PreeKem TOPEX User manual

Ver 1.0

2

TOPEX service manual

Preface

This manual is aim to guide maintenance engineer to solve instrument faults on spot.

Maintenance engineer need to understand the knowledge of electrical safety and electrical theory,that will

ensure the life safety in the process of maintenance.

Before troubleshooting , maintenance engineer should be familiar with instrument wiring diagram,fully

understand the components’ work voltage and working mechanism.

Please give special attention to the bold part of this manual.

Our company will not be responsible for any losses caused by secretly scrap build.

Please feel free to contact us if you confront problems via E‐mail: support@preekem.com. We will response

your question as soon as possible.

3

目录

Preface....................................................................................................................................................................... 2

1 Introduction.............................................................................................................................................................5

1-1 Summarize......................................................................................................................................................5

1-2 technical parameters.................................................................................................................................... 5

1-3 Safety precautions.........................................................................................................................................5

1-4 Safety standards............................................................................................................................................5

1-5 Application rules............................................................................................................................................ 6

2 Components describe.......................................................................................................................................... 7

2-1 Axonometric views........................................................................................................................................ 7

2-2 Safety door disassemble..............................................................................................................................8

2-3 Bottom view....................................................................................................................................................9

2-4 Main control board layout.......................................................................................................................... 10

3 Commonly used spare parts replacement.....................................................................................................12

3-1 Magnetron replacement.............................................................................................................................13

3-2 Magnetron cooling fan repalcement........................................................................................................13

3-3 HV transformers replacement...................................................................................................................14

3-4 HV capacitor replacement.........................................................................................................................15

3-5 Thyristor replacement.................................................................................................................................16

3-6 Exhaust fan replacement...........................................................................................................................18

3-7 Pressure sensor replacement...................................................................................................................20

3-8 Turntable motor replacement....................................................................................................................21

3-9 LCD replacement........................................................................................................................................ 23

3-10 Built-in camera and monitor replacement............................................................................................ 24

3-11 LED backlight replacement.....................................................................................................................26

3-12 Push style electromagnet replacement................................................................................................ 26

4 Trouble shooting................................................................................................................................................. 27

4-1 HV components measuring method........................................................................................................29

4

TOPEX service manual

4-1-1 Filament transformer...........................................................................................................................30

4-1-2 HV transformer.....................................................................................................................................30

4-1-3 HV capacitor.........................................................................................................................................30

4-1-4 HV diode................................................................................................................................................30

4-1-5 Magnetron.............................................................................................................................................30

4-2 Infrared sensor.............................................................................................................................................31

4-3 Pressure sensor.......................................................................................................................................... 31

5. Fault cause analysis..........................................................................................................................................32

5-1 No microwave generated...........................................................................................................................32

5-2 Garble microwave power match...............................................................................................................32

5-3 Infrared display value error........................................................................................................................32

5-4 Pressure display value error..................................................................................................................... 32

5-5 Other components faults.......................................................................................................................... 32

6 Parameter calibration........................................................................................................................................33

6-1 Temperature calibration (PT100).............................................................................................................33

6-2 Pressure parameter calibration................................................................................................................ 35

7 Wiring diagram.................................................................................................................................................... 35

5

1 Introduction

1-1 Summarize

TOPEX adopts the ultramodern apperance design, with high‐tech color touch screen and color humanized

graphical interface,real‐time imaging techiques,these all embody convenient and comfortable in modern

laboratory.TOPEX adopted microwave directional compression technology, that based on microwave vector

reflex design,Directional change field intensity distribution,Will be highly uniform microwave energy gathered

in the sample areas, improve the reaction of parallelism.

1-2 technical parameters

Microwave mode: dual magnetrons

Power supply: 50Hz,220‐240V

Microwave power: 0~1700W

Microwave frequency: 2450MHz

Power control: PID

Vessels type:10\15\40

Work temperature: 0~260℃

Work pressure:0~6MPa

1-3 Safety precautions

Dual interlock switches.

Pressure sensor: Pressure sensor is used to monitor pressure produced by sample reaction.Microwave

can only be generated when the real‐time pressure is under the setting value.

Temperature sensor:Temperature sensor is used to monitor samples’ temperature.Microwave can only

be generated when the real‐time temperature is not beyond setting value.

1-4 Safety standards

Troubleshooting should not be dealed with power on,please refer to the following rules if the condition needs

the power on:

Open the door to avoid microwave started by mishandling.

Make sure that you are clearly familiar with wiring diagram, understanding various electronic

components described on wiring diagram,understanding their working voltage and features.

6

TOPEX service manual

Directly measuring the output of high voltage transformers and filament transformers with the power

on is forbidden.

Directly measuring the high voltage diodes with the power on is forbidden.

Directly measuring the magnetrons with the power on is forbidden.

Directly measuring the high voltage diode with the power on is forbidden.

Replacing the high voltage components need the time elapsed 5 minutes after the power is turned

off,because of high voltage capacitor discharge.

1-5 Application rules

Samples of dangerous chemical reaction or explosive characteristic of atomic groups must be pay serious

attentions. Before make clear of microwave control ability and chemical reaction intensity, TOPEX can not be

put in use.

