PREFORMED Outside Plant Series User manual

1

COYOTE®HI-COUNT CLOSURE

FOR UNDERGROUND, AERIAL, AND BURIED SPLICES

NOVEMBER 2001

CONTENTS PAGE

1. NOMENCLATURE ..................................... 2

2. DESCRIPTION & CAPACITIES ............. 2,3

3. DETERMINING BLADE

SIZE AND LOCK-TAPE™

SEALANT REQUIREMENTS ................... 3

4. END PLATE PREPARATION—

CUTTER SET-UP....................................... 3

5. END PLATE PREPARATION—

DRILLING ............................................ 3,4,5

6. END PLATE PREPARATION—

LOCK-TAPETM SEALANT

APPLICATION ........................................... 5

7. CABLE PREPARATION—

APPLYING LOCK-TAPETM TO

CABLES FOR FIELD-DRILLED

END PLATES.......................................... 5,6

8. END PLATE ASSEMBLY........................ 6,7

9. BONDING AND/OR GROUNDING

CABLES WITH METALLIC

COMPONENTS ......................................... 7

CONTENTS PAGE

Be sure to read and completely understand this procedure before applying product. Be sure to select

the proper PREFORMED™ product before application.

10. INSTALL ORGANIZER ASSEMBLY ......... 7

11. ROUTING BUFFER TUBES

TO SPLICE TRAYS ................................... 7

12. SECURING BUFFER TUBES

AND ROUTING FIBERS

IN SPLICE TRAYS............................. 8,9,10

13. INSTALLING THE SHELLS .................... 10

14. UNDERGROUND INSTALLATION...........11

15. AERIAL INSTALLATION ..........................11

16. EXTERNAL BONDING .............................11

17. MAINTENANCE PROCEDURES .............11

18. SAFETY CONSIDERATIONS.................. 12

2

3.

1.

2.

4.

5.10.

9.

8.

7.6.

