegaugesareOPENEDpriortoperformingapressure

test.Notetheactualreadingsofthepressuregaugesbytakingapictureforlater

comparison.Allowthesystemtositunder150PSIforatleast1hourifthisisasecondary

test(betweenruns)or24hoursifitisaprimarytest(yourfirstpressuretest).Ifany

differenceinpressureisnoticed,thereisaleak,andtheunitisunsafetooperate.

Leakscanbeidentifiedbyfillingaspraybottlewithsoapywaterandsprayingthe

suspectedareawheretheunitisleaking.Theleakcanbeidentifiedbythepresenceof

bubbles.Themostcommonareastheleakarethevalveseats(whichcouldneedtobere-

taped),thesightglasses(whichmayneedtobetightened).Before

adjusting/tightening/re-tapinganypiecesontheunit,thesystemmustbeventeddown

to0PSI.

Oncetheunithaspassedapressuretest,youarenowreadytocharge/fillthe

solventvessel.

Youwillneedtodoseveralotherproceduresinordertopreparethemachineto

run.First,inspectitsoverallcleanliness.Ingeneral,Precisionkeepsourequipmentasclean

aspossiblepostproduction,however,shippingandhandlingoftheequipmentcancause

contamination.Becauseyouaremakingafoodgradeproduct,itisyourresponsibilityto

ensureallsurfacesusedarecleanandsanitaryatalltimes.

9|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

Itisrecommendedthatyoudoa“wetrun”withyoursolvent,withnomaterial,in

ordertocleanthesystemtoasteriledegree.Youmayalsowantcleanyoursolventvessel

withparticularattention.Thesolventvesselcanbevacuumedwiththethinhoseby

removingthecentertri-clampfitting.

Onceyoursystemiscleaned,youshouldrefertoourYouTubechannelinorderto

properlyconnectyourheaterandchillertothesystem.IfyouareusingONEchillertocool

MULTIPLEcolumns,youwillneedto“T”offyourfeedandreturnlines,inordertoservice

bothcolumns.Itisrecommendedtousesiliconehosingfortheselines,youmayneedto

purchaseextralengthsfromyourhardwarestoreinordertoplacetheheaterandchiller

inthemostdesirablespotsforyoursetup.InsulationonthelinesANDthecolumnsis

essential.

YoucanalsorefertothePrecision®ExtractionSolutionsmanualsfortheheater

andchillerunits,thesemanualsareavailableonourwebsite,precisionextraction.com,

underthe“support”portal.

Itismostdesirabletouse½”quickreleasefittingsforyourcollectionbowl.These

fittingsareavailablethoughPrecision®ExtractionSolutionsandmakethedisconnectof

theheatbathlinesmucheasier.

Onceyouhaveyourheaterandchillerinplace,andyouhavecheckedforleaks,

youwillneedtoinsulateallofyourchilledlinesandcolumns.ITISESSENTIALTHATYOU

INSULATEYOURLINESANDCOLUMNSTHATARECONNECTEDTOYOURCHILLER.THE

BETTERYOUINSULATETHEMTHEMOREEFFIECENTYOURMACHINEANDCHILLERWILL

FUNCTION.

ITISHIGHLYRECCOMENDEDTHATYOUPURCHASEASTAINLESSSTEELINSULATED

HOSEKITFROMPRECISION®EXTRACTIONSOLUTIONSFORYOURHEATERSAND

CHILLERS.

10|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER4

Charging/FillingtheSolventTank

AttachyoursolventsourcetothePX1solventtankviaa3/8"JICline.Ensurethat

youhavetheproperfittingsinordertoproperlyandsafelyattachyoursourcevesselto

yourPX1solventvessel.Thesefittingswillvarybysupplier,pleasetalktoyour

hydrocarbonsolventsuppliertoprocuretheproperfittings.

TochargeyourPX1solventvessel,beginbyvacuumingthetankdownto-30in/hg

oruntilthevacuumpumpbottomsout.MakesuretoalsoputthelinefromforPX1solvent

vesseltothesolventsourcetankunderavacuumalso.Vacuumreadingmaybeslightly

differentdependingonatmosphericconditions.

