PRESCO PRDA 3 Series User manual

123

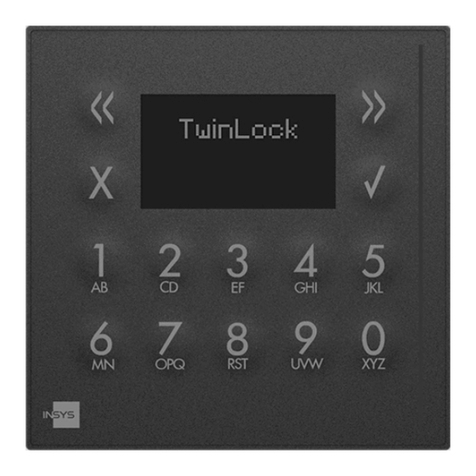

“PRESCO” KEYPAD SYSTEM.

INTRODUCTION.

The PRDA Digital Keypad System

utilises the latest microprocessor

technology to operate most electric

door locking devices on the market.

These keypads offer the ability to

access restricted areas by using easy

to remember codes. A Lexan overlay

protects the tactile (not membrane or

rubber) buttons in heavy traffic areas

and also offers water and dust

resistance to the keypad. Additional

keypads (total of 10) can be connected

to allow remote activation from a

reception desk etc.

FEATURES

Split system for maximum security, (Keypad & Decoder).

Door forced open detection.

Door Open Too Long (DOTL) function.

EGRESS function.

29 client programmable user codes (125 optional).

Digits can repeat ie. 12321.

3 to 7 digit management and user codes.

Minimum 19 million possible user code combinations.

Up to 10 keypads can be connected to one decoder.

10 year non volatile memory.

Audible/visual confirmation.

Sealed “Tactile” buttons.

17mm. thin surface mounting.

Hidden screw mounting.

Water resistant (with use of optional gasket).

Operating Temperature Range: 0

C to 70

C.

SPECIFICATIONS

DECODER Voltage: 12-24 Volt A.C./D.C.

Current: 20 mA. + 45 mA relay when

operated (24 Volt D.C).

35 mA. + 65 mA relay when

operated (24 Volt A.C).

KEYPAD Standby current: 0.25 mA.

ELC contacts: 30 Volt, 5 Amp A.C./D.C.

(Electric Latch Control) SPDT.

DOTL output: 1 Amp max. sink current

(Door Open Too Long) (open collector).

Maximum Keypad 1 KM (0.6 Miles) (max.

Decoder separation: return resistance 100

. Non

shielded).

Package size: 79 mm/123 mm/45 mm.

Weight: 200 gms.

MOUNTING

Use the supplied template to mark the position for mounting

and wire cut-out hole.

Disconnect all power during wiring.

Do not over-tighten terminal screws on decoder.

