PREFORMED LINE PRODUCTS COYOTE Dome Cross-Connect Closure 6-1/2" x... User manual

1

COYOTE®Dome Cross-Connect Closure 6-1/2" x 17"

FEBRUARY 2015

Be sure to read and completely understand this procedure before applying product. Be sure to select the

proper PREFORMED product before application.

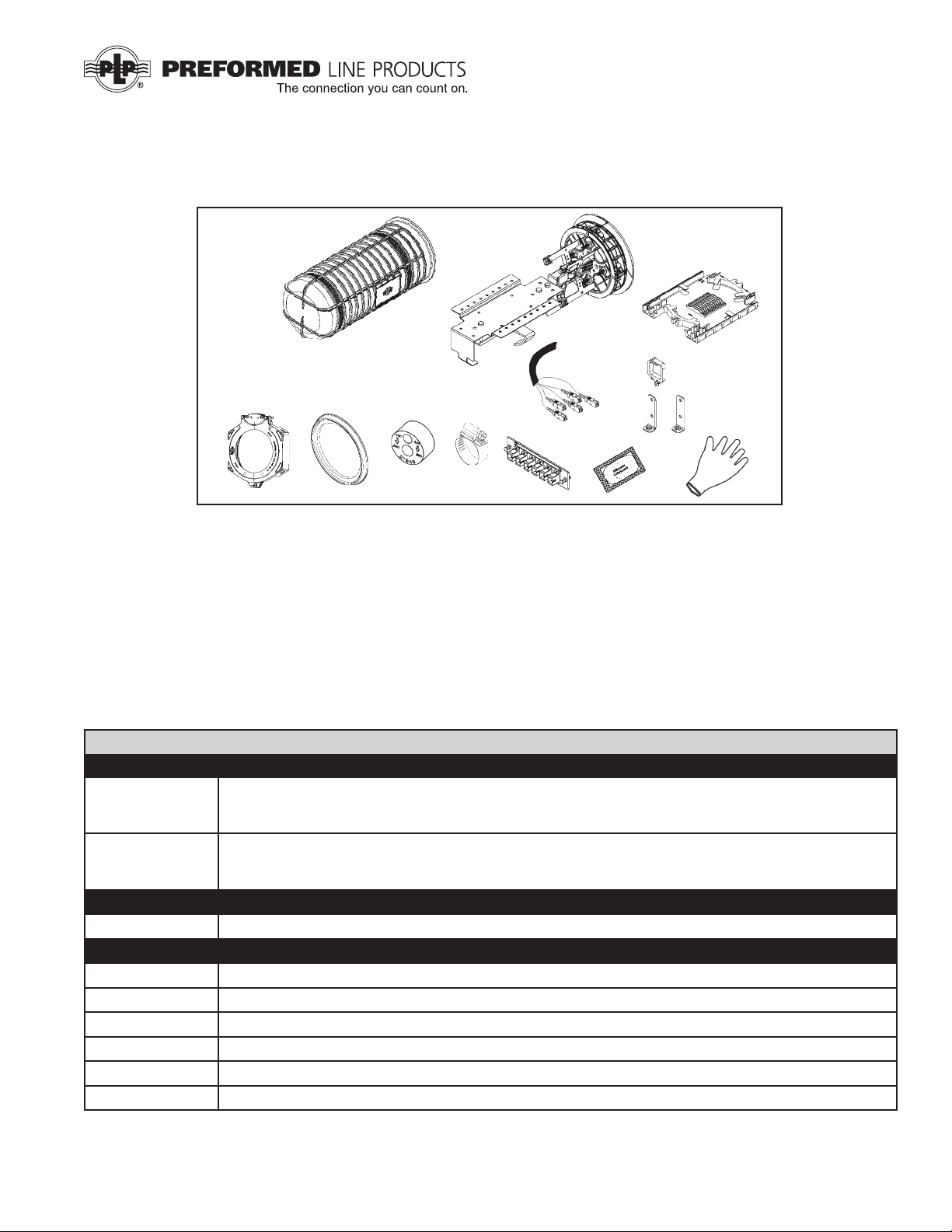

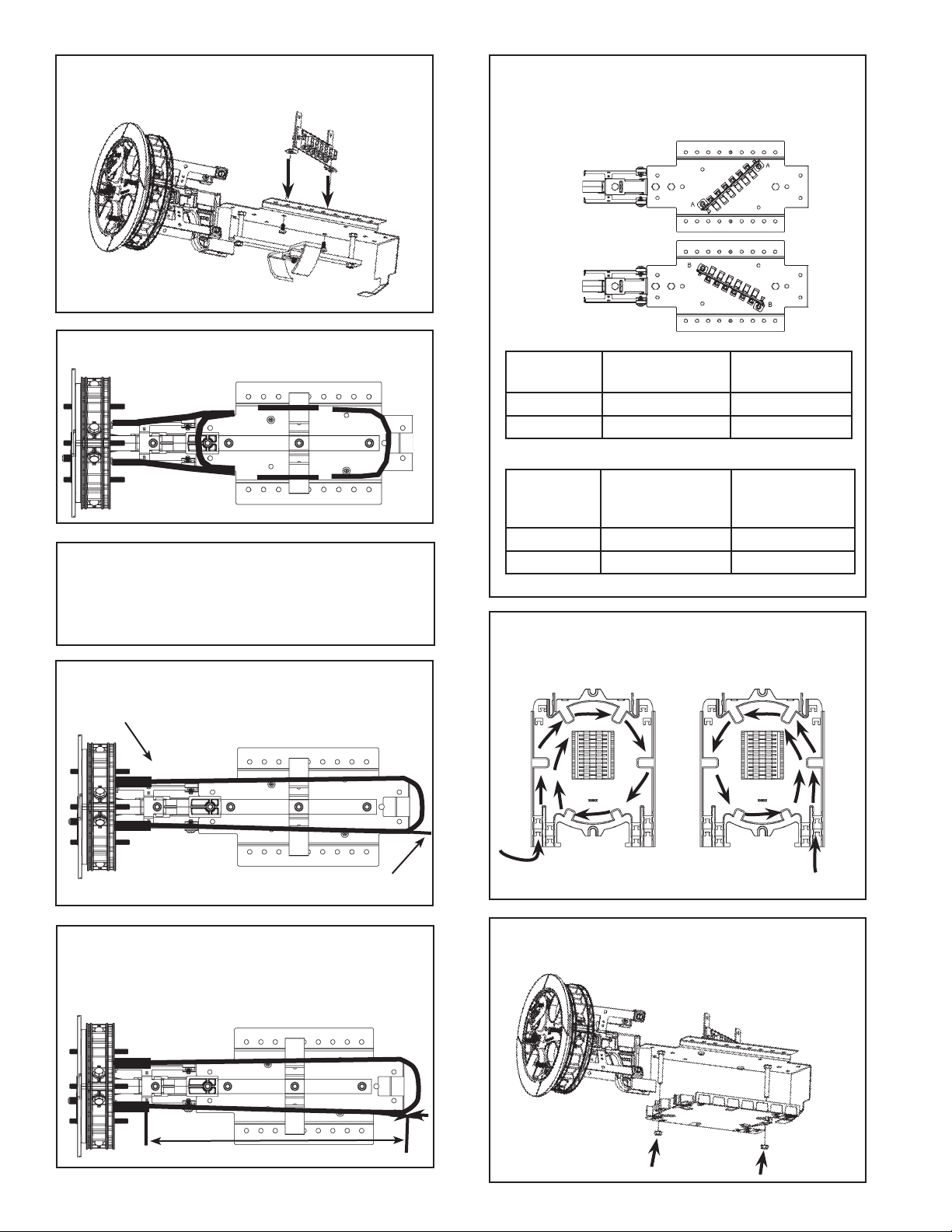

NOMENCLATURE

1. Dome cover (1)

2. Organizer with 4-port

end plate assembly (1)

3. *Splice Tray (Small LITE-GRIP™

tray shown)

4. Dome collar (1)

5. Dome gasket (1)

6. Cable grommets (2)

TOOLS REQUIRED

• 3/8" & 7/16" can wrench

or socket

• 1/4" nut driver or screwdriver

