PreeKem GT-400 User manual

2

GT-400 Vessels Operation Manual

Preface

Safety Declaration

Please read the entire manual carefully before operation. The operator needs follow up with the safety

declaration paragraph strictly. Otherwise PreeKem should not be responsible for all the accidents.

Symbol ATTENTION means danger exist, to remind you that you must pay

attention. Improper operation or failed to comply with the appropriate procedures

may result in equipment damage.

Symbol DANGER means danger exist , to remind you that you must pay attention.

Improper operation or failed to comply with the appropriate procedures may result

in injury or death.

ATTENTION

DANGER

3

Table of contents

Table of contents

Preface....................................................................................................................................................1

Safety Declaration...............................................................................................................................2

Table of contents.....................................................................................................................................3

GT-400 Vessels operation guide ............................................................................................................4

1 Safety instruction..................................................................................................................................5

2 Rotor introduction.................................................................................................................................7

2-1 Overview .......................................................................................................................................7

2-2 Technical Performance .................................................................................................................7

3 Rotor operation ....................................................................................................................................8

3-1 Turntable installation.....................................................................................................................8

3-2 GT-400 the vessel installation.......................................................................................................8

3-3 Install the digestion vessel into the cavity...................................................................................10

3-4 Uninstallation of digestion vessel................................................................................................11

3-5 Rinsing ........................................................................................................................................12

Hot rinsing......................................................................................................................................12

Complete rinsing............................................................................................................................13

Appendix 1: The standard operating procedures of the GT-400 vessels.............................................14

4

GT-400 Vessels Operation Manual

GT-400 Vessels operation guide

5

1 Safety instruction

1 Safety instruction

1.1 All the vessels and framework components must be dry and free of

particulate matter, drops of liquid or particles will absorb microwave energy,

causing localized heating which may char and damage vessel components,

leading to possible vessel failure.

1.2 Heating concentrated alkaline or salt solutions in vessel is prohibited

and the concentration solution should be no more than 10%, otherwise it will

cause precipitation of salts and formation of crystal deposits on vessel walls.

These crystal deposits will absorb microwave energy, causing localized

heating which may char and damage vessel components, leading to possible

failure.

1.3 To avoid the danger of explosion, perchloric acid is prohibited. Do not

singly heat high boiling point acids (concentrated sulfuric or phosphoric

acids) inside the vessels to avoid the temperature exceed the vessel

material’s melting point, resulting in the vessel damage.

1.4 Huge gas and heat will be generated during the digestion process of the

organic sample and the large size of sample, which may possibly cause the

fierce reaction, resulting in the pressure rising speed exceed the response

speed of the pressure-release module. The explosion will occur when the

pressure exceed vessel’s programmed limit.

1.5 Organic sample treatment: Generally the unsealed vessels containing the

organic sample and the digestion acid solvent will be pretreated, based on

the sample.

(1) Before placing the vessels into the cavity, operators shall put them inside

the fume hood for several minutes or hours, slightly shake it to release small

amount of bubble or gas.

(2) Before placing the vessels into the cavity, operators shall put the vessels

on the special heating instrument to release some gas and heat (the control

temperature should not exceed 150°C). After the above pretreatment, setting

the digestion process, starting from low temperature (100-120°C) to middle

temperature, finally adjust to high temperature.

The above steps not only enhance the safety but also are good for sample

digestion.

1.6 All the vessels should be filled with the same weight, volume of sample

and reagent also need to share the same starting temperature.

1.7 Check the turntable rotation prior to start the microwave heating, make

sure the turntable can be rotated, otherwise will result in explosion caused

by localized over temperature.

ATTENTION

DANGER

ATTENTION

DANGER

ATTENTION

DANGER

ATTENTION

6

GT-400 Vessels Operation Manual

1.8 All the digestion vessels should be cool down to 80°C prior to place them

into the fume hood. Slowly loose the pressure-release module, wait till the

gas completely released, otherwise the acid solution will spill to operator

and cause the injury.

1.9 The components of the vessel are easily prone to aging because of the

repeated heating and cooling which cause the expansion and the

contraction by themselves, together with the acid corrosion. Especially the

sleeve tends to be short lifespan, thus when crack occurred or crack

increasing, the sleeve has to be scrapped, otherwise explosion may occur.

1.10 The material of the sample cup is TFM, which melting point is 300°C

under common pressure. If place the sample into hot block to heat, the hot

block should be equipped with over temperature insurance.

1.11 The vessels contained with sample and the acid solution should be

operated as soon as possible, when the digestion completed the sample

should be taken out in time , the vessel sleeve and the seal lid will possibly

be damaged by acid leakage if the sample stays too long in the vessel.

1.12 Operation over the maximum working temperature (200°C) is prohibited.

1.13 The number of vessels should be applied more than 8 for every batch,

and should be put on the inner circle of turntable as priority.

1.14 The samples which not suit for air-tight microwave digestion are

prohibited. Please refer to the instrument operation manual “Samples

prohibited for air-tight microwave digestion system”. The GT-400 is a high-

throughput digestion vessel, if the operator is unclear about the type of the

range of the sample, please consult with the engineer for unknown samples.

DANGER

ATTENTION

ATTENTION

ATTENTION

DANGER

ATTENTION

DANGER

7

2 Rotor introduction

2 Rotor introduction

2-1 Overview

The GT-400 is a middle pressure vessel, which includes the anti-corrosion sample

cup, the seal lid and the sleeve which can hold the horizontal pressure. The GT-

400 is designed for pretreatment for various types of samples. At most 40 GT-400

vessels can be installed for each batch. The working temperature for GT-400 is

between 0-200°C, the pressure will be automatically released when pressure

exceed 2MPa.