7

2 Components describe

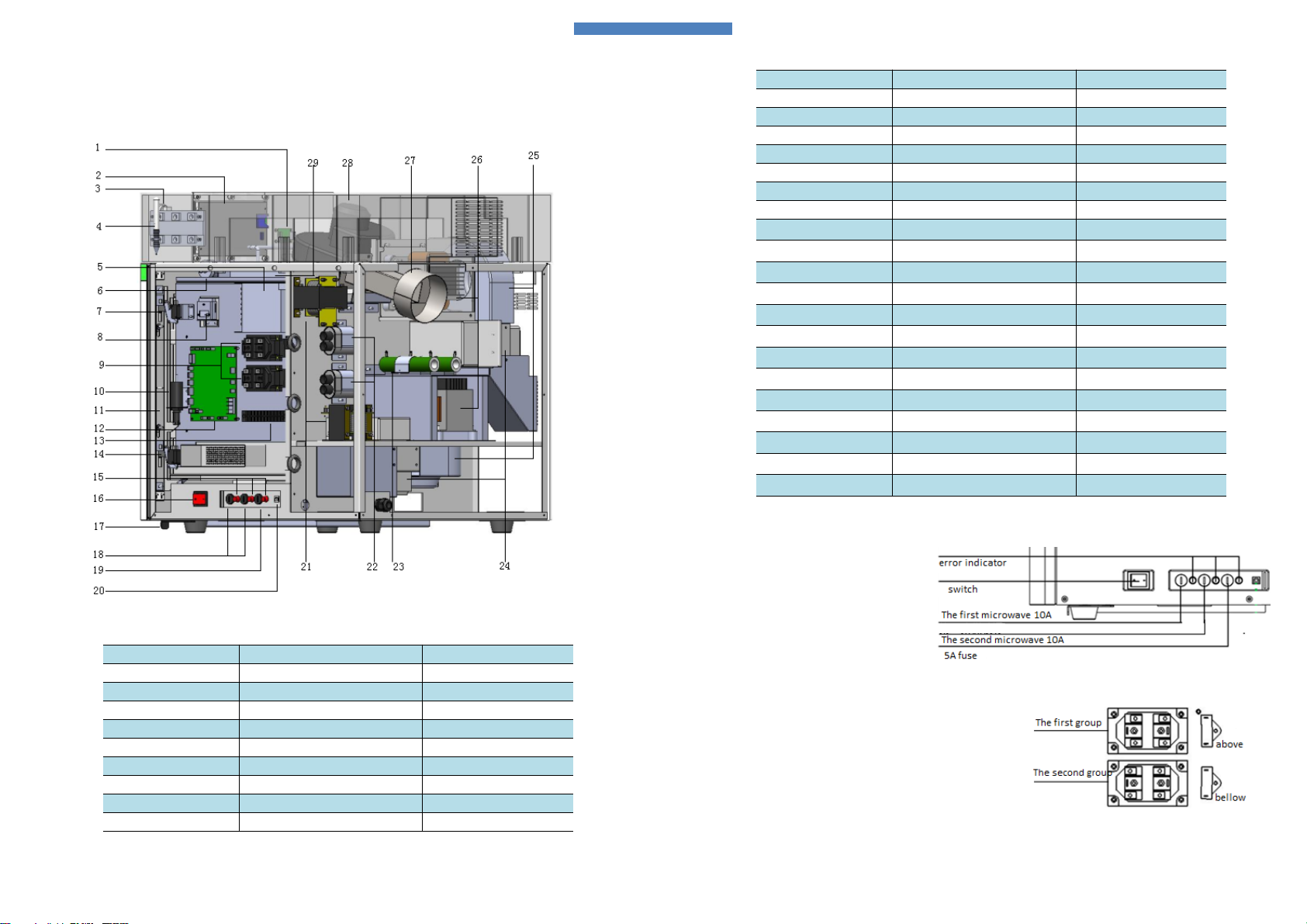

2-1 Axonometric views

Fig 2.1 axonometric view

No. Describe Inventory code

1LCDconnector

26ea002

2LCD 00fa715

3 Stop button 00ca809

4Touch pen 26tj202

5Power adapter(5/12V) 00fb310

6Pressure sensor 00fa602

7 Interlock switch 00ca801

8Pin hole camera 00fz005

9Thyristor 00ca211

8

TOPEX service manual

Note: We normally obey the rules that from left to right, front to back,upper to lower to define the first

microwave components and the second microwave components.

Forexample,wedefinetheleft fuse

holder and fuse belong to the first

microwave group, and the second

belongs to the second part,refer to fig 2.2

.

Fig 2.2 Fuse holders

We define the above thyristor belongs to fisrt group, and the

bellow one belongs to the second group.

Other components like magnetrons,high voltage items can be

define like this way.

