Prima Musa Apollo User manual

®

ESPRESSO COFFEE MACHINE

Multi Boiler System

Thermosiphonic System

ENGLISH

Apollo

Apollo

Apollo is the machine that Prima Musa created

to express the excellence of craftsmanship.

In Greek mythology, the prophetic symbols of Apollo

are the laurel, the bow and the arrows.

Apollo

Pag. 2

1. WARNINGS

1.1 READ CAREFULLY

Read this manual carefully in its entirety, before using the machine.

The espresso coffee machine you purchased was conceived and built with the latest generation methods and technologies

that ensure quality and reliability over time.

This manual is the guide that will allow you to know the advantages of choosing our brand. Inside you will find all the news

on how to best use the machine, how to keep it efficient and how to behave in case of problems.

Keep this manual carefully. In case of loss and / or deterioration of the present, a copy of the same can be requested from

the manufacturer.

1.2 HOW TO USE THIS MANUAL

The manufacturer ensures the right to make any changes and / or improvements to the product without any communication

to the customer. It is guaranteed that this manual reflects the state of the art when the machine was marketed.

We take this opportunity to invite our kind customers to report any proposals for improvement of both the product and the

manual, to our contact details.

1.3 GENERAL WARNINGS

• After removing the packaging, check the integrity of the appliance, if in doubt, do not use it and contact the dealer or

distributor directly.

• The packaging elements must not be left within the reach of children and must be disposed of according to current

regulations. We recommend that you keep the packaging until the warranty expires.

• Before using the machine, make sure that the mains voltage corresponds to the indications on the machine's data plate.

• The installation must be carried out by qualified personnel, in compliance with the current safety standards.

• The safety of this appliance is total only when it is connected to an effective earthing system, carried out as required by

current safety standards. The electrical system must be equipped with an adequate differential switch (circuit breaker). It

is important to have these requirements checked and in case of doubt, request an accurate check of the system by

qualified personnel. The manufacturer cannot be held responsible for any damage caused by an inadequate electrical

installation and / or installation.

• When installing the device, a qualified protective switch must be installed by qualified personnel as required by current

safety regulations, with a contact opening distance equal to or greater than 3 mm.

• The use of extension cords or electrical adapters with multiple sockets is not recommended. If their use becomes

indispensable, use only simple or multiple adapters, and extension cords that comply with current safety standards.

Never exceed the power value in kW indicated on the simple adapter and on the extensions, and the maximum power

value indicated on the adapter.

• The espresso coffee machine is intended for the preparation of hot drinks such as coffee, tea, hot milk. This appliance is

strictly intended for the use for which it was designed. Any other use is to be considered improper and therefore

dangerous. The manufacturer cannot be held responsible for any damage caused by incorrect and irrational use.

• The use of an electrical appliance must comply with the behavioral safety rules:

- Do not touch the appliance when you have wet or damp hands or feet.

- Do not use the appliance with bare feet.

- Do not use extension cables in rooms used for showers or bathrooms.

- Do not pull on the power cable to disconnect the appliance.

- Do not access inside the machine.

- Do not use the machine in the absence of external parts.

- Do not spill liquid on the machine.

- Do not allow the machine to be used by children or unable.

- Make sure that the machine is used in a sufficiently ventilated, hygienic and illuminated area.

• The spaces and access to the machine and the main switch must be left free, to allow the user to be able to intervene

without any constraint and also to be able to leave the area immediately if necessary.

• Position and install the machine leaving sufficient space for good ventilation of the machine on all sides and in a position

to allow good maneuverability for the operator.

• Do not use water jets on the machine for cleaning. Cleaning operations must be carried out as indicated in this manual.

• Before carrying out any maintenance operation, turn off the appliance from the mains using the main switch.

• In case of failure or malfunction, immediately switch off the appliance, contact the specialized technician immediately, do

not attempt any type of intervention and / or repair.

Apollo Pag. 3

• Any repairs must be carried out only by the manufacturer or by a technician or center authorized by the manufacturer. Use

only and exclusively original spare parts. Failure to comply with this standard can seriously compromise the safety and

functionality of the appliance and may void the warranty validity.

• Inside the machine there is a battery to avoid the loss of programming data in case the power supply is interrupted.

• In the event of damage to the power supply cable, it cannot and must not be replaced by the user, switch off the machine

and disconnect the power supply cable, and contact only a center or professionally qualified personnel for replacement.

• In the event that the appliance is not used for a long period, it is recommended to have it disconnected from the power

supply and to have it emptied by qualified personnel.

• To guarantee a good efficiency of the machine and for its correct functioning it is essential to follow the manufacturer's

instructions, having periodic and scheduled maintenance carried out by qualified personnel with the control of all safety

devices.

• Never expose with your hands or other parts of the body in the direction of the steam, hot water, coffee dispensing

terminals. Steam and water leaving the machine can cause burns.

• With the machine running and running, handle the steam wands, hot water wands and filter holders carefully and only at

the points provided as they are overheated parts.

• Cups and mugs must be placed on the special cup warmer surface only after they have been dried.

• Do not use the cup warmer to place dishes or similar objects.

• The device is not intended for use by people with reduced physical, sensory or mental abilities, by children and by people

without experience or knowledge of the device.

• Children must be supervised and not let them play with the appliance.

• Use the machine only with a temperature between 5 ° and 40 ° C.

• Unauthorized tampering with any part of the machine voids any warranty.

1.4 WARRANTY

The machine is covered by a 12-month warranty excluding electrical components as well as wearing parts.

2. PRESENTATION

This product is manufactured in compliance with the requirements for agri-food machines as indicated in paragraph 2.1 of

Directive 2006/42/CE.

The espresso coffee machine is intended for purely professional use, it has been designed for the preparation of hot drinks

such as coffee, tea, cappuccinos, hot milk, etc. If the model has two or more groups, the use can be carried out by two or

more people at the same time, the machine is capable of dispensing drinks seamlessly and guarantees intensive use of the

same.

3. WARNINGS FOR THE INSTALLER

3.1 POWER SUPPLY

The indicated power supply of the appliance must be made with water suitable for human consumption in compliance with

the provisions in force in the place of installation. The owner and / or operator of the system must confirm to the installer

that the water meets the requirements indicated above.

3.2 MATERIALS TO USE

When installing the machine, the components and materials supplied with the machine must be used.

If there is a need to use other components, the installer must verify the suitability of the same and be suitable for contact

with water for human consumption.

3.3 HYDRAULIC CONNECTIONS

The installer must make the hydraulic connections respecting the regulations in force in the place of installation.

3.4 ACTIVATION

At the end of the installation the appliance must be activated and brought up to the normal working condition and leave it in

the standby condition for a minimum of 30 minutes.

Subsequently, the appliance must be turned off and left to cool, then it must be completely emptied of the water inside it in

order to eliminate any initial impurities.

Afterwards, the appliance must be filled with water again up to normal operating conditions.

Turn the machine back on and wait for it to reach the state of use, then carry out the following operations:

• For each coffee group, make a continuous delivery to drain a minimum of 0.5 liters of water from the circuit.

• Drain the entire volume of water from the boiler by making a continuous supply from the special lance, drain a minimum

of 6 liters for 2 groups and a minimum of 8 liters for 3 groups.

• Drain for at least 1 minute continuously from each individual steam wand.

Apollo

Pag. 4

3.5 MAINTENANCE AND REPAIR

After a maintenance and / or repair, the components used must ensure that the hygiene and safety requirements initially

envisaged for the appliance are maintained, this condition occurs using only original components available from the

manufacturer.

After a repair or replacement of components involving parts in contact with water and / or food, the procedure described in

point 3.4 must be repeated

In case of not using the machine and / or reinstallation, before use repeat the procedure described in point 3.4.