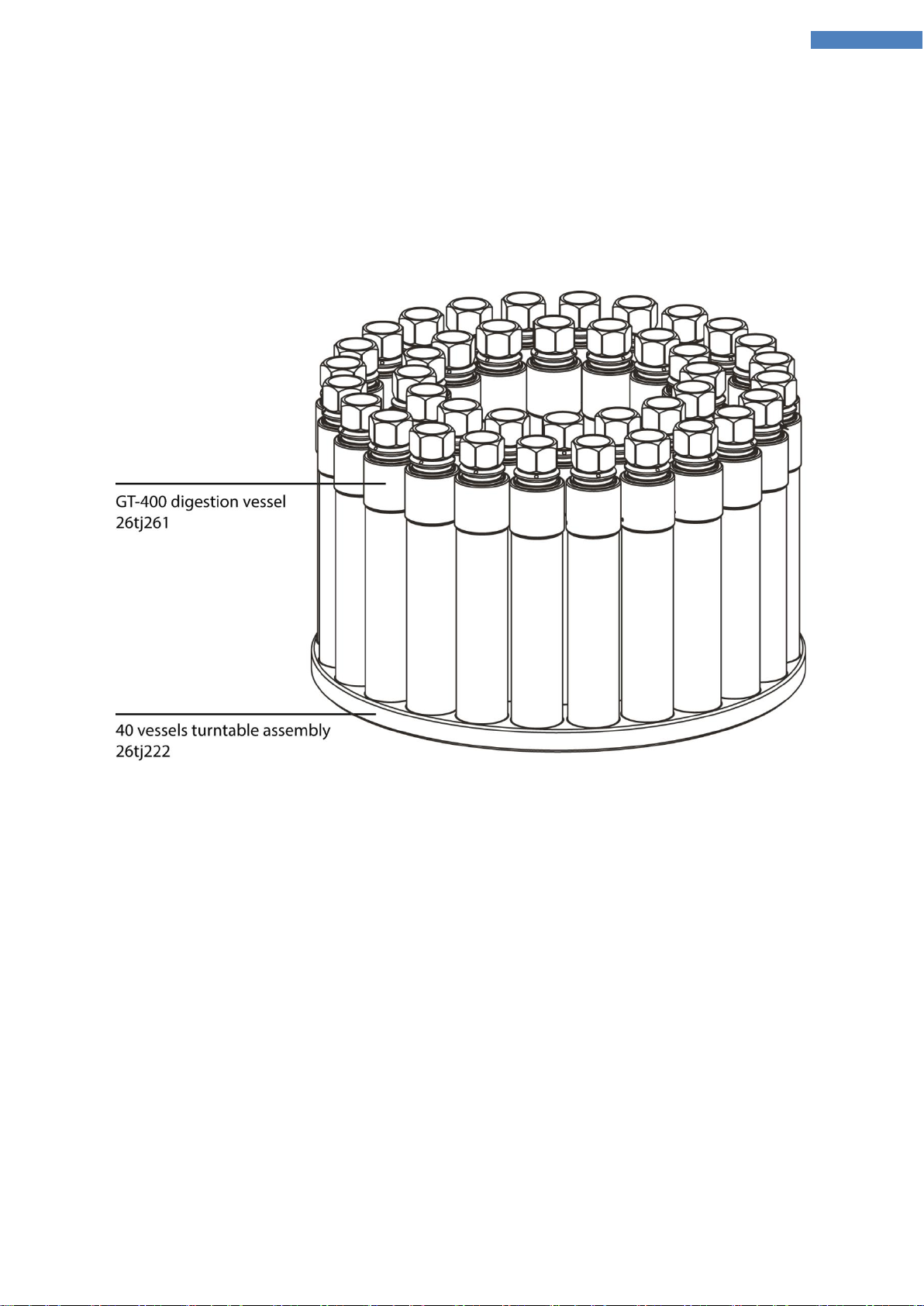

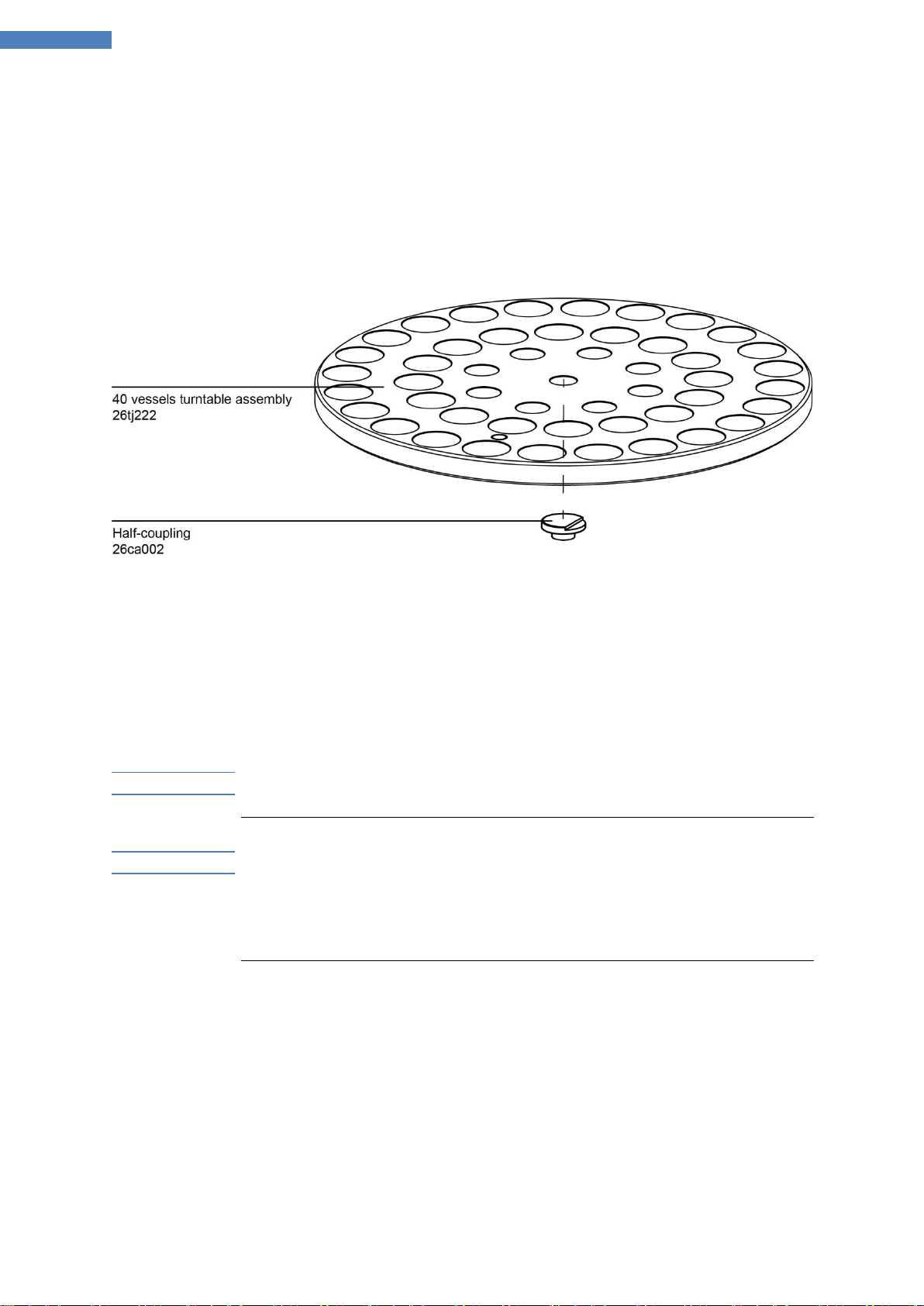

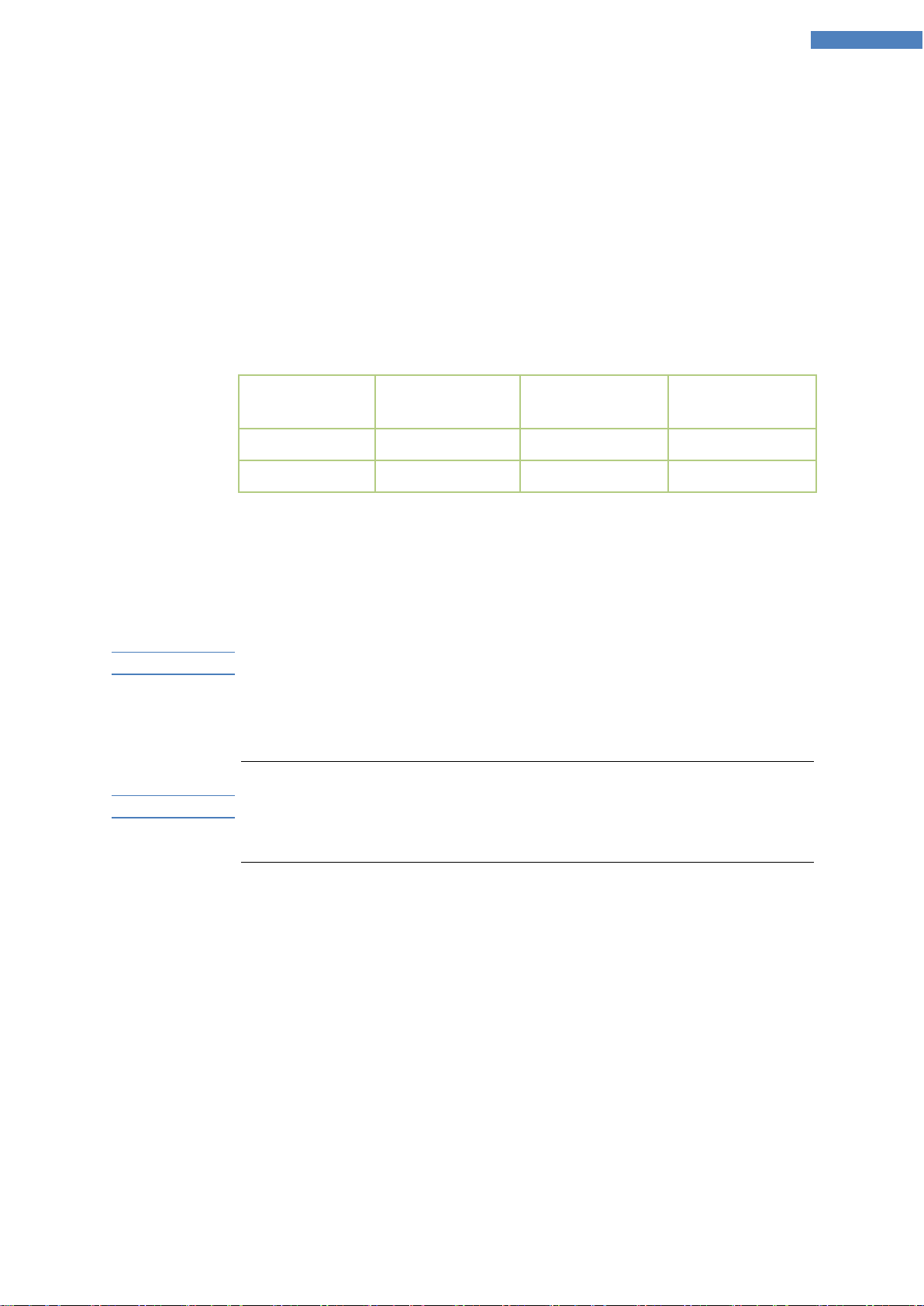

Figure 1: GT-400 Vessels

2-2 Technical Performance

Inner vessel material: TFM

Sleeve material: PEEK

Digestion vessel volume: 60mL

Maximum working pressure: The pressure will auto-released when pressure over

2MPa

Maximum working temperature: 200°C

8

GT-400 Vessels Operation Manual

3 Rotor operation

3-1 Turntable installation

Related components:

Instrument mainframe

Half-coupling (26ca002)

40 vessels turntable assembly (26tj222)

Figure 2: Turntable installation scheme

Procedure:

1. Open the door prior to the turntable installation.

2. Insert the half-coupling (26ca002) into the central hole of the bottom of the

cavity.

3. Install the turntable into the cavity. Align the central hole of the turntable with the

coupling shaft.

After installation, the turntable can be leaved in the cavity. It is not required

to install at every time of operation.

The Infrared temperature sensor which is installed out the bottom of the

cavity should be cleaned for every week. Use the cotton cloth or the cotton

ball to clean it, if the stain can’t be cleaned easily, a little of pharmaceutical

alcohol can be applied. If the instrument hasn’t been used for a long time,

the camera should be cleaned before operation.

3-2 GT-400 the vessel installation

Related components:

Seal lid (26tj263)

Seal plug (26ca306)

Sample cup (26ca307)

Sleeve (26tj262)

ATTENTION

ATTENTION

9

3 Rotor operation