• Snips

• Fiber optic cable opening

tools

7. Hose clamps (4)

8. *Adapter panel

9. Silicone lubricant (4-ve gram packets)

10. Plastic organizer clip (8)

11. Disposable glove (1)

12. *Fiber pigtail kit

13. *Adapter plate brackets (2)

2

*3

*13

*4 56

9

*12

1

10

7

11

*Customer Selected Items

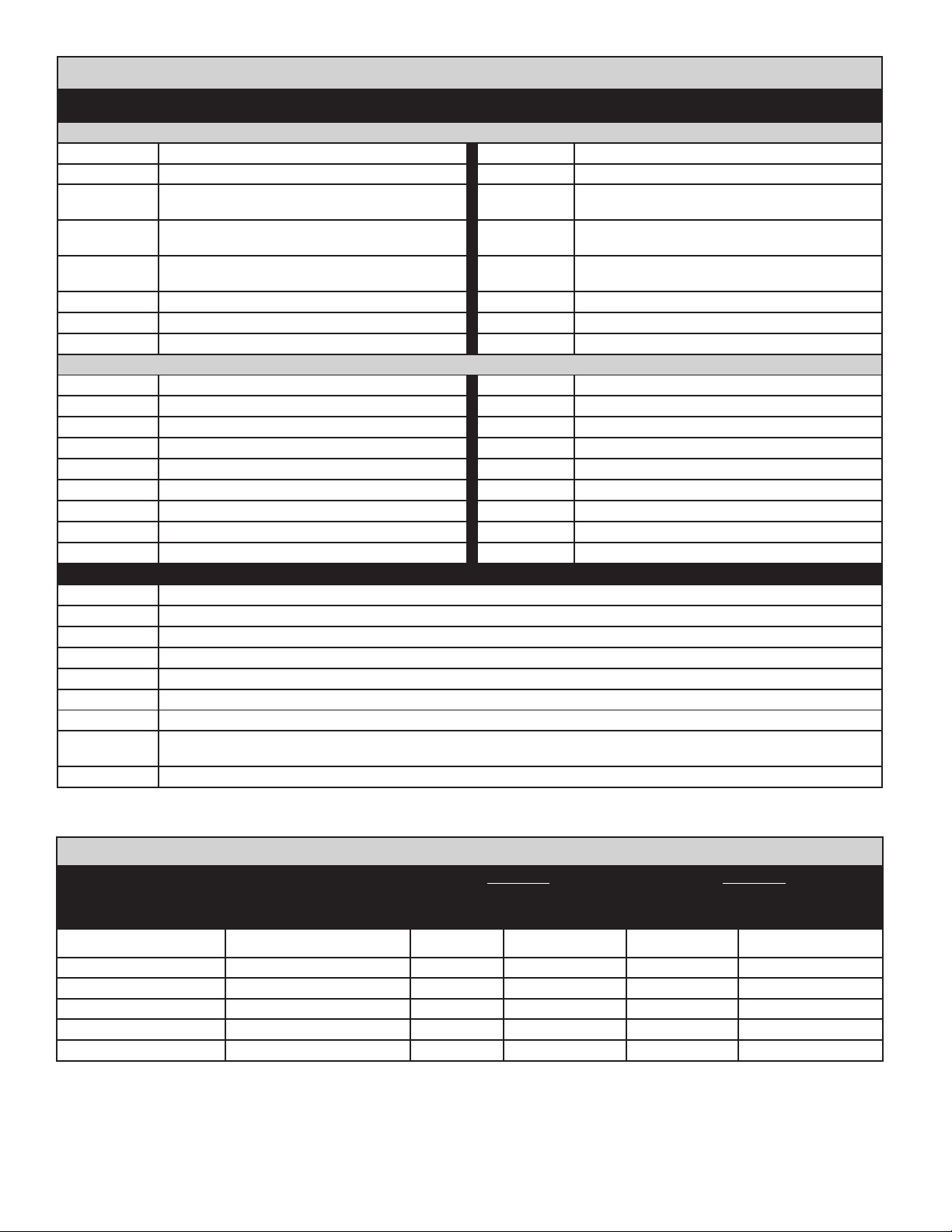

COYOTE Dome Cross-Connect Closure Kits 6.5" x 17" and 6.5" x 22"

Catalog Number Description

800012185 COYOTE Dome Cross-Connect Closure 6.5" x 17" – Includes: (2) Grommets, (1) Cross-Connect Organizer

Assembly with 4-Port End Plate Assembly, (1) Dome, (1) Collar Assembly, (1) Gasket, (8) Plastic Organizer