Fig 2.3 Thyristor define

No. Describe Inventory code

10 Electromagnet 00fb808

11 Door bracket 26aa003

12 Main control board 26ea001

13 Terminal board 00ce802

14 Interlock switch 00ca801

15 Error indicator light 00ca904

16 Switch 00ca806

17 Latch handle 23aa015

18 Fuse holder\10A fuse 00ca704\00ca606

19 Fuse holder\5A fuse 00ca704\00ca615

20 PC connector board 26ea003

21 Filament transformer 00fa311

22 High voltage capacitor 09tj222

23 Resistor 00ca521

24 Magnetron 26tj207

25 Cooling fan 00fa111

26 High voltage transformer 09tj210

27 Exhaust pipe 22aa006

28 Exhaust fan 09tj206

29 Power adapter(24V)00fb308

9

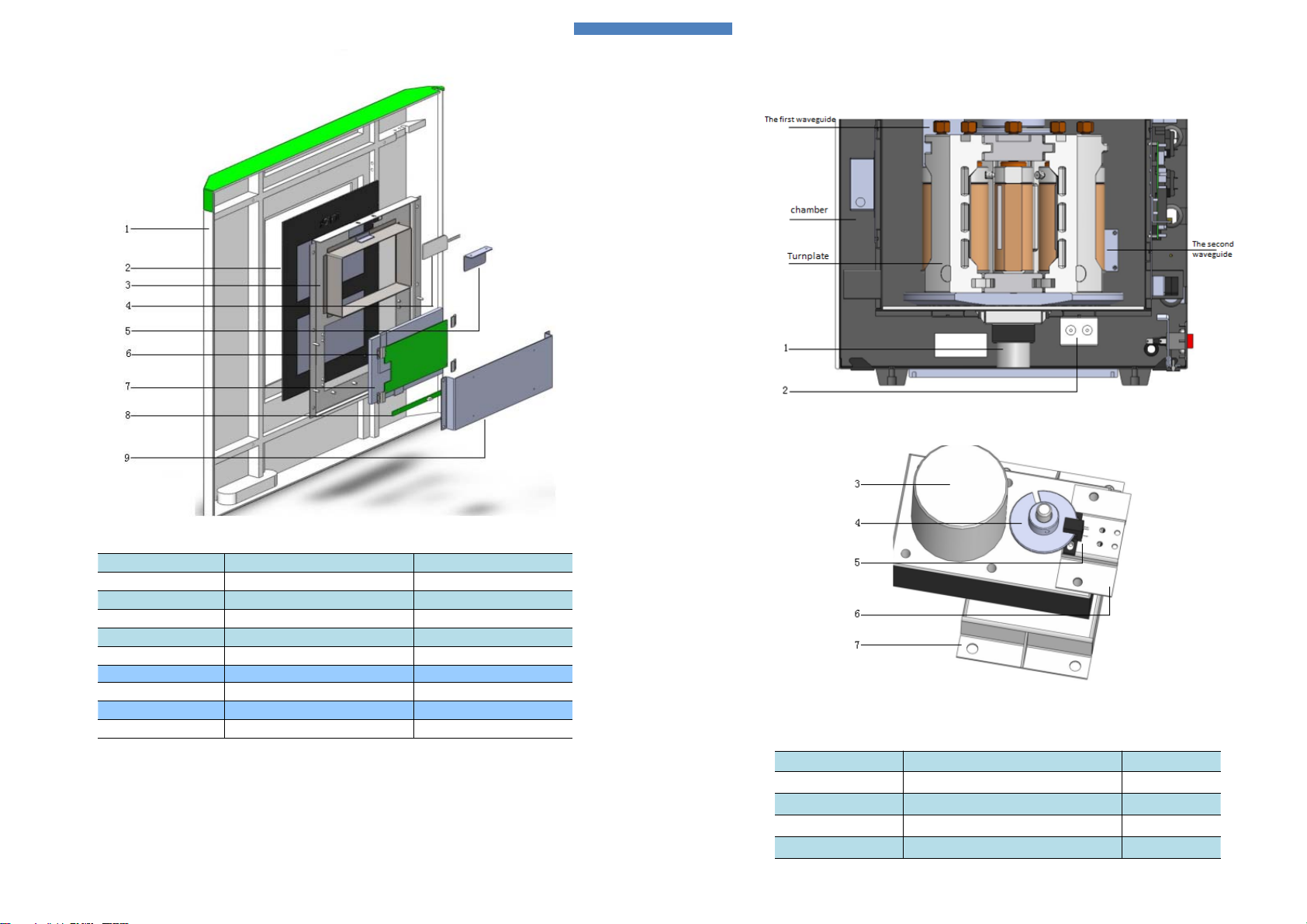

2-2 Safety door disassemble

Fig 2.2 safety door

No. Describe Inventory code

1Door shell 26da005

2Window board 26da011

3Bracket 26aa013

4LED light 00cz021

5Pressure plate 26aa015

6PCB board Built in monitor

7monitor 00fa704

8Power PCB Built in monitor

9Holder 26aa014

10

TOPEX service manual

2-3 Bottom view

Fig 2.3 bottom components

Fig 2.4 motor sub-assembly

No. Describe Inventory code

1 Motor components 26tj206

2Filter 00fb402

3 motor 00fa204

4grating 23ba004

11

2-4 Main control board layout

No. Describe Inventory code

5Photoelectric sensor 26tj205

6bracket 23aa020

7bracket 09aa042

12

TOPEX service manual

13

3 Commonly used spare parts replacement

This section introduce the process of spare parts replacement,please refer to these processes.

3-1 Magnetron replacement

Fig 3-1 Magnetron mounted position

Magnetrons are mounted at the back side of the chamber as fig 3‐1 described.We define the above magnetron

belongs to the first microwave group, the below one belongs to the second group.

Temperature relay is installed on the surface of the magnetron.

Note: Exhaust duct is mounted with magnetron, please don’t take dow

n

when replace the magnetron.

Fig 3-2 magnetron

The second magnetron

The first magnetron

温控器

风罩

Nuts

Exhaust duct Temperature

relay

14

TOPEX service manual

3-2 Magnetron cooling fan repalcement

Fig 3‐3 Magnetron cooling fan mounting position

Magnetron cooling fan is installed nearby the magnetron,mounted with bracket. Starting capacitance is

installed on the surface of the cooling fan.

Fig 3‐4 Cooling fan and bracket

Fig 3‐5 describes the wiring way for magnetron.

Fig 3‐5 wiring layout

The second cooling fan

The first cooling fan

Fixed holes

Nuts

15

3-3 HV transformers replacement

Fig 3‐6 HV transformer mounted position

Two magnetrons are covered by metal covers to form a duct reduce the temperature of transformers,refer to

fig3‐6.Therearetwopointsneedtonotewhenmaintenance engineer wants to take down the metal covers.

(1) It is no need for take down the fixed nuts, it is OK to unscrew,refer to fig 3‐7.

(2) two wiring resistors are installed on the surface of the metal cover,fixed nuts an

d

screws for mental cover need to be taken down, maintenance engineer should pa

y

more attention to the wiring layout and recover the wiring after replacement

Fig 3‐7Fixednuts

The first transformer is fixed like fig 3‐8, take down four fixed nuts and

disconnect the cord. We can do replacement process. Two HV

transformers are installed as the same way.

Wiring layout

We normally do not stipulate the input wiring way, that is to say live and

neutral cord can be connected with HV transformer randomly.

Make sure reliable grounding between HV transformer and chamber.

.

Fig 3‐8 HV transformer

The second HV transformer

The first HV transformer

Metal cover

16

TOPEX service manual

3-4 HV capacitor replacement

Fig 3‐9 HV capacitor mounted positon

Two HV capacitor are installed at the back side of the chamber, refer to fig 3‐9, both of them are fixed by a

metal bracket. It is relatively easy for replacement.

Wiring layout for HV components

Caution: Incorrect wiring may cause faults like fuse blown or no microwave generated.

Fig 3-10 Wiring layout

The first one

The second one

17

3-5 Thyristor replacement

Fig 3‐11 thyristor mounted position

Two thyristors are mounted at the right side of the chamber,refer to fig 3‐11,take down the right ABS

cover, you will see them.

Thyristor is fixed by four M4 screws, the left side is input terminal and the right side is output terminal.

Fig 3‐12 Thyristor

Thyristor wiring layout

Refer to fig 3‐12, one of the input terminals nearby signal teminal is neutral, and the other is live. Neutral side

is always conductive between input and output,but the live is controlled by thyristor,its conductive feature is

controlled by signal.Control signal is afford from JP4‐15~20 pins,pin 15,17 and 19 belong to the first

thyristor,pin 16,18 and 20 belong to the second one, the range of control signal is from 0 to 10 direct current

represent various power.