Oncethetankhasbeenvacuumeddown,itwillneedtobecooled.Ifusinga

Precisioncryogenicchiller,turnonthechillerandallowthetanktocool.Dependingon

youratmosphericconditions,thesolventsourcetankmayneedtobewarmed.Thiscan

bedonebyplacingitinahotwaterbath.Youarenowreadytofillthetank.WARNING:

NEVERINTRODUCEBUTANEORPROPANEINTOTHESYSTEMWHILETHEVACUUM

PUMPISRUNNING.ALWAYSDISCONNECTTHEVACUUMPUMPPRIORTO

INTRODUCINGSOLVENT.

Ifyouwish,youmayalsofillthePX1solventvesselwithitdetachedfromthe

mountingrack,whilesittingonarefrigerantscale,althoughthisisnotnecessary.

Startingwithallvalvesclosed,openthevalveonthePX1solventvesselleadingto

thesolventsource.Youmaynowopenthevalveonthesolventsourcetank.Remain

present,notingtheflowrateintothePX1solventvessel.Fortheinitialfillofthesystem,

arefrigerantscaleshouldbeuse.BeforefillingdisconnectthesolventvesselfromthePX1

mountingrackandtarethescaleto0withthesolventvesselonthescale.Thesolvent

vesselshouldbefilledwithnomorethan22LBSofsolventforthePX1V2016model,and

shouldappearthroughthesiteglassestobeabout75-80percentfull.

11|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CommonTroubleshooting

Problem

Thesolventdoesnotflowintothetank

OilscontaminatesareinthePX1tank

Solution

Youdonothaveasiphontubeonyour

solventsourcetank.Itwillneedtobe

turnedupsidedown.

Youdonothaveyoursolventsourcetank

warmenough,itwillneedtobewarmed.

Yourbutanesourceistainted,youwill

needabetterbutanesourceand/oryou

willneedtodistillyourbutanebefore

fillingyourPX1solventvessel.

12|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER5

PreparingtoOperate

PreparingtoOperate-Passive

YouarenowreadytopreparetooperateyourPX1V2016system.Pleaseselectthe

appropriatesizedmaterialcolumntomatchtheweightandvolumeofyourinputmaterial.

Ensurethatthereisa4"screenedgasketatthebottomofthematerialcolumnabovethe

reducer.Ensurethatyourmaterialcolumnisproperlymountedtothemountingrack.Fill

yourmaterialcolumnleavingabout1-2inchesofheadspaceatthetopofthecolumn.

Thepackingdensityofthematerialisattheoperator'sdiscretion.Attachthematerial

columncaptothetopofcolumn.

NOTE:IFYOUARENEWTOUSINGACLOSEDLOOPSYSTEM,ITISRECCOMENDED

THATYOUBYPASSTHEDEWAXINGCOLUMNUNTILYOUBECOMEMOREFAMILIAR

WITHTHEPX1.

Youarenowreadytoputyourfiltersinplace.Note:Thelipidfilteringcolumnsits

belowandisattachedtothecryocolumn.Thefilterisinsidethelipidfilteringcolumn(see

componentsdiagraminthismanual).

Filtrationcanbedonewithavarietyofdifferentfiltersandmediaviathelipid

filteringcolumn.Coffeefilters,aretheleastlikelytoclog,anditisrecommendedthatyou

usesingleordoubleunbleachedcoffeefiltersinthesystemuntilyoubecomemore

familiarwiththesystem.Formoreadvancedusers,Whatman™gradequantitativeand

qualitativefiltersmaybeabetteroption.Pleaseeducateyourselfonwhatgradeof

filtrationisbestforyourapplicationandyourdesiredendproduct.Formoreonfiltration,

pleaseseeourYouTubechannel.

Atthistime,attheoperator'sdiscretion,youmayalsofillyourexpansion/filter

columnwitha3Aor4Amolecularsieve,whichmaybepurchasedfromDeltaAdsorbents.