Clips, (2) Adapter Plate Brackets, (1) Disposable Glove, (1) Silicone Lubricant Packet, & (4) Hose Clamps

800012184 COYOTE Dome Cross-Connect Closure 6.5" x 22" – Includes: (2) Grommets, (1) Cross-Connect Organizer

Assembly with 4-Port End Plate Assembly, (1) Dome, (1) Collar Assembly, (1) Gasket, (8) Plastic Organizer

Clips, (2) Adapter Plate Brackets, (1) Disposable Glove, (1) Silicone Lubricant Packet, & (4) Hose Clamps

Catalog Number Accessory Kits

80808456 COYOTE Dome End Plate Fixture

Catalog Number Mounting Brackets

8003716 Aerial Mounting Bracket (End Plate Mount)

8003831 Aerial Mounting Bracket (Dome Mount)

8003833 Aerial Mounting Bracket for ADSS Applications (Dome Mount)

8003702 Pole/Wall Mounting Bracket

8003835 Universal Mounting Bracket Kit for Hand Hole Applications

8003707 Swing Arm for Hand Hole Applications

*8

2© 2015 Preformed Line Products Company. All rights reserved.

Splice Tray/Closure Capacities for Cross-Connect

Splice Tray

Depth Description

6.5" x 17" 6.5" x 22"

Trays per

Closure

Closure Splice

Capacity

Trays per

Closure

Closure Splice

Capacity

Low Prole Single Fusion 4 48 4 48

24 Count Low Prole Single Fusion N/A N/A 3 72

Standard Single Fusion or Mechanical 3 36 3 36

Ribbon Mass Fusion 2 144 2144

LITE-GRIP Single Fusion 2 80 2 80

LITE-GRIP Mass Fusion 2 360 2 360

COYOTE

®

Dome Cross-Connect Accessories

Catalog Number Description Catalog Number Description

Adapter Plate / Connector Kits

6SMSC Adapter Plate Module, 6 port, SC, SM, ceramic sleeve 6SMFC Adapter Plate Module, 6 port, FC, SM, ceramic sleeve

6SCAPC Adapter Plate Module, 6 port, SC, SM, APC, ceramic sleeve 8SMFC Adapter Plate Module, 8 port, FC, SM, ceramic sleeve

12SMDSC Adapter Plate Module, 12 port, six dual SC, SM, ceramic

sleeve 6FCAPC Adapter Plate Module, 6 port, FC, SM, APC, ceramic sleeve

12MMDSC Adapter Plate Module, 12 port, six dual SC, MM, metal

sleeve 6SMLC Adapter Plate Module, 6 port, LC, SM, ceramic sleeve

8SMSC Adapter Plate Module, 8 port, SC, SM, ceramic sleeve 12SMLC Adapter Plate Module, 12 port, six dual LC, SM, ceramic

sleeve

8SCAPC Adapter Plate Module, 8 port, SCAPC, SM, ceramic sleeve 6MMST Adapter Plate Module, 6 port, ST, MM, metal sleeve

6SMST Adapter Plate Module, 6 port, ST, SM, ceramic sleeve 600 Blank Filler Panel

8SMST Adapter Plate Module, 8 port, ST, SM, ceramic sleeve

Pigtail Accessory Kits

P6SCU3 6 Simplex, 900 Micron, Color Coded, SC, SM, 3 meter P6FC3 6 Simplex, 900 Micron, Color Coded, FC, SM, 3 meter

P12SCU3 12 Simplex, 900 Micron, Color Coded, SC, SM, 3 meter P12FC3 12 Simplex, 900 Micron, Color Coded, FC, SM, 3 meter

P6SCA3 6 Simplex, 900 Micron, Color Coded, SC, SM, APC, 3 meter P12FC5 12 Simplex, 900 Micron, Color Coded, FC, SM, 5 meter

P12SCA3 12 Simplex, 900 Micron, Color Coded, SC, SM, APC, 3 meter P12FCA3 12 Simplex, 900 Micron, Color Coded, FCAPC, SM, 3 meter

P12SCA5 12 Simplex, 900 Micron, Color Coded, SC, SM, APC, 5 meter P6LC3 6 Simplex, 900 Micron, Color Coded, LC, SM, 3 meter

R12SCU3 Ribbon, 12 Fiber, Color Coded, SC, SM, LC, APC, 3 meter P12LC3 12 Simplex, 900 Micron, Color Coded, LC, SM, 3 meter

R12SCA3 Ribbon, 12 Fiber, Color Coded, SC, SM, APC, 3 meter P6STM3 6 Simplex, 900 Micron, Color Coded, ST, MM, 3 meter

P6ST3 6 Simplex, 900 Micron, Color Coded, ST, SM, 3 meter P12SCM3 12 Simplex, 900 Micron, Color Coded, SC, 62.5, 3 meter

P12ST3 12 Simplex, 900 Micron, Color Coded, ST, SM, 3 meter

Splice Trays for COYOTE Dome Cross-Connect Closure Kits 6.5” x 17” and 6.5” x 22”

80807701 Low Prole Splice Tray with plastic splice blocks (12 splice count)

80807531 Low Prole Splice Tray (blank) – no splice blocks (12 splice count)

8003468 24 Count Low Prole Splice Tray with plastic splice blocks (36 splice count)

80806033 Standard Splice Tray with elastomeric splice blocks (12 splice count)

80806182 Standard Splice Tray (blank) – no splice blocks (12 splice count)

80807114 Ribbon Splice Tray with elastomeric splice blocks (72 splice count)

80808160 Ribbon Splice Tray (blank) – no splice blocks (72 splice count)

LGSTS16 LITE-GRIP® Splice Tray with Yellow 8-Hole LITE-GRIP splice blocks – single fusion splices (Splice tray is provided wth splice blocks to support 16

splices but has the capacity for 40 splices). Splice Block Kit (Cat. # LGSBS8-5) is required to achieve maximum tray capacity.