4. DESCRIPTION OF THE MACHINE

4.1 DESCRIPTION

1. Cup support grid

2. Pressure gauge

3. Faucet and steam wand

4. Tea temperature regulator

5. Display

6. Cup warmer top

7. Pushbutton

8. Switch

9. Launch water

10. Dispensing groups

4.2 TECHNICAL DATA

The machine data plate is fixed on the front left side. The machine data are also visible on the machine packaging

POWER SUPPLY VOLTAGE

ABSORBED POWER

BOILER CAPACITY

WIDTH

DEPTH

HEIGHT

SAFETY VALVE CALIBRATION

BOILER OPERATION PRESSURE

FEEDING WATER PRESSURE

V

W

Lt / gal UK

cm / inc

cm / inc

cm / inc

bar / psi

bar / psi

bar / psi

230 - 400

3.500

13 / 2,86

86 / 33,86

66 / 25,98

50 / 19 , 69

2,00 / 29,01

0,8 ÷ 1,4 / 11,6 ÷ 20,3

1,5 ÷ 5 (MAX)

21,8 ÷ 72,5 (MAX)

2 GP

4.3 PUSHBUTTON

In the diagram below you will find a description of the functions of the individual keys. The dual function keys are used when

programming the display items, if any.

K1GR1 K2GR1 K3GR1 K4GR1

K5GR1

K6GR1

a a a

a

1 2 3 4

K1GR1 - 1 Espresso coffee

K2GR1 - 1 Medium coffee

K3GR1 - 2 Espresso coffee

K4GR1 - 2 Medium coffee

K5GR1 - Manual dispensing

K6GR1 - Hot water

5. MACHINE PREPARATION

The preparation of the machine and the installation operations must be carried out exclusively by qualified personnel. The

installer must scrupulously observe the indications given in the chapter "warnings for the installer".

Using the machine without carrying out all installation operations by technical personnel will void the warranty.

1

2

3

4

56

78

9

3

7

10

WEIGHT Kg / lbs 81 / 178

230 - 400

3.500 + 2x1.000

11 / 2,42 + 2x0,6 / 0,13

86 / 33,86

66 / 25,98

50 / 19 , 69

2,00 / 29,01

0,8 ÷ 1,4 / 11,6 ÷ 20,3

1,5 ÷ 5 (MAX)

21,8 ÷ 72,5 (MAX)

2 GP - M. Boiler

91 / 200

Apollo Pag. 5

6. RENEWAL OF WATER

In the event that the machine remains inactive for more than a week, it is necessary to change the water contained within

the whole machine, follow the instructions as indicated in point 3. 4 ..

7. TURNING THE MACHINE ON

Before turning on the machine, make sure that the water level inside the boiler is sufficient (visible from the optical level,

located inside the machine on the right side, visible by removing the right side or the cup support grid), in the case of an

insufficient and / or absent level proceed with manual loading, in order to avoid overheating of the resistance. The machine

is equipped with a system that interrupts the power supply of the electric heater in case of insufficient and / or absent water

level, and will automatically load the water in the boiler before powering the resistance.

Open the water mains tap and the machine tap.

Turn the switch to position 1 or ON.

Wait for the machine to carry out all the checks and checks (any electrical and electronic problems, filling the boiler).

The display (if any) shows the water level inside the boiler and the steam temperature inside the boiler which, when fully

operational, must stabilize at around 120 ° C. If present, the temperatures of the individual groups are also displayed.

During the machine heating phase, the anti-depression valve may release steam for a few seconds, until the valve closes.

8. PRELIMINARY OPERATIONS

It is important to have a grinder-doser next to the machine with which to grind the coffee. To obtain a good espresso, it is

advisable not to keep large stocks of coffee beans and to respect the expiry date indicated by the manufacturer. Never grind

large volumes of coffee, it is recommended to grind only the quantity used daily. Do not buy and / or use already ground

coffee, as it quickly deteriorates.

Fill the filter with a dose of ground coffee (about 6-8 gr.) And compress it with the special press, hook the filter holder to the

group without closing it too much, to avoid rapid wear of the seal. For the same reason, it is advisable to clean the edge of

the filter every time before attaching the filter holder to the group.

Before using the machine, make several empty dispensings with the filter holders attached in order to release any air

present in the circuit and allowing the complete heating of the dispensing groups.

Also carry out some coffee dispensing with different grinding tests to check the most suitable grinding and to check the

operating pressures of the machine. Never remove the filter holder from the group when brewing coffee, risk of burns.

9. COFFEE PREPARATION

Hook the filter holder with the coffee to the group, place the cup or cups under the spout, press the desired dispensing

switch to obtain the coffee dispensing, which will stop automatically when the programmed quantity is reached or can be

stopped in advance by pressing the dispensing switch (the dispensing times are set by the manufacturer for a correct

quantity of coffee, the dispensing times can be changed by the operator or by technical personnel as reported in the

machine programming chapter).

Place the cup or cups under the spout and press the desired dose button and wait for the coffee to be dispensed (during

delivery, the LED corresponding to the button pressed will remain lit.

To stop coffee delivery early, press the button with the LED on.

10. PREPARATION OF HOT DRINKS

10.1 HOT WATER DELIVERY

Place the jug under the hot water wand and press the hot water button (function active on all keyboards) and wait for the

end of the supply, if the quantity of hot water is insufficient press the hot water button again, the water supply hot water can

be stopped early by pressing the hot water button.

Do not touch the hot water spout, contact with the spear can cause burns and damage to people, things and animals.

10.2 STEAM DELIVERY

Insert the steam wand (s) into the liquid to be heated and operate the joystick or the tap knob, return the joystick to the

central position or the knob closed after dispensing.

Turning the knob anticlockwise the tap opens and allows the steam to escape, turning the knob clockwise closes the tap.

Apollo

Pag. 6

By moving the joystick (if provided by the model purchased) vertically, there is a continuous opening of steam, manually

return the joystick to the central position to stop steam delivery. Moving the joystick horizontally opens the steam and

automatically closes the steam when the joystick is released.

To obtain optimal swarming, it is advisable to heat only the quantity of milk to be used, once heated, it must be poured

entirely from the jug and not re-heated. The milk to be frothed must be at room temperature and at a temperature not lower

than 4 ° C.

Before each use of the steam wand, drain the condensation inside the wand by operating the tap for at least 2 seconds.

Leave the steam wand immersed in the milk only for the time strictly necessary for heating the milk.

Handle the steam wand with care, use the special anti-scald rubber, contact with the nozzle and the steam can cause burns

and damage to people, things and animals.

Clean the lance (s) with a soft, damp cloth after each use, the milk residues left on the steam wand favor the proliferation

of bacteria and mold, highly harmful to the human organism. Do not use detergents for cleaning the steam wands.

Never open the tap of the steam wand immersed in milk or other liquid with the machine off, the machine is equipped with

an anti-vacuum and anti-suction valve, in case of valve malfunction the milk is sucked into the boiler with serious damage

to the machine itself (contact the service center).

11. CUP WARMER

Place the cups to be heated on the cup warmer top, the top is heated by induction from the heat generated by the boiler

inside the machine. It is not possible to adjust the heating temperature of the cups. Do not place cups or cups that are damp

or containing liquids on the cup warmer surface, spilling liquids inside the coffee machine through the openings on the cup

warmer surface can cause serious damage to the machine. In the event of liquid spillage inside the machine, immediately

turn off and unplug the machine from the power supply and contact the service center.

12.1 USER INTERFACE

12.2 KEYS

12. PARAMETERS AND MACHINE FUNCTIONS PROGRAMMING

K1GR1, K1GR2, K1GR3:

K2GR1, K2GR2, K2GR3:

K3GR1, K3GR2, K3GR3:

K4GR1, K4GR2, K4GR3:

K5GR1, K5GR2, K5GR3:

First coffee dose button

Second coffee dose button

Third coffee dose button

Fourth coffee dose button

Continuous key / programming

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

KEY

K1GR1

ADDITIONAL

FUNCTION

+ (MORE)

FUNCTION DESCRIPTION

"Increase" function of the numerical values or

selection of the "preset" options relating to the

parameter being programmed

NOTE: as will be better specified in the specific paragraph, some keys belonging to the

group 1 push-button panel perform specific functions (different from the delivery ones)

when programming is taking place:

K2GR1 - (LESS)

"Decrease" function of the numerical values or

selection of the "preset" options relating to the

parameter being programmed

K3GR1 ENTER Confirmation function of some operations during

programming

K5GR1 - (MENU) Selection / selection function of the parameter to be

programmed

Apollo Pag. 7

12.3 LED

K1GR1, K1GR2, K1GR3:

K2GR1, K2GR2, K2GR3:

K3GR1, K3GR2, K3GR3:

K4GR1, K4GR2, K4GR3:

K5GR1, K5GR2, K5GR3:

Led First coffee dose button

Led Second coffee dose button

Led Third coffee dose button

Led Fourth coffee dose button

Led Continuous key / programming

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

Group 1, 2, 3

13. TURNING THE MACHINE ON

By powering the machine through the external main switch, it returns to the "OFF" or "IDLE-ON" state that it had before

disconnecting from the network

(see "Procedures in the event of a mains failure").

