Premier Tech Aqua Solido Smart Series User manual

Operating Manual Including Operations Logbook

Manual for Installation, Commissioning, and

Maintenance

Single-Chamber Biological Nutrient Removal Wastewater Treatment

Plant

Premier Tech Aqua Ltd

2 Whitehouse Way

South West Industrial Estate

Peterlee, County Durham,

SR8 2RA

Tel: +44 (0)870 264 0004, Fax: +44 (0)870 264 0005

Email: ptauk-sales@premiertech.com, Web:www.premiertechaqua.co.uk

136262

OM0012 Solido SMART OM Rev 66 19022019

2

1. About this document......................................................................................... 8

1.1 Scope....................................................................................................... 8

1.2 Symbols used ........................................................................................... 9

1.3 List of abbreviations u sed ....................................................................... 10

2. Intended use................................................................................................... 10

3. Safety instructions .......................................................................................... 11

4. Description of functions .................................................................................. 13

4.1 Component overview ............................................................................. 13

4.2 General.................................................................................................. 15

4.3 Treatment process with the Solido SMART ICEAS SBR .............................. 15

5. Operating notes .............................................................................................. 20

5.1 Everyday conduct ................................................................................... 20

5.2 General r ecommendations ..................................................................... 22

5.3 Daily function check ............................................................................... 23

5.4 Monthly in -house inspection................................................................... 23

5.5 Half-yearly maintenance ......................................................................... 23

5.6 Other maintenance recommendations .................................................... 23

5.7 Important documents for operation and mainten ance ............................. 23

6. Monthly in -house inspection and half-yearly maintenance ............................... 24

6.1 Opening and c losing the Top Cov er ......................................................... 24

6.2 Monthly in -house inspection................................................................... 25

6.3 Half-yearly maintenance ......................................................................... 26

7. Installation and start-up .................................................................................. 28

7.1 Checking the system components for completeness ................................ 28

7.2 Checklist BEFORE assembling the Solido SMART package sewage

treatment plant ...................................................................................... 30

7.3 Assembly steps for the Solido SMART package sewage treatm ent plant .... 32

7.3.1 Installin g the shaft assemb ly set ................................................. 32

7.3.2 Filling up the lifter with water .................................................... 32

7.3.3 Assembling the tube diffuser ..................................................... 32

7.3.4 Positioning th e pump at the appropriate level (pumped version). 33

7.3.5 Connecting the air inlet supports ............................................... 33

OM0012 OM0012 Solido SMART OM Rev 65

3

7.3.6 Laying the control cable............................................................. 33

7.3.7 Connecting the t echnology capsule ............................................ 34

7.3.8 Installing outlet (Pumped version).............................................. 34

7.3.9 Installing the flap valve in the pump (pumped version ) ............... 35

8. S40 control unit and available settings ............................................................. 37

8.1 About the S40 control unit ...................................................................... 37

8.2 Navigat ion in the control m enu ............................................................... 38

8.3 Installation ............................................................................................. 38

8.4 Settings during start-up .......................................................................... 39

8.5 Power failure recogn ition........................................................................ 40

8.6 Menu structure...................................................................................... 40

8.6.1 Basic screen .............................................................................. 40

8.6.2 Other main menu levels............................................................. 41

8.6.3 Application example in the password-protected ......................... 43

8.6.4 “Start125%” start-up phase ....................................................... 46

8.7 Solido SMART S40 m enu overview .......................................................... 47

8.8 Alarm r elay (for an external signaller) ...................................................... 49

8.9 Service and maintenance (specialist companies only)............................... 49

9. Operational failures and r esolving them ........................................................... 50

9.1 S40 control alarm m essages.................................................................... 50

9.2 Other failures ......................................................................................... 52

10. Appendix ........................................................................................................ 55

10.1 Technical data and environmental conditions for the control unit ............ 55

10.2 Wire configuration/terminal scheme for Solido SMART with S40 control .. 56

10.3 Technica l data for So lido SMART t echnology capsule ............................... 57

10.4 EC declaration of conformity ................................................................... 58

10.5 Declaration of performance according to the Construction Products

Regulat ion (BauPVO) .............................................................................. 59

11. Solido SMAR T®operat ions logbook .................................................................. 60

12. Master data sheet for your Solido small wastewater treatment p lant ................ 62

OM0012 OM0012 Solido SMART OM Rev 65

4

Overview of the MOST IMPORTANT information for the operator

Safety instructions

Caution:

The electrical components must be connected, started up, and opened

only by qualified authorised personnel. The power cord must be protected

witha 30 mA residual-current circuit breaker.