LGSTR144 LITE-GRIP Splice Tray with Purple 3-Hole LITE-GRIP splice blocks – mass fusion/ribbon splices (144 splice count)

3

COYOTE Grommet Chart

For use in COYOTE ONE Dome, Dome, GLC, In-Line RUNT, Terminal, Taut, LCC, & Aerial Drop Closures

PLP Catalog

Number Cable Range Inches (mm) Description Splitting Location

8003701 .42 - .60 (11 - 15 mm) &

.60 - .85 (15 - 22 mm) 2-entry grommet

8003691 .42 - .60 (11 - 15 mm) 1-entry grommet

8003692 .60 - .85 (15 - 22 mm) 1-entry grommet

8003693 .85 - 1.0 (22 - 25 mm) 1-entry grommet

8003694 1.0 - 1.25 (25 - 32 mm) 1-entry grommet

8003663 .42 - .60 (11 - 15 mm) 2-entry grommet

8003990

.50 - .60 (12.7 - 15.2)

.125 - .25 (3.2 - 6.4)

and at drop

4-entry grommet

8003664 .30 - .43 (8 - 11 mm) 4-entry grommet

8004065 .250 - .312 (6.4 mm - 7.9 mm) 4-entry grommet

8003665 .125 - .25 (3 - 6 mm)

and at drop cable 6-entry grommet

8003676

.42 - .60 (11 - 15 mm),

.125 - .25 (3 - 6 mm),

and at drop cable

7-entry grommet

8003677 .125 - .25 (3 - 6 mm)

and at drop cable 8-entry grommet

NOTE: Grommet Kit contains (1) Grommet, (1) Cable Measure Tape, (2) Silicone Lubricant Packs, (1) Set of Plugs

(Multi-Entry Grommets only)