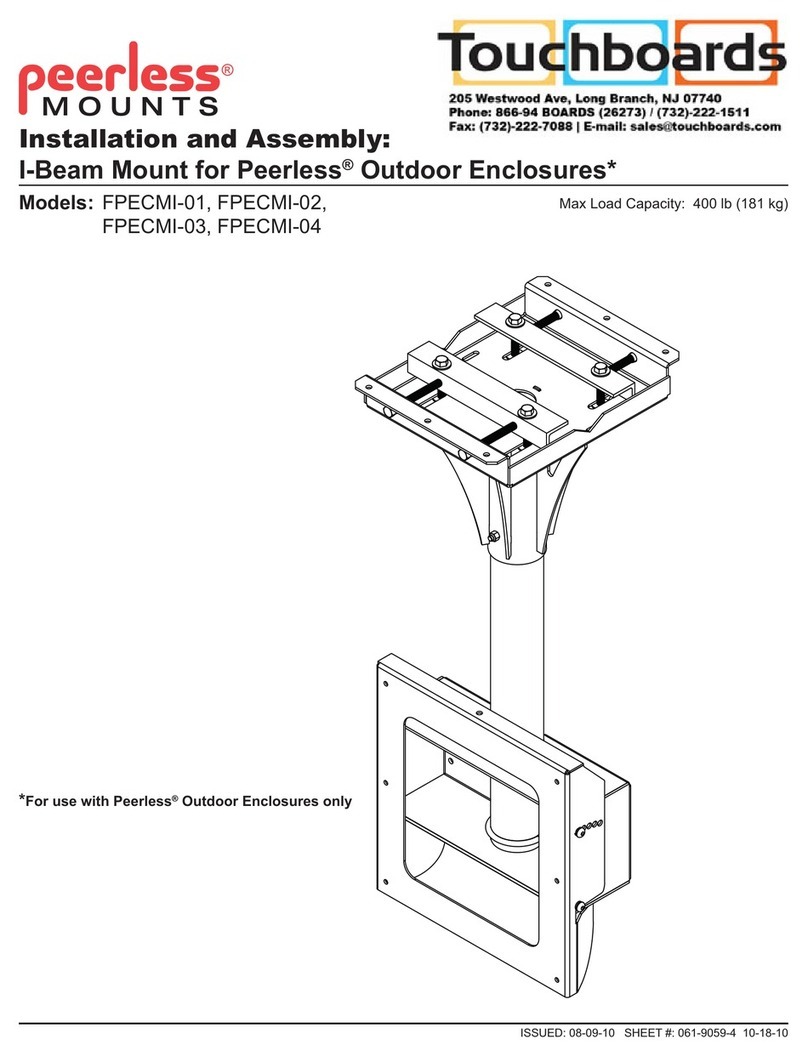

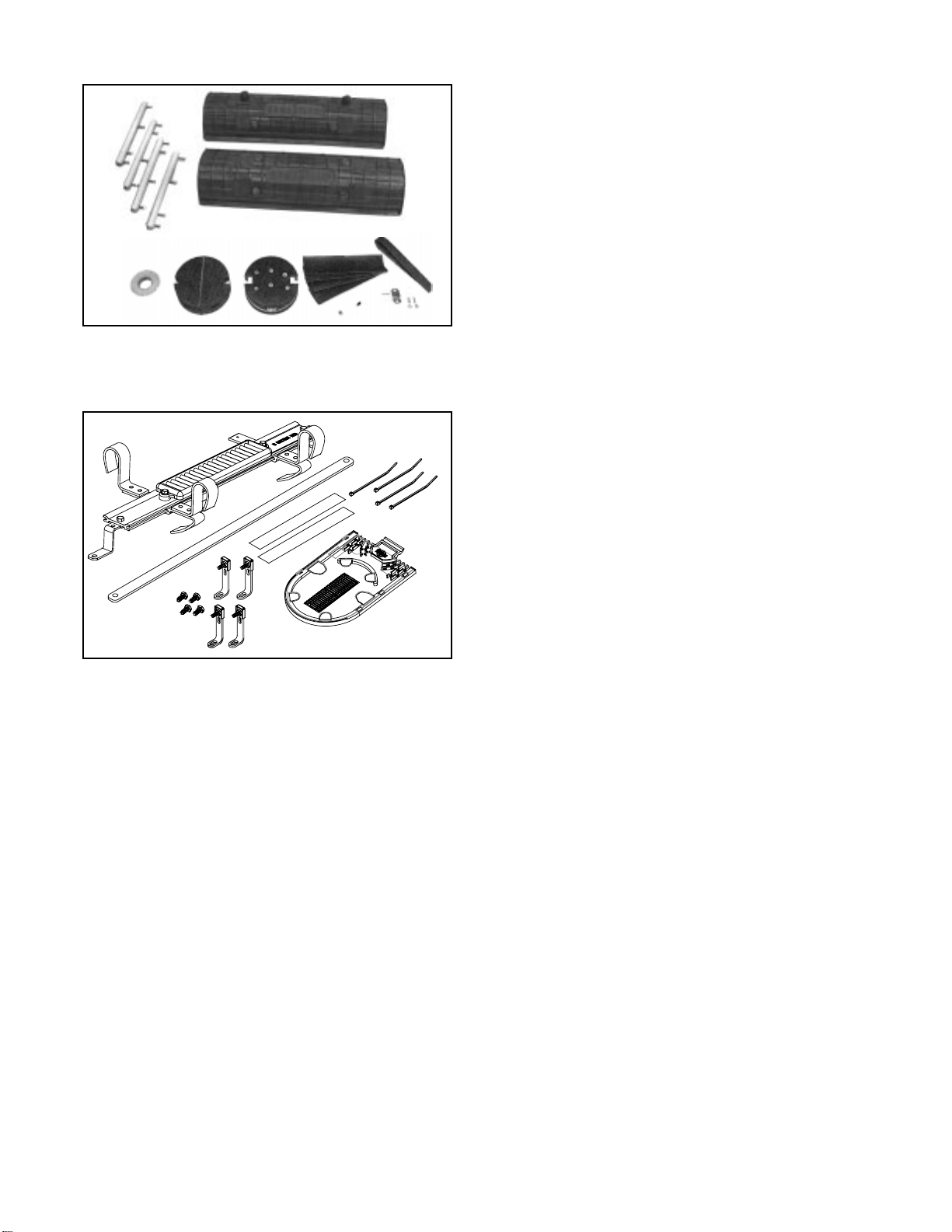

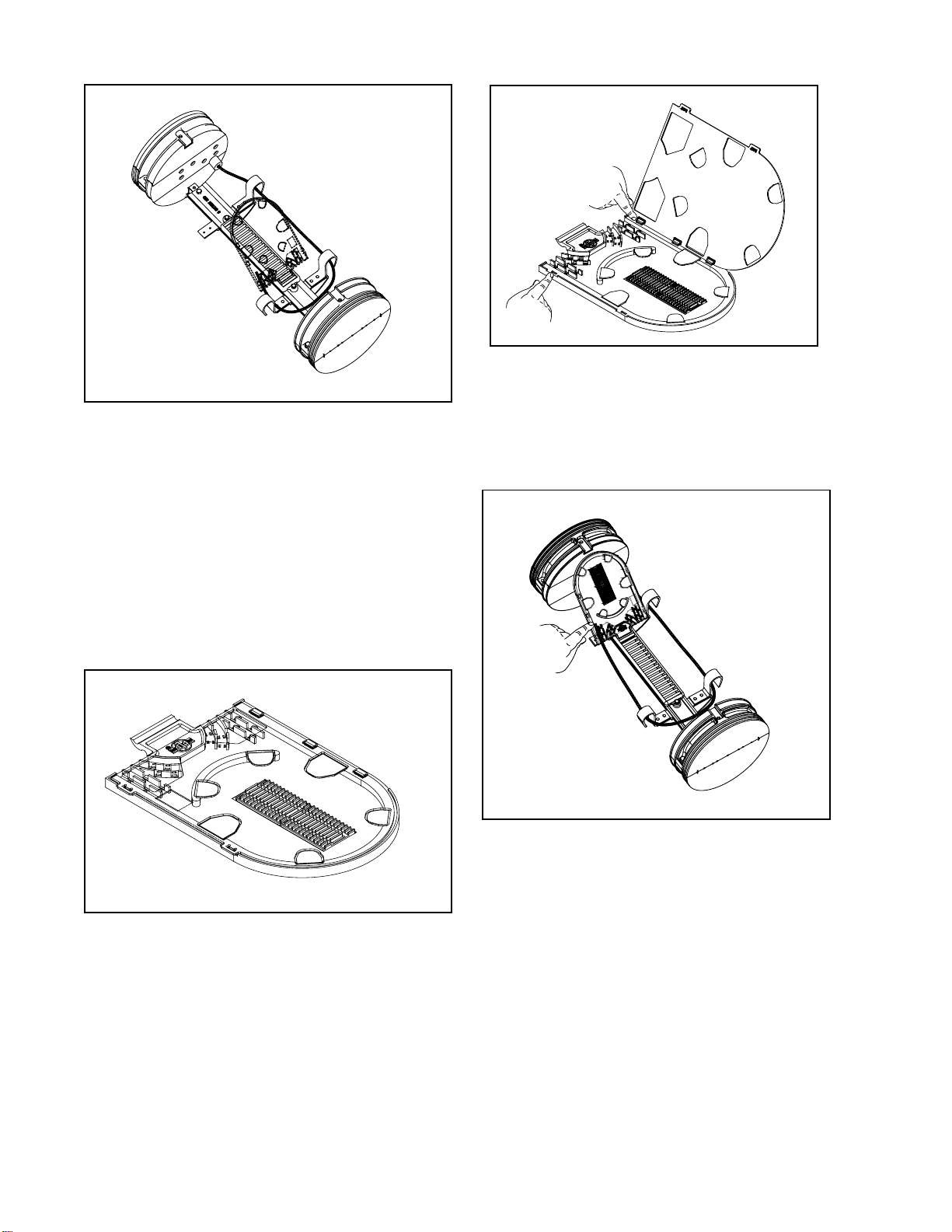

1.00 NOMENCLATURE (See Figures 1&2):

1. Bolt Bars

2. Shell Halves

3. 3/4" LOCK-TAPE™ Sealant

4. End Plates

5. LOCK-TAPE Sealant Strips

6. Cap/Blank Cap (shell kit w/air flange only)

7. Cable Mea-SURE™ Tape

8. Aerial Hanging Brackets

9. Bond Clamp

10. Emery Cloth

FIGURE 1 - COYOTE CLOSURE

COMPONENTS (TYPICAL)

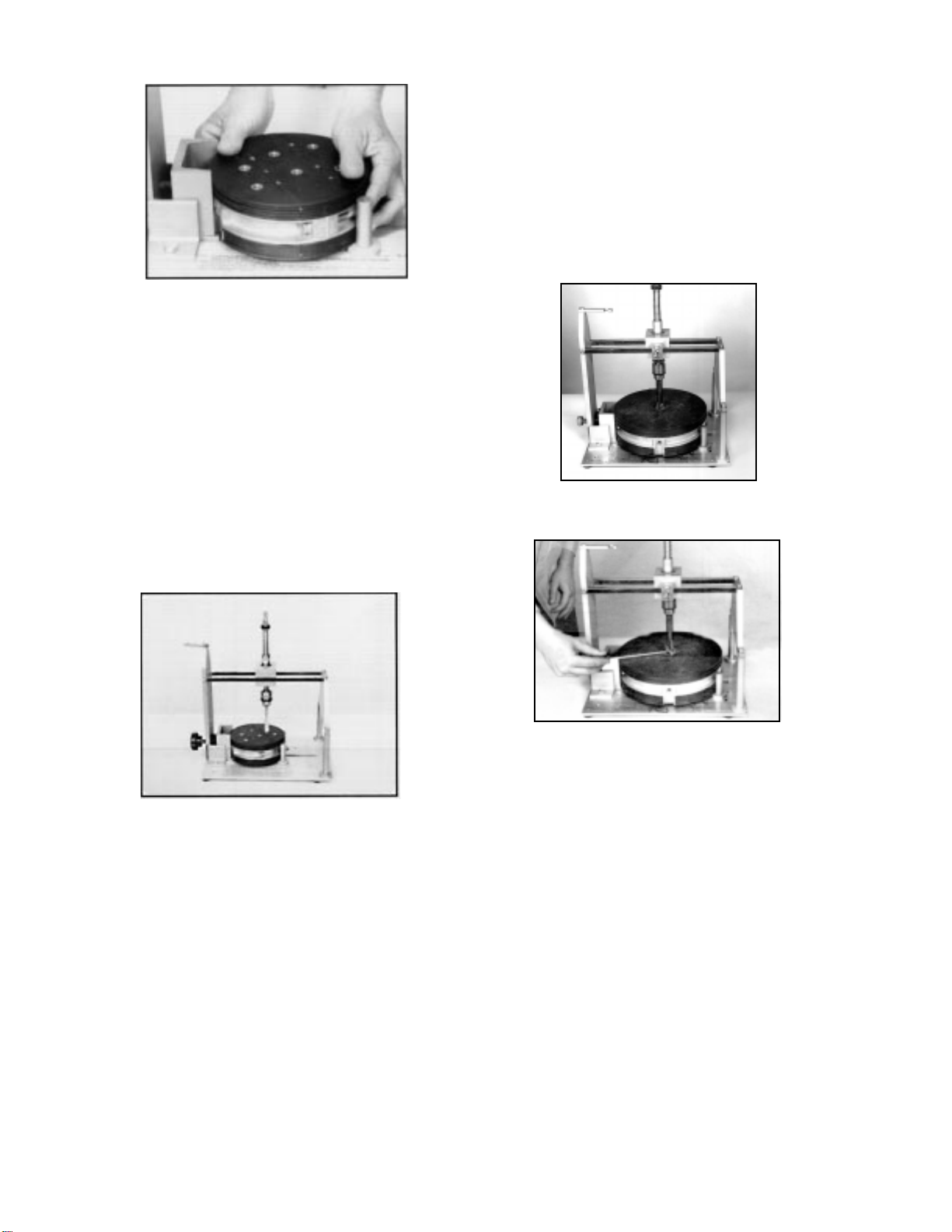

1. “L” Brackets

2.Top Run Torque Bar

3. Buffer Tube Storage and Splice Tray Rack

4. Splice Tray Kit with Clear Cover, Felt Strips, and

Tie Wraps(1)

NOTES:

1. Splice Trays sold separately.

FIGURE 2 - COYOTE HI-COUNT CLOSURE

BUFFERTUBE STORAGE ASSEMBLY AND

RELATED COMPONENTS

1.01 The COYOTE®HI-Count Closure contains

everything needed for installation except

hand tools, vinyl tape, filled cable cleaning fluid,

and C-Cement.

1.02 Tools Needed:

— Splicer’s scissors

— Splicer’s knife

— Tabbing shears

— Common screwdriver

— 1/2" deep well socket*

— 3/8" nutdriver or socket

— Needlenose pliers

— Buffer tube removal tool and/or slitter

— Sidecutters

— Torque Wrench (inch pound readings)*

— Power End Plate Cutter*

*Available from Preformed Line Products

2.00 DESCRIPTION

2.01 For Safety Considerations, refer to section

18.00 of this procedure.