Figure 3: GT-400 Digestion vessel

Procedure:

1. Weigh the sample by balance and place it into sample cup.

Place the sample to the bottom of the sample cup and avoid adhering to the

wall of the sample cup.

For unknown sample the weight should be controlled less than 0.1g,

avoiding the explosion caused by fierce reaction.

The sample cup is slender and can easy to fall down.

2. Place the sample cup contained with sample into the fume hood, adding a

suitable amount of acid solution into the sample cup and immersing the sample.

Slightly shake the sample cup or stir it to make it evenly dispersed. If needed, the

sample cup loaded with sample and acid solution can be heated on the hot block

for a certain time (15-30min).

Observe if violent reaction occurs after sample is dispersed in the solvent. If

the reaction is too violent, please DO NOT close the seal plug until the

reaction almost completes.

ATTENTION

DANGER

ATTENTION

DANGER

10

GT-400 Vessels Operation Manual

The volume of solvent added should be in the range of 3-15mL.

3. Close the sample cup with seal plug.

4. Put the sample cup into sleeve.

5. Screw the seal lid tightly.

3-3 Install the digestion vessel into the cavity

Related components:

GT-400 Digestion vessel (26tj261)

40 vessels turntable assembly (26tj222)

Procedure:

1. Check the Infrared temperature sensor camera inside the cavity, ensure this

area is dry and clean.

Before use the GT-400 digestion vessels, the temperature sensor assembly

and air-guide tube assembly should be uninstalled.