Atthispoint,youwillcommencerunningyourrecirculatingchiller(i.e.,theDFR-50

orDFR-80,deepfreezerecirculators,sometimesreferredtoas“chillers”).Attheoperator's

discretion,youmaycoolthesolventvesseltoyourdesiredtemperatureviathechiller.

Whenrunningpassive,youdon’twanttogettoocold,asyouwillloseallsolventpressure

topushthroughthesystem.Youmayalsobegintocoolthecryocolumnviayourchiller.

Itwilltakesometimeforthecryocolumntoreachthedesired-25Cto-30Ctemperature,

approximately45-60minutes.THEDFRCHILLERISMEANTTOBEINSERVICE24/7

WITHOUTFAILURETOMINIMIZESYSTEMDOWNTIMEANDMAINTAINTEMPERATURES

EVENWHENNOTINUSE.

13|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

Whileyouhavethesolventvesselandcryocolumnscooling,vacuumdownall

remainingcolumnsandhosesbyattachingyourvacuumpumptothecollectionvessel

andopeningthepropervalves.Vacuumthesystemuntilyourpump"bottomsout"or

untilyoureachapproximately-30in/hg.

Forapplicationsinhazardousenvironments,youmayberequiredtorouteyour

vacuumlineoutsidetheclassifiedroom,tocomplywithClass1,Division1orClass1,

Division2standards.

Withthesolventvesselandcryocolumnschilled,andthesystemunderafull

vacuum,youarenowreadytorunthesystem.

14|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER6

RunningtheExtractor

Allvalvesshouldnowbeclosed.

Openthesiphontubevalveonthesolventvessel(leadingtothematerialcolumn)

andtheinletvalveonthematerialcolumn(locatedonthelid)allowingsolventtoflood

thematerialcolumn.ThematerialcolumnisfullwhenthepressureiswithinafewPSIof

thetankpressure.Youmaynowclosethesiphontubevalve.Besurethatwhenrunning

passiveyoursolventisnottoocold,otherwiseallpressurewillbelostandthesolventwill

notwanttomoveoutofthetank.

Whenthedesiredmaterialcolumnsoaktimehasbeenreached,begintoopenthe

inletvalvetothecryocolumn.Itiskeytoallowthesolventto“stall”inthedewaxing/cryo

columninordertoallowforproperlipidcoagulation.Startwithonehourandadjustfrom

there.Youwillbeabletoviewtheclarityoftheoutputmaterialthoughthesightglasses

onthecollectionvessellid.Youcanadjustthespeed,temperature,andfiltration

dependingonthedesiredendproduct.

Asthecollectionvesselfillswithsolvent,thepressurewillbegintorise,andthe

vacuumpressurewillbelessthanadequatetocontinuetopulltheremainingsolvent

thoughthefilters.

Atthispoint,youmayexperienceacompletestopofsolvententeringthe

collectionvessel.Inordertopulltheremainingsolventintothecollectionchamber,turn

ontheheatingsourceforthecollectionvesselandexpansionfilter/columnandturnon

thecryogenicstocoolyoursolventvessel,andopenallthepropervalvestobegin

recovery.Thetemperaturevariationwillpullthecollectionvesselbackintoavacuumand

allowtheremainingsolventtoenterthecollectionvesselandre-condense.Throttlingof

theinletvalveonthesolventvesselisnecessarytoachieveamaximumpressure

differentialbetweenyourcollectionvesselandsolventvessel.Thehigherthepressure

differentialbetweenthesetwovesselsduringyourrecoveryprocess,thefasteryour

ultimatepassiverecoverywillbe.

Moreadvancedusers,usingfinegradefiltration,mayalsoopttouseavaporassist

atthetopofthematerialcolumnifthepumpisinadequateatpullingthesolventthrough.

Thiscanbedonebyconnectinganyvaporportofthesolventvesseltothevaporinput

onthetopofthematerialcolumn.