The first one The second one

18

TOPEX service manual

Fig 3‐13 is the wiring layout of thyristor.

Fig 3‐13 Thyristor wiring layout

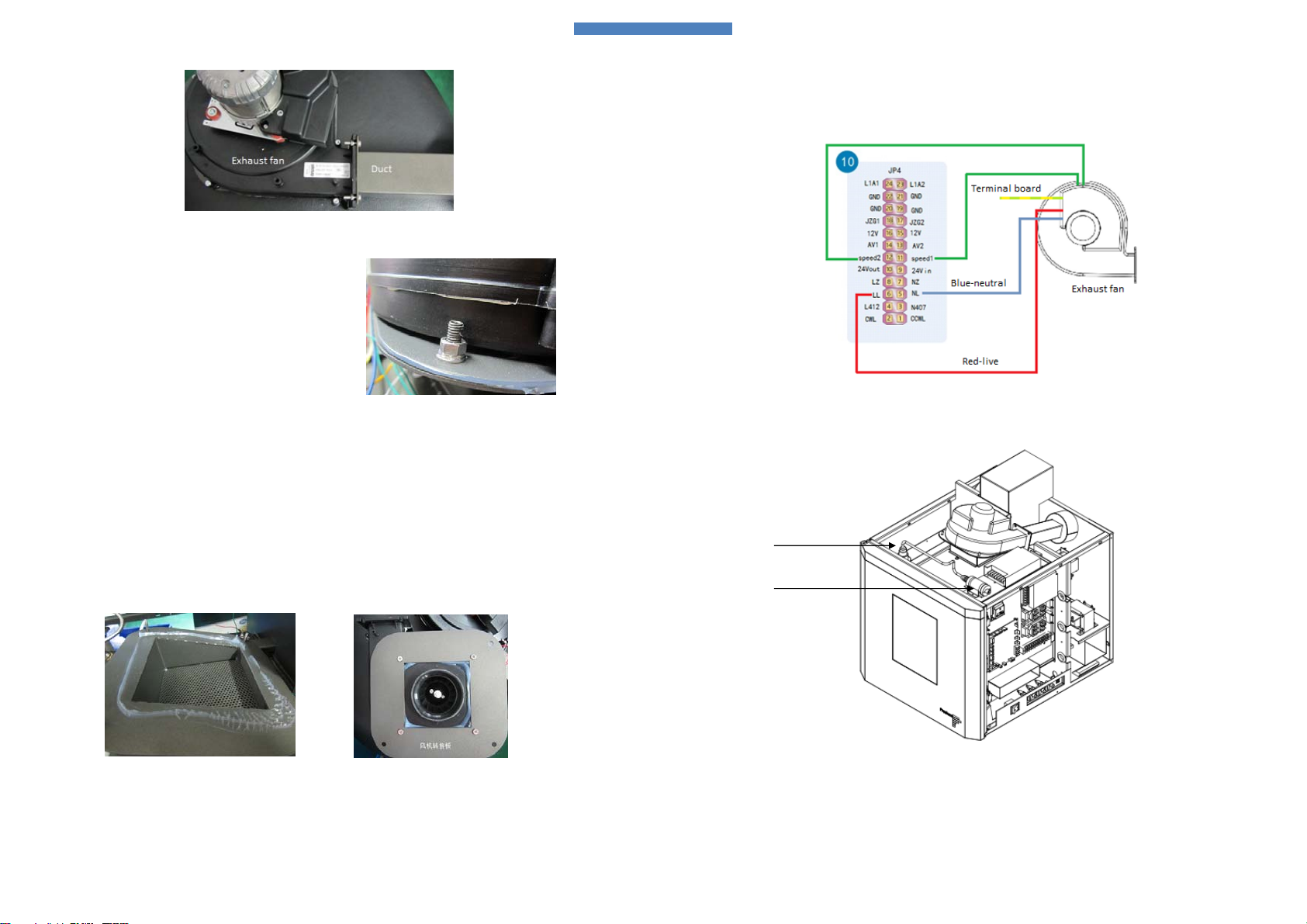

3-6 Exhaust fan replacement

Fig 3‐14 Exhaust fan mounted position

Exhaust fan is installed at the top of chamber ,refer to fig 3‐14. Take down plastic covers,then you can

replace the exhaust fan.Exhaust fan is assembled with exhaust duct together, so it is no need for disassembling

them when you want to replace exhaust fan,refer to fig 3‐15.

19

Fig 3‐15 Exhaust fan unit

Exhaust fan replacement sequence:

(1) Take down three M5 nuts, refer to fig 3‐16.

(2) Disassemble the exhaust fan and duct.

(3) Take down the connection bracket installed with exhaust

fan.

Fig 3‐16 M5 fixed nuts

Exhaust fan installation

(1) Clean up the sealing silicone,cover with a layer of silicone again,refer to fig 3‐17.

(2) Use four screws to fix the connection bracket onto the exhaust fan with a layer of sealing silicone,refer to

fig 3‐18.

(3) Use four screws and nuts to fix exhaust fan and duct, the gap should be filled with sealing silicone.

(4) Remount the exhaust fan fixed by three M5 nuts,refer to fig 3‐16.

(5) Restore wiring connection.

Fig 3‐17 Sealing silicone Fig 3‐18 Connection bracket

Exhaust fan wiring diagram

20

TOPEX service manual

Exhaust fan wiring is divided into power cord and speed regulating signal lines,these wires ard controlled by

main control board JP4,JP4‐6 controls live and JP4‐5 controls neutral,seeped regulating signal is controlled by

JP4‐11,12,refer to fig 3‐19.