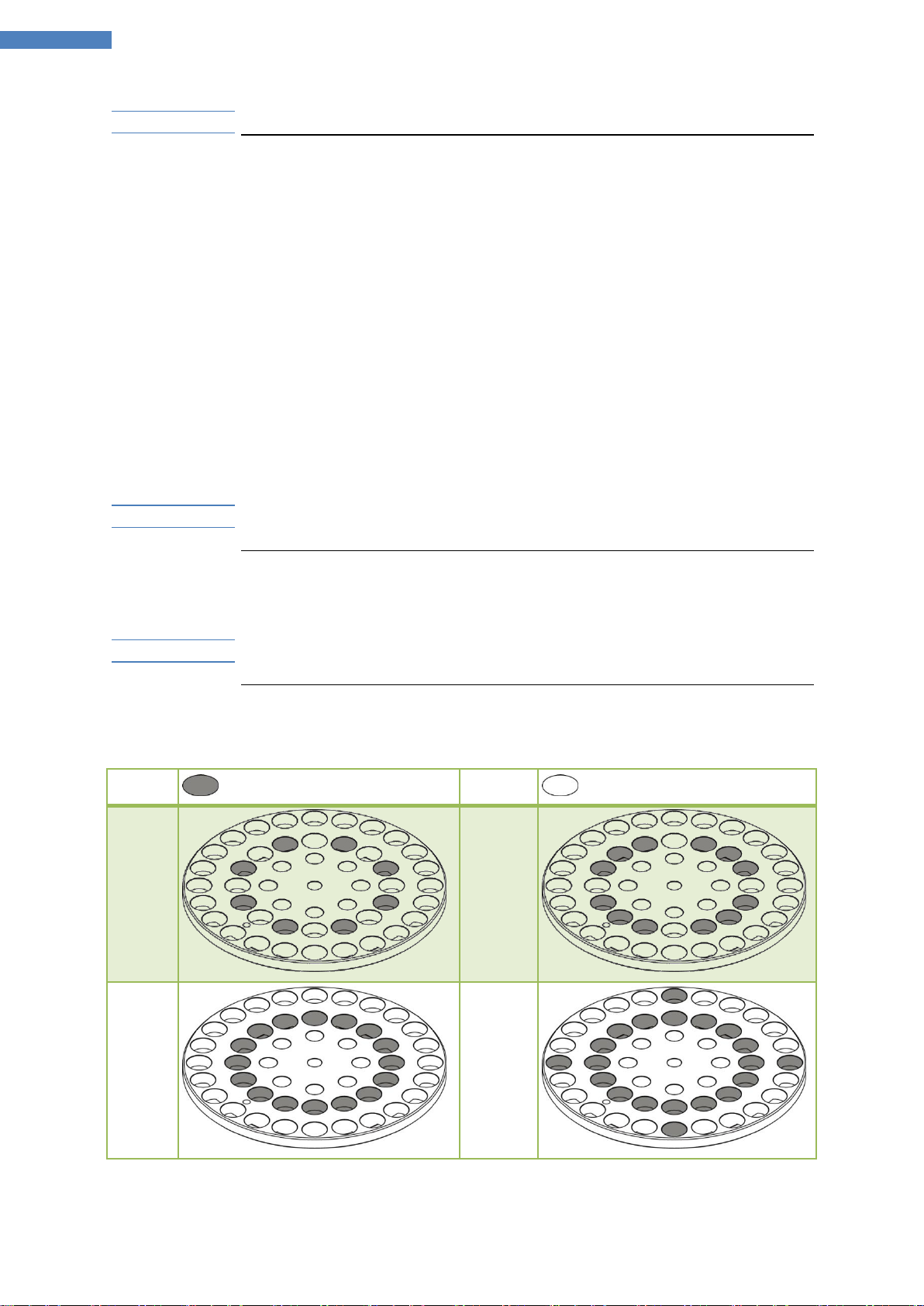

2. Install the digestion vessel onto the turntable.

The digestion vessel should be placed on inner circle of turntable as priority

and should be installed not less than 8.

The placement of digestion vessel should strictly follow the bellowing placing

diagram.

Sample

Vacancy

8

vessels

12

vessels

16

vessels

20

vessels

DANGER

ATTENTION

DANGER

11

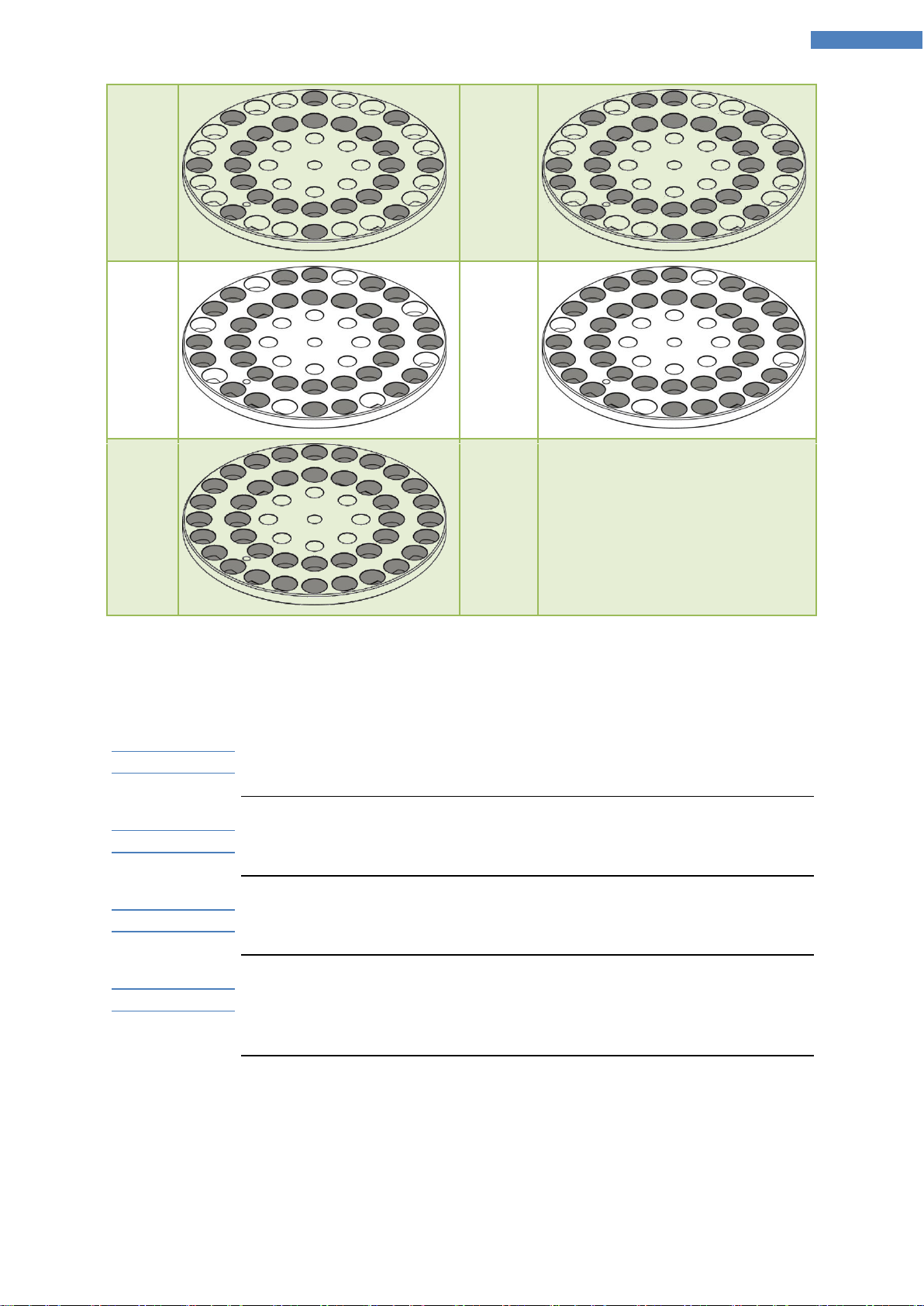

3 Rotor operation

24

vessels

28

vessels

32

vessels

36

vessels

40

vessels

3-4 Uninstallation of digestion vessel

The digestion vessel can be taken out after the temperature is cooled down to

80°C. The operators should follow the steps as below to operate after taking out

the digestion vessel. Misoperation will cause the injury by pressure release.