4

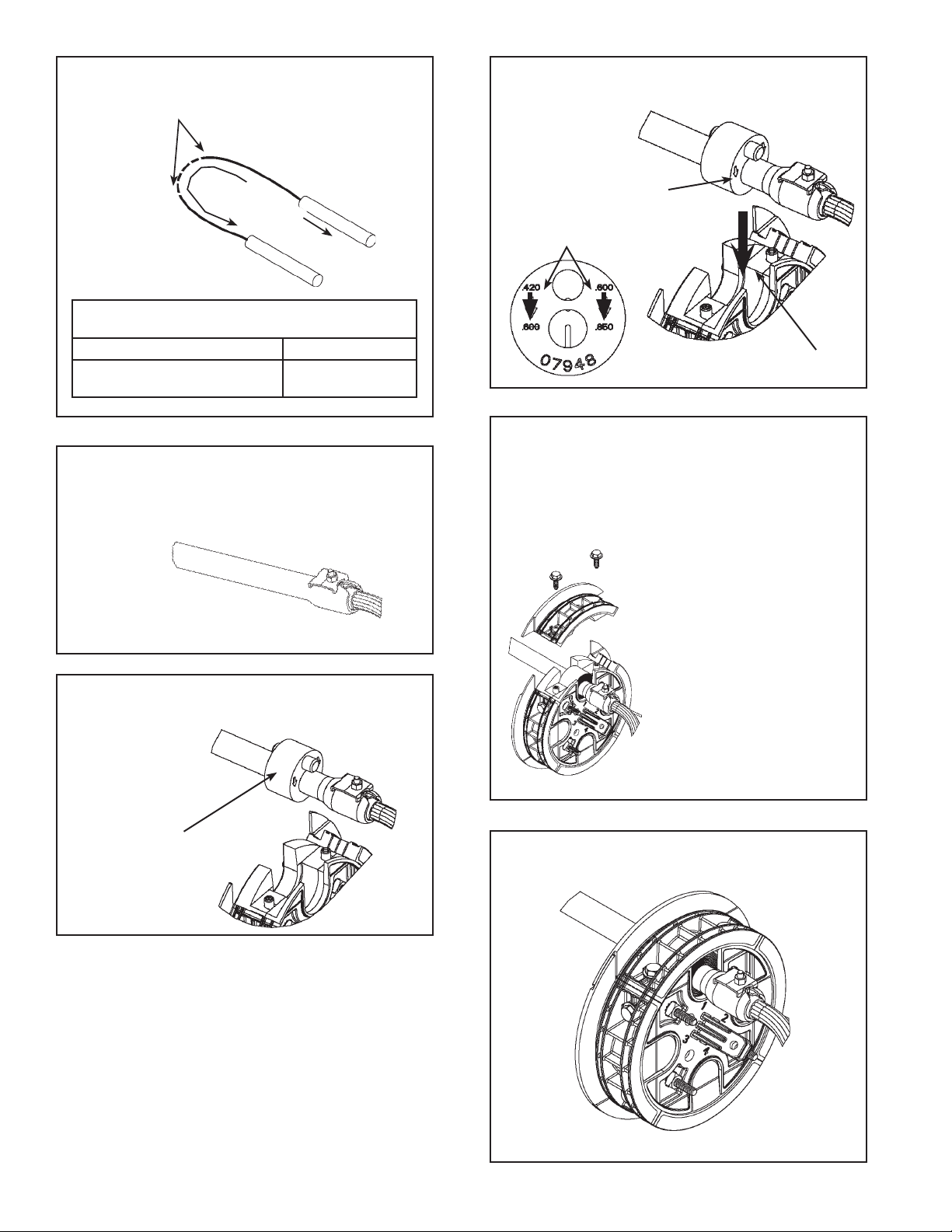

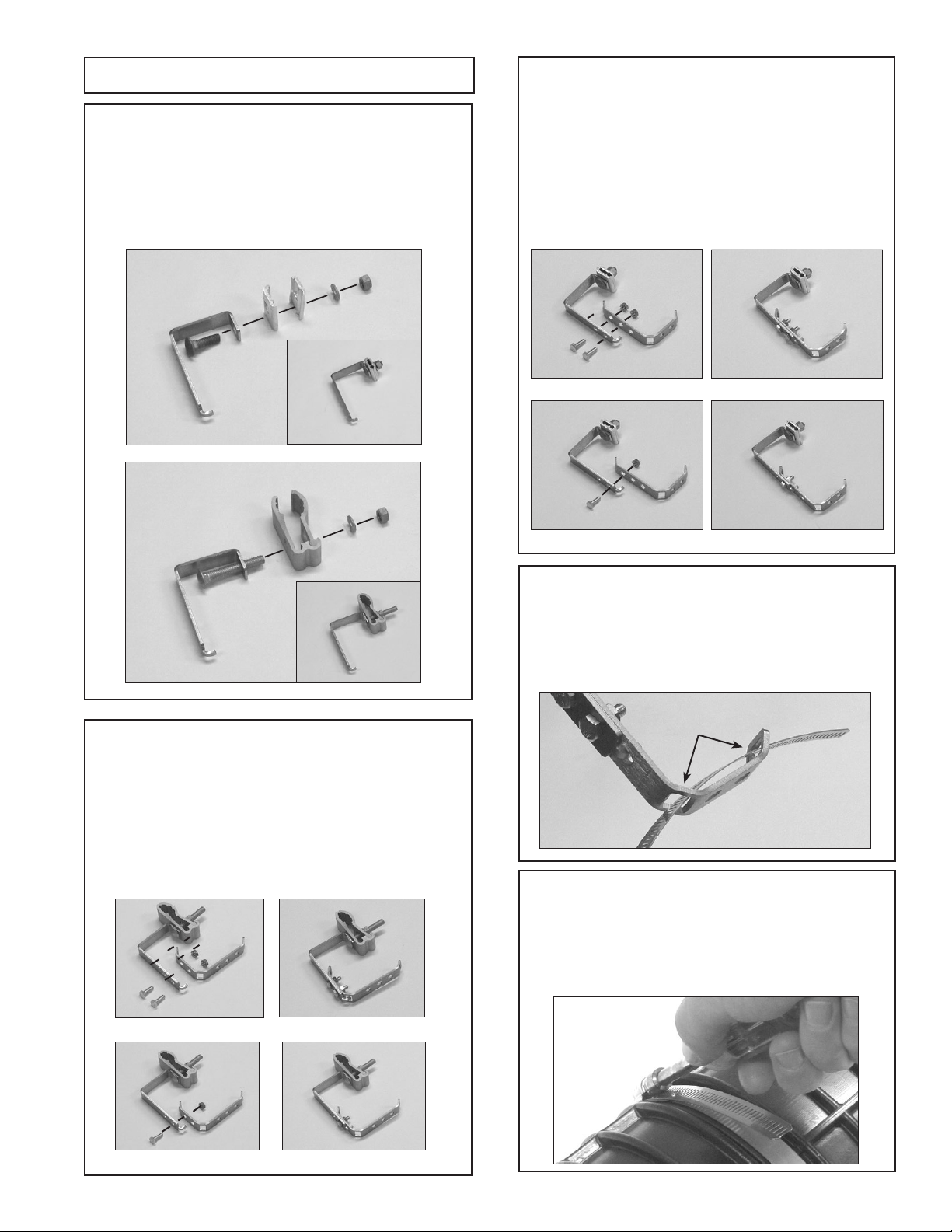

Step #1a Remove end plate from organizer

assembly.

Step #1b Remove the end plate caps from the

selected cable ports and break out

the tabs.

PLP Tip:

Scoring edges of tabs with knife

makes them break out easier.

End Plate Preparation

Break out entrance ports 3 and 4

for expressed feeder ber.

Step #1d Break out entrance port 2 for local ber.

Step #2 Optional Step

For better stability during cable instal-

lation and ber splicing, install the end

plate onto the COYOTE®Dome End

Plate Fixure (see Steps 3a-b for

installation details).

Optional Step

Install support bracket onto base.

Position sup-

port bracket

onto base and

secure with

wing nuts.

Note: Do not

tighten wing nut

until end plate is

installed.

Base can be

secured to

work surface

with either

clamps or

with bolts.

Loosen wing

nut so slotted

tab of support

bracket can

slide behind

wing nut.

Step #3b Optional Step

Seat the end plate onto the cushion

wedges and secure the support bracket

to the stud of the end plate.

Hand tighten any loose wing nuts to secure end

plate to xture.

The outside surface of the end

plate must rest against the support

bracket.

Support Bracket

PLP Tip:

Hole in strength member bracket is a guide for

sheath opening.

Step #4 Lay cable into entry point and mark for

grommet and sheath opening locations.

Mark for

sheath

opening

1.75" (45 mm)

Grommet

location

Step #3a

Step #1c

5

Step #6a If using cut cable, insert cable

through grommet. If your application

requires express/balloon/ring cut

cables, see Step 7 for grommet

slitting procedure.

Install plug in

unused port

Diameter

range

top hole Diameter

range bottom

hole

Step #5 Measure cable to determine diameter

and hole location to use in grommet.

Step #6b Installing Figure 8 Style Cables and

Cables with Tracer Wires – Remove

tracer wire or ground wire from the por-

tion of the cable that will be positioned

in the grommet and insert the cable into

the grommet.

Cable with

Tracer Wire

Figure 8

Style Cable

Not Correct

Installation

Correct

Installation

Not Correct

Installation

Correct

Installation

Step #7 Grommet Slitting – If slitting is

required, lay grommet on a stable at

surface. Position utility knife with the

cutting edge against the top surface and

cut through grommet.

Consult grommet chart on page 3 for

slitting locations of all grommets.

PLP Tip: Use a pen to sketch slitting lines on top

surface of grommet prior to cutting.

Not Correct

Slitting Angle Correct

Slitting Angle

Slit

Slit

Step #8a Trim strength members to length.

Prepare feeder and local cable(s) for

cut applications.

Minimum Sheath Opening for

Cut Cable Applications

77" 2.0 m

Buffer (Loose)

Tube Cable

2.5" (6.4 cm)

Strength Member

Step #8b Prepare cable(s) for mid sheath appli-

cations. (Express/Balloon/Ring Cut).

For Applications Where Fiber is

Dedicated to the Splice Point

Sheath Opening 77" (2.0 m)

Fiber/Buffer Tube

Cut Location A (see image above)

Buffer (Loose)

Tube Cable

A

X

77" (2.0 m) OFFICE/C.O.

6

Prepare cable for expressed ber

(buffer tube window cut) applications.

For Applications Where Fiber is

Expressed through the Buffer Tube

Sheath Opening 96" (2.4 m)

Buffer Tube

Opening Location

C (see image

above)

Buffer Tube

Opening

Locations for

Window Cut

C

X

X

C

96" (2.4 m)

OFFICE/C.O.

Step #9 If shielded cable is being used, install

shield connector on shielded cables.

See Step #16 for recommended

bonding practice.

Follow standard company practices.

Step #10a Lubricate the outer surface of the

grommet.

Lubricate seal-

ing surface of

grommet with

silicone lubri-

cant provided.

Step #10b Position grommet in end plate slot.

For Wide Range 2-Hole

Grommets, make sure

arrows are pointing down

when inserting grommet(s).

Do not align grommet slit

with end plate seam.

Step #12

Step #11 Install cable cap and secure with hex

bolts. Tighten bolts by hand evenly

until cable cap is fully seated. (DO

NOT USE POWER TOOLS TO

TIGHTEN BOLTS).