When the machine is powered up, the display briefly shows the version of the software installed (x.yy).

13.1 OFF STATUS (MACHINE OFF BUT POWERED)

With the dosage off, the display shows the word OFF, time and date:

OFF

hh:mm

day

- all outputs are disabled

- all the functions are disabled, except for the TECHNICAL Programming ones

IDLE ON STATUS

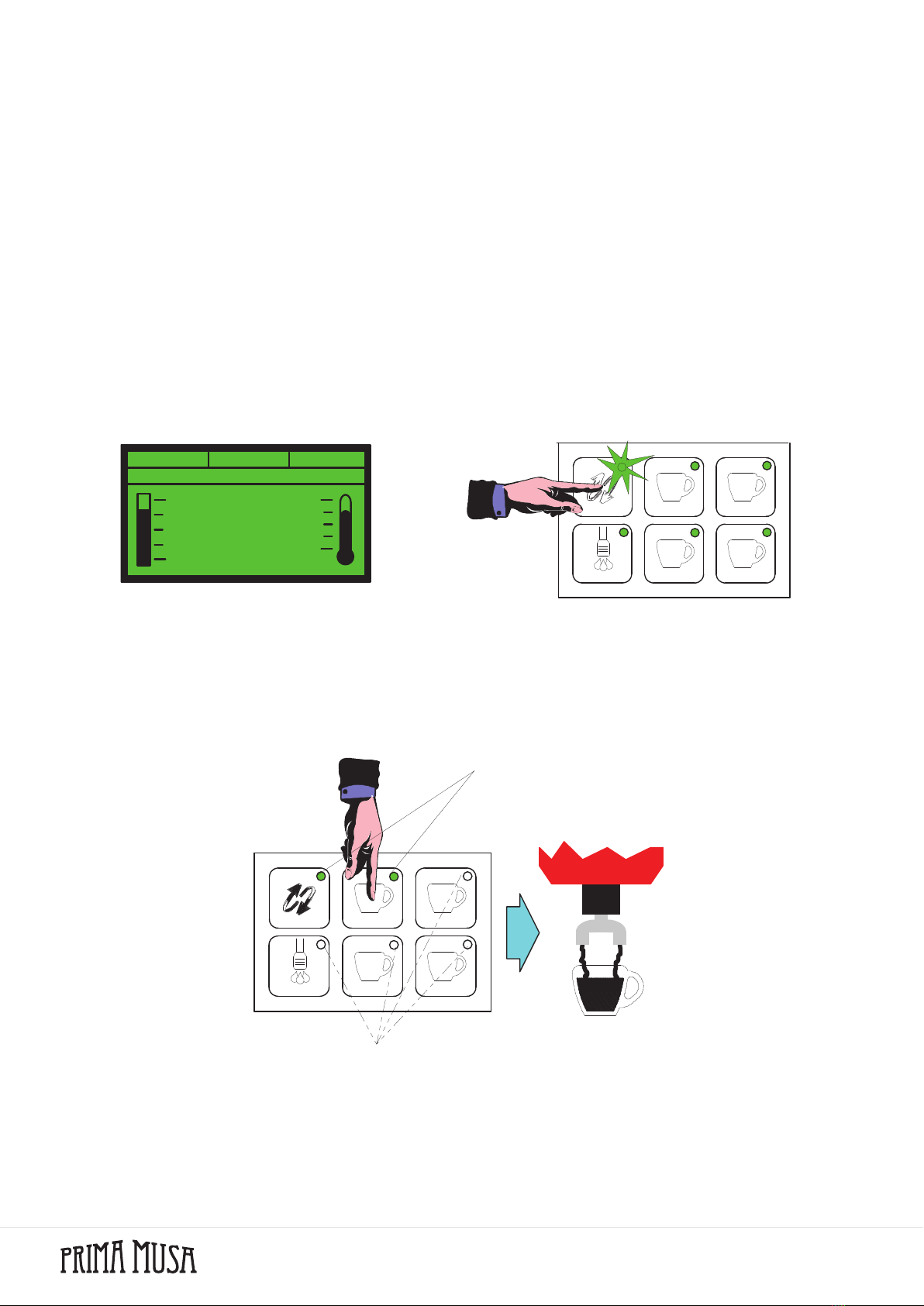

13.2 POWER ON

To switch on the dosage, press the K3GR1 button.

1a

2

a

a

a

3 4

In idle-on status, the dosage detects the status relative to the level and

minimum level probes; if the probe detects the lack of water in the boiler,

filling of the same is arranged by activating the EVLIV filling solenoid valve

and the PUMP until the correct water level is restored

(Filling time-out - see ALARMS paragraph).

When filling is complete, heating is activated (see paragraph ''boiler

heating")

In the event that the correct levels are detected, or after the phase of

restoration of the same, the dosage is predisposed to the enabling of the

coffee dose selections or to a possible programming of the same (see

following paragraphs).

The authorization to dispense is not subject to reaching the set-point temperature in the boiler.

The display shows the following messages:

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxxx

T°gr1 T°gr2 T°gr3

where is it

hh = current time (0 ÷ 23)

mm = current minute

day = day of the week

xxxxxxxxxxxxx = customer name of your choice, functional states, alarms

……. that flow from right to left

T°grx = group temperature

T°cald = boiler temperature

Max = boiler level

Min = minimum boiler level

IN IDLE-ON STATUS ALL LEDS ARE ON

Apollo

Pag. 8

13.3 SHUTDOWN

To switch off the dosage, first hold down the K5GR1 key and immediately after the K3GR1 key.