Before opening the digestion vessel, the operators should be equipped with

the anti-acid glove, the eye protection, the mask and the lab coat

The digestion vessels are not allowed to be open when the temperature is

above 80°C.

The door is not allowed open to take out the digestion vessels when the

temperature is above 120°C.

After disassembling the digestion vessel, the sample cup and the sleeve

should be put into the sample holder, other parts should be stored into the

cupboard in case of losing.

Related components:

GT-400 digestion vessel (26tj220)

Opener (26ca308)

Procedure:

DANGER

DANGER

DANGER

ATTENTION

12

GT-400 Vessels Operation Manual

1. Open the cavity door.

2. Move the digestion vessels from the turntable and place them into the fume

hood.

3. Loosen the seal lid in fume hood to release the pressure and then screw off the

seal lid.

Make sure the fume hood is open before loose the pressure-release module

to release the acid gas.

Be careful with the acid gas when loosening the seal lid.

4. Take out the sample cup from sleeve and place to the sample rack to avoid the

fall off.

5. Remove the seal plug and transfer the solution to other container.

The inner vessel should be cleaned every time, while the sleeve can be

cleaned in a certain period, for details please check the Maintenance Manual.

3-5 Rinsing

After finishing, you must rinse the sample cup and vessel lid, specific method is as

follows:

Procedure

1. Rinsing sample cup at least three times with deionized water.

2. Standard seal lid and sample cup should be soaked in 10%-15% nitrate cylinder

through the whole night.

3. Taking one sample cup, pouring 10%-15% nitric acid to nearly full, then putting

on seal lid and soaking. You should make the vessel cup straight all the time.

4. After soaking, rinsing sample cup at least three times with deionized water and

ultrapure water.

Hot rinsing

The effect of hot rinsing is similar to the common rinsing, its operation is more

complicated than common rinsing, but it has higher speed. So it can finish rinsing

quickly.

Procedure:

1. Rinsing sample cup at least three times with deionized water.

2. Pouring 5mL nitric acid and 5mL ultrapure water into every sample cup.

3. Doing the experiment in the following table:

Step

Temperature

(°C)

Time

(min)

Pressure

(atm)

1

120

2

10

2

180

10

20

ATTENTION

DANGER

ATTENTION

13

3 Rotor operation

4. After opening vessel, rinsing sample cup and seal lid at least three times with

deionized water and ultrapure water.

Complete rinsing

When common rinsing can’t accomplish the requirement such as it is polluted

seriously or it has a high require of blank, you must use complete rinsing method.

Procedure

1. Rinsing sample cup and seal lid at least three times with deionized water

2. Pouring 5mL hydrochloric acid and 5mL ultrapure water into every sample cup.

3. Doing the experiment in the following table:

Step

Temperature

(°C)

Time

(min)

Pressure

(atm)

1

120

2

10

2

180

10

20

4. After opening vessel, rinsing sample cup and seal lid at least three times with

deionized water.

5. Pouring 5mL nitric acid and 5mL ultrapure water into every sample cup.

6. Do the experiment as the procedure 3.

7. Rinsing sample cup and seal lid at least three times with ultrapure water.

If user needs to do digestion, synthesis and extraction on one microwave

system, we suggest use two rotors for the separate using. If you only have

one rotor, you should clean the vessels strictly following the orders between

two different using, and then put the vessels in the oven to dry them at

120°C for no less than 24 hours.

The cleaning method for synthesis and extraction is as below: use ethanol

or acetone to clean the inner vessels and wash with pure water two or three

times before drying.

ATTENTION

ATTENTION

14

GT-400 Vessels Operation Manual

Appendix 1: The standard operating procedures of the GT-400

vessels

Notice: before operation, the operators should be

equipped with the anti-acid glove, the eye protection,

the mask and the lab coat.

1. Check all the components of the digestion vessel, make

sure there is no crack, stain, liquid and the sample cup, the

seal plug is in good shape.

Attention: the above check should be strictly proceed,

otherwise the experiment will possibly be failure or the

digestion vessel will be in danger of damage due to the

vessels can’t hold the high pressure and temperature during

the microwave heating process.

Components: Seal lid (26tj263), Seal plug (26ca306),

Sample cup (26ca307) and Sleeve (26tj262)

2. Sample cup in the sample holder.

Attention: The sample cup is slender and easy to fall down,

place the sample cup on the desk directly is prohibited.

3. Other components can be temporarily placed in the box

and put aside the fume hood.