2.02 The COYOTE Hi-Count Closure is specifi-

cally designed for organizing and protecting

the buffer tubes (loose tubes) and individual fiber

splices of high count (up to 432 fibers), loose tube

optic cables.

2.03 The unique buffer tube management system

and inclined, snap-in splice tray arrangement

combine to provide space for splicing up to 432

individual fibers in a compact 9.5" X 28" (241.3 mm x

711.2 mm) Closure. The COYOTE Hi-Count Closure

will accommodate up to 18 individual 24 count

Splice Trays.

2.04 The COYOTE Hi-Count Closure End Plates

have cable capacity for six cables with

L-Bracket supports (Figure 3).

©2001 Preformed Line Products Company. All rights reserved.

3

FIGURE 3 - END PLATE CAPACITY

(VIEW FROM INSIDE END PLATE)

NOTE: An additional 3.0" (76.2 mm) of space is

available on each seam of the COYOTE

Hi-Count Closure. However provisions for

securing the L-Brackets are only provided for

six entries as shown in Figure 3.

3.00 DETERMINING BLADE SIZE AND

LOCK-TAPE SEALANT REQUIRE-

MENTS

3.01 The CABLE Mea-SURE Tape is used to de-

termine the correct Power End Plate Cutter

blade size and the required layers of LOCK-TAPE

Sealant.

3.02 To use CABLE MeaSURE Tape:

— Wrap it around the cable tightly. (Figure 4)

— The index line will point to a letter and

number.

— The letter indicates the correct blade size.

— The number indicates the correct number

of layers of half-lapped LOCK-TAPE

Sealant. (Figure 4)

FIGURE 4 - WRAP CABLE MEA-SURE TAPE

AROUND CABLE

NOTE: If the index line falls on a line between two

numbers, always use the number to the right of

the line. (Figure 5)

FIGURE 5 - SKETCH OF CABLE MEA-SURETAPE

CAUTION: Cable may vary in diameter from place to

place along its length, so be sure to measure

each cable at the area where the End Plate is

to be placed.

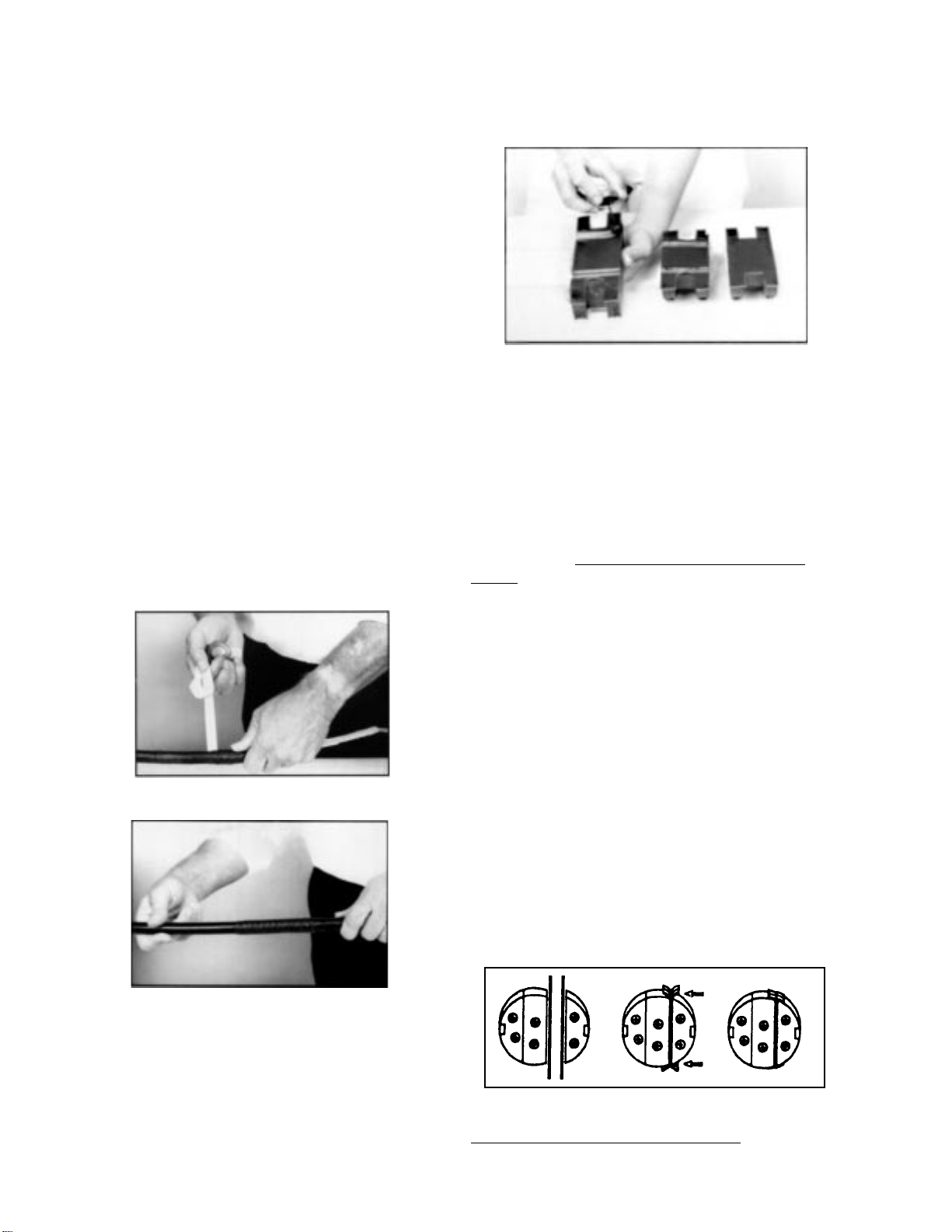

4.00 END PLATE PREPARATION -

CUTTER SET-UP

4.01 When using blades A-D, install the blade

directly into the chuck. For blades E-DD, first

install blade into drill adapter.