Fig 3-19 Exhaust fan wiring layout

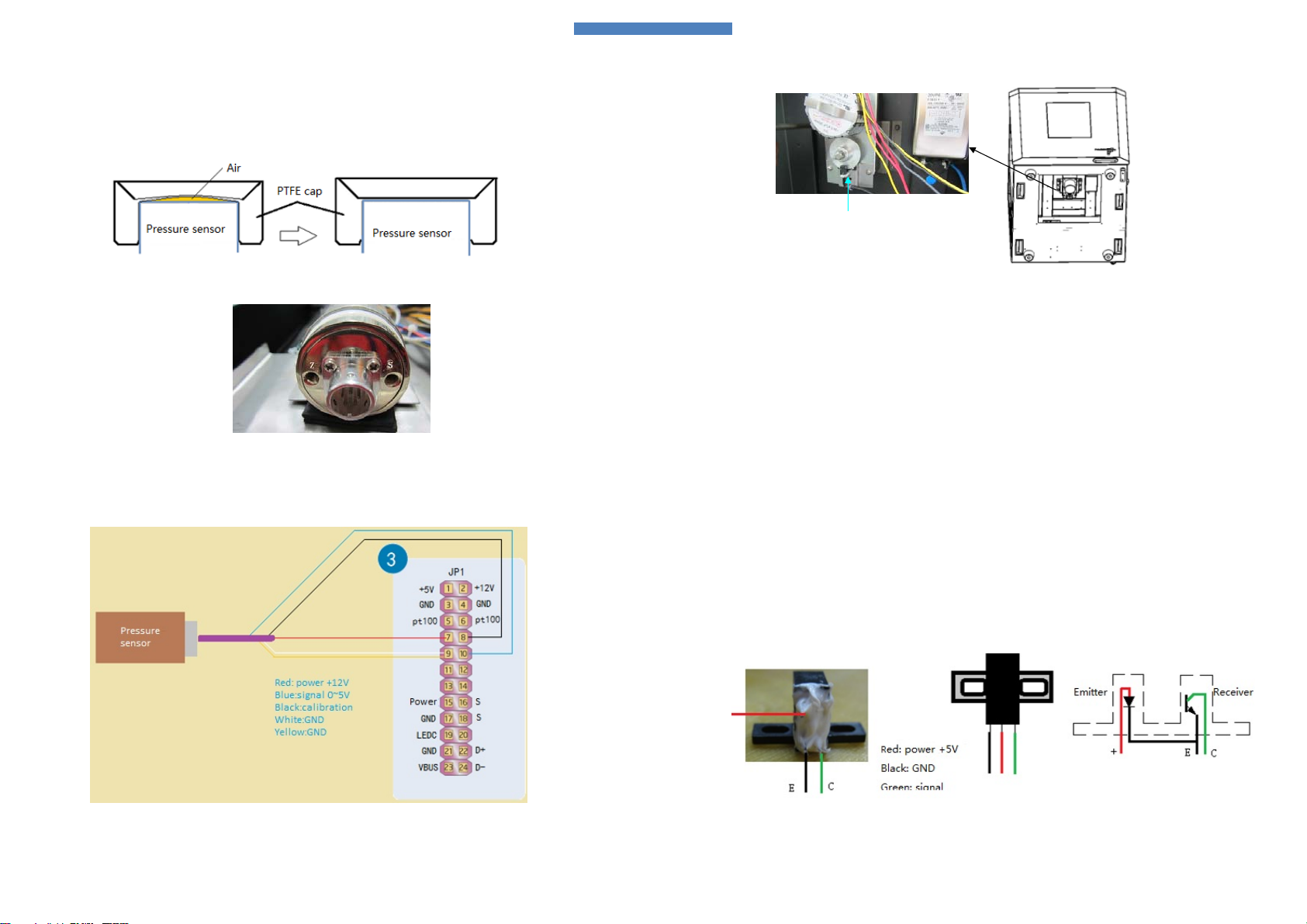

3-7 Pressure sensor replacement

Fig 3-20 Pressure sensor mounted position

Pressure sensor is mounted on the top of chamber, refer to fig 3‐20.One side is inductive terminal and the

other side is data cable.

Installation matters

Pressure sensor

Metal bracket

21

(1) Residual air between PTFE gap and pressure sensor should be drained entirely, or may cause insensitive

response and pressure lingering, refer to fig 3‐21.

(2) Screw thread of the pressure sensor should be covered with teflon seal tape about 3 layers.

(3) Side Z should be adjusted towards operator,refer to fig 3‐22.

Fig 3-21 Residual air

Fig3-22SideZ

Pressure sensor wiring layout

Pressure sensor data lines are connected with main control board JP1 pin7 to pin10,refer to fig3‐23.

Fig 3‐23 Pressure sensor wiring diagram

22

TOPEX service manual

3-8 Turntable motor replacement

Fig 3‐24 Turntable motor mounting position

Turntable motor is mounted at the bottom of the chamber by four M4 nuts.Turntable motor is a subassembly

gathered with metal bracket, photoelectric sensor and grating.

Note:

(1) Instrument should be overturned ,take down the black cover.

(2) Take the turntable and vessels out of chamber to avoid damage the sensors. It is no need to take down

thepressuresensorandgaspipe.

Photoelectric sensor replacement

Photoelectric sensor is installed on the surface of grating, used for turntable direction control.There are two

points need to know when operate the photoelectric sensor replacement.

(1) Cut the signal lines nearby the photoelectric sensor, peel off a short of insulating layer,then put insulating

heat shrink tube about D2 on signal lines separately.

(2) Weld the signal lines and photoelectric sensor together,refer to fig 3‐2, use heat shrink tube cover the

welding part finally to avoid short circuit.

Fig 3‐24 Photoelectric sensor feature

Photoelectric sensor

23

Wiring diagram for turntable motor subassembly

Turntable motor power cord is connected with main control board JP4 pin1 and pin 2, decide clock wise or anti

clock wise according to the signal from photoelectric sensor. Photoelectric sensor provides signal to main

control board through pin 15, pin 16 and pin 17, refer to fig 3‐25.

Fig 3‐25 Turntable motor subassembly wiring layout

3-9 LCD replacement

Touch screen is mounted in top ABS cover, refer to fig 3‐26.

Fig 3‐26 LCD subassembly

24

TOPEX service manual

LCD is fixed by four M3*6 screws, data communication type is serial communication via a LCD connector

connected with main control board, refer to wiring diagram.There are four points need to pay more attention

when maintenance engineer disconnect the FPC flat cable.

(1) Clean up the locking silica gel, refer to fig 3‐27.

(2) Open the FPC fixed cover upward.

(3) Takedown FPC flat cable.

(4) Restore the FPC flat cable installation, use silica gel to lock the fixed cover at the same time.