Important Note:

Tighten all unused cable caps.

Complete end plate assembly.

PLP Tip:

To start cable cap bolts, apply

pressure with thumb and line

up bolts with inserts. Engage

1 or 2 threads on one of the

bolts. Repeat the process on

opposite bolt. Alternate tight-

ening until fully seated.

Step #8c

7

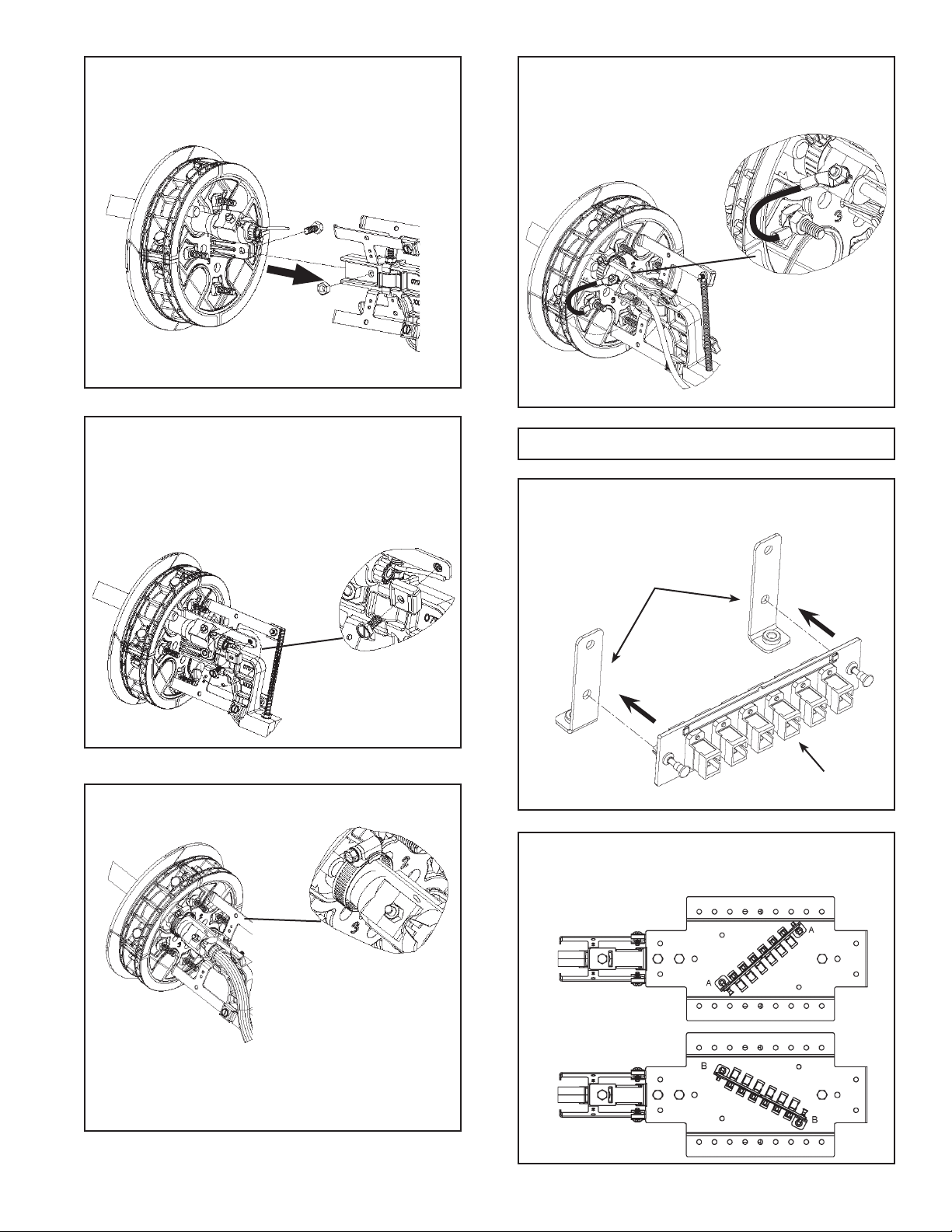

Step #13

Step #14

Step #15

Secure organizer assembly to

end plate with 1/4" hex bolt and

hex nut.

Trim cable strength member(s) even

with the edge of the cable restraint

bracket. Secure strength member(s)

and **KEVLAR®under clip and

tighten screw.

Secure cable sheath with hose

clamp.

PLP Tip:

Avoid contact between hose clamp and shield

connector to maintain isolation of each cable

ground.

Organizer Preparation

Step #16 Attach bonding device between the

cable and ground stud in the end

plate and ground per your accepted

company practice.

Step #18

Step #17 Properly orient brackets. Secure

adapter plate(s) to brackets.

Select adapter plate assembly

location.

Brackets

Adapter plate

**KEVLAR® is a registered trademark of the DuPont™ Company.

8

Step #24 Install tray(s) onto mounting studs

and secure with nuts. Do not over

tighten nuts.

Step #22 Determine feeder and local pigtail

length based upon adapter plate

location. See charts below.

Plate

Location

Feeder

Pigtail Length

Local

Pigtail Length

A 56" (142 cm) 44" (112 cm)

B 56" (142 cm) 44" (112 cm)

Plate

Location

Yellow Braid

Length Feeder

Pigtails

Yellow Braid

Length Local

Pigtails

A 18-3/4" (48 cm) 9 -1/2" (24 cm)

B 18-3/4" (48 cm) 9-1/2" (24 cm)

Step #21a

Step #20

Select feeder ber to be spliced.

Route and store buffer tubes in

storage brackets.

X

Cut ber to be spliced here

Cut ber

Secure adapter plate assembly to

mainframe with fasteners provided.

Step #21b Measure and mark buffer tube 43"

from cable sheath opening. Remove

buffer tube beyond this mark to

expose ber to be spliced.

43" (109 cm)

Step #23 Route incoming bers and outgoing

pigtails, and splice per standard

company practices.

INCOMING FIBER OUTGOING PIGTAILS

Critical Step:

Position assembly according to image in

Step 21a to insure selected ber is cut at

the proper location.

Step #19

Bottom view of organizer.

9

Step #25 Install storage bracket bar and

secure with nuts.

Step #26 Install organizer clips into desired

holes. Organizer

clips.

Route and install feeder pigtails

to adapter plate.