4.02 Secure blade or adaptor into drill chuck.

Tighten drill chuck in all three locations.

CAUTION: To prevent blades from coming in

contact with base of Power End Plate Cutter,

insure that blade or adapter is inserted as far

into the drill chuck as possible.

4.03 Insert stop-posts in tapped holes in base of

cutter corresponding to the 9.5" (241.3 mm)

End Plate diameter and hand tighten firmly.

(Figure 6)

FIGURE 6 - PUT STOP POSTS INTO CUTTER

5.00 END PLATE PREPARATION -

DRILLING

5.01 Locate the designated drill marks on the End

Plate (highlighted in yellow). These marks

should face up when placing End Plate in the Power

End Plate Cutter. (Figure 7)

9.5" (241.3 mm) DLX

THREE-SECTION

END PLATE

3 ENTRIES

PER SEAM

MAX. DIA.

1.1" Use D blade and

one half-lap of

LOCK-TAPETM

Sealant.

Use D blade and

one half-lap of

LOCK-TAPETM

Sealant.

Use M blade and

two half-laps of

LOCK-TAPETM

Sealant.

Use O blade and

two half-laps of

LOCK-TAPETM

Sealant.

The shaded area = two half laps. The clear area = one half lap.

4

FIGURE 7 - END PLATE SHOWING THE

DESIGNATED DRILL MARKS

5.02 To enable bonding/strain relief brackets to be

properly applied, the cable holes must be

drilled at the designated drill marks highlighted in

yellow.

5.03 To position End Plate in the cutter:

— Rotate End Plate and slide bearing block

along the guides until the drill is positioned over

designated drill marks.

— Then, tighten the clamp screw and

thumbscrew on the bearing block. (Figure 8).

FIGURE 8 - BLADE POSITION

CAUTION: A small nylon pellet backs up the

thumbscrews in the bearing block. Using

cutter with pellet missing could cause damage

to the guide rails.

To prevent damage, remove the thumbscrews and

insert a small piece of cable sheath. Additional nylon

pellets are available from PLP®.

5.04 Mount a 3/8" drill, drill blade adapter, and one

1/2" deep well socket to the upper end of the bearing

block shaft.

PLP TIP: A special drill motor is available from

Preformed Line Products. No matter what type

of electric drill you use, be sure to press down on

the body of the drill so that pressure is not

exerted sideways on the shaft. This will result in

a much longer life of the bearing blocks. Drill

through the End Plate slowly.

5.05 When using blades E-DD in the drill adapter,

cut through the black plastic of the End Plate

until foam is just visible in the outer ring. (Figure 9)

Use a screwdriver to pop out the plastic disk (not

necessary for A-D drill bits). (Figure 10)

FIGURE 9 - CUTTING THROUGH PLASTIC SHELL

FIGURE 10 - REMOVING PLASTIC DISK

5.06 Drill through the End Plate until the shaft

bottoms out on the stop collar. When the

drill has bottomed out, stop the drill.

CAUTION: Never bring the blade back up through

End Plate while it is still turning. This could

result in an oversized hole. Do not exert

sideways pressure on drill shaft, it may cause

damage to the bearing block.

5.07 If additional holes are needed, repeat

preceding steps 5.03 - 5.06.(Figure 11)

5

FIGURE 11 - END PLATE WITH HOLES DRILLED

5.08 Remove the End Plate from the cutter and

disassemble End Plates by removing both bolts.

6.00 END PLATE PREPARATION -

LOCK-TAPE SEALANT

APPLICATION

6.01 Remove sharp edges on plastic and foam in

area of opening with emery cloth (provided).

(Figure 12)

SCUFF LIGHTLY.

DO NOT REMOVE TOO MUCH MATERIAL

FIGURE 12 - SCUFFING CABLE OPENINGS

PLP TIP: This simple operation will help prevent

catching the LOCK-TAPE Sealant when drawing

the End Plates together. ONLY USE EMERY

CLOTH PROVIDED FOR THIS PROCEDURE.

6.02 Apply a thin coat of C-Cement to each inside

surface of the End Plate sections.

6.03 When the C-Cement becomes tacky, remove

protective backing from a strip of LOCK-

TAPE Sealant.

PLP TIP: Use removed backing from a LOCK-

TAPE Sealant strip to dry and remove excess C-

Cement applied to End Plate. (Figure 13)

FIGURE 13 - C-CEMENT ON END PLATE

6.04 Without stretching, apply LOCK-TAPE

Sealant over prepared surface of the End

Plates, following the contour of the cable holes.

Allow approximately 3/4" (19.05 mm) of LOCK-TAPE

Sealant to extend beyond each end of the End Plate.

This will serve as a tighting indicator during the End

Plate assembly.

6.05 Square cut the tape away from the bolt

holes. (The area just beyond the metal

insert.) (Figure 14)

FIGURE 14 - SQUARE CUT BOLT HOLES

7.00 CABLE PREPARATION - APPLYING

LOCK-TAPE SEALANT TO

CABLES FOR FIELD-DRILLED END

PLATES

7.01 Measure and mark the cables at 80" (2.03 m)

for the opening of the sheath.

7.02 Remove the cable sheath to open the

appropriate amount of cable. Remove any

other coverings to expose the buffer tubes in the

center of the cable.

7.03 The cable must now be marked for the

installation of the LOCK-TAPE Sealant.

6

— For cables with metallic components, the cable

must be marked in two places. Measuring from the

opened cable end, make one mark at 1.5" (38.10

mm) and the second at 5.5" (139.7 mm).

— For cables without metallic components, only one

mark is required. Again measuring from the opened

cable end, make one mark at 4" (101.6 mm).

Now that the cable is marked, take the emery cloth

provided and scuff the cable between the marks for

cables with metallic components and from the open

end of the cable to the mark for dielectric cables.

Always scuff around the cable, never scuff length-

wise.