Caution:

The technology capsule must be opened ONLY by a specialist company

and ONLY w henthe power is sw itchedoff.

Caution:

The Solido SMART should be installed by qualified personnel only. Make

sure that the technical components can be accessed without any danger.

Any deviations from the installation instructions provided are the

responsibility of the specialist company and must be agreed upon w ith

PTAU. Any access to the system whenrequired to do so is permitted only

if the power has been switchedoff and the applicable accident prevention

regulations are observed (oxygen deficiency).

Observe the safety instructions in the relevant chapters.

For reliable operation

The purification efficiency of the Solido SMART is based on micro-organism

activity. It is a living system.

Therefore,observethe following:

•Do not discharge any harmful or damaging substances (sanitary products,

chemical or oily wipes,food leftovers,chemical cleaner, hair) into the plant.

•Check the control unit display on a daily basis.

•Ensure maintenance is performed on your system in half-yearly intervals

(or as specified in your legal water permit), for example, by concluding a

maintenance contract withan authorised specialist company.

OM0012 OM0012 Solido SMART OM Rev 65

5

Failures

If the control unit beeps and the red LED

warning light flashes:

•Note the error text fromthe display

•Turn off the warning signal by pressing

the middle key on the control unit once

•Inform your maintenance provider

immediately.

Legal grounds

You require a legal water usage permit to operate a small wastewatertreatment

plant if you discharge more than 2m3 of w astewater per day. The approval/start-

up of a small wastewater treatment plant can be performed only by an authorised

specialist company and must be documented witha start-up log. Otherwise the

manufacturer warranty period is reduced to the statutory time.

Warranties

Note:

The following warranty assurance is dependent on the proper handling

and correct operation of the plant (also refer to the section “For reliable

operation”).

The tank shell is subject to a factory w arranty of 10 years.

The Solido SMART technology is subject to a factory warranty of up to 1 year.

•A factory warranty of 1 year for the Solido SMART treatment system covers

the service life of all electrical and mechanical components, provided that

start-up and maintenance are performed by an authorised specialist

company.

Note:

Any unauthorised interference with the Solido SMART (for example,

changes to the airlift, opening the junction box/connection plug,

manipulation of the control unit by non-qualified personnel, etc.) and/or the

improper use of the plant and/or deviations from the configuration

specified by PREMIER TECH AQUA (see the relevant section in the

chapter “Installation instructions”) are prohibited and w ill void any w arranty

claims.

Additional documents

Please use the “Master Data Sheet” at the end of this document and retain all

important documents if you wishto submit a warrantyclaim.

Start-up log

Operations logbook

Maintenance log

OM0012 Solido SMART OM Rev 64 0112.2017

6

An overview of the MOST IMPORTANT information for installation

and assembly

Installing the container

Caution:

When installing the tank, you must observe the accident prevention

regulations andthe specificinstallation instructions for the tank (see

the referencein chapter 1.1).

On-site conditions

The subsurfacemust be sufficiently stable and water permeable.

In particular, observe:

•Water table level

•Installation depths (recommendation: do not exceed a maximum installation

depth of 1.2m from inlet invert)

•Distances to buildings and property boundaries

•Traffic loads

Filling material

The filling material around the tank must be compactable, permeable, and free

of sharp objects. Excavated soil or “filler sand” often does not meet these

criteria.

The thickness of the backfill material should be at least of 250 mm.

Note:

Our recommendation: Gravel witha maximum grain size of 8/16 mm

Work procedure

Please refer to the Installation Guidance notes.

OM0012 Solido SMART OM Rev 64 0112.2017

7

Assembling the Solido SMART®wastewater treatment technology

Please observe the following safety instructions and assembly steps:

1. Determine the location for the controlunit

Note:

The control unit should not be positioned in direct rain or sunlight.

It should be located between 10m and max. 30m from the tank

(standard cable length: 15m).

2. Lay the cable

Caution:

Never disassemble the cable plug.

Protect the plug from moisture.

