6

Introduction

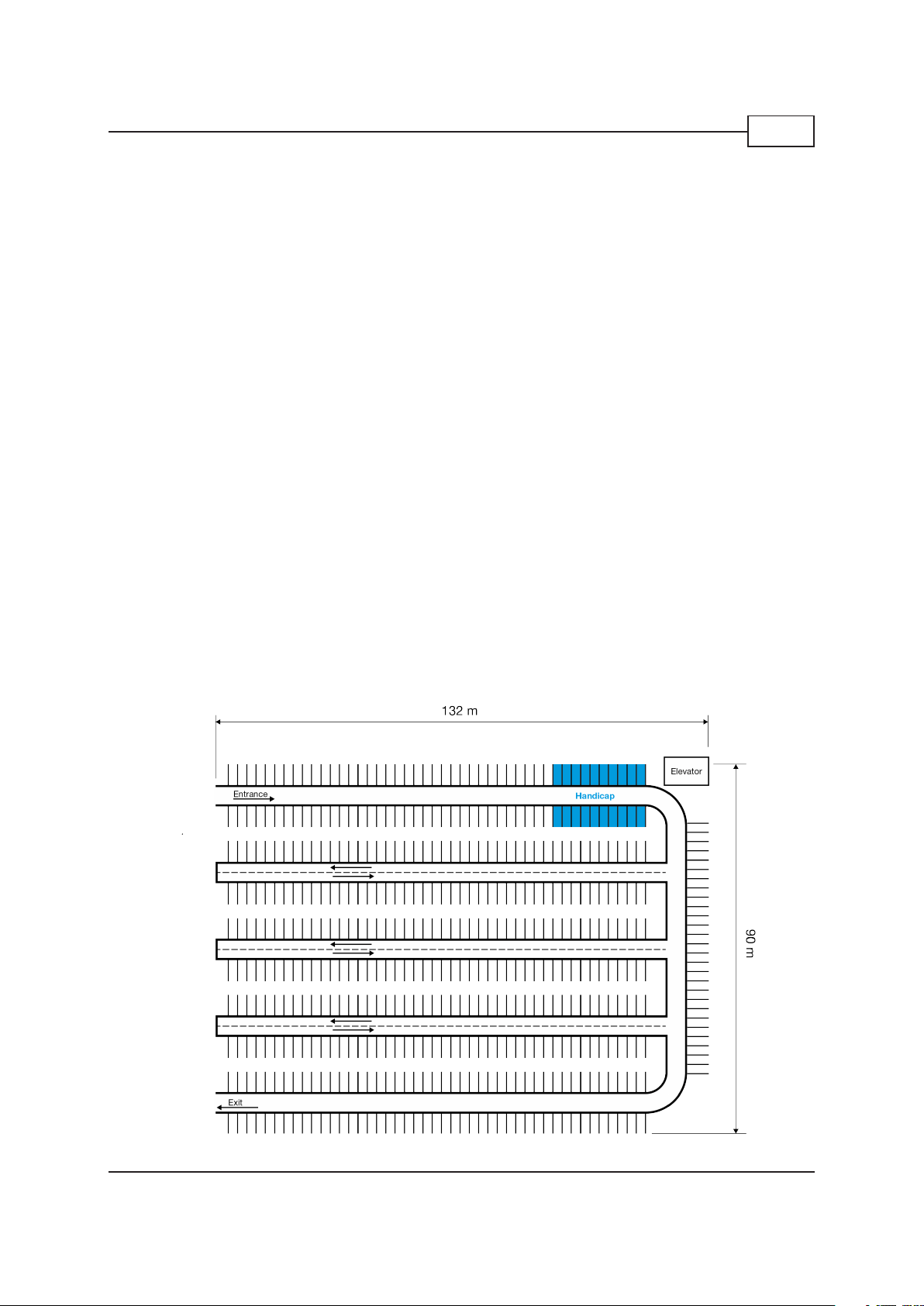

The Dupline®Parking Guidance system saves time and reduces stress for drivers�

Dynamic displays strategically positioned throughout the facility provide “space available” counts and

efficiently guide the driver to open spaces with clear and bright green arrows pointing the way�

If there are no open parking spaces in an area, the sign will display a bright red cross to discourage

the drivers from entering this area� Other displays can be made to display the total number of open

spaces on a particular level or in the entire parking facility� Dynamic message displays can also be

used in the facility to provide additional information to drivers� Some examples could be Caution;

Construction Ahead; Buckle-Up, and any other message that needs to be communicated to the driv-