Note:BluesidetowardsfixedcoverandtheothersidefacetoPCB.

Fig 3‐27 FPC connector

Stop button wiring layout

Fig 3‐28 Stop button define

Stop button is mounted at the upper right of TOPEX,is used to stop the microwave in emergency, refer to fig 3‐

28.

25

Metal bracket

PCB board

Monitor screen

Signal board

3-10 Built-in camera and monitor replacement

Monitor screen is mounted inside door shell, and the pin hole camera is located on the right side of the

chamber, there are two points need to pay more attention when disassemble the subassembly.

(1) Take down black cover fixed by eight M3*10 screws, then you will see six screws to fix the door shell, refer

to fig 3‐29.

(2) Take down door shell, replace relevant components.

Fig 3‐29 Safety door subassembly

Monitor subassembly relationship is described like fig 3‐30.

Fig 3‐30 Monitor screen subassembly

Note: Monitor and its PCB connection style is push‐pull way strange form LCD, refer to fig 3‐31.

Fig 3‐31 Push‐pull style

26

TOPEX service manual

Monitor system wiring diagram

Monitor system power supply is control by stop button,yellow line is video signal, refer to fig 3‐22.

Fig 3‐32 Monitor system wiring diagram

3-11 LED backlight replacement

LED backlight replacement needs to pay attention to plus‐n‐minus,refer to fig 3‐33.

Fig 3‐33 LED backlight

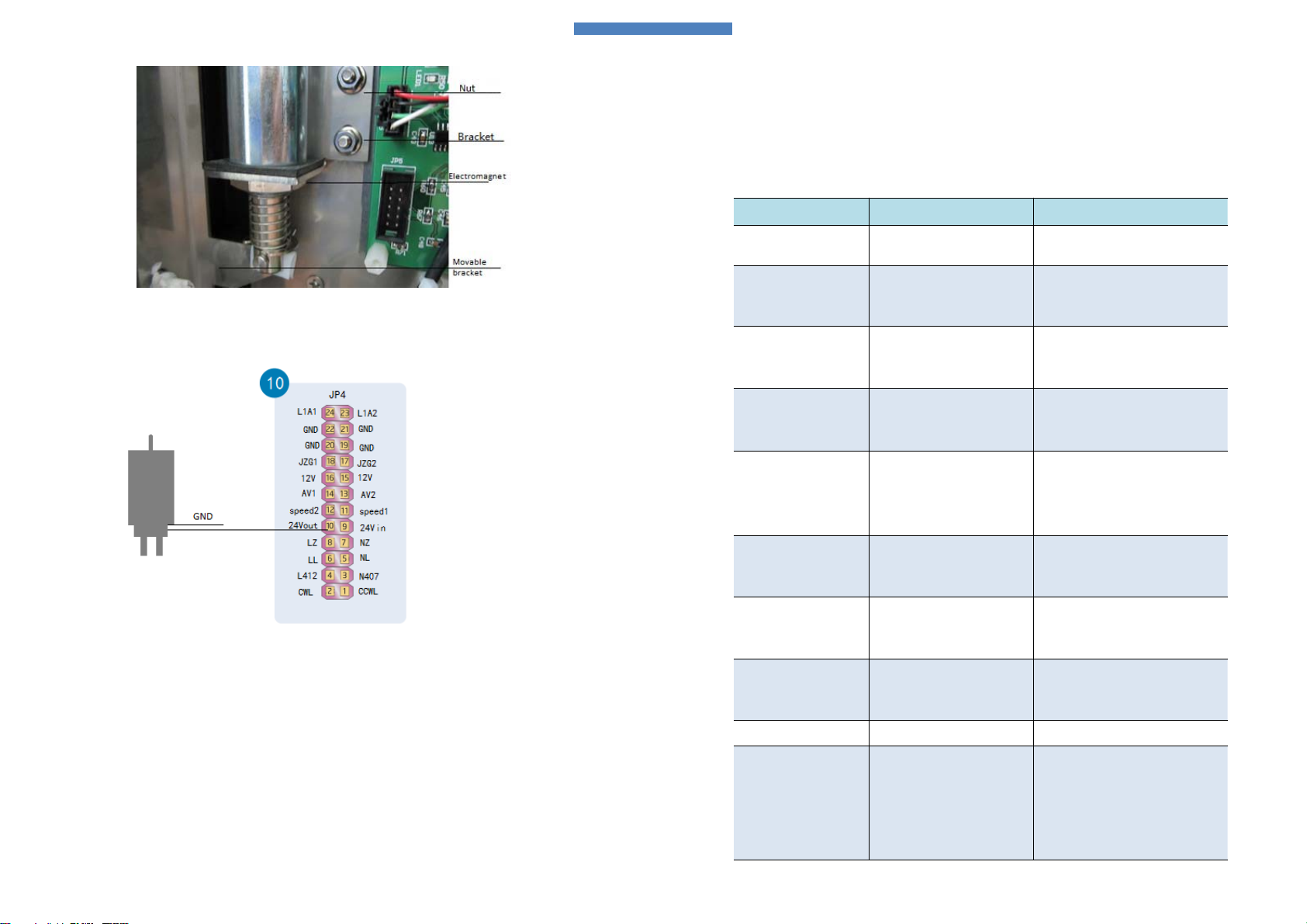

3-12 Push style electromagnet replacement

Push electromagnet is use to open the door automatically, located right side of chamber, its work voltage is

24V controlled by main control board, refer to fig 3‐34.

27

Fig 3‐34 Push style mounting location

Wiring diagram

Fig 3‐35 Electromagnet wiring layout

28

TOPEX service manual

4 Trouble shooting

For safety considering, maintenance engineer who can do some service work should be trained and approved

by PreeKem, and get the qualification.