NOTE:IMPROPERKNOWLEDGEOFPROPERFILTRATIONGRADESAND

APPLICATIONSCANLEADTOCLOGSINTHESYSTEM.STARTWITHCOARSE

GRADESANDWORKYOURWAYDOWNTOFINERGRADES.

15|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

Atthispoint,youshouldbewellonyourwaytorecoveryofthesolvent.Uponall

ofthesolventbeingpulled/pushedfromyourmaterialcolumn,closetheinputvalveto

thecollectionvessel.

Youcanmonitoryourrecoveryrateviathesightglassesonthecollectionvessel

lid.Youshouldalsobemonitoringyoursolventvesselpressureduringrecovery,never

allowingittoreachabove100psi.Werecommendpre-purgingthematerialinthe

collectionvesseltoascloseto-30in/hgaspossible,sothatlittletonoflammablegases

escapeintotheatmospherewhenopeningthesystemtoremoveyourmaterial.

USINGNITROGENASSISTINGWITHCOLDSOLVENT

YOUMAYOPTTOUSEANITROGENPRESSUREASSISTWHENDROPPINGYOUR

SOLVENTTOLOWTEMPURTURES.TOUSEANIRTOGENASISST,YOUWILLNEEDALARGE

BOTTLE(100+LB)BOTTLEOFGASEOUSNITROGEN,ASWILLASANAPPORVED

NITROGENREGULATORANDCONVERSIONFITTINGSTOMATETOA3/8”FEMALEJIC

FITTINGONYOURPX1HOSES.

SETYOURREGULATORTO30PSIABOVETHEVESSELPRESSUREYOUWISHTO

INCREASE.INJECTTHENITROGENUNTILTHEDESIREDPRESSUREINCREASEOFTHEPRE-

SETREGULATORISREACHED.OPENTHENECESSARYVALVESTOMOVEYOURSOLVENT

TOTHETARGETEDVESSELINTHEPROCESS.WHENTHESOLVENTHASFULLYREACHED

YOURTARGETEDVESSEL,YOUWILLNEEDTOVENTOFFTHEACCESSNITROGEN.

NITROGENVENTINGSHOULDHAVEANITROGENVENTDOWNLINEATTACHED

TOTHEAPPPOPRIATEVESSELINORDERTOROUTETHENITROGENDIRECTLYINTO

YOURCLASSIFIEDVENTALATIONSYSTEM.

WARNING-NEVERVENTNITROGENORHYDROCARBONVAPORDIRECTLY

INTOTHEATMOSPHERE!

16|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER7

VentDownandPourOff

VentDownandPourOff

Withyoursolventrecoverycomplete,youarenowreadytoventdownyoursystem

andextractyourproduct.Afterremovinganyhoseonthecollectionvessel,openthevalve

toventdownthechamberandallowtostabilizeat0psi.

Youmaynowremoveyourextractbyremovingthe2-5/8"boltsthatattachthe

pouroffbowl.

Removeyourextract.

Youmaynowcleanyourcomponentsandvesselstoprepareforyournextrun.

17|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

CHAPTER8

PeriodicMaintenance

Periodicmaintenanceisessentialtothesafeandproperoperationofyourequipment.

ContactPrecision®ExtractionSolutionsdirectlyforreplacementcomponents.Obtaining

replacementcomponentsfromathirdpartyvoidsyourwarrantyandinvalidatesthe

engineeringpeerreviewoftheequipment.

Vitongasketscreens,extractioncolumns,andcollectionvesselandbowlshallbecleaned

aftereveryusewithanapprovedfood-gradedisinfectant.

Itisrecommendedthatafterevery10thuse,asolventonlyrunbecompletedtohelp

preventoilbuildupinthesystem.

AcompletesystemcleaningisrecommendedEVERYMONTH.Rememberthatyoumay

beproducingafood-basedproduct.UseONLYapproved,food-safecleanersand

sanitizers.

WARNING:Ifthecleanersand/orsanitizersareflammable,ensurecleaning

activitiesareconductedinanareawithadequateventilationorunderanexplosion-

prooffumehood.