ers in the facility�

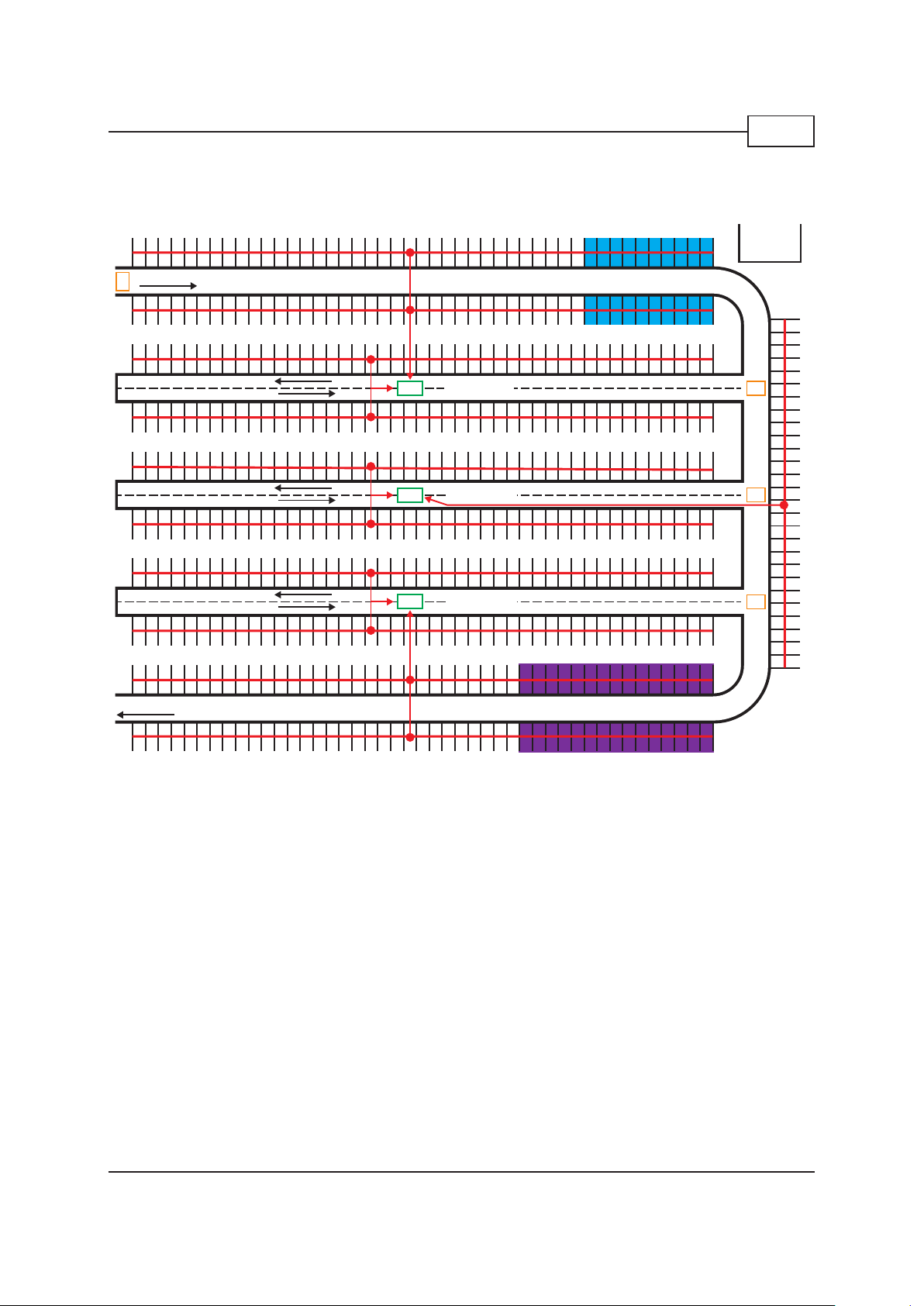

In the parking space

Each parking space is equipped with a clear indicator light, which is green when the space is open

and red when it is occupied� If the space is for handicap parking, the colors become blue and red� The

bright LED indicators provide a visual reference as drivers seek out open parking from a distance� The

indicator lights are combined with an ultrasonic sensor as a complete set�

The Dupline®Parking sensors utilize a special ultrasonic frequency, much like a bat uses to search

for flying insects� A sophisticated microprocessor contained in the sensor knows how much time that

it should take for a sound wave to “bounce” from the floor back to the sensor� If a vehicle is parked

in the space, this time is measurably shortened and the logic in the microprocessor determines that

a vehicle is present in the space� Once detection has been confirmed, the indicator lights will switch

from green or blue to red and the displays and the software counts will be accurately updated as well�

Master Zone Counter “MZC”

This installation manual does not describe the MZC in details� The MZC has its own installation man-

ual which describes in details the programming of the MZC, programming and installation of the sen-

sors, using the configuration unit, installation examples and a lot more� This manual informs about the

overall features of the MZC and in which Carpark installations it can be used� Moreover, it will describe

how to combine spot detection and counting�

The Software…

The Dupline®Parking Guidance System is inherently robust and a stand-alone system� This system

does not require a PC to run� However, optional software makes it possible to monitor the real-time

situation of each parking space or level in a facility� It also has a full alarm component that can provide

logging and indication of a variety of conditions exceeding user-defined limits�

Some typical alarm functions include time-limits for individual spaces, occupied levels, and maximum

occupied indications� Additionally, the software graphically displays tables and graphs showing the

occupancy rates for the areas, the floors and the entire facility�

The software is also a tremendous tool for data logging and historical trending and analysis� Data can

be stored and utilized for multiple facilities, a single facility, a level, or even to an individual space�

The software allows authorized operators to book or reserve spaces� When an open space is booked,

the associated indicator light in the parking space will turn red and it will provide a connection to the

software's overview where the corresponding virtual indicator light turns red