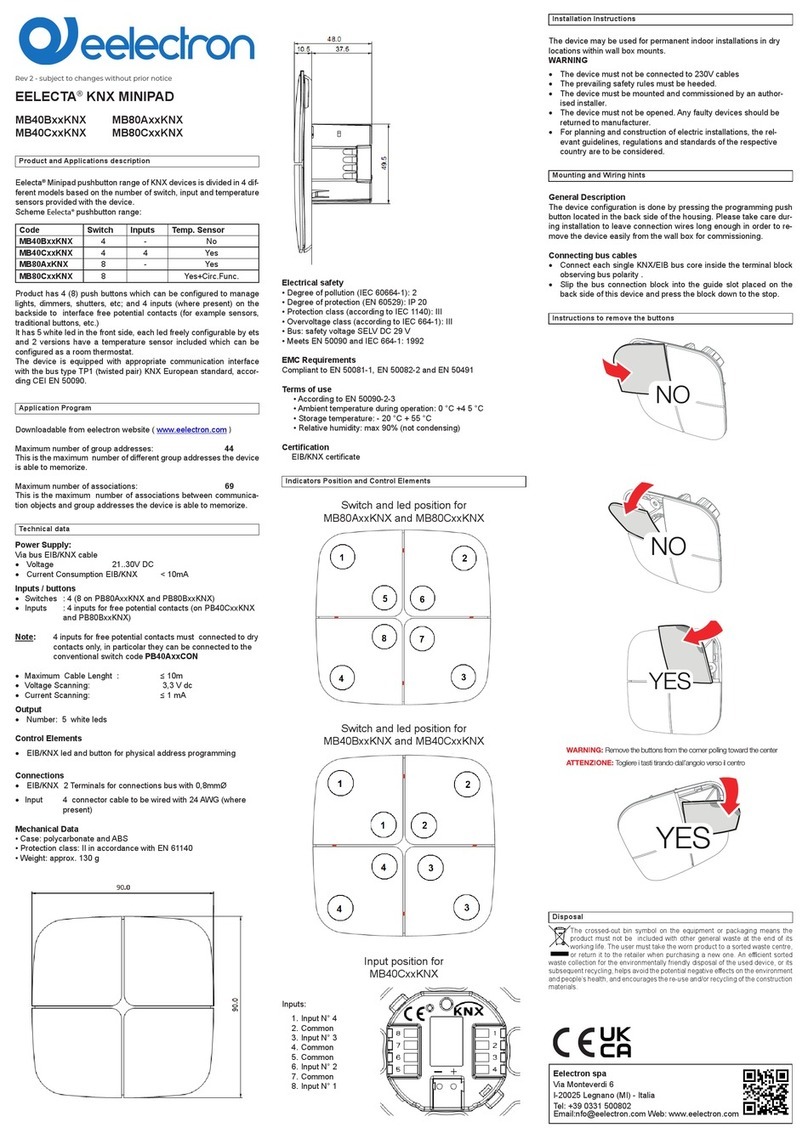

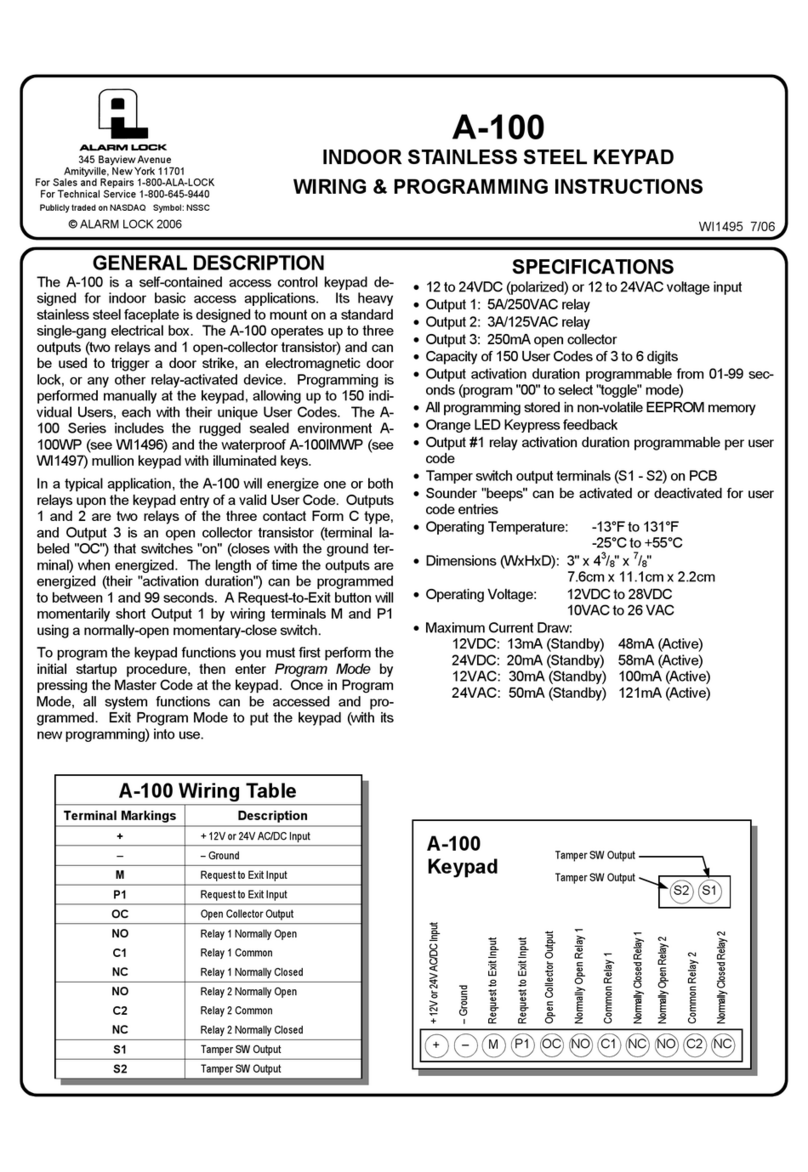

DECODER TERMINAL DESCRIPTIONS

Negative output or Ground from Power Supply.

AC or DC 12-24 Volt from Power Supply.

Data (white wire from Keypad).

(Electric Latch Control) 5 Amp. Relay operates

momentarily with each correct code entered. This

output can be varied for operating times between 1

and 255 seconds (factory set for 10 seconds).

A. Use CM and NO for fail/secure operation.

ie. power applied to unlock latch.

B. Use CM and NC for fail/safe operation.

ie. power removed to unlock latch.

A normally closed input to GND, goes open circuit

when the door is open. The DOOR input is used to

detect when the door has been opened for use by

the door forced open, DOTL and automatic re-lock

functions. The automatic re-lock function turns the

ELC output off 1 second after the door opens,

allowing the door to automatically re-lock when

closed. Note: If the DOOR input is to be used it

must be enabled via Memory 6.

(Door Open Too Long) open collector output

operates when the door has been left open for

longer than the programmed DOTL time or when

the door has been forced open. See

DOOR OPEN

TOO LONG

and

DOOR FORCED OPEN

DETECTION

sections. The DOTL output is

capable of sinking up to 1 Amp.

A normally open or normally closed input to GND.

See

SELECT EGRESS SWITCH TYPE

section.