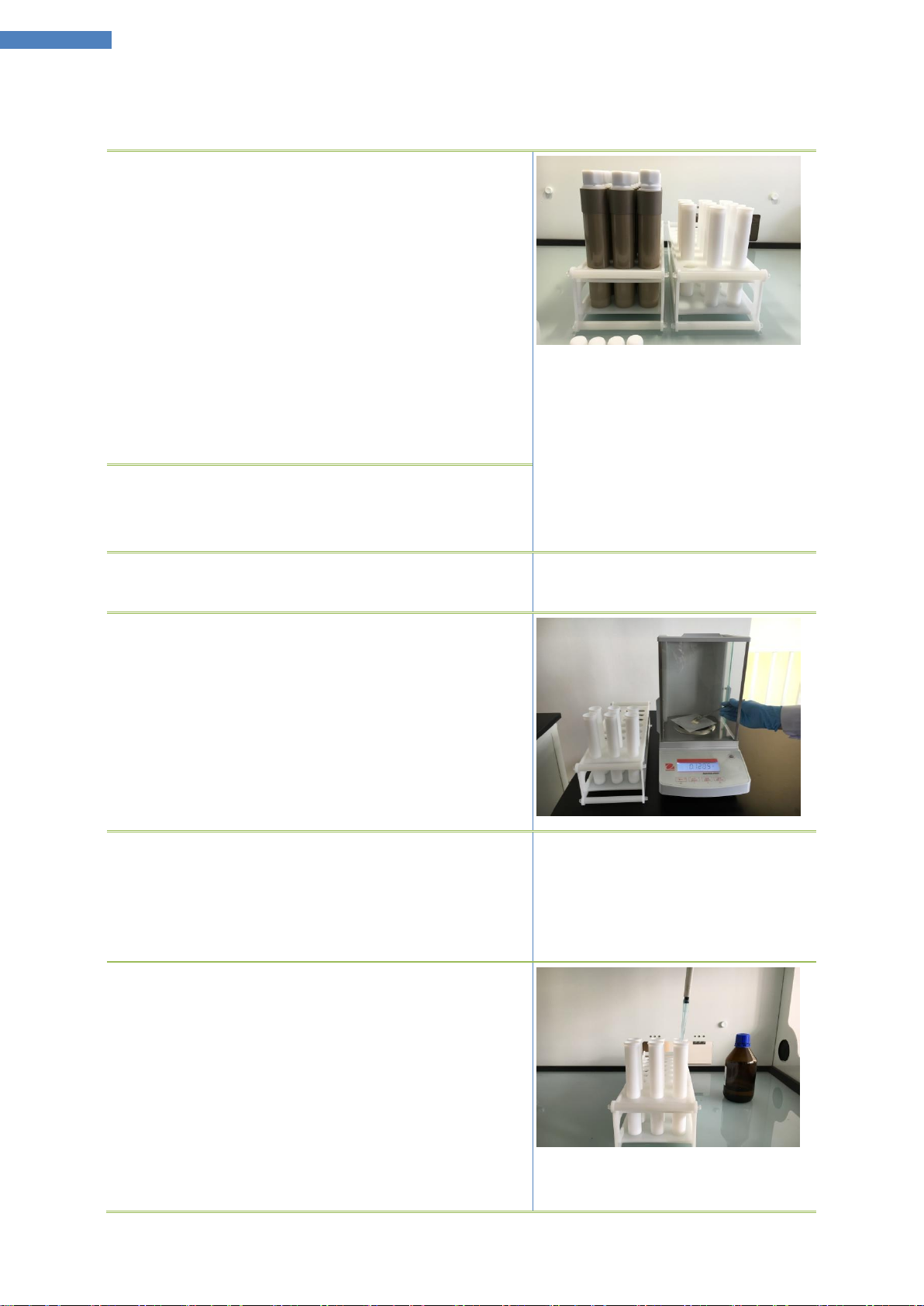

4.Weigh the sample precisely

Attention: The sample weight should be between 0.1-0.5g, if

the operator is not sure about the sample weight, please

contact with the application engineer.

The particle size of the sample should be able to pass

through the10 mesh sieve which is benefit to fully digest the

sample. Suggesting to crush the sample before digestion.

5. Place the sample into the sample cup

Attention: The operators should try their best to place the

sample to the bottom of the sample cup to avoid attaching

the sample onto the wall. If the wall is sticked with large

amount of sample powder, rinsing it with reagent of acid.

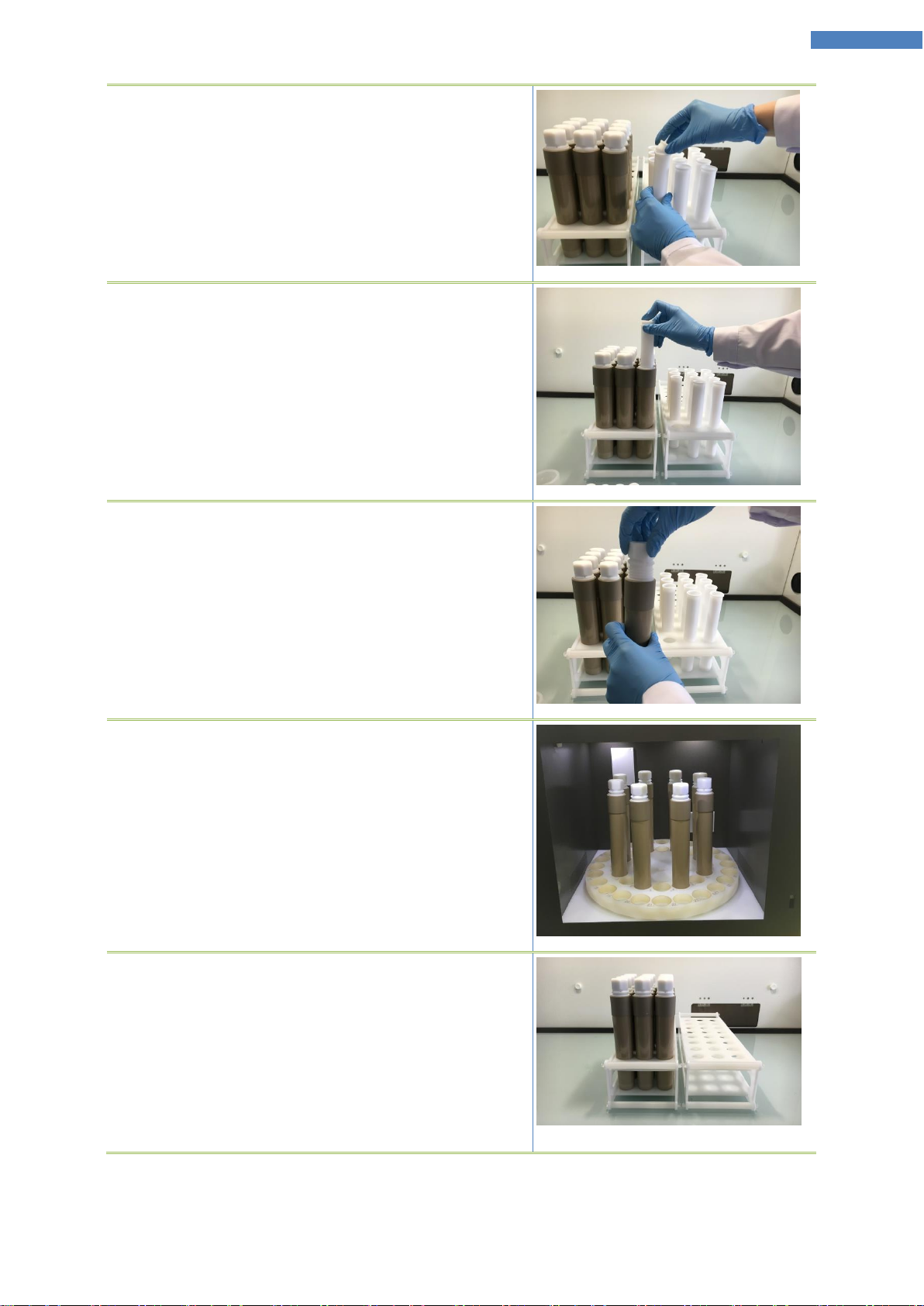

6. Use the suction pipet or the transfer liquid gun to weigh a

certain amount of reagent into the sample cup.

Attention: The reagent volume should be at least 3mL, while

maximum volume is controlled within 15mL.

