flexbar 15947 User manual

ULTRASONIC THICKNESS GAGE

MODEL NO. 15947 & 15949

OPERATION MANUAL

250 Gibbs Road • Islandia, NY 11749

Tel: (631) 582-8440 • Fax: (631) 582-8487

E-Mail: [email protected]

www.flexbar.com

2

INDEX

1) GENERAL

1.1)APPLICATIONS 3

1.2) BASIC WORKING PRINCIPLE 3

2) SPECIFICATIONS 3

3) DIAGRAM Model#15947 & 15949 4

4) MAIN FUNCTIONS 5

4.1) PREPARING FOR MEASUREMENT 5

5) SETTING PARAMETERS 5

5.1)Velocity 6

a) Velocity Setting

6

b) Velocity Measuring

6

5.2)Probeselection 6

5.3)Resolution 7

6) TESTING PROCEDURE 7

7) CALIBRATION 7

8) MEASURING THICKNESS 7

9) MAINTENANCE 8

9.1) Battery replacement 8

9.2)Storage 8

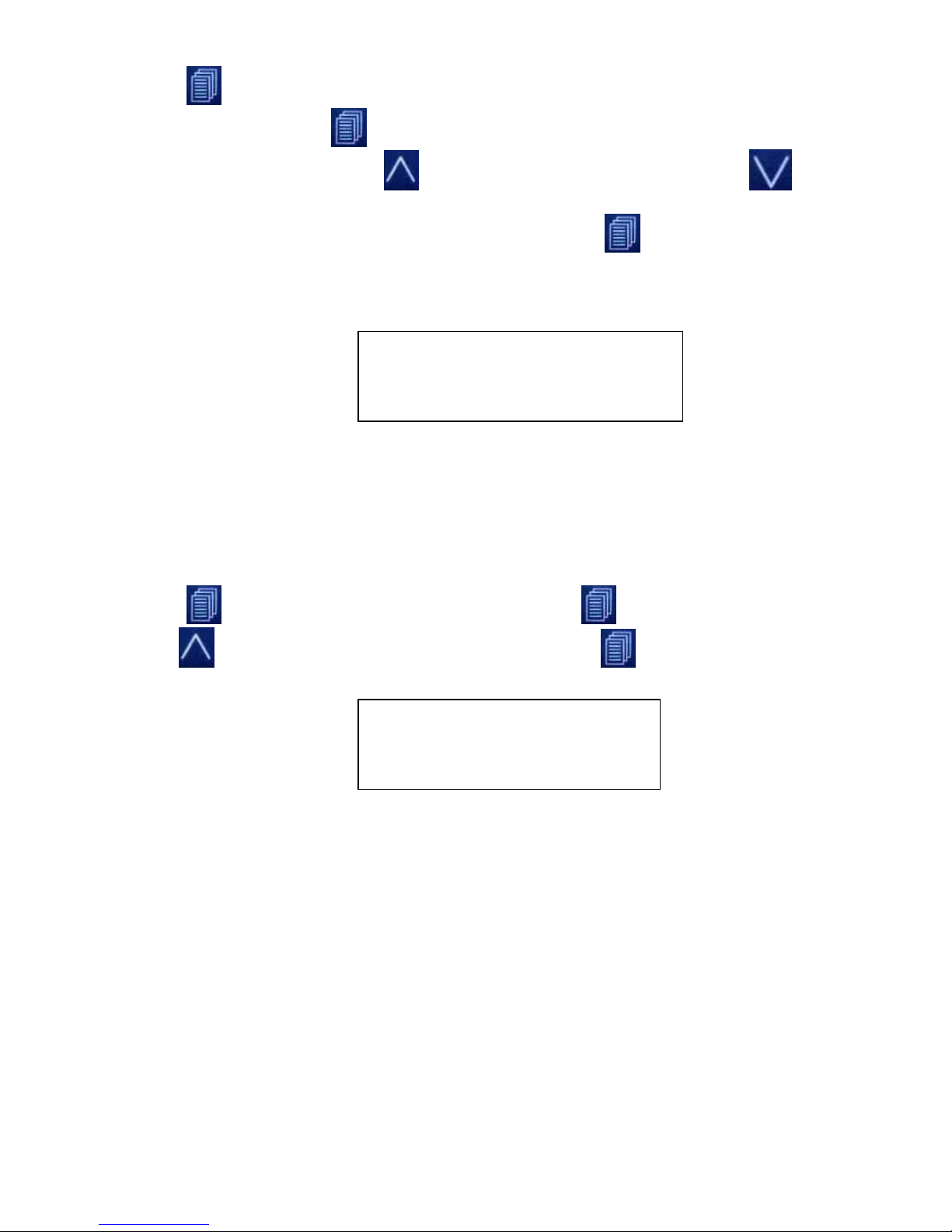

Appendix A: Decimal and Fractions to Millimeters 9

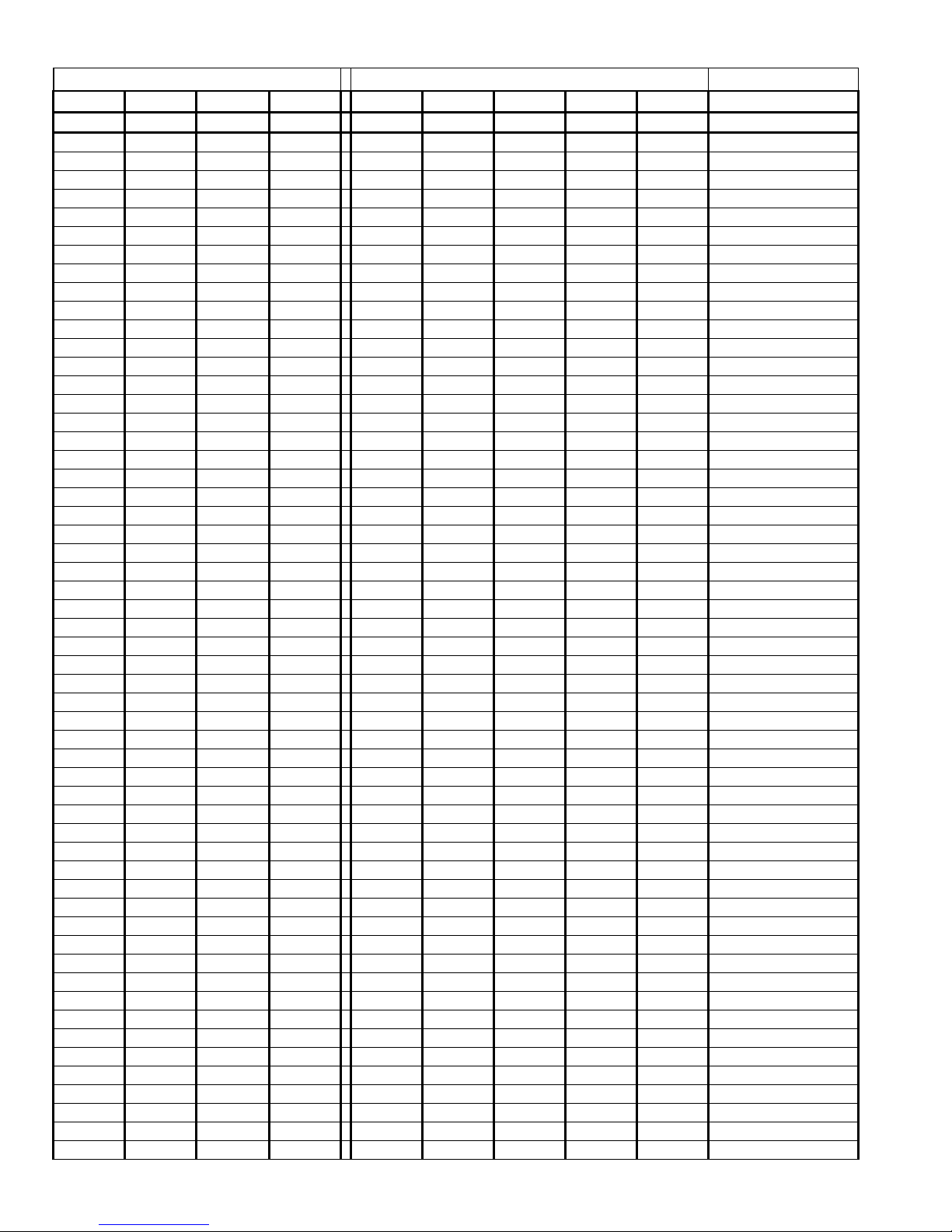

Appendix B: Millimeters to Inches 10

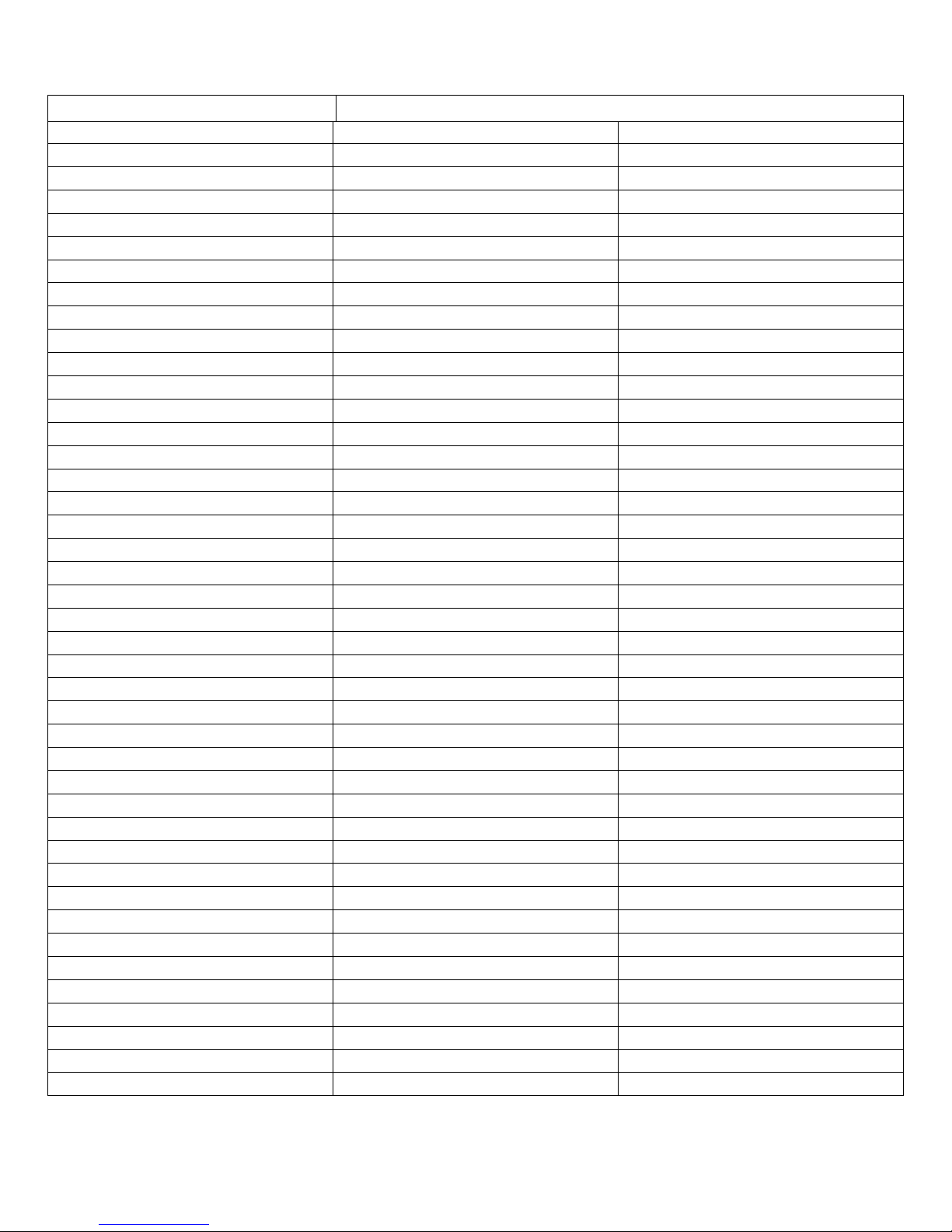

Appendix C: Sound Velocity in Materials 11

3

1. GENERAL

1.1) APPLICATIONS