3

1a 2a

a 4a

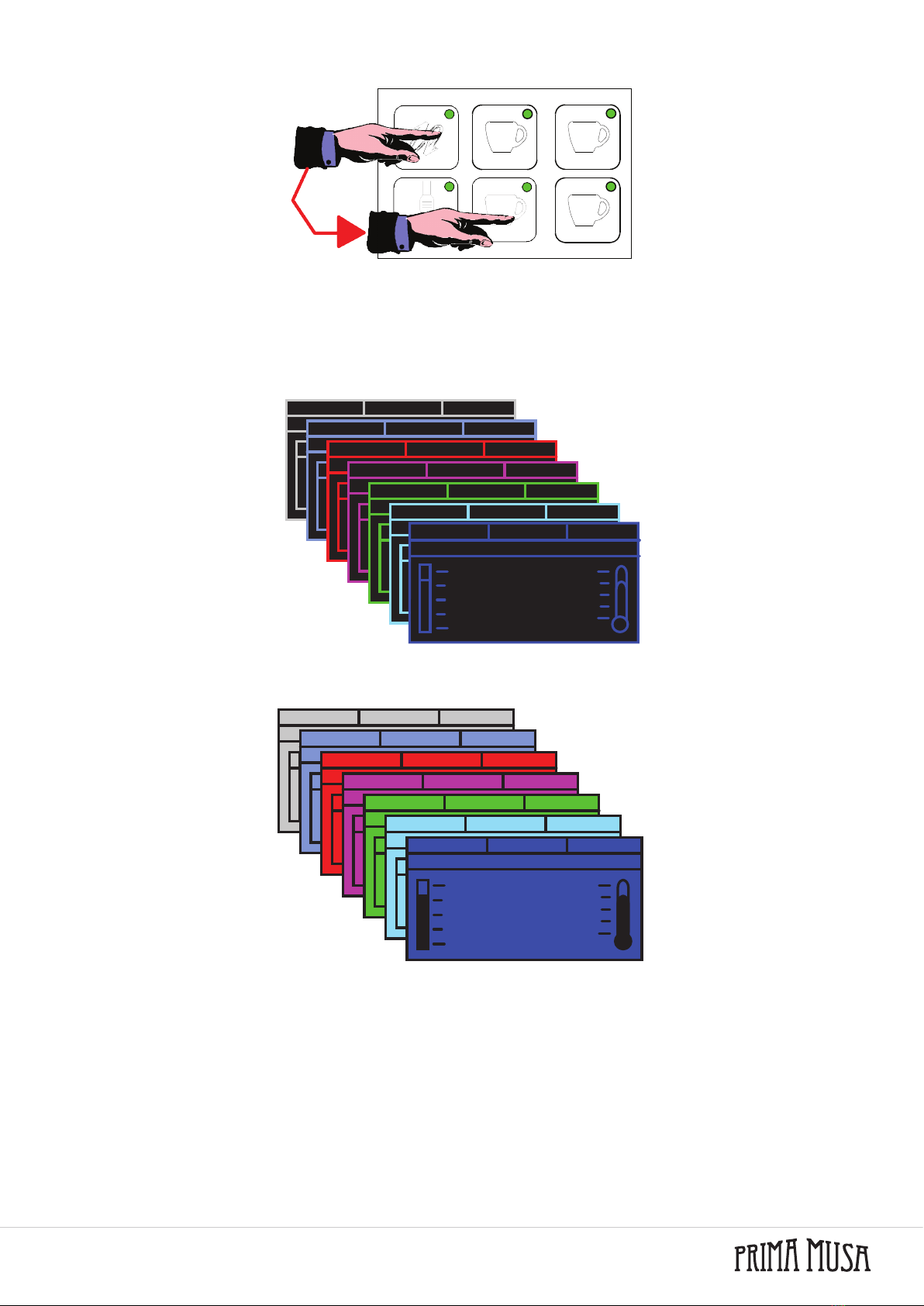

14. COLOR GRAPHIC RGB DISPLAY

The RGB graphic display allows the choice of the desired background color with the colors that can be set in the

TECHNICAL PROGRAMMING.

14.1 NORMAL MODE

In normal mode, the display has a black background and colored writing.

14.2 REVERSE MODE

In normal mode, the display has a colored background and black lettering.

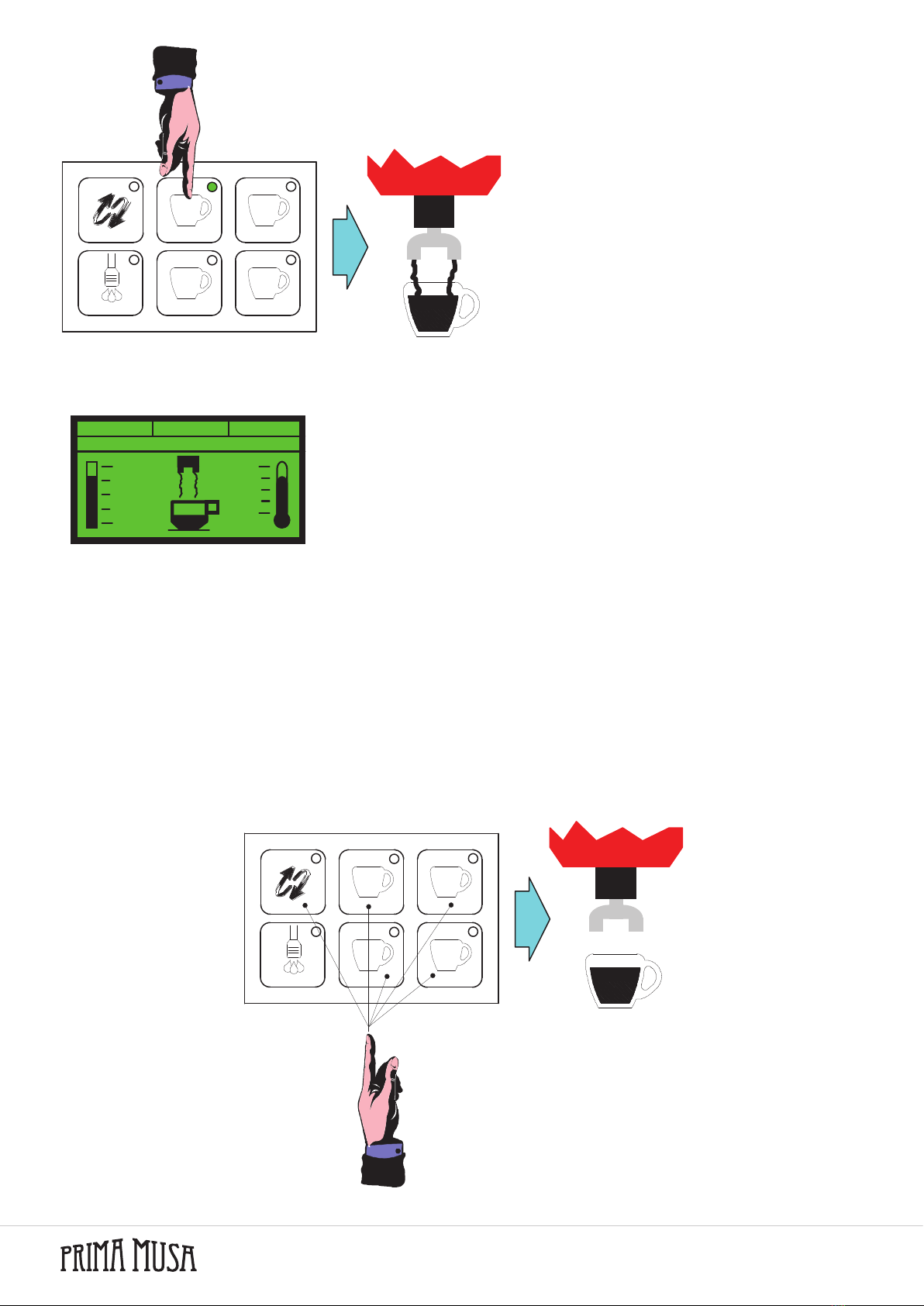

15.1 COFFEE CYCLE

15.2 DELIVERY

15. DONATIONS

From the idle-on state, pressing one of the four dose keys belonging to the group from which you wish to dispense (for

example K1GRx) both the EVx dispensing solenoid valve and the PUMP are energized, starting the dispensing phase.

Pump and solenoid valve will remain active until the quantity of product (volumetric counter pulses) previously programmed

is reached.

The LED relating to the button for the selected dose remains lit for the duration of coffee brewing.

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxx

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

scrolling custom name

T°gr1 T°gr2 T°gr3

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxxxx

T°gr1 T°gr2 T°gr3

Apollo Pag. 9

1 2

34

a a

aa

START DELIVERY

While dispensing is in progress, the display shows

the ICON of the dose running with the cup that fills

up:

MaxLiv

Min

T°Cald

T°gr1 T°gr2 T°gr3

xxxxxxxxxxxxxxxxx

Once the dose is complete, the display keeps the icon displayed for 5

seconds.

NOTE 1: The dosage allows the simultaneous dispensing of coffee, tea and steam from all the groups required by the

dosage. The display shows the icon of the first selected dose.

NOTE 2: If the BUZZER function is enabled from the technical menu (see dedicated chapter), at each delivery start the

buzzer on the back of the RGB display board emits an acoustic signal.

15.3 STOP COFFEE BREWING IN EXECUTION PHASE

There is the possibility of interrupting the delivery in progress before reaching the pulses relating to the volumetric counter

programmed by pressing any of the dose keys on the keyboard of the group used for dispensing the product.

This operation de-energizes with immediate effect both the EVx delivery solenoid valve and the PUMP, interrupting the

product delivery and returning the dosage to the IDLE-ON state

1 2

34

a a

aa

STOP DELIVERY

Apollo

Pag. 10

15.4 PRE INFUSION

The dosage can be configured in such a way that the delivery relative to the volumetric control coffee doses is preceded by

the pre-infusion.

At the start of the dose, after the time t1 (on) the solenoid valve group EVx turns off and remains off for the time t2 (off), only

to then re-energize itself to bring the dose to an end as scheduled. This timed on / off does not apply to the PUMP actuator.