When this input is activated the ELC output will

turn on and remain on until the input is removed.

Once the EGRESS input has been removed, the

ELC output will continue to operate for the

programmed momentary time and the automatic

re-lock and DOTL functions are also enabled.

OPERATING MODE RULES

1/ 1 beep = successful code (ELC output turned on).

2/ 2 beeps = successful code (ELC output turned off).

3/ 5 beeps = management code entered.

4/ a long beep = a non existent code.

a pause then a long beep = 5 unsuccessful “tries”.

(System is locked out for 1 minute, if enabled in mem 5).

The

and Memory number are NOT required in the

OPERATE mode.

5/ Cancel a wrong entry with

, then re-try.

THE MEMORIES

Memory0 Memory1 Memory2 Memory 3 Memory 4

Toggle

operation user

codes.

Momentary

operation user

codes.

Selects

EGRESS

switch type.

Enable/disable

door forced

open detection.

Door Open

Too Long

time.

Memory5 Memory6 Memory7 Memory 8 Memory 9

Enable/disable

1 minute

lockout.

Enable/disable

Door input for

reed switch.

Use two

codes to

operate ELC.

ELC relay

operate

time.

Management

code.

BASIC SETUP SEQUENCE

1/ Select EGRESS switch type (Currently N/O). [Memory 2]

2/ Set ELC OPERATE TIME (Currently 10 seconds).

[Memory 8]

3/ Enable/Disable DOOR INPUT (Currently disabled).

[Memory 6]

4/ Set Door Open Too Long time (Currently 60 seconds).