7.04 Coat the scuffed area of the cable with C-

Cement and allow to dry to tacky base.

7.05 Apply required number of half lapped layers

of 3/4" (19.05 mm) LOCK-TAPE Sealant

around the cable in the area coated with C-Cement.

Stretch tape while applying. (Figure 15)

PLP TIP: Stretch tape enough to reduce its width

to 1/2" (12.7 mm). Figure 16 shows the com-

pleted application of one half-lapped layer of

LOCK-TAPE Sealant.

FIGURE 15 - APPLYING LOCK-TAPE SEALANT

FIGURE 16 - COMPLETED LOCK-TAPE SEALANT

APPLICATION

8.00 END PLATE ASSEMBLY

8.01 Using the hex bolts provided, fasten the “L”

bracket and retaining clip to the End Plate.

8.02 Before installing prepared cables into End

Plate halves, apply 1/4" (6.35 mm) wide bead

of C-Cement adjacent to the drilled hole. (Figure 17)

FIGURE 17 - BRUSH C-CEMENT OVER LOCK-

TAPE SEALANT

NOTE: If cables being placed in End Plate require

bonding and/or grounding, review Section 9.00

before installing End Plate.

8.03 Position prepared cables into lower End

Plate section, allowing 1/2" (12.7 mm) of the

LOCK-TAPE Sealant to extend beyond the inside of

the End Plate. THIS IS A CRITICAL MEASURE-

MENT.

8.04 For cables containing non-metallic strength

members, insert strength members into

retainer clip and tighten. Cut off excess strength

member.

8.05 Where applications dictate, position prepared

cables into upper End Plate seam per step

8.03 and insert End Plate bolts.

8.06 Using a socket and ratchet, tighten each bolt

evenly in rotation 2 to 3 turns at a time.

CAUTION: Do not use power tools for this operation.

8.07 While tightening, the excess LOCK-TAPE

Sealant extending from the End Plate section

will fold back. When the LOCK-TAPE Sealant stops

moving (folds back), the bolts are sufficiently tight.

(Figure 18)

FIGURE 18 - TAPE FOLDING BACK

CAUTION: DO NOT OVER TIGHTEN!

7

8.08 Trim excess LOCK-TAPE Sealant to within

1/8" (3.18 mm) of the End Plate. DO NOT

STRETCH TAPE DURING TRIMMING PROCESS.

9.00 BONDING AND/OR GROUNDING

CABLES WITH METALLIC COMPO-

NENTS

NOTE: Installation of bonding and grounding

components may be easier if installed prior to

placing cables into End Plate.

9.01 If cable contains a metallic shield, install

shield connector and/or bonding assembly per

company instructions. A shield connector is available

separately from PLP under Catalog No. 80803989.

FIGURE 19 -BONDING ASSEMBLY

9.02 After the bond connector is installed on the

cable and the cable placed in the End Plate

next to the appropriate “L” bracket, attach the bond

connector to the “L” bracket through the slot pro-

vided.

9.03 If cable contains a strength member, insert

the strength member into the retainer clip

and tighten. Cut off excess strength member.