By pressing one of the volumetric control dose keys, the "normal" dispensing cycle is preceded by a short timed jet of water

used to moisten the coffee tablet before the actual dispensing step.

CAUTION: the times of t1 (on) and t2 (off) can be set in the TECHNICAL Programming for all coffee doses. If one or more

data are set to zero, this function is not performed even if it is active! For enabling see TECHNICAL Programming.

EVx

PUMP

t1 (on) t2 (off) scheduled dose

total duration of delivery

15.5 COFFEE BREWING IN CONTINUOUS MODE

From the IDLE-ON state, by pressing one of the dose keys K5GRx (continuous / programming) both the EVx delivery

solenoid valve and the PUMP are energized, starting the delivery phase. The L5GRx LED relating to the button for the

selected dose remains lit for the duration of the coffee dispensing.

1 2

34

a a

aa

START DELIVERY

To stop dispensing in continuous mode, perform the STOP dose by pressing any dose button on the keyboard of the group

used for dispensing the product. The de-energization of the solenoid valve and pump occurs with the consequent turning off

of the signaling LED.

1 2

34

a a

aa

STOP DELIVERY

Continuous delivery is automatically stopped (if no stop is performed) when the maximum quantity of product is reached;

this quantity can be controlled both in volumetric mode when 6000 pulses are reached, and through a delivery time-out (see

ALARMS paragraph).

IMPORTANT: THE START CONTINUOUS TO THE "CONTINUOUS" CYCLE IS ON THE RELEASE (WITHIN 5 SECONDS

PENALTY TO THE PROGRAMMING PHASE) OF THE K5GRx KEY AND NOT ON ITS PRESSURE.

THE POSSIBLE STOP DOSE, ON THE OTHER HAND, OCCURS ON PRESSING THE BUTTON ITSELF.

Apollo Pag. 11

15.6 TEA CYCLE

15.7 DELIVERY

By pressing the button for the Tea dose (K6GRx), the Tea solenoid valve (EVTEA) is activated, initiating the delivery of hot

water. The operation is highlighted by the lighting up of the LED (L6GRx) corresponding to the button pressed.

1 2

34

a a

aa

START DELIVERY

At the time of the cycle start, a timer is

activated which, once the value set in the

programming phase is reached, interrupts

the supply of the product.

While dispensing is in progress, the

display shows the icon of the dose running

with the cup that fills up.

Once the dose is completed, the display

keeps the icon displayed for 5 seconds.

NOTE 1: The dosage allows the simultaneous dispensing of coffee, tea and steam from all the groups required by the

dosage. The display shows the icon of the first selected dose.

NOTE 2: If the BUZZER function is enabled from the technical menu (see dedicated chapter), at each start of delivery the

buzzer on the back of the RGB display board emits an acoustic signal.

15.8 STOP TEA DELIVERY IN EXECUTION PHASE

There is the possibility of interrupting the delivery in progress before reaching the programmed time by pressing the same

button used to start dispensing the tea dose.

1 2

34

a a

aa

STOP DELIVERY

This operation de-energizes the EVTEA

solenoid valve with immediate effect,

interrupting product delivery and returning

the dosage to the IDLE-ON state.

CAUTION:

DOSAGE PROVIDES THREE DIFFERENT TEA DOSES (ONE PER GROUP)

15.9 TEA + PUMP

It is possible to combine tea delivery with the pump (See TECHNICAL Programming).

15.10 STEAM PUMP DELIVERY CYCLE

Through a temperature probe positioned appropriately on the steam wand and connected to the STLVAP input, the

temperature of the liquid heated by the steam is measured.

Pressing the K6GRx key (of the group

selected in the TECHNICAL

Programming, see paragraph) activates

the EVVAP until the temperature set in the

Simulation Programming has been

reached (see paragraph below).

1 2

34

a a

aa

START DELIVERY

However, you can stop early by pressing

the steam button.

Apollo

Pag. 12

It is possible to continue dispensing steam which has arrived at the programmed temperature by keeping the steam button

pressed.

If the temperature is not reached within a time-out of 120seconds, the steam supply is automatically terminated.

NOTE 1: The dosage allows the simultaneous dispensing of coffee, tea and steam from all the groups required by the

dosage. The display shows the icon of the first selected dose.

NOTE 2: If the BUZZER function is enabled from the technical menu (see dedicated chapter), at each start of delivery the

buzzer on the back of the RGB display board emits an acoustic signal.

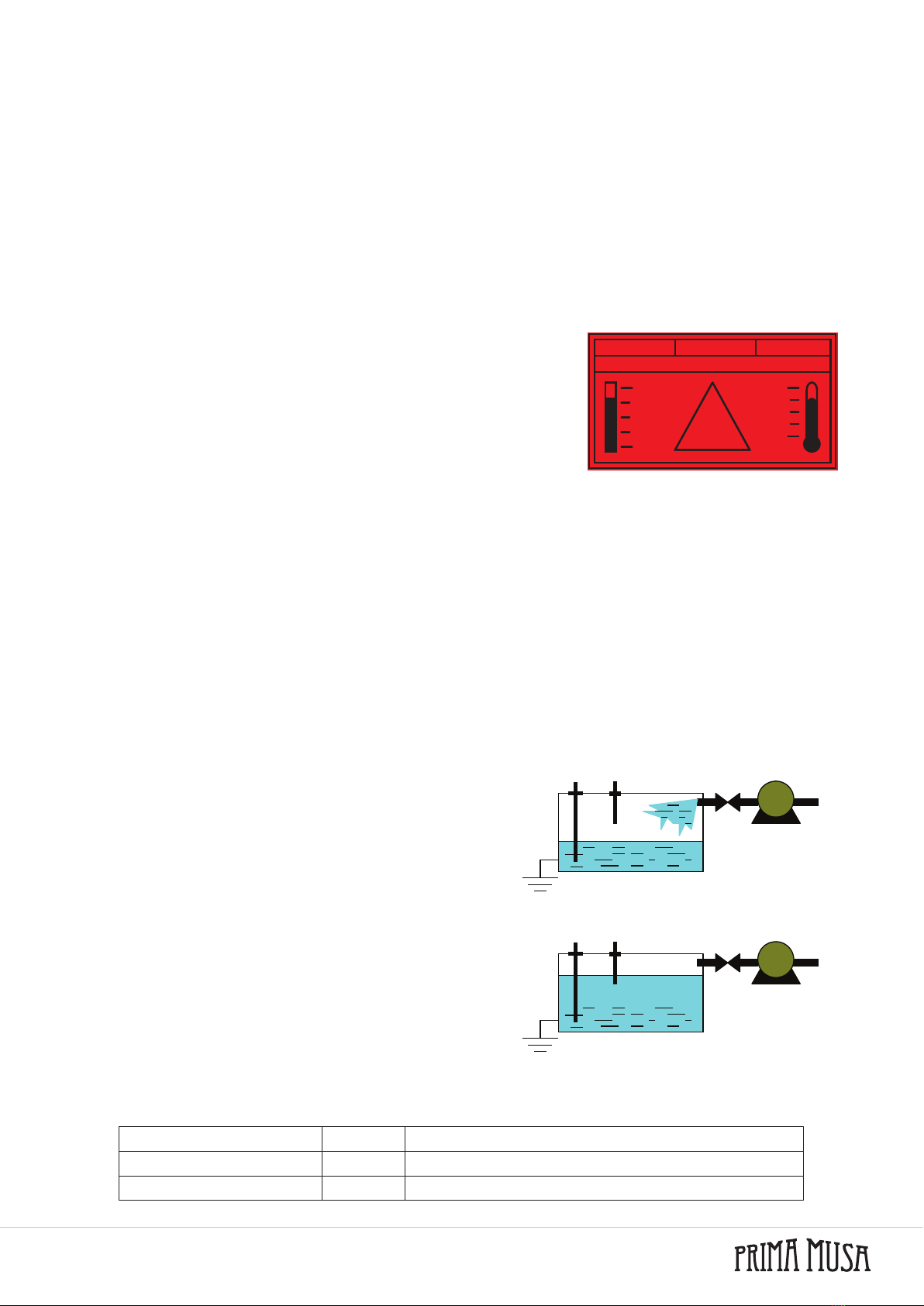

16. LEVEL MANAGEMENT AND ADJUSTMENT

16.1 MINIMUM LEVEL PROBE

At the time of the Power-on, the dosing detects the status relative to the minimum level probe. In case of lack of water, the

ON / OFF / HEATING / TEA actuator (which the customer will have connected to the remote control switch and / or power

relay at will) is kept de-energized to preserve the heating element from dry running.