[Memory 4]

5/ Enable/Disable DOOR FORCED OPEN DETECTION

(Currently enabled). [Memory 3]

6/ Enable/Disable 1 MINUTE LOCKOUT (Currently

disabled). [Memory 5]

7/ Enable/Disable USE TWO MOMENTARY CODES

(Currently disabled). [Memory 7]

8/ Program MANAGEMENT CODE. [Memory 9]

9/ Program USER CODES. [Memory 1 & Memory 0]

NOTE: Use the Program Link for steps 1 to 8 above (and

step 9 if the management code is not used).

Remove link when finished.

“Series 3”

ELC

GND

AC-DC

DTA

IMPORTANT!

DOOR

DOTL

EGRESS

Enter

456

SELECT EGRESS SWITCH TYPE. (MEMORY 2)

Factory preset to: Normally Open - N/O.

Memory 2 stores whether the EGRESS switch to be used is

Normally Open (N/O) or Normally Closed (N/C).

Note that this memory should only be altered if a N/C

EGRESS switch is to be used, otherwise the EGRESS switch

should be left as N/O.

1/ The program link must be on.

2/ The single digit after the 2determines which type of

EGRESS switch is to be used. The digit after the 2must

be either 0or 1.

Select Switch type..

.................N/C EGRESS switch selected (Warble).

.................N/O EGRESS switch selected (Warble).

ELECTRIC LATCH CONTROL (ELC) OPERATE TIME.

(MEMORY 8)

Factory preset to: 10 seconds.

Memory 8 stores the time the ELC relay operates for when a

momentary user code is used. It can be set to operate

momentarily from 1 to 255 seconds.

1/ The Program link must be on.

2/ The digits after the 8determine the operate time for ELC.

The value must be between 1and 255.

Set ELC Time..........

.................Sets ELC for 5 sec operation (Warble).

.............Sets ELC for 60 sec operation (Warble).

DOOR INPUT ENABLE. (MEMORY 6)

Factory preset to: Door Input Disabled.

Memory 6 stores whether the decoder is to use the door reed

switch input. When the door reed switch input is enabled the

automatic re-lock, Door Open Too Long and Door Forced

Open functions are then enabled.

Note that if the Door input is enabled, but a N/C reed switch

is not used, the PRDA will not function correctly.

1/ The program link must be on.

2/ The single digit after the 6determines whether the door

reed switch input is enabled. The digit after the 6must be

either 0or 1.

Enable/Disable Door reed switch input

.................Enables door input (Warble).

.................Disables door input (Warble).

DOOR OPEN TOO LONG (DOTL) TIME. (MEMORY 4)

Factory preset to: 60 seconds.

Memory 4 stores the time that the door is allowed to remain

open before the DOTL output is activated. It can be set from

0 and 9999 seconds. The DOTL time commences after the

door has been unlocked and opened through the use of a

valid code or EGRESS. If the door is held open for longer

than the programmed DOTL time then the DOTL output will

activate until the door is closed.

Note that a 0value for the DOTL time will give the door an

infinite time to remain open for, ie. DOTL is disabled.

1/ The program link must be on.

2/ The digits after the 4determine the DOTL time to use.

The value must be between 0and 9999.

Set DOTL time.........

.................Set DOTL time to infinite (Warble).

.............Set DOTL time to 30 secs (Warble).

..........Set DOTL time to 480 secs [8 mins]

(Warble).

DOOR FORCED OPEN DETECTION. (MEMORY 3)

Factory preset to: Door Forced open Detection Enabled.

Memory 3 stores whether the decoder is to detect when the

door has been opened without the use of a valid code or

EGRESS. If detection is enabled and the door is forced

open, the DOTL output will activate for 30 seconds or until the

door is closed again (whichever is the longer time). However

if detection is disabled, then the PRDA will go into the DOTL

time-out loop as soon as the door is opened. If the door then

remains open for longer than the programmed DOTL time,

the DOTL output will activate until the door is closed again.

Note that Door Forced Open Detection must be disabled if

the door can be opened without the use of a code or

EGRESS switch.

1/ The program link must be on.