Fault Probable cause Solution

No power

Fuse is blown

Socket is loosen

Replace related fuse

Insert socket again

No microwave

Fuse is blown

HV components error

Main control board error

Replace related fuse

Check HV components

Replace PCB

Microwave can not be

regulated

Thyristor fault

Main control board error

Mutual inductor broken

Replace related thyristor

Replace PCB

Replace mutual inductor

Discontinuous microwave Temperature error

Replace cooling fan (fan does not work)

Replace related temperature

Temperature value

unstable

Microwave interference

Temperature socket loosen

Temperature sensor

Main control board error

Check door gap

Re‐mount the temperature

Replace temperature

Replace PCB

Temperature reading value

error

No temperature signal

Main control board error

No calibration

Replace temperature sensor

Replace PCB

Calibrate temperature valve

Pressure value is not zero

when the actual pressure is

zero

No calibration

Main control board error

Pressure fault

Calibrate pressure error

Replace PCB

Replace pressure sensor

Pressure value unstable

Microwave disturb

Pressure sensor fault

Main control board error

Check door gap

Replace pressure sensor

Replace main control board

Spark in chamber Improper microwave power Set right microwave power

Crackle

Check HV transformers

Check HV diodes appearance

Check HV ca

Check filament transformer terminals

Check magnetrons appearance

29

Fault Probable cause Solution

Turntable does not work

Photoelectric sensor fault

Motor fault

Main control board error

Replace photoelectric sensor

Replace motor

Replace main control board

Touch screen fault

Resistance broken

No calibration

Main control board error

Replace touch screen

Calibrate touch function

Replace main control board

Garble code on screen

Bad data lines connection

LCD fault

Main control board error

Re‐installation the data lines

Replace LCD

Replace main control board

No video show

No video signal

No working voltage

Monitor screen fault

Replace pin hole camera

Check 12V power and its wiring

Replace monitor screen

No response for ‘auto open

door’ function

Exhaust fan is open

Main control board error

No 24V work voltage

Electromagnet fault

Axis of electromagnet decentration

Stop exhaust fan

Replace main control board

Replace power adapter (24V)

Replace electromagnet

Re‐mount the door mechanism

Warning :

“Time‐out”

No microwave

Wrong microwave power setting

Poor microwave absorb ability

Heating time is short

Check microwave generated components

Set right microwave power

Increase microwave power

Prolong heating time and set multi‐step

Warning:

“Temperature error”

Air leakage

Pressure sensor fault

Main control board error

Power is setted too large

Check the air impermeability

Replace pressure sensor

Replace main control board

Set related microwave power

Warning:

‘Pressure limited’

Power is setted too large

Pressure setting value is lower

Samples have good microwave

absorbing ability

Pressure sensor fault

Reduce microwave power

Increase setting value

Reduce microwave power

Replace pressure sensor

Warning:

‘Pressure control’

Lower pressure setting value

Main control board error

Increase setting value

Replace main control board

Warning:

‘Turntable fault’

Photoelectric sensor fault

Main control board error

Turntable motor fault

Replace Photoelectric sensor

Replace main control board

Replace motor

30

TOPEX service manual

4-1 HV components measuring method

Measuring the HV components input or output terminals with the power on is forbidden.These HV

components can be estimated by measuring its resistance.Test behavior can only be operated 5 minutes

latter after power off.

4-1-1 Filament transformer

Disconnect the primary and secondary wiring terminals,the resistance of primary is about 20 Ωand the

secondary is 1 Ωnormally. If resistance is right, we can eliminate the doubt of filament transformer fault

4-1-2 HV transformer

Disconnect the primary and secondary wiring terminals,the resistance of primary is about 1.5Ωand the

secondary is nearly 100Ωnormally (between secondary and grounding).

Fault type: open circuit

4-1-3 HV capacitor

The resistance between two terminals is about 10MΩ.

Lower or higher resistance indicate the capacitor has been break down.

Resistance should escalate while the measuring process, if the resistance is directly fixed at 10MΩ,no

escalation process, that indicates the HV capacitor has been break down.

Fault type: Break down

4-1-4 HV diode

Take down HV diode

If no microwave generated and the surface temperature is too high that indicates HV diode has been

break down.

The resistance between anode and cathode is about 30 to 70MΩ.

The resistance between cathode and anode is infinite.

If the forward direction resistance is too high or reverse is too low beyond the standard indicates break

down.

The anode must be connected with HV capacitor and reliable grounding for cathode.

4-1-5 Magnetron

Resistance of filament cathode is nearly 1Ω.

Resistance between filament cathode and grounding is infinite.

Magnet flaws on magnetron is not allowed.

31

Fig 4-1 Magnetron appearance

Fault type: filament cathode open circuit, antenna spark, magnet flaws.

Caused faults: no microwave, lower microwave efficience, blown fuse and HV diode.

4-2 Infrared sensor

Type: OPTCSMLT15

Temperature range: 0~350℃

Output: 0~3.5V

Ratio: 15:1

Scale: 1℃\10mV

Wiring define:

4-3 Pressure sensor

Range: 0~5Mpa

Output: 0~5V

Scale: 1atm / 50mV

Filament cathode

32

TOPEX service manual

5. Fault cause analysis

5-1 No microwave generated

Maintenance engineer should confirm the fuses are not blown. If the fuse blown continually when start

microwave, the problem must be caused by short circuit hidden in HV components, such as thyristor, HV

capacitor,HV transformers and so on. Measuring method refer to chapter 4.

If HV components have good quality, the possible reasons are terminals spark.

Confirm related thyristor has input or output voltage. If no input voltage, the problem may caused by the

former components described on wiring diagram, and if no output voltage, the problem maybe caused by

thyristor error.

If the problem is still encounter, change the magnetron and have a try.

5-2 Garble microwave power match

Thyristor can not control its output voltage may cause this fault, there are three cause reasons.

(1) Power control signal afford by main control board is error.

(2) Thyristor is broken.

(3) Mutual inductor is broken.

5-3 Infrared display value error

Infrared temperature is compensated, so the real temperature is lower than reading value displayed on

screen, but they are both have a certain proportion relation.

Measuring the output signal, if the signal is too large or stable, this problem must be caused by fault main

control board.

If the signal does not up while the temperature go up, the IR sensor may be broken.

5-4 Pressure display value error

Observe the pressure value displayed on screen whether change or not to affirm fault through press the

sensitive terminal by thumb.

Measuring the output signal between blue and white, if the signal can match the displayed value, the

problem maybe caused by pressure sensor.

If there is no output signal or weak signal change, that’s probably the pressure sensor error.

Replace the pressure sensor after the fault confirmed to avoid difficult installation.

5-5 Other components faults

Other components work mechanism are relatively simple,right work voltage and good quality, these

problems can be easily deal with according to the wiring diagram.