The Flexbar Ultrasonic Thickness Gage, Model No. 15947 & 15949 are

designed for measuring the thickness of metals, plastics, ceramics, glass and other

ultrasonic wave conducting materials with two parallel surfaces (top & bottom).

The 15947/15949 can be used in industrial applications to perform precise

measurements on various kinds of materials, parts and components. Additionally, it can

be used to monitor various kinds of pipes and pressure vessels for decreasing thickness

due to corrosion and/or erosion.

1.2) BASIC WORKING PRINCIPLE

The basic principle of the ultrasonic wave in a thickness measurement is similar to that

of an optical wave. The ultrasonic wave pulses are transmitted by the probe face and

are coupled to the object to be measured using a viscous fluid called “couplant”. These

ultrasonic pulses propagate through the measured object and reflect back to the

transducer when they encounter the back surface. The thickness of the object is

determined by precisely measuring the time the ultrasonic wave travels in the object.

2) SPECIFICATIONS

DISPLAY:

FOUR DIGIT LCD DISPLAY

RESOLUTION:

0.01in / 0.1mm &0.001” / 0.01MM

WORKING FREQUENCY:

5MHz

MEASURING RANGE:

.047in – 8.0in (1.2 - 200.0 MM) (STEEL)

LOWER MEASURING LIMIT FOR PIPES:

0.8 X 0.1” or 20 X 3mm (STEEL)

MEASURING ERROR:

+/- (1%H+0.004”) or ±(1%H+0.1)MM

H = actual thickness of the object to be

measured

ADJUSTING RANGE OF SOUND VELOCITY

0.039 to 0.3937in/us or (1000-9999 M/S)

MEASUREMENT OF SOUND VELOCITY WITH

KNOWN THICKNESS VALUE:

MEASUREMENT RANGE:

37-373 MILES/MIN (1000-9999 M/S)

IF THICKNESS IS LESS THAN 0.8” (20mm):

+/- 0.004”H x 100% or ±1mm/H X 100%

IF THICKNESS IS GREATER THAN 0.8” (20mm)

±5%

RANGE OF OPERATING TEMPERATURE:

32-104 DEGREES F (0-40 DEGREES C)

POWER SUPPLY:

TWO AAA BATTERIES

POWER CONSUMPTION:

3 Volts at less than 20MA

Auto Power Off

2Minutes

DIMENSIONS:

4.3 X 2.4 X 0.9IN

WEIGHT:

4.7oz

4

Model 15947/15949

1. LCD Screen 2. Calibration Block

3. Increase/Change Setting/Backlight 4. Decrease/Change Setting/AutoCalibrat

5. Power On/Off 6. Menu Program/Save

7. Probe Ports

7

1

5

3

6

4

2

UTG-

5

Model 15947/15949

1. LCD Screen 2. Test Shim

3. Increase/Change Setting/Backlight 4. Decrease/Change Setting/Auto

Calibration

5. Power On/Off 6. Menu Program/Save

7. Probe Ports 8. Memory Recall (15947/15949 Only)

9. Store Data (15947/15949 Only)

7

1

9

5

4

2

6

8

3

UTG-

6

MODEL 15947/15949

1. LCD Screen 2. Calibration Pad

3. Increase/Change Setting/Backlight 4. Decrease/Change Setting/Auto

Calibration

5. Power On/Off 6. Menu Program/Save

7. Probe Port 8. Memory Recall (15947/15949 Only)

9. Store Data 10. RS-232/Printer Port

7

10

1

3

8

6

2

4

5

7

4) MAIN FUNCTIONS

•Automatic error correction capabilities

•Automatic linear compensation to improve accuracy (involves the correction of

non-linear errors resulting from the probe).