Step #27b Route and install local pigtails to

adapter plate.

Dome & Collar Installation

Step #29 Slide end plate gasket onto end plate

and press into groove.

Make sure gasket is seated

in groove of end plate

Step #30 Re-tighten all cable cap bolts (step #11) to

assure that the cable caps are fully seated.

When using a can wrench or nut driver, the

installed torque is 35 to 40 in-lbs.

Step #27a

Step #31 Work the gasket into the groove.

Step #32 Position the dome over end plate.

Step #28

Lubricate all inner and outer surfaces of the gasket.

Lubricate all surfaces around gasket

with silicone lubricant to assure easy

assembly and closure re-entry.

10

Step #33 Position the collar at on the work

surface in front of the closure as

shown below.

Step #34 While holding the collar in place,

compress a portion of the end plate

into the dome and insert them in the

groove of the collar near the latch, as

shown below.

Step #35 While holding the collar in place, push

against the end of the dome and

slightly lift and push the other half of

the dome up and over the lip of the

collar with your ngers to fully install

the dome in the collar half.

Step #36 Check to make sure the lip of the

dome is captured within the collar half.

Front Side

Back Side

Lip of dome

is captured

within collar.

Lip of dome

is captured

within collar.

Step #37 Install the other collar half onto

the closure.

Step #38 Secure the collar with the latch and pin.

11

Flash Test Procedure

Step #39 Remove cap from air valve of end plate.

Step #40 Pressurize closure up to a max of 10 psi. Step #42 Release the pressure in the closure

using the bump on the top of the air

valve cap.

Step #41 Spray all sealing surfaces of the

dome end-plate with soapy water to

determine if there are any leaks.

12

Common End Plate Leaks During

Flash Testing

Leak occurring at the corner of the cable

port due to the cap of the cable port not

being fully tightened.

To resolve, remove collar, remove End Plate/

Organizer Assembly from the Dome, and

tighten bolts on end cap where leak occurred.

Reassemble and ash test to conrm that the

leak has stopped.

Leak occurring at the

corner of the cable port

Leak occurring at the cable entry of the

grommet due to the cable not being within the

stated cable diameter range of the grommet

To resolve, remove collar and remove End

Plate/Organizer Assembly from the Dome.

Remove end cap where leak occurred, remove

grommet, remeasure cable with measure

tape provided and select proper grommet.

Reassemble the components and ash test the

closure to conrm that the leak has stopped.

Leak occurring at the cable

entry of the grommet

17.85" (453 mm)

8.57" (218 mm)

10.04" (256 mm)

22.60" (574 mm)

8.57" (218 mm)

13

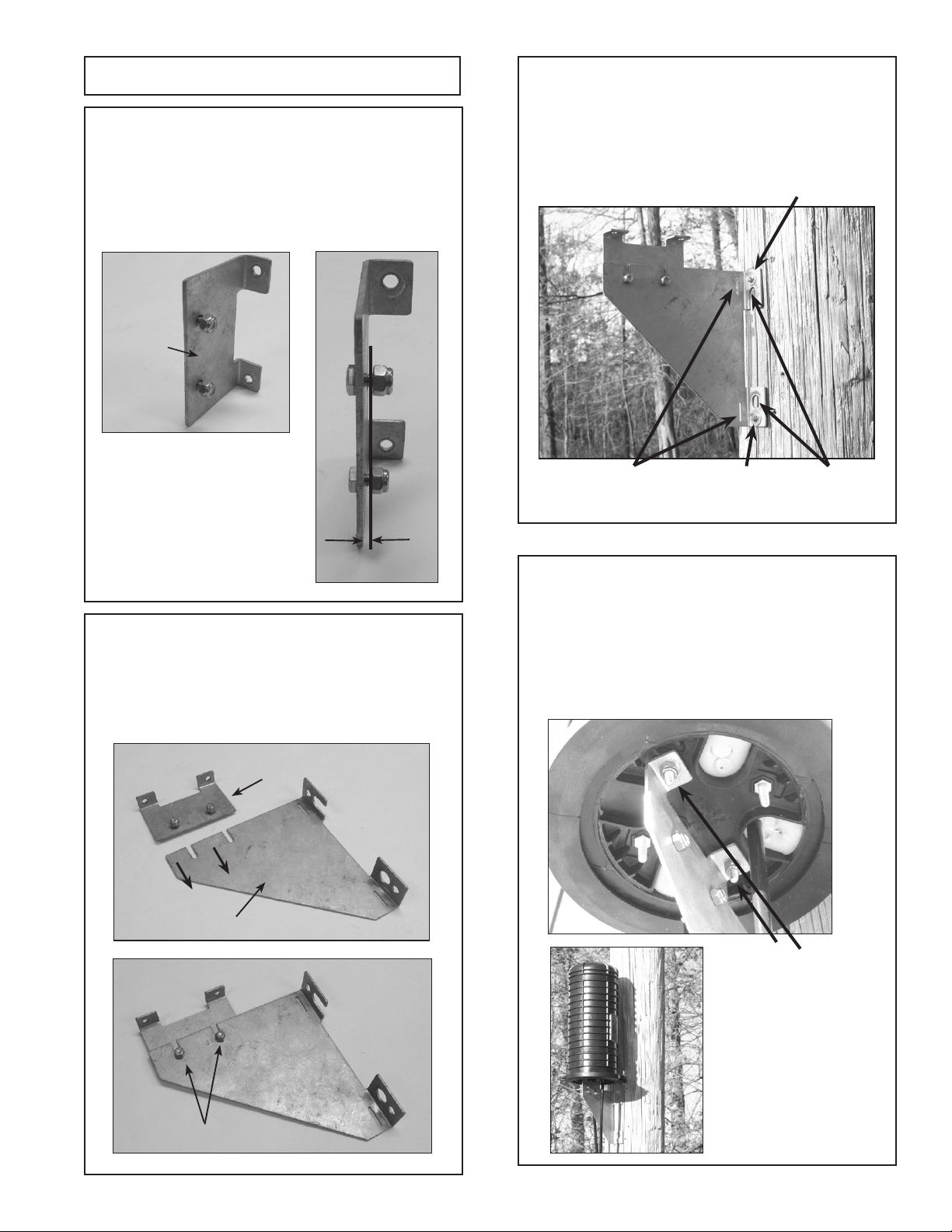

Aerial Mounting Options

Step #43a For 6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035)

and 6.5" Dome ADSS Mount Aerial

Offset Bracket Kit (P/N: 8004036).