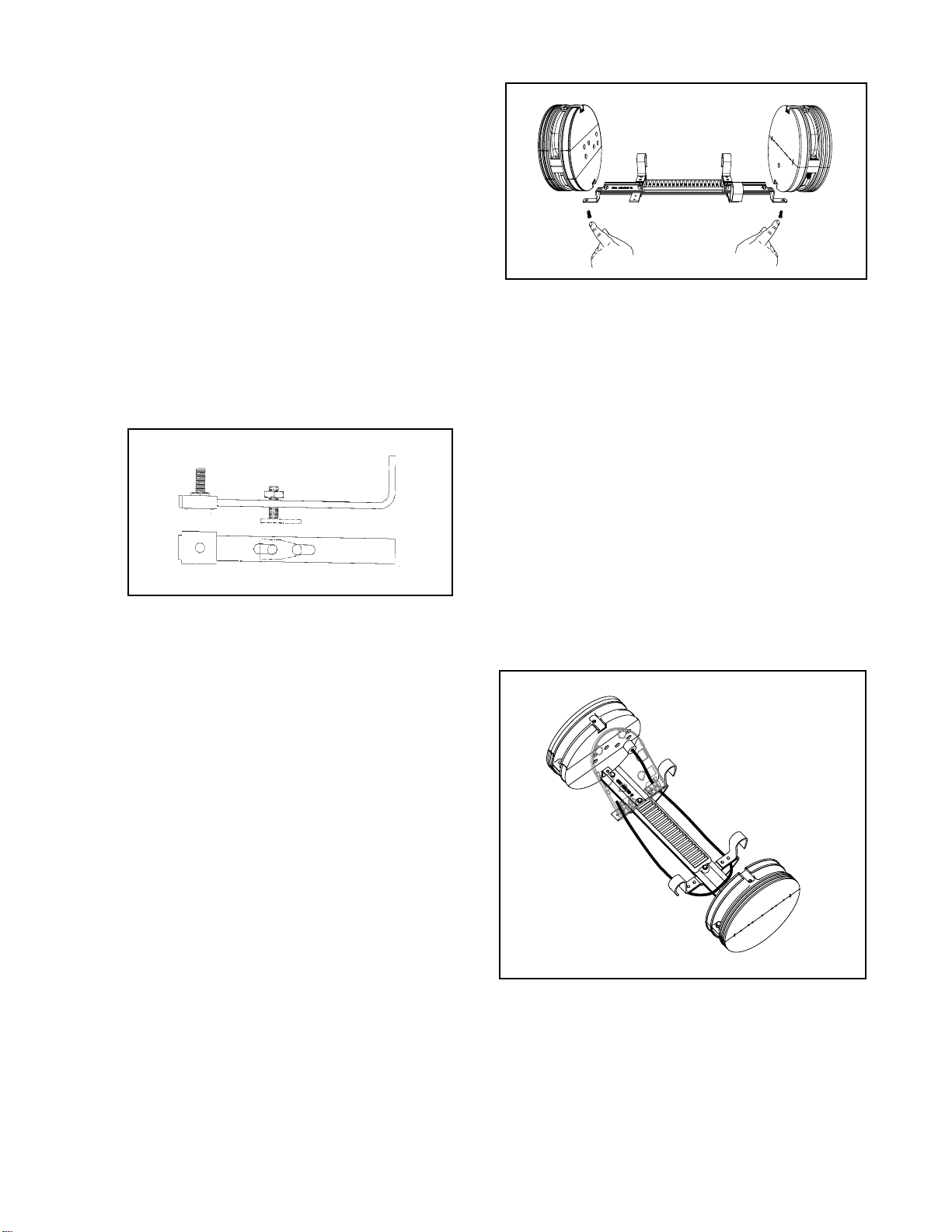

10.00 INSTALL ORGANIZER ASSEMBLY

10.01 Remove the torque bar attachment bolt from

the End Plate and secure the Buffer Tube

Storage and Splice Tray Rack Torque Bar to the End

Plate. (Figure 20)

FIGURE 20 - BUFFERTUBE STORAGE AND

SPLICE TRAY RACK ASSEMBLY SECURED TO

END PLATES

11.00 ROUTE BUFFER TUBES TO

SPLICE TRAYS

11.01 Route buffer tubes as follows:

— Buffer tubes for the back nine splice trays are to

be routed beneath the Splice Tray Rack Assembly

through the buffer tube storage clips as shown in

Figure 21.

— Buffer tubes for the front nine splice trays are to

be routed above the Splice Tray Rack Assembly

through the upper buffer tube storage clips as shown

in Figure 22.

FIGURE 21 - ROUTING OF BUFFER TUBES FOR

BACK SPLICE TRAYS

8

FIGURE 22 - ROUTING OF BUFFER TUBES FOR

FRONT SPLICE TRAYS

12.00 SECURING BUFFERTUBES AND

ROUTING FIBERS ON SPLICETRAYS

12.01 The trays to be used in the COYOTE Hi-

Count Closure are single fiber trays designed

for single fusion heat shrink protected splice applica-

tions. These trays can accommodate up to 24 single

fusion heat shrink protected splices. (Figure 23)

FIGURE 23 - COYOTE HI-COUNT SPLICE TRAY

12.02 Open cover of splice tray. Note that the cover

is hinged on the right side and has two

locking points on the left-hand side. (Figure 24)

FIGURE 24 - REMOVE SPLICE TRAY COVER

12.03 Position the back splice tray on the Splice

Tray Rack and route the buffer tubes into the

LEFT corner of the splice tray. Mark the buffer tubes

just beyond the tie down holes. (Figure 25)

FIGURE 25 - MARK THE BUFFER TUBES

12.04 Remove the buffer tube to the mark and

thoroughly clean the fibers per standard

company practices.

12.05 Apply a wrap of blue felt over the buffer tube

at the end where they will be tied down.

12.06 Position the buffer tubes onto the splice tray

so that they extend 1/4" (6.35 mm) past the

tie down holes and apply provided tie wraps as

shown in Figure 26 A & B.

PLP TIP: For easy tie wrap installation, insert the

tie wrap with the ridges on the inside of the loop,

with the head opposite the notch in the splice

9

FIGURE 27 - ROUTING FIBERS FROM THE

OFFICE BUFFER

12.08 Route fibers 1-12 of the field buffer tube

1-1/2 times counter-clockwise around the

splice tray entering the upper splice block from the

right side. Route fibers 13-24 of the field buffer tube

1-3/4 times counter-clockwise around the splice tray

entering the lower splice block from the left.

(Figure 28)

FIGURE 28 - ROUTING FIBERS FROM THE

FIELD BUFFER

12.09 Splice fibers according to accepted company

practices.

tray. Insert the tail into the head. Press head

down to the tray and hold in place while pulling

the tail to tighten the tie wrap.

FIGURE 26A - INSERT TIE WRAPS

FIGURE 26B - POSITION AND SECURE

BUFFER TUBES

12.07 Route fibers 1-12 of the office buffer tube

1-1/4 times clockwise around the splice tray

entering the upper splice block from the left side.

Route fibers 13-24 of the office buffer tube 1-3/4

times clockwise around the splice tray entering the

lower splice block from the right. (Figure 27)