•Up and down keys allow for quick adjustment of sound velocity and thickness,

as well as fast checking of memory unit.

•Automatic coupling icon indicates the coupling state: stable/unstable.

•Direct determination of the sound velocity according to the thickness of the

master testing block.

•Low battery indicator

Automatic instrument shut down during idle use period

4.1) PREPARING FOR MEASUREMENT

Place the probe into the probe socket of the unit , push to turn the unit on. After a few

seconds, the screen will display 0.00in, 0.000in, 0.0mm, or 0.00mm (depending on previous

setting), the sound velocity used during the last testing procedure along with the probe type

and location. (See Below)

5) SETTING PARAMETERS

A) Press the button. The screen will display as follows:

Model# 15947 Model# 15949

1. Measurement 1. Measurement

2. Velocity 2. Velocity

3. Probe Setting 3. Probe Setting

4. Resolution 4. Resolution

5. Location 5. Location

6. Limitation 6. Default

7. Average

8. Print

9. Default

Note: 1. Measurement = Main test screen

0.000IN

VEL:0.230 PT-12

0.00mm

VEL:5920m/s PT-12

8

5.1) Velocity

Press the button once to select 2. Velocity. Press the button to enter into the

velocity parameter. The screen will display as follows:

a) Vel. Setting

Press the button to enter VEL SETTING. Use the button to move the cursor from

column to column. Use the button to change the number value. When the parameter has

been set, press the button to save entry.

b) Vel.Measuring

In the normal measurement mode, take a thickness reading on the sample to be tested. Press

the button to enter the menu mode. Press the button to move the cursor to the 2.

Velocity menu. Press the button to enter this mode. Then press the button to move

the cursor to 2. Velocity Measuring. Next press the button to enter this mode. The screen

looks similar to this.

Press the button and the button to change the sound velocity parameter such that

the thickness number agrees with the actual thickness of the sample being measured.

Press the button to accept this velocity and exit the Velocity menu.

To measure the sound velocity of a specific material, use a testing block with a known thickness value. Similar to the measurement

of the materials thickness, use a vernier caliper or micrometer to obtain an accurate measurement of the testing block. Then couple

the probe to the testing block until a thickness value is displayed. Remove the probe and use the keypad to adjust the displayed

value to match the actual thickness of the testing block.

5.2 PROBE SELECTION

A) Press the button and scroll down to: 3. PROB SETTING.

Press the button to enter parameter.

Using the arrow keys, select your probe type and highlight the number. Press the button to

select and store in memory. (This gage is supplied with a PT-12 probe)

Visible on first screen:

Visible on 2

nd

screen:

1. Vel. Setting

2. Vel. Measuring

INPUT VELOCITY

5920 m/s

INPUT THICKNESS

2.016in 0.2340

1. PT-12

1.0-200

2. PT-06

0.8-50

3. ZT-12

2.0-250

4. GT-13

3.0-100

9

5.4 LOCATION (Memory Groups)

*Models 15947 & 15949only

•Model# 15949 has a memory capacity of 2000 measurements. These can be stored in

any group from 0000 to 1999.

•Model# 15947 has a memory capacity of 4000 measurements. These can be stored in

any group from 0000 to 3999.

To choose a specific memory location, you must go to the main menu and scrol down to

#5 LOCATION. Press the button to enter location parameter. The screen will display

input location and show the four digits for entering and recording your desired memory location.