Alwaysreplaceworncomponentsimmediately.Ataminimum,itisrecommendedthat

thefollowingcomponentsbereplacedaccordingtothemaintenanceschedulebelow:

ComponentReplacementFrequency

HosesEvery12

months

GasketsEvery10thuse

re-tightenedoratfirstvisiblesignofwear

SanitaryClampBolts/NutsEver

y

10th

use

oratfirstvisiblesignofwear

ReliefValvesTestoncepermonthtoensureperformance–replaceas

needed

18|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

BallValvesEvery12

months

QuickConnectsEvery12

months

Thewearontheindividualcomponentsofyourmachinewillvarygreatlydependingon

theamountofusageinagiventimeframe.ItisEXTREMLYIMPORTANTthatallnuts,

bolts,andgasketsbeinspectedbeforeeveryuseofthesystem.Ifthereisanyquestion

astotheintegrityofanygivencomponent,replaceitimmediately.

_____________________________________________________________________________________________

IffurtherassistanceisneededpleasevisitourYouTubechannelforvideotutorials

orcontactPrecision

®

ExtractionSolutionstechnicalsupportdirectlyat855-420-0020.

19|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

APPENDIXA

FacilityRequirements

InstallationofthisequipmentmustbeapprovedbythelocalAuthorityHavingJurisdiction

(“AHJ”).TheAHJwilldeterminethefacilityrequirementsforoperationofextractors.Ata

minimum,thefollowingshallapply:

Adequateventilation/exhaustasdeterminedbytheEngineerofRecordinorderto

maintainthelocalatmospherebelow25%oftheLowerFlammabilityLimit(“LFL”)

forsolventused.

ExhaustsystemsshallbedesignedinaccordancewiththeInternationalMechanical

CodeandshallbeONwheneverLPGisstoredorusedintheextractionarea.

Ancillaryequipmentshouldbelocatedinanotherroom.

Ahydrocarbonmeter,alarmingatorbelow25%oftheLFLshallbeemployedin

theextractionarea.Thedetectorshouldbeinstalledneartofloorleveltodetect

heavyhydrocarbongases.Additionally,thedetectorshouldbeinstalledbya

qualifiedindividualandshouldbecalibratedtotheappropriatesolventofuseat

leastannually.

Openingofthecollectionbowlorcollectionpottoremovetheproductshallbe

withinafumehoodorinanareathatprovidesadequateventilation/exhaustto

maintainthelocalatmospherebelow25%oftheLFLasdeterminedbytheEngineer

ofRecord.

OSHAStandardsintheWorkplace

Ifthissystemisusedinaworkplacesetting,pleasebeawarethatitistheresponsibilityof

theemployertofurnishaworkplacewhichisfreefromrecognizedhazardsthatare

causingorarelikelytocausedeathorseriousphysicalharmtoemployees.Occupational

HealthandSafetyAdministration(“OSHA”)standardsthatshouldbereviewedforsite-

specificapplicabilitypriortotheoperationofthissysteminclude(butmaynotbelimited

to):

40CFR§1910.22–Generalrequirementsforhousekeepingand

aisles/passageways

40CFR§1910.38-39–EmergencyActionandFirePreventionPlans

40CFR§1910.101–Generalrequirementsfortheuseofcompressedgases

40CFR§1910.110–StorageandhandlingofLiquefiedPetroleumGases(“LPG”)

40CFR§1910.132-138–PersonalProtectiveEquipment(“PPE”)

40CFR§1910.144-145–Specificationsformarkingphysicalhazardsandaccident

preventionsignsandtags

40CFR§1910.147–Controlofhazardousenergy(lockout/tagout)

40CFR§1910.151–Medicalservicesandfirstaid

20|Page

ModelPX1V2016OperationalManual–ForHazardousEnvironments

Precision®ExtractionSolutions

©2015PX2Holdings,LLC.Allrightsreserved.

40CFR§1910.157-Portablefireextinguishers

40CFR§1910.1000–Controlofoccupationalexposuretoaircontaminants(e.g.,

solvents1).