Pull the control cable through the cable conduit (DN 50/DN100).

Install the sealing to the building in such a way that it is possible to change

the cable at a later point.

3. Connect the hoses

Attach the pre-fitted hose on the lifter (Gravity version only), pre-fitted hose

on the diffuser and the supply air hose to the Solido SMART capsule

connections. For pumped version, connect outlet hose to pump and outlet.

4. Install the Solido SMART capsule

Set the Solido SMART capsule on the lifter in the container or for the

pumped version set the Solido SMART capsule on the shelf placed within

access turret.

5. Fix the cable in place

Place the control cable into the cable bundle holder.

6. Pumped Version

Suspend the pump on the hooks attached to the turret.

7. Check the complete installation

Check the plant for pipeline gradients, aeration and de-aeration, and

accessibility.

8. Perform start-up

Set up the plant, perform a test run, and brief the operator (prepare the

protocol).

OM0012 Solido SMART OM Rev 64 0112.2017

8

1. About this document

1.1 Scope

The “Technical Documentation for the Solido SMART SBR Wastew ater

Treatment System” refers primarily to the handling of the Solido SMART as a

technical configuration of Solido SMART small w astewater treatment plants.

It is part of a series of technical documents that describe the installation, start-

up, operation, function, maintenance, and repair of Solido SMART small

w astew ater treatment plants and their options:

List of applicable documents:

•Installation and assembly instructions for Solido SMART MILL3SR tank.

•Short description of the Solido SMART complete system

•Installation instructions for outer column

The Solido SMART technology uses the Mill3SR shell. Its function and technical

configuration are dependent on the type. This documentation uses container

MILL3SR as an example.

Approvals

The Solido SMART wastewater treatment system forms a part of the follow ing

plant types, whichhave received the approvals listed below fromthe Deutsches

Institut für Bautechnik (DIBt - German institute for civil engineering):

Product

Filtration

level

DIBt

no.

Created

on

Valid until

Doc.

no.

Solido SMART

C

Solido SMART

N

Solido SMART

D

The CE declaration of conformity as per EN 12566-3 is available (see the

appendix).

Note:

The approvals are currently being applied for from the DIBt (status as of

May 2016).

OM0012 Solido SMART OM Rev 64 0112.2017

9

1.2 Symbolsused

In this document, special information and safety instructions are indicated with

the following symbols:

Warning:

Disconnect the w astew ater treatment plant from the power supply before

you continue withthe measures described below (repair, maintenance).

Caution:

Safety instructions that have to be follow ed to prevent a risk to life, risk of

injury to persons and damage to the wastewatertreatment plant.

Note:

Special information that must be observed to ensure the optimum

operation of the wastewatertreatment plant.

This document contains both instructions for the operator of the Solido SMART

small wastewater treatment plants and the instructions for installation

and maintenance personnel.

The chapters that the operator must read and instructions upon which the

operator must act are indicated withthe operator symbol:

Descriptions that the operator of a small wastewater treatment

plant should know and observe.

Instructions that can be or must be carried out by a specialist

company.

Installation and maintenance personnel must have read and understood the

entire documentation to provide support for the operator when working with the

small w astewater treatment plant.

The followingsymbols are used in the control unit and technology capsule:

Caution:

Electrical devices are installed; observe the safety

instructions!

Caution/Note:

Read the technical documentation!

Caution/Note:

Do not dispose of obsolete devices as domestic waste;

hand them into the specially designated collection points.

Caution/Note:

Disconnect the mains plug before you carry out repairs.

OM0012 Solido SMART OM Rev 64 0112.2017

10

1.3 List of abbreviationsused

These instructions frequently use abbreviations (abb.) to make the document

easier to read. You can find the meaning of these abbreviations in the list below:

2. Intended use

Thank you for choosing a Solido SMART small wastewater treatment plant. To

ensure a long, reliable service life, it is important that you read and observe the

information in this instruction manual.

The Solido SMART SBR wastewatertreatment systemis used toclean and purify

w astew ater indomestic areas. This w astewater treatment systemis not intended

for any other use.

Any other improper use may cause damage and unexpected hazards.

The manufacturer is not liable for any damages to the plant or people if this is the

case.

As the operator, you must follow all of the notes about the operation and

maintenance of the plant (see chapter “6. Monthly in-house inspection and half-

yearly check-up”).