2/ The single digit after the 3determines whether door

forced open detection is enabled. The digit after the 3

must be either 0or 1.

Enable/Disable Door Forced Open Detection

.................Disables door forced open detection

(Warble).

.................Enables door forced open detection

(Warble).

DISABLE 1 MINUTE LOCKOUT. (MEMORY 5)

Factory preset to: 1 Minute Lockout Disabled.

Memory 5 stores whether the PRDA is to lockout all codes for

1 minute after 5 invalid codes have been tried. Enabling of

the lockout feature may be desirable for higher security.

Disabling of the lockout feature is necessary if door access

must be guaranteed at all times.

1/ The program link must be on.

2/ The single digit after the 5determines whether the lockout

is enabled or disabled. The digit after the 5must be either

0or 1.

Enable/Disable 1 Minute Lockout

................ 1 minute lockout Enabled (Warble).

................ 1 minute lockout Disabled (Warble).

USE TWO MOMENTARY CODES. (MEMORY 7)

Factory preset to: Do NOT use Two momentary Codes.

Memory 7 can be used to set up the PRDA as a “two code”

system. What this means is that two different momentary

user codes stored in the PRDA must be used before the ELC

relay will operate for the time programmed in memory 8. The

value stored in memory 7 is the time (in seconds) allowed

between the two codes being entered. If the value stored

here is zero (0) then only one code is required to operate

ELC. If a second different code has not been entered before

the programmed time has elapsed then the PRDA will wait for

another two codes to be used.

Note that when “Two codes” is enabled (Memory 7 is not set

to 0) then the toggle user codes (Memory 0) are not valid.

1/ The program link must be on to set Memory 7.

2/ The digits after the 7determine the “Two codes” time to

use. The value must be between 0and 255.

Set “Two codes” time

................ Only one momentary code required

(Warble).

............. Allow 30 secs between the 2 codes

(Warble).

............. Allow 60 secs between the 2 codes

(Warble).

789

PROGRAMMING

PROGRAMMING MODE RULES.

1/ The

key = Add.

2/ The

key = Delete.

3/ Enter memory number (

for momentary operation codes,

for the management code, etc.) before any

programmable information. This ensures the information is

directed to the correct memory location.

4/ Warble = successful Add or Delete.

5/ Long beep warns that either codes are already in use, too

long or short, or more than 29 codes have been used.

6/ Press each digit within 10 seconds after the preceding

digit, otherwise information will be lost. If a wrong number

is pressed, wait 10 seconds then start again.

NOTES:

1/ After trying the example codes below, delete them then

add your own unique code/s. Avoid obvious codes like

1234.

2/ Up to 29 different user codes can be stored between

Memory 1 & 0.

3/ Repeating digits, including the

, are allowed in codes

eg.

provided that

is not the first digit.

4/ Codes can be from 3to 7digits in length.

5/ There are NO factory preset codes programmed.

THE MANAGEMENT CODE. (MEMORY 9)

Memory 9 stores the Management code which allows the

Program mode to be entered from any keypad without the

Program link. Use this feature if regularly changing codes, or

the decoder is difficult to access. As supplied, no

Management code exists.

To add, change or delete the Management code, the

Program link must be on. The digits after the

are the

Management code.

Add Management Code

..........246 is the management code (warble).

..........369 has now over written 246 (warble).

................................. Restore operate mode.

Using the Management code

..................Program mode entered (5 beeps).

..........456 added to memory 1 user codes

(warble).

.................................Operate mode entered automatically.

Note: that the system automatically returns to the Operate

mode after a single management function has been

performed. ie. add or delete a code. If the

management function was not successful, the system

still returns to the Operate mode (after a long beep).

Note: how 369E replaces the Program link function but with

the addition of the 5 beeps to clearly indicate which

mode is current. All momentary and toggle user code

programming examples on pages 6 & 7 below could

be done with the management code. 369 is an

example only. With link ON either overwrite it with a

new code or delete with

. REMOVE LINK.