40CFR§1910.1200–Hazardcommunication

1TheAmericanConferenceofGovernmentalIndustrialHygienists(ACGIH)recommendsthatexposuretobutanebe

controlled to a level of less than 1000 parts per million (ppm) as an 8‐hour time‐weighted average (TWA).

Occupationalexposurestopropanemustbecontrolledtoalevellessthan1000ppminaccordancewiththeOSHA

PermissibleExposureLimit(PEL).

Table of contents

Other Precision Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Jäger

Jäger Z100-H636.05 S11W2V manual

Chicago Valves & Controls

Chicago Valves & Controls CGO Series Installation, operation and maintenance manual

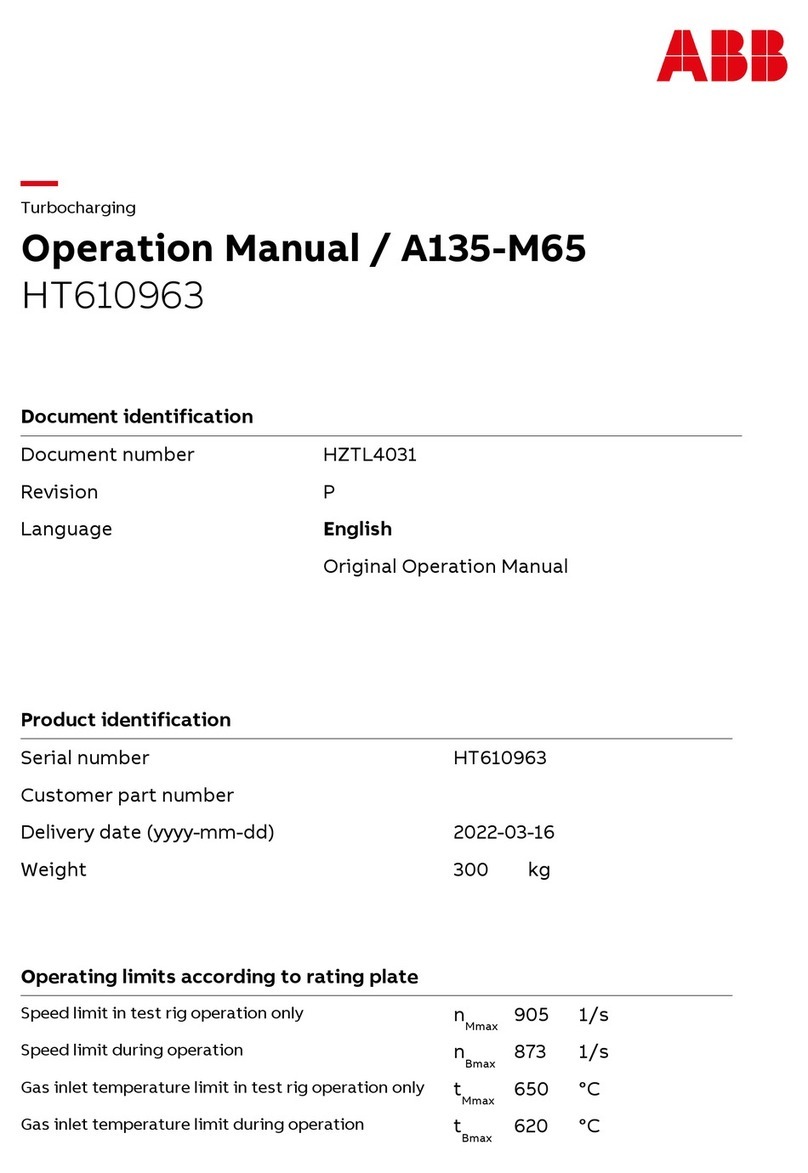

ABB

ABB HT610963 Operation manual

Duro Dyne

Duro Dyne GBAC ROTO BONDER owner's manual

BRAHMA

BRAHMA MF2 quick start guide

Daikin

Daikin ECORICH R 40 Series instruction manual