Acid for digestion: we suggest the nitric acid, hydrochloric

acid, hydrogen peroxide, hydrofluoric acid. Perchloric acid,

solo concentrated sulphuric acid and phosphoric acid are

prohibited.

The type, weight, volume of sample and reagent for same

batch should be the same.

15

Appendix 1: The standard operating procedures of the GT-400 vessels

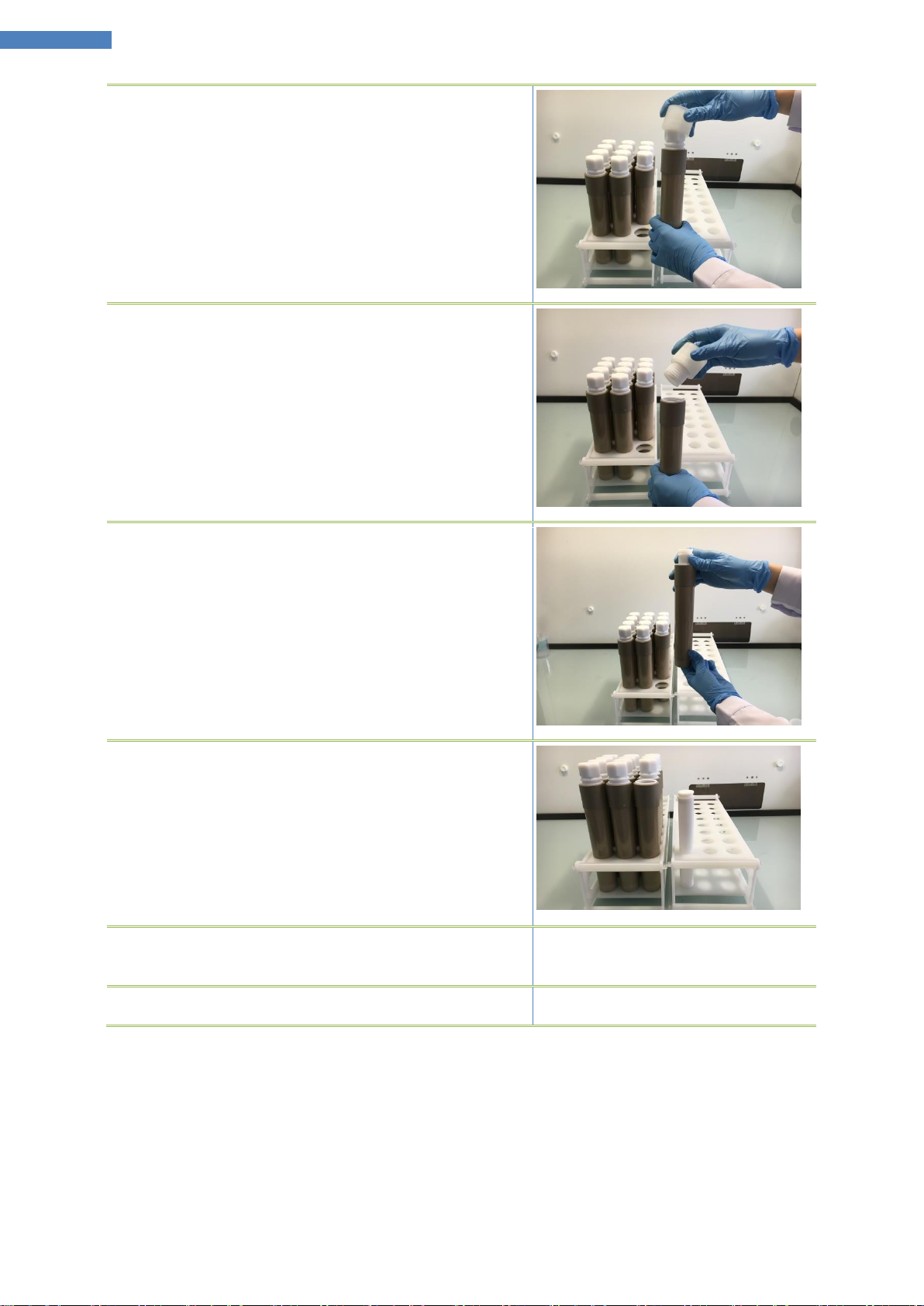

7. Cover the sample cup with seal plug.

8. Put the sample cup into sleeve.

9. Screw the seal lid tightly.

10. Install the digestion vessel into the cavity.

Attention: the digestion vessel should be evenly positioned

and placed on the inner circle of turntable as priority.

Notice: The digestion vessel can only be taken out when

the temperature is cooled down to 80°C after the

reaction is completed.

11. Take out the digestion vessel from the cavity and place

them onto the sample holder in fume hood.

Attention: The digestion vessel is slender and easy to fall

down, place the sample cup on the desk directly is

prohibited.

16

GT-400 Vessels Operation Manual

12. Cover the opener on the seal lid.

13. Loosen the seal lid in fume hood to release pressure,

and then screw off the seal lid.

14. Take out the sample cup from the sleeve and place onto

the sample rack.

Attention: The sample cup is slender and easy to fall down,

place the sample cup on the desk directly is prohibited.

17. Hold the sample cup which is placed onto the sample

holder and pull out the seal plug.

18. Move the digested solution into the specialized

container.

19. Clean all the components of the digestion vessel.

17

Appendix 2: Examples of Digestion Methods (Reference)

Appendix 2: Examples of Digestion Methods (Reference)

The following examples of digestion methods are for reference only, you can use the same method

for reference if you have the similar sample; but the same sample may have different components, so

the digestion method may be different. you can make a relative adjust according to the actual

condition.

Food

Name of sample

Weight

soybean oil, chocolate

0.2g

flour, rice, sweet twist, fried bread stick, flour of millet, corn flour, buckwheat flour, wheat

gluten, oatmeal, hot dry noodles, canned eight-treasure porridge, potato, soybean power,

sesame powder, peanut powder, sunflower seed, essence of chicken, sesame paste,

tomato sauce, corn starch, pea starch, plum paste, ice-cream, teething biscuit, steamed

bun, rice flour, jelly, egg oil, donkey-hide gelatin, caramel color, skim milk powder

0.3g

fresh vegetables, kidney bean, leafy vegetables, fresh fruits, berries, small fruits, white

granulated sugar, starch sugar, fruit grape syrup, dried vegetables, dried fruit, dried figs,

walnut flesh, hazelnut flesh, fresh mushroom

0.5g

yogurt, soy sauce, vinegar, sweetened condensed milk

0.5mL

orange juice, concentrated juice, grape, milk

1mL

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

5mL

1

100

3

H2O2

1mL

2

130

3

3

160

3

4

190

20

Note: Add reagent into sesame oil and liver sample wait 10 minutes until no obvious reaction, then

start subsequent operation

Name of sample

Weight

ground pork, pork liver, bacon, Sausage, Instant Noodle seasoning packet, sesame oil

essence, plant hydrolysis protein

0.3g

coffee, cheese, bread, cake, salmon, tomato mud, dried meat floss, potato chips, honey,

pollen, tyrosine

0.5g

eggs

1mL

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

5mL

1

80

3

H2O2

1mL

2

120

3

3

150

3

4

180

3

5

200

20

Note: Add reagent into sesame oil and liver sample wait 10 minutes until no obvious reaction, then

start subsequent operation

Name of sample

Weight

oyster(fresh), ribbonfish(fresh), squid(fresh), clam(fresh), eel(fresh)