When the plant is taken out of use, it must be properly decommissioned.

Commission an authorised specialist company that decommissions the plant and

properly disposes of the components.

Make sure that the systemis safely disconnected fromthe mains supply, that the

tank has structural integrity, and that the inlets and outlets are disconnected.

OM0012 Solido SMART OM Rev 64 0112.2017

11

3. Safety instructions

For the operation ofthe smallwastewater treatmentplant installation

Caution:

Electrical components are to be connected, started up, and opened only

by authorised specialist personnel. The power cordmust be protected with

a 30 mA residual-current circuit breaker.

Caution:

The small wastewater treatment plant should be installed by qualified

personnel only. Make surethat the technical components canbe accessed

without any danger. Any deviations from the installation instructions

provided are the responsibility of the specialist company and must be

agreed upon with the manufacturer. Never enter the system unless the

power has been switched off and the applicable accident prevention

regulations are being observed (oxygen deficiency).

Caution:

The connection of the small wastewater treatment plant to the mains

supply must be performed only by a specialist electrical company.

•30 mA residual-current circuit breaker provided

•Check the correctoperation of the mains connection (forexample: is the

protective earth conductor intact?)

Operation

Caution:

Never disconnect the mains plug during regular plant operation.

The bacteria in the Solido SMART must have a regular supply of oxygen.

For this reason, do not interrupt the power supply to the treatment plant,

even during longer periods of absence (suchas holidays).

OM0012 Solido SMART OM Rev 64 0112.2017

12

In-house inspection, repair, and maintenance

Caution:

Maintenance work must be carried out only by an authorised specialist

company. The proper operation of the small wastewater treatment

plant must be checked regularly (twice a year, ideally) as part of a

maintenance contract.

Caution:

The technology capsule must be opened ONLY by a specialist company

and ONLY w henthe power is sw itchedoff.

Caution:

Disconnect the plugs for all electrical plant components before entering

the small w astew ater treatment plant.

Caution:

There may be a lack of oxygen in wastewatertreatment plants.

Actwith special care when you enter the small wastewater treatment plant

for repair or maintenance purposes.

Caution:

Comply withthe relevant accident prevention regulations at all times.

There should always be twopeople present whena wastewatertreatment

plant is entered.

Never enter after a person has fallen unconscious; call for help instead.

Caution:

Secure open treatment tanks fromrolling over.

Always closethe treatment tank securely after completing the workon the

wastewater treatment plant by turning the child safety latch on the

TopCover to the lock position.

Caution:

Before opening the control unit or performing repairs on the plant, you

must disconnect the mains plug.

Note:

A small wastewater treatment plant is a stationary electrical system.

Like all electrical systems of this type, its safety should be tested every

year by an electrical technician according to BS EN 61557 or BS

7919:2000. Recommended checks are: the measurement of the insulating

resistance, protective earth conductor resistance and the replacement

leakage current.

OM0012 Solido SMART OM Rev 64 0112.2017

13

4. Description of functions

4.1 Component overview

Solido SMART

Component overview

Legend for the component overview:

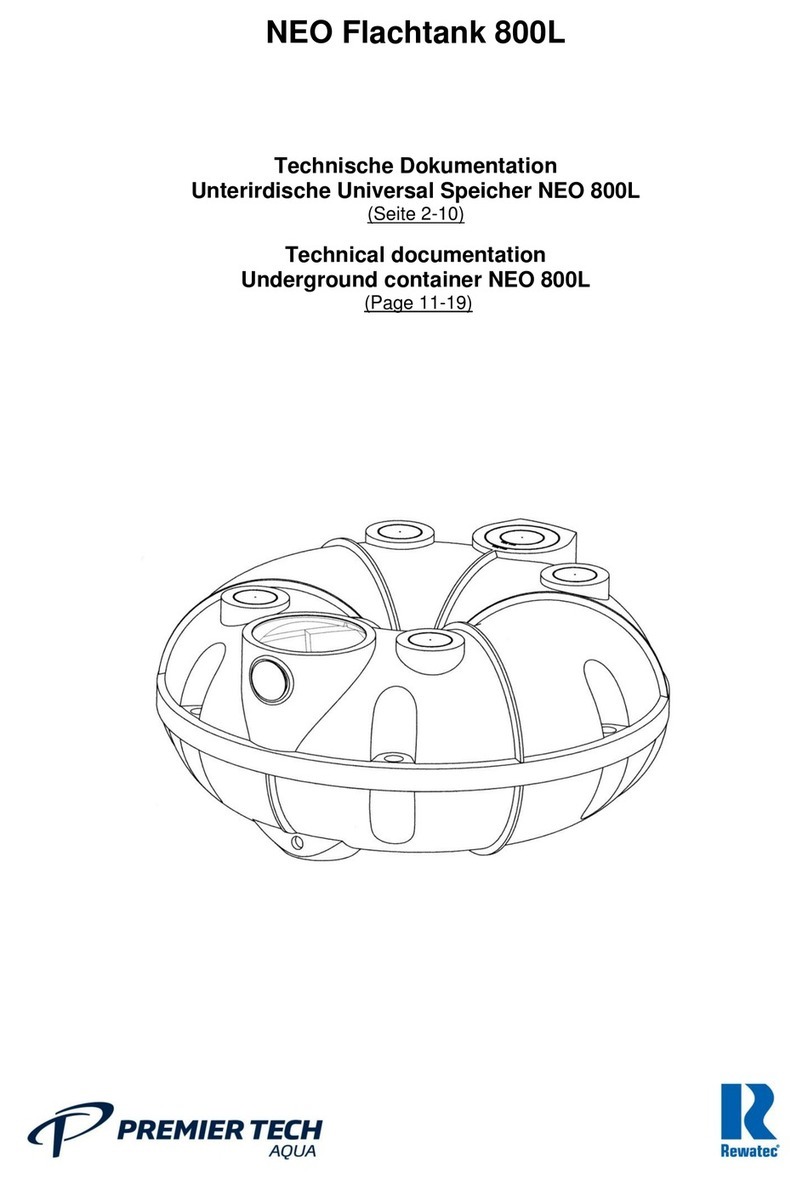

1 - MILL3SR tank (example)

2 - Solido SMART technology

capsule with compressor and

solenoid valves

3 - Tube diffuser (BEL)

4 - Air hose

5 - Lowerpart of the inlet and sludge

pipe

6 - Supply air hose and support

7 - Calmed inlet DN110

8 - Clearwater lifter (KWH)

9 - Outlet (100mm)

10 - Float sw itch(SWS)

11 - Sampling pot with emergency

overflow that is safe from

floating material

12 - Lid Top Cover

13 - De-sludge Pipe DN160

1

2

3

4

10

5

6

7

8

9

11

12

13

OM0012 Solido SMART OM Rev 64 0112.2017

14

Solido SMART Pumped

Component overview

Legend for the component overview:

1 - MILL3SR tank (example)

2 - Solido SMART technology

capsule with compressor and

solenoid valves

3 - Tube diffuser (BEL)

4 - Air hose

5 - Lowerpart of the inlet and sludge

pipe

6 - Supply air hose and support

7 - Calmed inlet DN110

8 - Clearwater Pump c/w withaflap

valve on hanging Chains

9 - Outlet (32mm Compression)

10 - Float sw itch(SWS)

11 - Lid Top Cover

12 - De-sludge Pipe DN160

13 - Chain Hooks

14 - Capsule Shelf

5

1

2

3

4

6

7

8

9

9

10

11

12

13

14

OM0012 Solido SMART OM Rev 64 0112.2017

15

4.2 General

The Solido SMART small wastewater treatment plant combines all the benefits

of the trusted SOLIDO technology in an extremely compact space. The SBR

procedure used works ina similar w ay toa municipal treatment plant - by directly

aerating the incoming w astewater withouta primary treatment compartment. This

ensures very effective wastewater purification and prevents the build-up of

harmful biogases.

The Solido SMART small wastewater treatment plant is shown with the tank in

the sketch drawings on the previous pages.

The volume and shape of the container foryoursmall wastewater treatment plant

may differ, but the functional principle shownhere is the same.

4.3 Treatment processwith the SolidoSMART ICEAS SBR

The Solido SMART Intermittent Cyclical Extended Aeration System (ICEAS)

SBR small w astew ater treatment plant is comprised of high density polyethylene

plastic tank and works as a sequencing batch reactor.