10

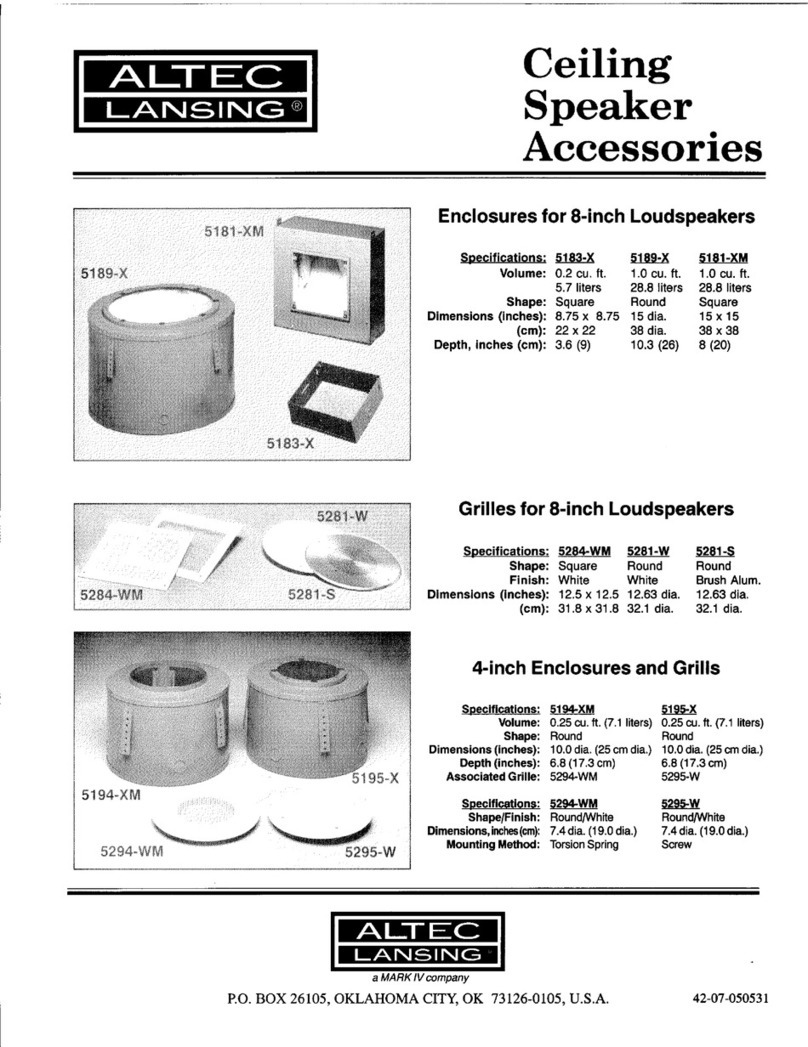

13.01

13.00 INSTALLING THE SHELLS

13.02

13.03

For aerial suspension, attach aerial suspension plates to

bolt bars before installation on shells.

For Manhole Support Bracket applications, attach support tees to

Bolt Bars.

13.05

13.04

Cap With Air Valve

Install SolidCap

After Flash Test

Flash Test To

10 PSI (Max) (69 Kpa)

A

B

First

Then

Finally

Hand Tighten in Sequence with Ratchet (All #1 Bolts

First, Followed by all #2 Bolts, and so on...

Torque Each Bolt Following the Sequence to 125 in.-lbs.

(14 N.m) (90 in.-lbs.(10 N.m) for 4” Closure)

Wait 15 Minutes then Re-Torque all Bolts to 125 in.-lbs.

(14 N.m) (90 in.-lbs.(10 N.m) for 4” Closure)

DO NOT Line Up Shell Seams with End Plate Seams

12344321

12344 321

12.10 Close the splice tray cover and place the tray

in the Splice Tray Rack.

12.11 Repeat steps 12.02 through 12.10 for the

remaining splice trays.

11

14.00 UNDERGROUND INSTALLATION

14.01 The Closure should be installed between

the manhole racks.

14.02 COYOTE Closures are very light and will

float in a water-filled manhole.They must be

tied down.

NOTE: It is recommended that the PREFORMED

Manhole Support, Catalog No. 8003527, be

used to support and tie down the Closure.

15.00 AERIAL INSTALLATION

15.01 For aerial applications, use the Adjustable

Aerial Hanger Bracket Kit (Catalog No.

8003426).

15.02 Be sure all nuts and washers are in their

proper position. Tighten nuts securely.

16.00 EXTERNAL BONDING

External bond methods will be described, but com-

pany practices should be followed.

16.01 If cable contains metallic components, all

cables must be bonded together. Remove

bolt from threaded inserts on outside of the End

Plate, install continuous length of bonding ribbon to

each threaded insert through bonding clips and

secure to End Plate with the removed bolts.

16.02 For manhole installations, extend a length of

bonding ribbon (not supplied) from one of the

threaded inserts bonding and grounding harness of

the manhole. Securely tighten all connections.

16.03 For direct buried installations, extend a

length of bonding ribbon (not supplied) from

one of the threaded inserts to a ground rod. Securely

tighten all connections.

16.04 For isolation of individual external grounding

connections, use the COYOTE EXTERNAL

ISOLATION TERMINAL KIT (Catalog No. 8003463 or

8003464). Refer to application procedure SP2891

for specific installation application.

17.00 MAINTENANCE PROCEDURE

17.01 The COYOTE Closure is designed for

numerous re-entries. However, certain

precautions must be taken prior to reapplication.

17.02 Be sure to clean shells and End Plates

thoroughly to remove sand, dirt, and other

foreign substances.

17.03 Any bent studs or stripped nuts should be

replaced. Only use hardware supplied by

Preformed Line Products.

17.04 The shells should be lubricated prior to re-

application. A uniform thin layer is all that is

necessary. Only use lubrication supplied by Pre-

formed Line Products (Catalog No. 80801566).

17.05 Any shells that are bent, cracked or distorted

should not be used.

17.06 Prior to reinstallation, the neoprene on the

shells should be allowed to return to its

original state. Warming the shells speeds up the

process.

12

18.00 SAFETY CONSIDERATIONS

18.01 This application procedure is not intended to supersede any company construction or safety

standards. This procedure is offered only to illustrate safe application for the individual.

CAUTION: FAILURE TO FOLLOW THESE PROCEDURES AND RESTRICTIONS MAY RESULT

IN PERSONAL INJURY OR DEATH.

18.02 This product is intended for the specified application. CAUTION: DO NOT MODIFY THIS

PRODUCT UNDER ANY CIRCUMSTANCES.

18.03 This product is intended for use by trained craftspeople only. This product SHOULD NOT BE

USED by anyone who is not familiar with and trained in the use of it.

18.04 When working in the area of energized lines with this product, EXTRA CARE should be taken to

prevent accidental electrical contact.

18.05 For PROPER PERFORMANCE AND PERSONAL SAFETY be sure to select the proper size

PREFORMED™ products before application.

18.06 PREFORMED™ products are precision devices. To insure proper performance, they should be

stored in cartons under cover and handled carefully.

SP2924

P.O. Box 91129, Cleveland, Ohio 44101 • 440.461.5200 • www.preformed.com • e-mail: [email protected]

This manual suits for next models

1

Table of contents