0.3g

18

GT-400 Vessels Operation Manual

beef extract, river prawn(fresh), crab(fresh)

0.5g

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

5mL

1

80

3

H2O2

1mL

2

120

3

3

150

3

4

180

3

5

200

15

Name of sample

Weight

garlic

0.5g

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

5mL

1

80

3

HF

1mL

2

120

3

3

150

3

4

180

3

5

200

30

Medicine

Name of sample

Weight

honeysuckle flower, astragalus root powder, peony powder, skullcap powder, liquorice root

powder, hawthorn fruit powder, ginseng powder, salvia root powder, chinese angelica

powder, saposhnikovia powder, dahurian angelica root powder, rehmannia root powder,

tuber fleeceflower root powder, rsm extraction, safflor yellow extraction

0.5g

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

6mL

1

80

2

2

120

2

3

150

2

4

180

2

5

200

20

Note: Add reagent into sesame oil and liver sample wait 10 minutes until no obvious reaction, then

start subsequent operation. If it contains sunscreen, you can add 0.2 mL HF during the digestion

Biological samples

Name of sample

Weight

pork bones, snake bones

0.2g

human hair powder

0.3g

beef liver, urine , tissue fluid

0.5g

blood serum, bull's blood

1mL

19

Appendix 2: Examples of Digestion Methods (Reference)

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

6mL

1

100

3

2

130

3

3

160

3

4

190

20

Environmental samples

Name of sample

Weight

soil, precipitation, river mud, soil polluted by oil

0.1g

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

6mL

1

120

3

HCl

2mL

2

150

3

HF

2mL

3

180

3

4

200

20

Note: This method is suitable for testing element such as: Pb, Cr, Cd, Cu, Zn, Ni.

Name of sample

Weight

soil, precipitation, River mud, soil polluted by oil

0.1g

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

2mL

1

120

3

HCl

6mL

2

150

3

3

180

3

4

200

15

Note: This method is suitable for testing As, Hg, S

Name of sample

Weight

finished water and incoming water from waste water plant

5mL

Solvent

Volume

(mL)

Step

Temperature

(°C)

Time

(min)

HNO3

5mL

1

100

3

2

120

3

3

150

3

4

180

20

PreeKem Scientific Instruments Co., Ltd.

Address: No.100-101 Building, No.2338 Duhui Road, Shanghai, China

Postal code: 201108

Tel: 86(21) 5442 7057, 18916066078(maintenance line), 18918169066(complaint line)

Fax: 86(21) 5442 7063

Web: www.preekem.com

E-mail: service@preekem.com

Technical Maintenance File

Operation Manual

Edition: 201607007

All right reserved. This manual in any manner in whole or in part without prior written

permission is prohibited.

PreeKem Scientific Instruments Co., Ltd. is responsible for the interpretation.

Table of contents

Other PreeKem Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

GE

GE AKTApure operating instructions

Idexx

Idexx Quanti-Tray/Legiolert manual

Tuttnauer

Tuttnauer TIVA2 TD Instructions for use

Thermo Scientific

Thermo Scientific Thermo Scientific Orion Star T900 Series General Settings Guide

Tuttnauer

Tuttnauer 6690 STS-1V Operation & maintenance manual

scigiene

scigiene INFY-1 Operation manual

Appleton

Appleton appSTIR instruction manual

Thermo Scientific

Thermo Scientific Ion Torrent S5 user guide

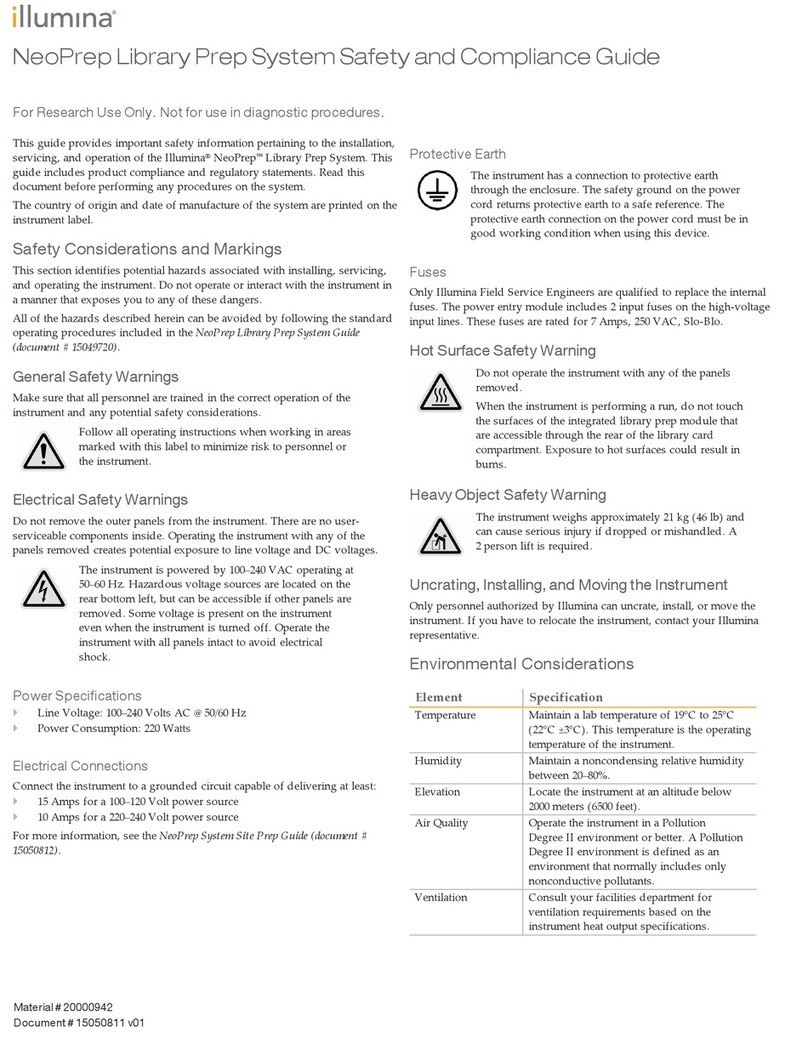

illumina

illumina NeoPrep Library Prep System Safety and compliance guide

Macherey-Nagel

Macherey-Nagel URYXXON Relax manual

Teledyne

Teledyne T640 Standard operating procedure

DLAB Laboratory Instruments

DLAB Laboratory Instruments D3024 user manual