Note: If after entering the Management mode you decide

not to add or delete a code, then press

to return to

the Operate mode.

Note: If the Management code is forgotten, use the program

link to over write the forgotten code with a new code.

This feature obsoletes factory preset or “house codes”

which can compromise security.

MOMENTARY OPERATION USER CODES. (MEMORY 1)

The codes programmed into Memory 1 are used to operate

the ELC relay for the length of time set in Memory 8 (ELC

OPERATE TIME).

Note: The digits after the

are the momentary operation

user code.

Add user codes ...... Link on both pins (Program mode).

..........567 is added to memory 1 (warble).

..........678 is also added to memory 1 (warble).

Try user codes........ Park link on 1 pin (Operate mode).

..................ELC operates (1 beep).

..................ELC operates with this code also

(1 beep).

Delete a user code .

..........678 is deleted from memory 1 (warble),

567 remains.

Delete all user codes

.....................Deletes all codes stored in Memory 1

(warble).

................................. Restore operate mode.

TOGGLE OPERATION USER CODES. (MEMORY 0)

The codes programmed into Memory 0 are used to toggle the

state of the ELC relay. These codes can be used as override

codes to keep a door open during certain times. These codes

are useful for a business where the door is to be unlocked

during business hours but kept locked after hours, requiring

people to use a momentary code to open the door.

Note: that when the ELC relay has been turned on (door

unlocked) by using a toggle operation code, then the

momentary operation codes are not valid until the ELC relay

is turned off (door locked) and also that the DOTL time out

routine does not start until the ELC relay is turned off.

Note: The digits after the

are the toggle operation user

code.

Add toggle codes ..

......... 852 is added to memory 0 (warble).

......... 741 is also added to memory 0 (warble).

Try toggle codes....

................. ELC relay turns on (1 beep).

................. ELC relay turns off (2 beeps).

Delete a toggle code

......... 852 is deleted from memory 0 (warble),

741 remains.

Delete all toggle codes

.................... Deletes all codes stored in Memory 0

(warble).

................................ Restore operate mode.

Design Philosophy - Problems and Solutions.

1/ Most keypads contain the switching relay and control

wiring within the keypad housing. A skilled person could

easily bypass the keypad function simply by removing it

then manipulating the control wiring, a disastrous

situation. “Presco” is “split” in 2 parts, so that the decoder

can do all the processing at a remote protected

environment. The code is transmitted between keypad

and decoder in “computer” language, therefore cutting or

shorting wires won’t compromise security.

2/ Typical keypad installations require 7 or more wires thus

increasing labour and cost. “Presco” uses only 3 wires to

operate the door release, LED/buzzer feedback of code

entry, acknowledgment of correct code, state of door

strike, remote management code programming and

power. Up to 10 keypads can be connected to PDA by

simple parallel wiring. No synchronising is required.