33

6 Parameter calibration

6-1 Temperature calibration (PT100)

Disconnect the temperature sensor in chamber, use standard resistance box to calibrate the temperature

parameter, refer to fig 6‐1.

Fig 6-1 Wring layout for temperature calibration

(1) Use super password entering calibration interface, refer to fig 6‐4. There are one thing need to notice, that

is gray status represents lowercase and highlight represents uppercase, refer to fig 6‐2and6‐3.

Fig 6-2 Lowercase status

Status button

34

TOPEX service manual

Fig 6-3 Uppercase status

Fig 6-4 Temperature and pressure calibration interface

(1) Set 100.00Ω,clickbuttonRT0,refertofig6‐4, it’s no need to click OK button.

(2) Set 199.50Ω, click button RT1, finally click OK button to save.

(3) Disconnect resistance box, reinstall the temperature sensor, if the temperature value displayed on screen is

not right, the temperature should be calibrated again.

35

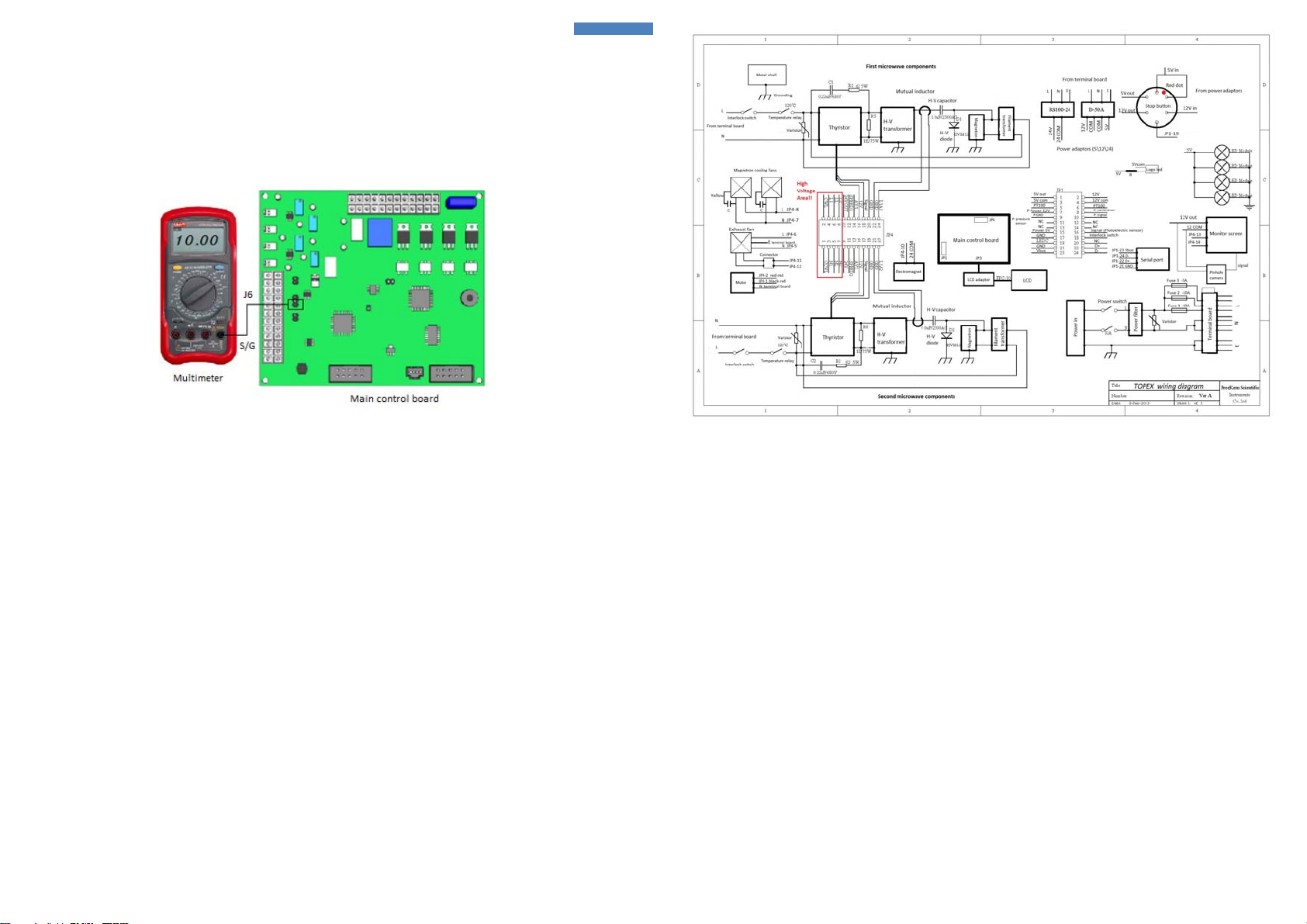

6-2 Pressure parameter calibration

Pressure parameter calibration should calibrate zero first then span, this sequence can not be reversed.

(1) Multimeter connects with J6 pin S and G on main control board, refer to fig 6‐5, adjust side Z until the

output voltage is 10 mV . This operation process is zero calibration

Fig 6-5 Wiring layout for pressure calibration

(2) Connect J6 pin G and J with a mini jumper, adjust side S until the output voltage is 4.00 V then entering

setting interface and press button RP, refer to fig 6‐4, finally click button OK to save calibration value. If the

value displayed on screen is not right, pressure parameter should be calibrated again.

7 Wiring diagram

Preekem Scientific Instruments Co.,Ltd.

No.2 Building,No.4299 Jindu Road,Shanghai,201108,China

Tel:86‐021‐5442‐7057

Fax:86‐021‐5442‐7063

E‐mail:[email protected]

Service manual

Ver 1.0

Table of contents

Other PreeKem Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Omega Engineering

Omega Engineering WTM-1000 user guide

Thermo Scientific

Thermo Scientific Finnpipette FOCUS Instructions for use

Cleverscope

Cleverscope CS1090 Usage Guide

MRC

MRC LOM-150DIG Operation manual

Endress+Hauser

Endress+Hauser OXY5500 QF Safety instruction

Andrew Alliance

Andrew Alliance Waters Andrew+ user manual