NOTE: On power-up, the control of the minimum level probe is enabled after about 6 seconds.

Max

Min

T°Cald

Boiler Empty

T°gr1 T°gr2 T°gr3

!

(RED display background)

Whenever the minimum level probe placed in the boiler does not

detect the presence of liquid for 3 seconds, it is de-energized ON /

OFF / HEATING / TEA2 to preserve the heating element and the

message '' 'BOILER EMPTY' '' is shown on the display

When the minimum level probe returns to detect the presence of

water for 3 consecutive seconds, the ON / OFF / HEATING / TEA2

actuator is re-enabled and consequently the heating and the alarm

disappears on the display.

NOTE 1: The minimum level probe does not perform filling control or management tasks, as this function is performed by

the level probe. (next paragraph)

NOTE 2: If the BUZZER function is enabled from the technical menu (see dedicated chapter), every time the minimum level

probe is discovered as described above, in addition to the signaling on the display, the buzzer on the back of the RGB

display board will also report the acoustic signal. , through 5 consecutive "beeps".

16.2 LEVEL PROBE

At the time of the Power-on, the dosing detects the status relative to the level probe placed in the boiler and, if necessary

(lack of water), arranges the execution of the filling phase by energizing the EVLIV filling solenoid valve and the PUMP until

the correct water level in the boiler is restored.

(Time-out foreseen in the programmable filling phase - see TECHNICAL Programming)

NOTE: When the system is turned on, the level control and adjustment is enabled after about 6 seconds.

Whenever the level probe placed in the boiler does not detect

the presence of liquid for 3 seconds, the filling phase is

arranged by energizing the EVLIV loading solenoid valve and

the PUMP. When the probe returns again to recognize the

presence of water for 3 consecutive seconds, the filling phase

is interrupted by de-energizing the EVLIV loading solenoid

valve and the PUMP.

BOILER LEVEL KO EVLIV + PUMP = ON

BOILER LEVEL OK EVLIV + PUMP = OFF

SLIVSLIV Min

SLIV Min SLIV EVLIV

EVLIV

PUMP

PUMP

The filling phase does not affect the possibility of making both

coffee or tea or steam selections and a new programming of

the same. Only the intervention of the Time-out combined

with the filling phase inhibits the functionality of the keyboard

and actuators.

In the first adjustment of the water level in the boiler, the level

probe is waited for before activating the ON / OFF / HEATING

/ TEA2 relay.

It is possible to vary the sensitivity of the level probes through a parameter in the TECHNICAL Programming in the following

possibilities:

-> LOW sensitivity

-> MEDIUM sensitivity

-> HIGH sensitivity

150 kΩ

400 kΩ

1 MΩ

for example in the presence of a softener

normal water

for example in the case of mountain water or level glass

Apollo Pag. 13

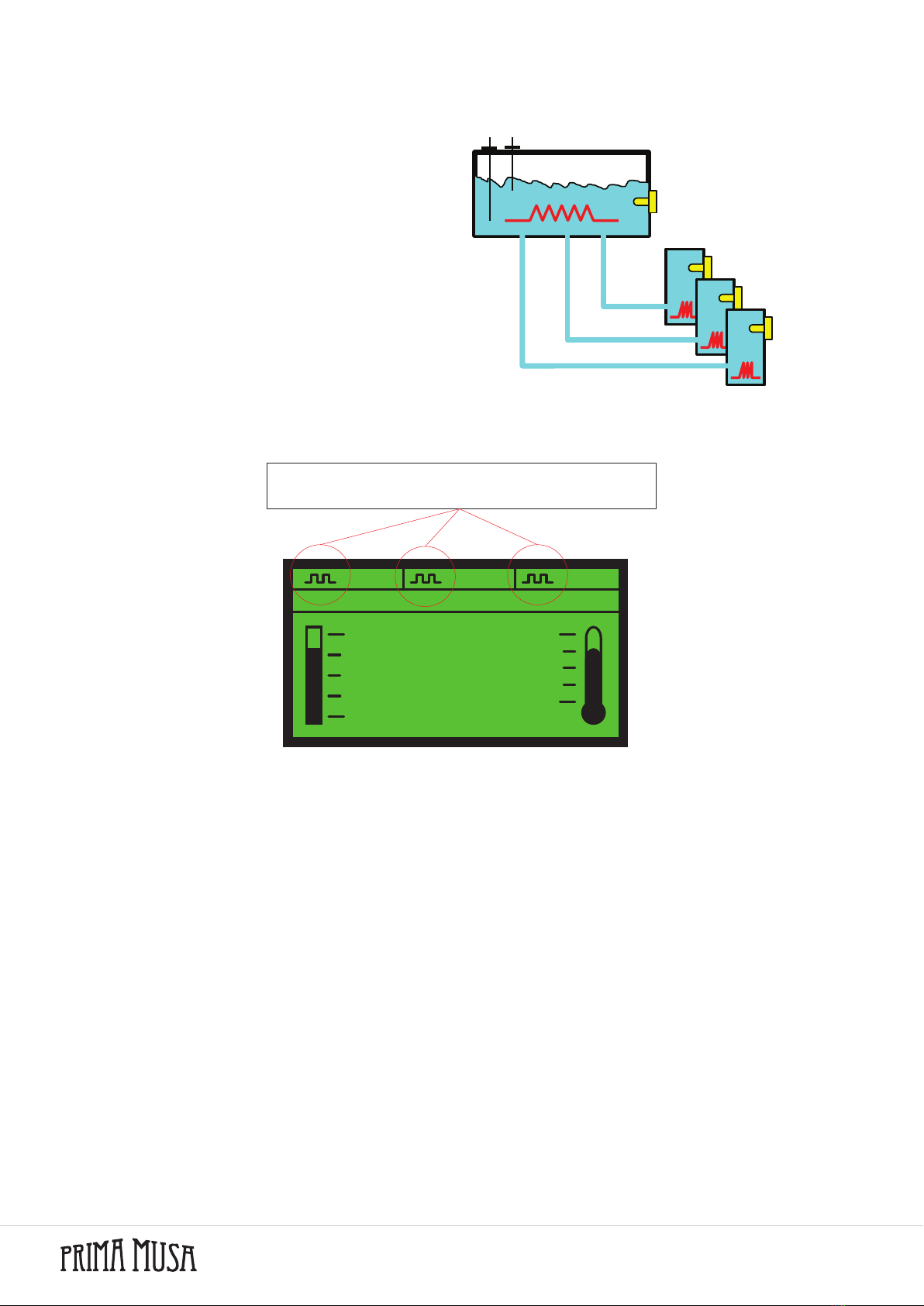

17. HEATING STEAM BOILER AND COFFEE BOILER *

17.1 FEATURES

* ONLY ON MACHINE WITH MULTI BOILER SYSTEM

The dosage controls the heating of the steam boiler and up to

3 coffee boilers.

STEAM BOILER

BOILERS

Resistance

Ntc 1st Group

Ntc 2nd Group

Ntc 3rd Group

NTC Boiler

Resistance

Heating control of all boilers is enabled in IDLE-ON;

each uses an NTC type probe and a 4 ÷ 30Vdc low voltage

command which excite solid state relay (SSR) type actuators

or specific triac modules which in turn control the heating

resistors.

In the first setting, the heating is activated only AFTER

the level in the boiler has been reached to safeguard the

resistance.

In all other cases, heating is active if necessary except when

the minimum level probe is discovered ... condition in which

heating is immediately blocked.