The special feature of the plant design is that all form of pre-treatment is

dispensed with. All primary and secondary sludge is aerobically treated in one

chamber.

The simultaneous aerobic sludge stabilisation leads to a significant reduction

in sludge accumulation and unwelcome odours in comparison to SBR plant

designs withtwostages

Using a time-controlled twelve-hour SBR cycle (intermittent aeration,

sedimentation, discharge of clearw ater), the same multi-purpose chamber

is used as a reactor, sludge reservoir, and buffer.

As a result, the whole volume benefits from practically the full scope of relevant

functions at the various cycle times.

Process cycles are performed by an electronic controller that includes an

operating hour meter, a logbook function, visual and audible warning signals to

indicate faulty hydraulic or electrical functions and a mains-independent power

failure monitoring system. An overfill alarm is provided using sensors (float

sw itches) in the tank.

OM0012 Solido SMART OM Rev 64 0112.2017

16

Intermittent aeration

Aeration/mixing is performed with tube diffusers. During a cycle, aeration is

performed intermittently to supply micro-organisms w ithoxygen and ensure the

required level of mixing.

Intermittent aeration/sedimentation and discharge of clearwater

Sedimentation and discharge of clearwater

At the end of a cycle, phase separation between the activated sludge and

clearwater is performed in a sedimentation phase lasting 90 minutes at minimum,

followedby the discharge of clearw ater.

The clearw ater is extracted using a compressed air lift or a submersible pump.

Automaticbackflush system (Airlift version only)

The patented design of the compressed air lifter allows backflushes to be

performed automatically before each operation. The discharge of activated

sludge in the effluent from the SBR reactor is significantly reduced and the

lifetime of the soakaway is increased as a result. The automatic backflush system

also effectively prevents potential lifter blockages.

Pumps, capacity and rates (pumping version only)

The pumping set is installed to precisely empty the tank and ensure a consistent

operation. The pumps are set to the desired level and flow to guaranty that a

specific amount of effluent liquid will be driven out of the system per the

fundamental design criteria.

The employed submerged pump(s) is manufactured by Jung Pumpen (OXYLIFT

2 (S)), ideal for applications related to w astewater engineering. The pumping rate

is equal to 1.2 m3/d (0.6/cycle x 2 cycles) that would correspond to a maximum

working height of 5.2m (see picture next page).

OM0012 Solido SMART OM Rev 64 0112.2017

17

Plot provided by the manufacturer, pump performance is subjected to ISO 9906 tolerances

OM0012 Solido SMART OM Rev 64 0112.2017

18

Plant control unit

The Solido SMART system is equipped with an S40-type electronic controller.

The sequence program is designed in a way that guarantees that the required

outflow values are maintained through the proper adjustment of the parameters.

When you enter the number of inhabitants for the plant, the pre-set control

parameters are automatically loaded.

If it appears that the plant is underloaded or overloaded, these parameters must

be adjusted according to the actual conditions by a specialist company upon

consultation withPremier Tech Aqua.

For a detailed description of how the controller w orks, see chapter “8. S40 control

unit and available settings”.

Holiday economymode

For longer periods where no wastewater is generated, e.g. holidays, you can

select an economymode for max. 30 days.

•In this case, the aeration time is reduced to 50% of the set value.

Afterthis time, the controller automatically switches back to normal mode.

Consult your service technician and refer to the menu overview and navigation

in chapter “8. S40 control unit and available settings”.

Operating hour meter and logbook functions

The electronic controller in your plant has an operating hour counter and logbook

function.

Consult your service technician and refer to the menu overview and navigation

in chapter “8. S40 control unit and available settings”.

Float switch

The Solido SMART system is equipped with a sensor (float sw itch)that is used

as an overfill alarm.

The plant triggers an alarm as soon as the sensor detects that the fill level is too

high.

OM0012 Solido SMART OM Rev 64 0112.2017

19

Sampling device

The Solido SMART system allows you to take samples using

•an integrated sampling pot in the reactor with an emergency overflow

function that is safefrom floating material

The sample is a mixed sample from the preceding clearwater discharge that

provides a sufficiently representative sample; also see chapter “6. Monthly in-

house inspection and half-yearly maintenance”.

Device for sludge removal

The Solido SMART system has a sludge pipe that is permanently installed in

the tank and that ensures proper desludging.