Using the button, choose your desired numeral for the first column. Using the

button, change the column. Continue to change numerals and columns in this manner. When

the desired memory location has been chosen, press the button to save this entry.

Method of saving your measurement:

1) Take a measurement of the sample piece to be tested. As soon as the measurement is

displayed on the LCD screen, you must push the button to save the measurement in

your chosen memory location. For each time you save a measurement, the gauge will

automatically store the chosen value in the next consecutive memory location.

For instance, if you chose your first memory location to be 0560. That number will be your first

saved value. The next saved measurement value will be stored in location number 0561 and so

on. You can always change your location group at any time by following the instructions in the

previous paragraph.

Test#1 Test#2

5.5 MEMORY RECALL

if you need to start retrieving measurements starting from 0001, you should be in the main test

screen. Press the button and the gauge will display the measurement saved in memory

location 0001. You can press the button as many times as you need to display the saved

values in ascending order.

Example: push the button and the display will show location 0001. Push the same button

again and the display will show the saved value from location 0002, etc.

INPUT LOCATION

0001

3.02mm

VEL:5920 PT-12 LOC: 0002

3.02mm

VEL:5920 PT-12 LOC: 0003

10

5.6 LIMITATION (Model# 15947 only)

Press the button and return to the main menu. Scroll down until you see the

6. LIMITATION. Press the button to enter the limitation parameter.

Set your lower limit by pressing the button to advance the numerals. Press the

button to change your column. Proceed to enter upper limit using the same method. When the

data has been entered to your requirements, you must press the button to save the entry.

While taking measurements, if your value is lower than the set limit, the letter “ L” will be

displayed in the top right corner of the LCD screen. If the value is greater than the set limit, the

letter “H” will appear in the top right corner of the screen.

5.7 AVERAGE (Model# 15947 only)

The mean value can be achieved by programming from 2 to 9 times.

Example: If you need to show an average after 3 tests, you would enter 3 as your average

number. You then perform 3 tests(SEE DIRECTIONS BELOW) and the gauge will then display

the average of those 3 tests. If you need an average displayed after 9 tests(maximum), you

should enter 9 as your average number.

Press the button and proceed to 7.AVERAGE. Press the button to enter parameter.

Using th button, change the number form 2 to 9. Press the button to save entry.

a) Directions for testing for averages:

1)

Place the probe on your test sample. Get your measurement value.

2) Remove the probe from the test sample. Wait for 3 seconds. The gauge will “beep” and the

average number shown on the LCD screen will descend from 3 to 2.

3) Perform this procedure again. Wait for the beep and the gauge will change the average

number from 2 to 1.

4) Perform the 3rd and final test. Remove the probe from the test sample. The gauge will beep

and automatically show the average of the 3 tests you just performed.

Note: a new average time must be entered before each set to be performed.

LO. LIM. 00.00mm

UP. LIM. 99.00mm

AVERAGE TIMES

3

11

5.8 PRINTING (Model# 15947 only)

If you want to print the stored values, you must first determine the initial location number and

the last location number to be printed.

•Press the button to enter main menu. Scroll down to the 8.PRINT.

•Press the button to enter parameter.

•The display will show a start location and an end location.

•Use the button to change the numerals

•Use the button to change the columns.

•When the data entry has been set, press the button to save this entry.

•The gauge will automatically begin displaying and printing all values stored in the entered

location numbers.

a) Printing to your PC

(Model# 15947 only)

•Follow the instructions noted above. Instaed of printing to your mini-printer, the values will

be displayed on your PC screen.

Note: Use supplied cables to connect the gauge to the PC.

6) TESTING PROCEDURE

•Assuming all parameters have been entered, place a small drop of coupling gel

(supplied) to the surface of the sample to be tested.

NOTE

:

Do not apply Gel to the probe as that may result in attempted measurements with no sample

touching the probe.

•Place the probe directly on the gel spot holding steady and firm. Do not move the probe

until the measured value has been displayed. At this time, you can remove the probe from

the test sample.