During the activation of the group heaters, the resistance symbol appears on the display

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxxx

T°gr2 T°gr3T°gr1

when this symbol is present on the display it

means that heating is active

SEQUENTIAL HEATING

The system provides the possibility to enable the "Sequential heating" function through a technical menu (see dedicated

chapter) which, when only one group heating SSR is activated, these have priority over the SSR output of the coffee boiler

which is

In the condition in which the "Sequential heating" function is deactivated from the technical menu, the management of the

SSRs present in the system (Coffee boiler + groups) will be without priority constraints between them.

CAUTION:

- in the first setting (temperatures not at full capacity) the heating priority will be of the boiler.

- any request for steam or tea dispensing without a coffee in progress keeps the boiler temperature active regardless of

whether the coffee group heaters are active or not

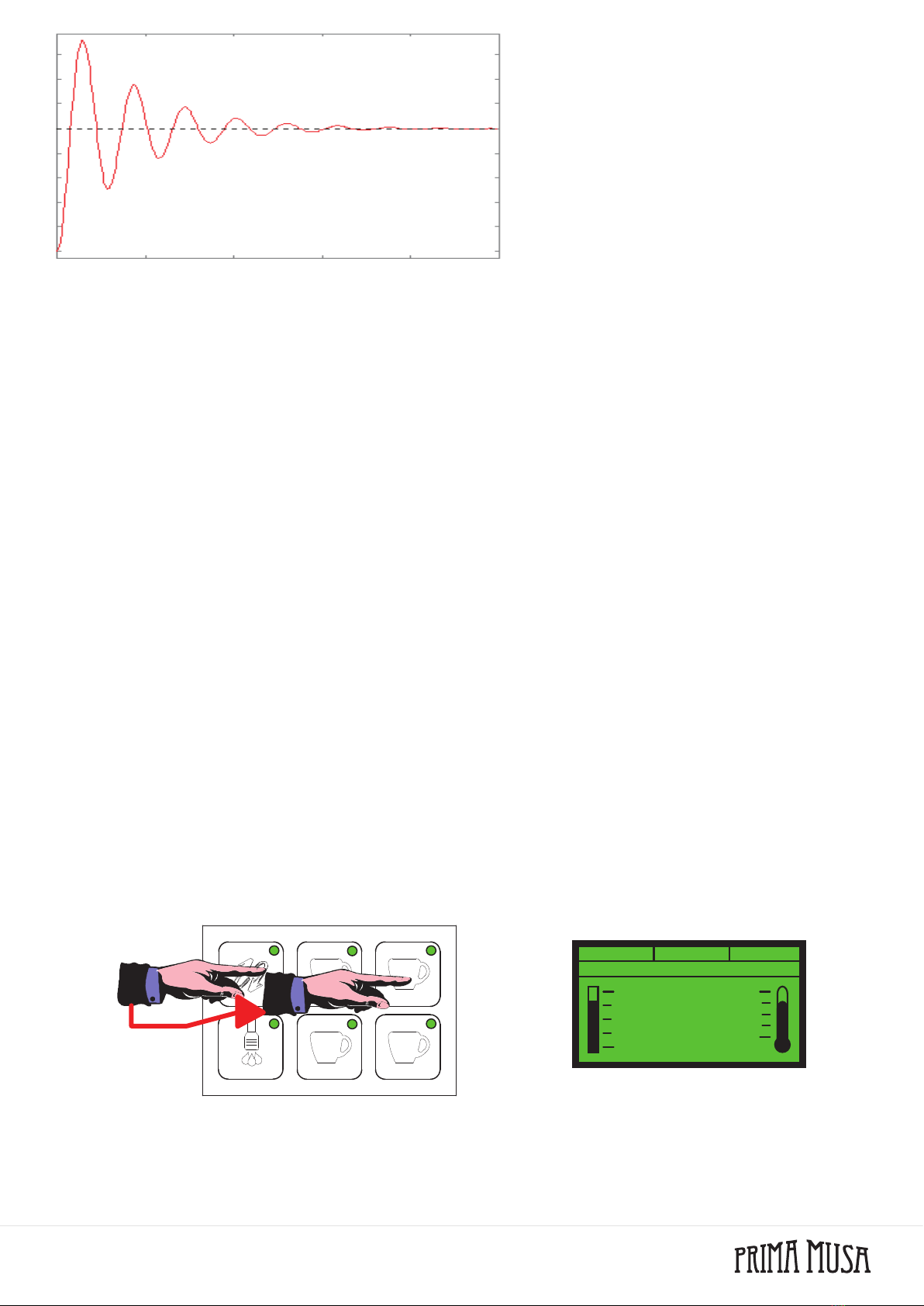

17.2 PID ADJUSTMENT (DEFAULT SETTING)

The default temperature adjustment is made following an algorithm called PID.

The constants that determine thermoregulation are called

Apollo

Pag. 14

PID T°SET

Proportional constant

Integrative constant

Derived constant

Proportional range

Kp

Ki

Kd

is the range within which

the PID is managed

outside of it the resistance

is controlled in ON / OFF

mode

The three constants and the proportional range must be adapted to each type of coffee machine based on the power

characteristics of the resistance, the size of the boiler, the fluidics, its dispersion, etc., etc ... and it is usually a job that also

requires some time to get the best possible result.

"Setpoint value or T ° SET" is defined as the temperature that the boiler must be in normal operation

- If during the heating or maintenance phase the temperature fluctuates excessively around the T ° SET, with peaks of

value that does not decrease over time, it is necessary to decrease the proportional constant: Kp

- If during the maintenance phase the temperature fluctuates excessively around the T ° SET, with a very long period

of oscillation and with peaks that do not decrease over time, it is necessary to decrease the integrative constant: Ki

- If during the heating or maintenance phase the temperature fluctuates excessively and often greater than the T °

SET, but which decreases over time, it is necessary to decrease the derivative constant: Kd

- If during heating the temperature tends to stay below the T ° SET value, moving further and further away from it, it is

necessary to increase the derivative constant: Kd

- If during heating the temperature tends to stay constantly below T ° SET, it is necessary to increase the proportional

constant: Kp and also slightly increase the integrative constant: Ki

- If during the maintenance phase the temperature tends to stay below or above the value of T ° SE T it is necessary

to increase the integrative constant: Ki and slightly increase the proportional constant: Kp

(see TECHNICIAN programming for parameter setting)

17.3 ON / OFF REGULATION WITH HYSTERESIS OF 2 ° C ONLY FOR STEAM BOILER

The temperature regulation of the steam boiler can also take place in another mode and more precisely with a hysteresis

of 2 ° C. The resistance is controlled by the ON / OFF / RISC / TEA2 actuator (which the customer will have connected to

the remote control and / or power relay at will) which de-energises when the programmed temperature T ° SET is reached

(see TECHNICAL Programming) and it re-energizes when it has decreased by 2 ° C. To avoid vibrations on the intervention

threshold, a time filter is also inserted.

To activate this function, it is necessary to set all pid constants to 0 in TECHNICAL Programming (see dedicated

paragraph).

17.4 SWITCHING OFF AND SWITCHING ON OF INDIVIDUAL GROUPS

It is possible to switch off the heating of the individual boilers of the groups by pressing first the K5GRx key and immediately

after the K2GRx key. OFF is displayed instead of the temperature.

1 2

34

a a

aa

1° 2°

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxxx

OFF T°gr2 T°gr3

supposing to turn off group 1 we will have:

To turn on the heating, first press the K5GRx button and immediately after the K1GRx button.

It is possible to switch off the heating of the steam boiler by following a specific procedure described in TECHNICAL

Programming.

Apollo Pag. 15

17.5 ECONOMY MODE

The ECONOMY mode is activated when the inactivity time set in the technical menu under "ECONOMY TIME" is exceeded.

The ECONOMY mode provides for the automatic lowering of the steam boiler tset to the value set by the technical menu

(see dedicated paragraph).

With economy mode active, the display shows the wording "ECO" instead of the steam boiler temperature (on the right of

the display).