•Desludging is required if the sludge level reaches 70% of the max. permitted

waterlevel at the end of the settlement phase.

•You must check whetherthe functions of the calmed inlet, aeration devices,

and clearwaterlifter are impacted by damaging substances. Substances that

are damaging to functions should be removed each time that maintenance is

performed.

•During desludging, you must ensure that airlift and aeration devices are not

damaged, the plant is not in the middle of the sedimentation phase

whenever possible, and that at least 15% of the sludge quantity remains in

the container.

OM0012 Solido SMART OM Rev 64 0112.2017

20

5. Operating notes

You help to prevent operating failures through your everyday conduct as the

operator of the Solido SMART small wastewatertreatment plant and by

performing regular checks.

If you observe the operational guidelines listed here, you willsave unnecessary

costs while protecting the environment.

You can:

•Ensure safew astewaterpurification by not exceeding the limit values

•Loweryour costs through optimum consumption quantities and energy

consumption for the w astewater treatment plant (by avoiding unnecessary

amounts of washingand cleaning agents)

•Avoid unnecessary repair costs due to damaging substances

•Lowerenergy consumption and extend the service life by having the

optimum settings configured by a specialist maintenance service

•Ensure longer permeability in the downstreamfiltration systems and

therefore a longer service life for your plant

5.1 Everyday conduct

Please observe the codes of conduct recommended in this chapter in your

everyday workto ensure the faultless operation of the Solido SMART small

wastewater treatment plant and protect the environment.

Please instruct all persons living, working, or staying as guests in your

household about the codes of conduct and ensure that they comply withthem.

Violations of the codes of conduct lead to:

•Blockages in the small wastewater treatment plant or piping, a

backflow of wastewater,servicevisitsand possibly to plant repairs.

•An overload of the treatment plant and untreated water,and to service visits.

•Contamination of the environment and damage to the small wastewater

treatment plant, whichmay require intensive cleaning and repair of the

treatment plant and the erosion of the surrounding soil.

