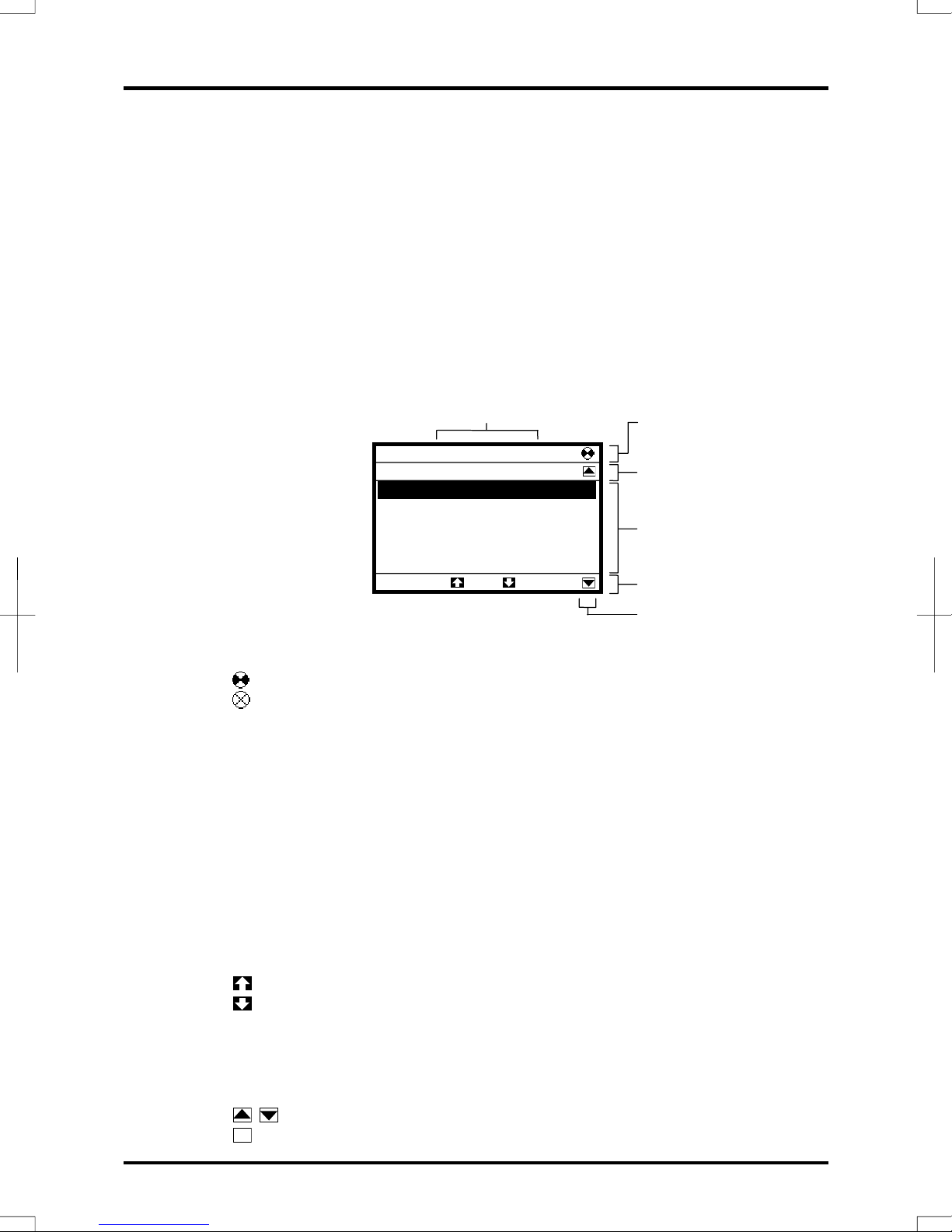

7. 状態モニタモードでの操作

ⅲ

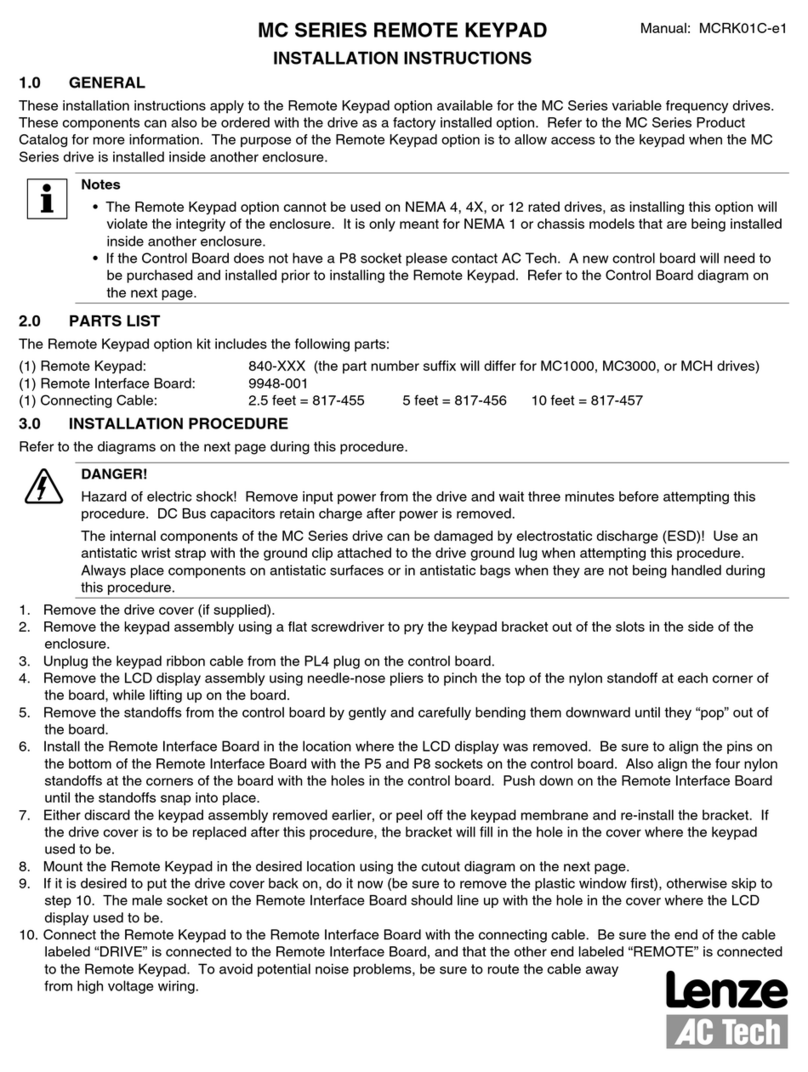

This section provides important information that the user must always keep in mind

when using the product in order to avoid personal injury and damage to property. Read

these instructions carefully and follow them strictly.

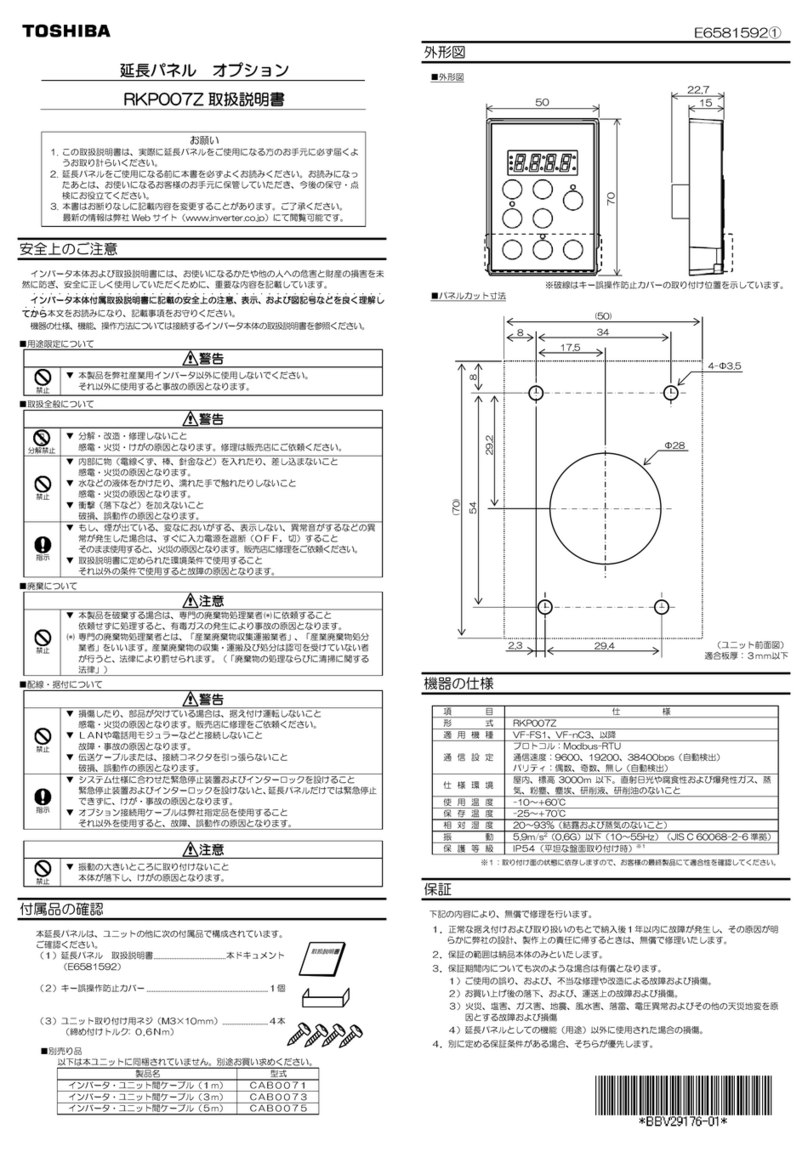

■Limits in purpose

●Be sure to contact your retailer if you wish to use the product with a system, such as a

nuclear facilities control system, aerospace system, transportation system, or safety

system, that could threaten human life or do harm to human body if the inverter breaks

down or malfunction.

●When using the unit with important facilities, provide the facilities with a safety device that

prevents the occurrence of a serious accident, for example, when the inverter fails to put

out a failure signal. (For more information, contact your retailer.)

●Do not use the product for any purposes other than the control of the rotational speed of a

general-purpose industrial three-phase induction motor. (Use under any other conditions

may result in malfunction.)

■General Operation

Danger

Disassem

bly

prohibited

●Never disassemble, modify or repair. This can result in electric shock, fire and

injury. For repairs, call your sales agency.

Prohibited

●Don't place or insert any kind of object into the inverter (electrical wire cuttings,

rods, wires). This can result in electric shock or fire.

●Do not allow water or any other fluid to come in contact with the inverter. This can

result in electric shock or fire.

●Do not use any cable other than a dedicated interconnect cable (optional).

Failure to observe this might result in an electric shock or fire.

Mandatory

●If the inverter begins to emit smoke or an unusual odor, or unusual sounds,

immediately turn power off. If the equipment is continued in operation in such a

state, the result may be fire. Call your local sales agency for repairs.

■Transportation & installation Danger

Prohibited

●Do not place any inflammable objects nearby. If a flame is emitted due to

malfunction, it may result in a fire.

●Do not install in any location where the inverter could come into contact with

water or other fluids. This can result in electric shock or fire.

Mandatory

●Must be used in the environmental conditions prescribed in the instruction

manual. Use under any other conditions may result in malfunction.

Safety precautions