Economy mode is deactivated when:

1. the measured temperature is 2 ° C lower than the set economy tset

2. any delivery is made

3. the level probe does not detect water and the loading phase is activated

18. PROGRAMS AND READINGS

18.1 COFFEE DOSES PROGRAMMING

It is possible to modify and memorize the quantities relating to the volumetric coffee doses by following the procedure below

1. In IDLE-ON state, press the K5GRx key (1..3) and keep it pressed for 5 seconds; check the transition from fixed to

flashing of the LEDs L5GRx (1..3)

The display shows the writing

hh:mm

Max

Min

T°Cald

day

xxxxxxxxxxxxxxxxx

T°gr1 T°gr2 T°gr3

1 2

34

a a

aa

KEY PRESSURE > 5 seconds

Flashing

3. Once the quantity of coffee with which you want to program the dose is reached, press any of the "coffee" buttons on the

keyboard relating to the group being programmed to stop dispensing the product with the consequent de-excitation of EVx

+ PUMP.

The new dose value expressed in pulses of the volumetric meter is stored in EEPROM.

At the same time the LED relative to the programmed dose turns off and the remaining LEDs turn on; it is therefore possible

to proceed with the programming of the remaining doses (also tea and steam doses if enabled) without having to repeat the

entry operation (see point 1).

1 2

34

a a

aa

START DELIVERY

LED ON

LEDS OFF

2. Within 30 seconds (exit time-out from the programming phase) press any of the keys associated with the 4 doses that

can be programmed (for example K1GRx). The LED relating to the K5GRx key remains lit as is the dose LED during

programming (in our example L1GRx). EVx + PUMP actuators are enabled for the entire duration of coffee dose

programming.

Apollo

Pag. 16

NOTE: during the programming of a group the other groups remain disabled and the delivery of tea and steam if enabled.

1 2

34

a a

aa

STOP DELIVERY

EVx + PUMP = OFF

· To proceed with the programming of the remaining coffee doses (if the programming time-out of 30 seconds has

not been exceeded) repeat steps 2 and 3 in sequence.

· In case of intervention of the time-out (30 seconds) on the programming phase, to proceed with the execution of

the same it is necessary to repeat the entire sequence described in points 1, 2 and 3

· ILEDs relating to the "already programmed" doses are off if you decide to return to the programming

environment. However, this does not prevent a "new" programming of the already programmed doses (this

condition is not verifiable if an ON / OFF operation of the dosage has been carried out after programming).

IMPORTANT:

the programming carried out on the FIRST GROUP is ALWAYS transferred automatically for convenience also to

all the other groups. However, this does not affect the possibility of programming the remaining groups

independently of the first one by means of the operations described in points 1, 2 and 3 also to remedy any

difference in water in the cup caused by possible "fluidic differences" with the various groups.

18.2 IF A VOLUMETRIC COFFEE DOSE IS NO LONGER ACTIVATED ...

Solving problems

if after programming a volumetric dose, it is no longer carried out, IT IS NOT TO BE attributable to the inability to store the

dose by the dosage but it is really possible that, for some reason, the dosage itself has not received the impulses from the

volumetric counter and has therefore programmed a dose equal to 0 pulses.

IMPORTANT AND VERIFY THAT THE LED OF THE DOSE SELECTED DURING PROGRAMMING DOES NOT FLASH

THE POSSIBLE CAUSE IS TO BE SEARCHED IN:

- volumetric meter wrongly connected

- volumetric meter exchanged with that of another group

- water circuit not working

- coffee filter and blocked water passages that need cleaning

- solenoid valve group that does not allow enough water to pass

- ground coffee too fine or too pressed which allows a little water to filter

18.3 TEA DOSING PROGRAMMING

It is possible to modify and memorize the quantities related to the tea doses (through timed control) following the following

procedure:

CAUTION:

IF THE "PRE-INFUSION" FUNCTION IS ACTIVATED (SEE DEDICATED PARAGRAPHS), THE DOSING IN THE

PROGRAMMING PHASE ENABLES THIS PARTICULAR FUNCTION IN ANY CASE. WAIT THEREFORE THAT THE

SAME IS COMPLETED BEFORE STOPPING THE CURRENT PAYMENT

Apollo Pag. 17

1. In IDLE-ON state, press the K5GRx key (1..3) and keep it pressed for 5 seconds; check the transition from fixed to

flashing of the LEDs L5GRx (1..3).

The display shows the wording '' Doses Setting Select within 30sec '' in the xxxxxxxxxxxxxx zone.

2. Within 30 seconds (exit time-out from the programming phase) press the K6GRx key associated with the tea dose. The

LED relating to the K5GRx key remains on

The EVTEA actuator is enabled for the entire duration of the tea dose programming.

3. Upon reaching the amount of tea with which you want to program the dose, press the K6GRx key used previously to stop

dispensing the product with the consequent de-excitation of EVTEA.

The new time relating to the duration of the tea dose is memorized.

· To proceed with the programming of the other tea doses (if the programming time-out of 30 seconds has not been

exceeded and you have entered the programming environment from group 1 by pressing the K5GR1 key) repeat steps 2

and 3 in sequence.

· In case of intervention of the time-out (30 seconds) on the programming phase, to proceed with the execution of the same

it is necessary to repeat the entire sequence described in points 1, 2 and 3.

· The LEDs relating to the "already programmed" doses are off if you decide to return to the programming environment.

However, this does not prevent a "new" programming of the already programmed doses (this condition cannot be verified if

an ON / OFF operation of the dosage has been carried out after programming).

IMPORTANT:

the programming of the tea dose carried out on the FIRST GROUP is NEVER automatically transferred to all the

other groups. To program the tea dose on the remaining groups, simply repeat the operations described in points

1, 2 and 3.

NOTE: during the programming of a Tea, the groups and the delivery of the other teas remain disabled.

18.4 CLOCK PROGRAMMING

In IDLE-ON state, press the K5GRx key (1..3) and keep it pressed for 5 seconds; check the transition from fixed to flashing

of the LEDs L5GRx (1..3)

The display shows the wording 'Clock Adjust'.

NOTE: when the "Doses Setting" screen is displayed, keep the K5GRx button (1..3) pressed to go to the "Clock Adjust"

phase.

the display shows in the foreground

Clock adjust

Press K3GR1 (ENTER) to confirm

1 2

34

a a

aa

the display shows in the foreground

Clock adjust

hh.mm XXXXXXXXX

where is it hh = current time (0...23)

mm = current minute

XXX = day of the week

If you want to change the parameter, use the K1GR1 (+) or K2GR1 (-) keys then confirm with K5GR1.

Pressing the K5GR1 key again switches to the automatic ignition setting.

Apollo

Pag. 18

18.5 AUTO ON / OFF - AUTOMATIC SWITCHING ON / OFF

Allows the definition of the automatic switching on and off times of the dosage and the weekly closing day.

the display shows in the foreground

Auto ON/OFF

aaa : hh.mm

They are programmed in the order:

- ignition time (AAA = On)

- minute of ignition (AAA = On)

- time of shutdown (AAA = Off)

- minute of shutdown (AAA = Off)

- day of rest

To switch from one to the other, press the K5GR1 button.

1 switch on and 1 switch off can be set and are valid for all days of the week.

If you do not wish to have automatic switching on or off, go to the corresponding time programming and press K1GR1 (+)

or K2GR1 (-) until the following appears on the display:

the display shows in the foreground

Auto On/Off

On : --.--

Auto On/Off

Off : --.--

Or

the display shows in the foreground

(pressing K2GR1 (-) when the time 00 is indicated on the display or pressing K1GR1 (+) when the time 23 is indicated).

In this case:

- if the ignition has been disabled, the shutdown and the day off are also automatically disabled, pressing K5GR1 skips the

relative settings and goes directly to the next parameter. Switching on and off can thus only be done manually through the

procedure described in the previous paragraph.

- if the ignition is enabled, pressing K5GR1 switches to the setting of the shutdown and subsequently of the closing day, if

necessary.

18.6 DAY OF REST

It is possible to define a weekly rest day, in which the dosage ignores the automatic ignition and can only be turned on

manually.

The automatic switch-off is also active on the day off.

the display shows in the foreground

Closed On

xxxxxxxx

With K1GR1 (+) or K2GR1 (-) the day (XXX) is selected.

If you do not wish to set a day off, select "------------".

Only one day off can be set.

18.7 CONSUMPTION READING, LITERS, MAINTENANCE

the display shows in the foreground

Clock adjust

pressing the K5GR1 key again switches to the reading of the counts:

Table of contents