Table of contents

Other Premier Tech Aqua Plumbing Product manuals

Popular Plumbing Product manuals by other brands

KEUCO

KEUCO IXMO 59516 010101 Mounting instruction

Felton

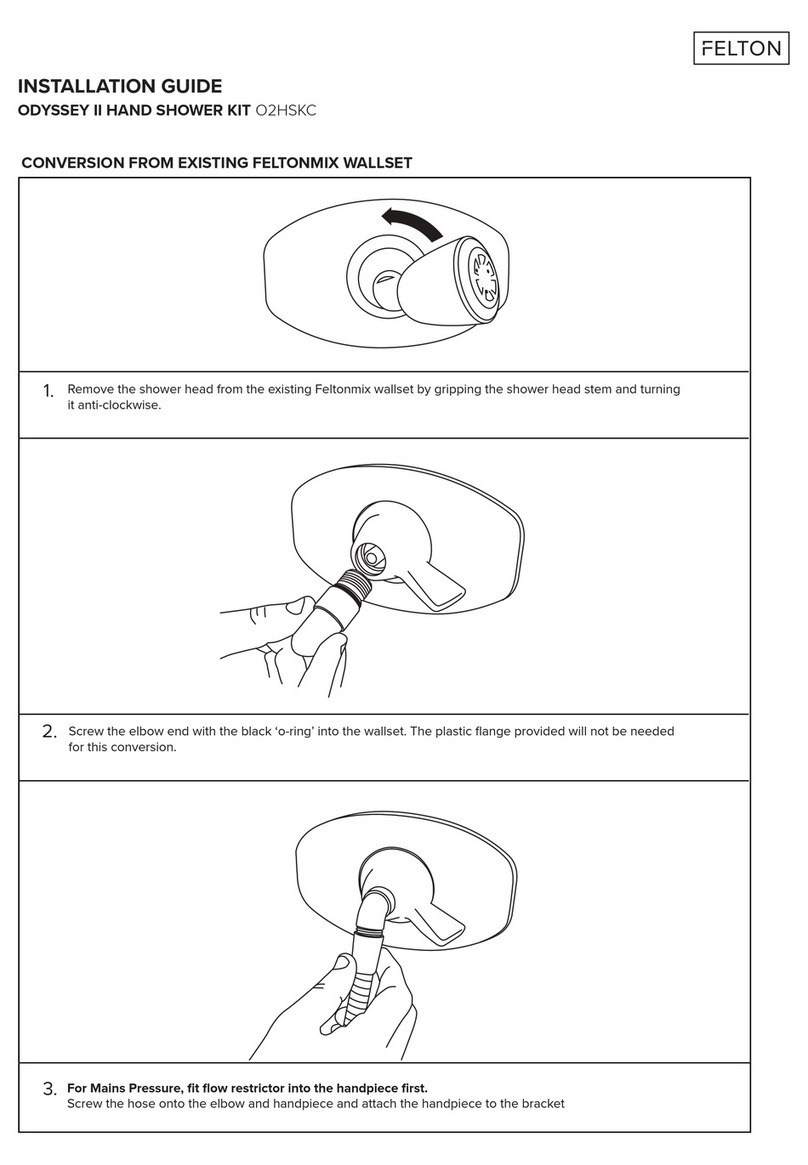

Felton ODYSSEY II O2HSKC installation guide

ITT

ITT Lowara DUPERBOX DUO Installation and operating instructions

Viega

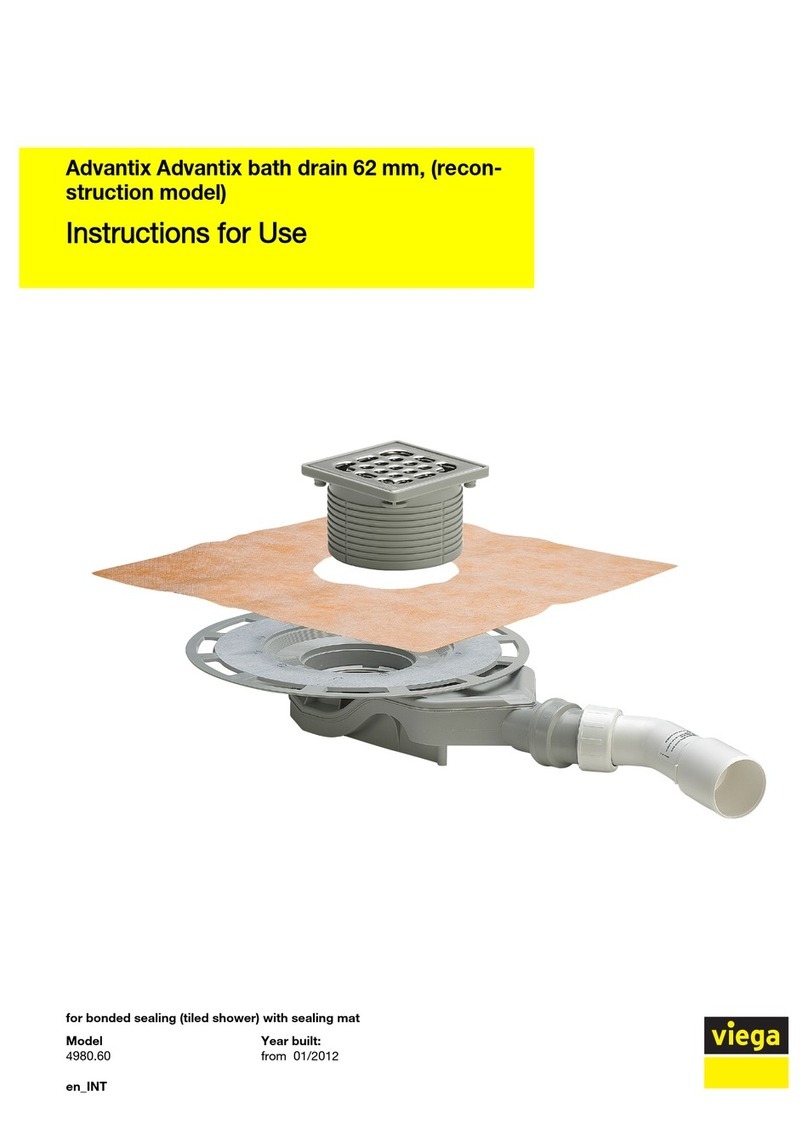

Viega 4980.60 Instructions for use

Hans Grohe

Hans Grohe 32128000 Instructions for use

VADO

VADO warwick Installation & maintenance instructions