10 11 12

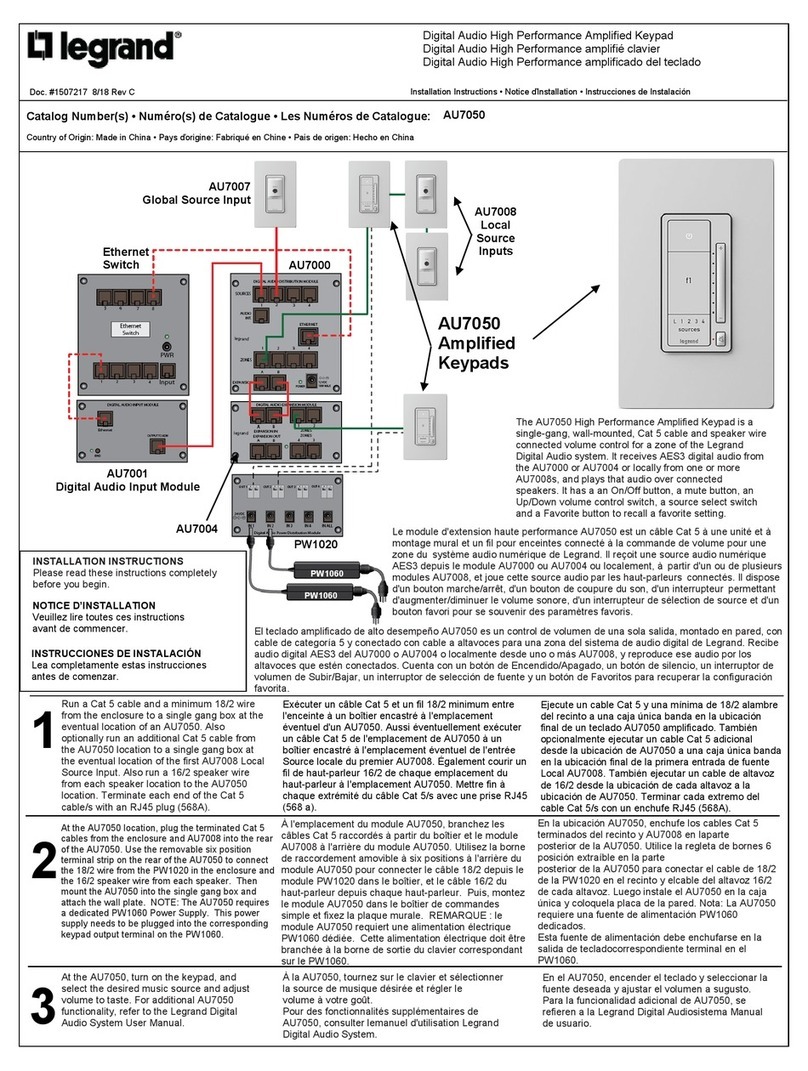

PRDA A.C. Wiring Diagram

PRDA D.C. Wiring Diagram

NOTE: The 3 1N4004 diodes referred to in the A.C.

and D.C. diagrams are packaged with the PRDA.

OTHER MODELS AND ACCESSORIES.

PRDA/125 PRDA with 125 user codes.

P2 1 Amp. 30 Volt Control and Duress SPDT relays,

timed or toggled operation, 29 user codes, 12

Volt D.C. operation.

P6 Six (6) open collector logic outputs, timed or

toggle operation, 29 user codes, 12 Volt D.C.

operation.

PRE Additional keypad encoder for any “Presco”

decoder. Up to 10 per system allowed.

PKG Watertight gasket for PRE.

PRC Magnetic card reader. 12-24 Volt A.C./D.C.

Compatible with any “Presco” decoder.

PROTECTION.

The NIDAC “Presco” keypad system has a high immunity to

all types of static, EMF, and RF transmissions including those

of Police and CB radio systems. Reverse polarity and

overvoltage protection from lightning strike up to 10Kv is

provided.

WARRANTY.

NIDAC SECURITY PTY. LTD. will repair or replace this

product if proven to be faulty (excluding accidental or

malicious damage) under the 36 month warranty offered from

the date of purchase.

As NIDAC SECURITY PTY. LTD. or it’s agents do not perform

the final installation, inspection or training in the use of this

product, they cannot be held liable for injury, loss or damage

directly or consequentially arising from the use or misuse of

this product.

“Presco” is a pending Trade Mark belonging to NIDAC

SECURITY PTY. LTD. The “Presco” Keypad system is

protected by provisional and pending patents in various

countries including Australia.

The software design is protected internationally and remains

the intellectual property of NIDAC SECURITY PTY. LTD.

Design improvement and specification are subject to change

without notice. All designs are copyright 1992.

Designed and Manufactured by:

NIDAC SECURITY PTY. LTD.

2 Cromwell Street, 3125 Burwood Victoria Australia.

Phone: (03) 9808-6244 Fax: (03) 9808-9335

International: 61+3+9808...

“

”

PRDA Series 3 Instructions.doc 3/10/97Revision 6