Assemble each bug nut or ADSS

clamp to each top aerial offset

bracket as shown below.

For 6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035) and

6.5" Dome ADSS Mount Aerial Offset

Bracket Kit (P/N: 8004036).

Step #43b

Strand Clamp

ADSS Clamp

Position 1 – ADSS Clamp Shown

Position 2 – ADSS Clamp Shown

For Shorter Spacing. Align the top aerial offset

bracket with the bottom aerial offset bracket in either

Position 1 or Position 2 as shown below. Secure the

top aerial offset bracket to the bottom aerial offset

bracket with the bolts and keps nuts provided.

For 6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035)

and 6.5" Dome ADSS Mount Aerial

Offset Bracket Kit (P/N: 8004036).

Step #43c

Position 1 – Strand Clamp Shown

Position 2 – Strand Clamp Shown

For Taller Spacing. Align the top aerial offset bracket

with the bottom aerial offset bracket in either Position

1 or Position 2 as shown below. Secure the top aerial

offset bracket to the bottom aerial offset bracket with

the bolts and keps nuts provided.

Step #44

Slots

6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035)

and 6.5" Dome ADSS Mount Aerial

Offset Bracket Kit (P/N: 8004036).

Tighten each hose clamp around

the dome.

Step #45

6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035)

and 6.5" Dome ADSS Mount Aerial

Offset Bracket Kit (P/N: 8004036).

Insert hose clamp through slots in each

of the bottom aerial offset brackets.

14

6.5" Dome Strand Mount Aerial

Offset Bracket Kit (P/N: 8004035)

and 6.5" Dome ADSS Mount Aerial

Offset Bracket Kit (P/N: 8004036).

Bracket installed on dome closure.

Step #46

Strand Aerial

Offset Bracket

shown secured

on a 6.5"

Dome

Step #47

Hand Hole Mounting Option

COYOTE Universal Mounting

Bracket for Hand Hole

Applications (P/N: 8003835).

Secure the Universal Mounting

Bracket to the inner wall of the hand

hole using 2 screws.

Step #48 COYOTE Universal Mounting

Bracket for Hand Hole Applications

(P/N: 8003835).

Insert banding (plastic or metal) through

the slots of the hanger brackets.

COYOTE Universal Mounting

Bracket for Hand Hole

Applications (P/N: 8003835).

Step #49

Position the brackets in the banding channels of

the dome. Tighten the banding until the brackets

are secure.

COYOTE Universal Mounting

Bracket for Hand Hole

Applications (P/N: 8003835).

Step #50

Slide the hanger brackets into the proper

slots of the Universal Mounting Bracket and

snap the hinged lid into place to secure the

hanger brackets.

15

Pole/Wall Mounting Option

The 6.5" COYOTE Dome Pole/Wall

Mount Bracket (P/N: 8003702).

Step #51

Position the bolts through the stud mount plate as

shown, and install lock nuts on bolts until there is

a 1/8" (3 mm) gap between the nut and the stud

mount plate.

The 6.5" COYOTE Dome Pole/Wall

Mount Bracket (P/N: 8003702).

Step #52

Slide the bolts of stud mount plate into the slots

of the pole/wall mount bracket as shown and

tighten the lock nuts until the plates are secure.

Stud Mount

Plate

1/8" (3mm)

Stud Mount Plate

Pole/Wall Mount Bracket

Secure Lock Nuts

The 6.5" COYOTE Dome Pole/Wall

Mount Bracket (P/N: 8003702).

Step #54

Attach the COYOTE Dome closure to the pole/

wall mount bracket by inserting the studs of the

dome closure end plate through the stud holes of

the stud mount plate and securing with the lock

nuts provided.

Secure Lock

Nuts

The 6.5" COYOTE Dome Pole/Wall

Mount Bracket (P/N: 8003702).

Step #53

Attach the dome pole/wall mount bracket to a

pole or wall with either 5/8" through bolts, 1/4"

lag screws, or banding straps.

Banding

Slots

1/4" Lag

Screw Hole

1/4" Lag

Screw Hole

5/8" Through

Bolt Holes

16

SP3074-2

SAFETY CONSIDERATIONS

This application procedure is not intended to supersede any company construction or safety standards. This procedure

is offered only to illustrate safe application for the individual. FAILURE TO FOLLOW THESE PROCEDURES MAY

RESULT IN PERSONAL INJURY OR DEATH.

Do not modify this product under any circumstances.

This product is intended for use by trained technicians only. This product should not be used by anyone

who is not familiar with, and not trained to use it.

When working in the area of energized lines, extra care should be taken to prevent accidental electrical contact.

For proper performance and personal safety, be sure to select the proper size PREFORMED™product before application.

PREFORMED products are precision devices. To insure proper performance, they should be stored in cartons under

cover and handled carefully.

P.O. Box 91129, Cleveland, Ohio 44101 • 440.461.5200 • www.preformed.com • e-mail: inquiries@preformed.com

**KEVLAR® is a registered trademark of the DuPont™ Company.

Step #55b The COYOTE Dome Mount Aerial

Bracket Kit for ADSS (Cat. No.

8003833) can be used to suspend

the COYOTE 6.5" x 17"

or 6.5" x 22" Dome Closure from

ADSS cable. To install the dome

mount aerial brackets, position the

brackets in the banding channels

of the dome and insert banding

(plastic or metal) through the slots

of the brackets. Tighten the banding

until the brackets are secure before

mounting the closure to the ADSS

cable with the ADSS clamp. Banding

Channels

ADSS Clamp

Dome Aerial Hanger Bracket

Strap

Dome Mount Aerial Brackets

COYOTE®Dome Aerial Mounting

Bracket – Dome Mount – for 6.5" x

17" or 22" Dome Closures. The

COYOTE®Dome Mount Aerial

Bracket Kit (Cat. No. 8003831) can be

used to suspend the COYOTE Dome

Closure from the messenger wire. To

install the dome mount aerial brack-

ets, position the brackets in the band-

ing channels of the dome and insert

banding (plastic or metal) through

the slots of the brackets. Tighten the

banding until the brackets are secure

before mounting the closure to the

messenger wire with the bug nuts of

the brackets.

Step #55a Bug Nut

Dome Aerial Hanger Bracket

Strap

Dome Mount Aerial Brackets

Banding Channels

This manual suits for next models

2

Table of contents