Note: Coupling gel must be used to perform all ultrasonic tests.

7) CALIBRATION

Each time the probe or battery is changed, a calibration should be performed in order to

guarantee measuring accuracy. If necessary, repeat the calibration several times. Adjust the

sound velocity to 2330in/us (5981m/s) (steel/iron).

•Apply the coupling gel to the testing block(see fig. 1, #6) (metallic disc on face of

gage), which is built into the unit, and couple the probe to the testing block. At this time,

the screen displays .157in(4mm),. This indicates that the calibration is over. If the screen

displays something other than .157in (4mm), you should press the button and the

gauge will automatically calibrate itself to .157in(4mm).

At that time, you can begin to perform your testing.

START LOC. 0000

END LOC. 0000

12

8) MEASURING THE THICKNESS

Apply the coupling gel to the material to be measured and then couple the probe to the

material. This will begin the measurement, and the screen will then display the thickness of the

material (see fig.2).

NOTE: when the probe is coupled to the material, a coupling indicator will be displayed on the LCD

screen. If the coupling indicator flickers or does not appear, the coupling process is erroneous or

incomplete.

Once a thickness measurement has been obtained, remove the probe. The thickness value will remain on

the LCD screen, however, the coupling indicator will disappear (see fig.3)

NOTE

:

Do not apply Gel to the probe as that may result in attempted measurements with no sample

touching the probe.

* AUTOMATIC SHUT-OFF

If the 15947/15949 remains idle for 2 minutes, the unit will automatically shut off.

* PRECAUTIONS

The surface of the probe is made of Polypropylene resin and is very sensitive to heavy scratches and rough

surfaces. Therefore, it is recommended to apply only a light to moderate amount of pressure on the probe during

testing.

The temperature of the surface of the object to be measured should not exceed 140°F (60°C).

Keep the 15947/15949 clean and avoid exposure to dust, iron chips, carbon particles.

10) MAINTENANCE

10.1) REPLACING THE BATTERIES

Once the low battery indicator appears on the screen, the batteries should be replaced.

Use the following procedure when replacing the batteries.

•Power unit off or wait until the unit turns off automatically.

•Open the battery compartment by pressing your thumb down on the cover and sliding it outwards.

•Remove the used batteries and insert new batteries into the compartment, paying close attention to the

polarity of the battery.

10.2) STORING THE GAGE

Be sure to clean the probe and cable after each use. Grease, oil and dust will cause the cable of the probe to age

and crack.

If the unit is not to be used for a long period of time, remove the batteries to avoid battery leakage and corrosion

of the battery contacts.

Avoid storing the unit in a damp or extremely hot environment.

13

Inch to Millimeter Conversion Table

Decimals to Millimeters Fractions to Decimals to Millimeters

Decimal mm Decimal mm Fraction Decimal mm Fraction Decimal mm

0.001 0.0254 0.500 12.7000 1/64 0.0156 0.3969 33/64 0.5156 13.0969

0.002 0.0508 0.510 12.9540 1/32 0.0312 0.7938 17/32 0.5312 13.4938

0.003 0.0762 0.520 13.2080 3/64 0.0469 1.1906 35/64 0.5469 13.8906

0.004 0.1016 0.530 13.4620

0.005 0.1270 0.540 13.7160

0.006 0.1524 0.550 13.9700 1/16 0.0625 1.5875 9/16 0.5625 14.2875

0.007 0.1778 0.560 14.2240

0.008 0.2032 0.570 14.4780 5/64 0.0781 1.9844 37/64 0.5781 14.6844

0.009 0.2286 0.580 14.7320 3/32 0.0938 2.3812 19/32 0.5938 15.0812

0.580 14.7320 7/64 0.1094 2.7781 39/64 0.6094 15.4781

0.010 0.2540 0.590 14.9860

0.020 0.5080

0.030 0.7620

0.040 1.0160 0.600 15.2400

0.050 1.2700 0.610 15.4940 1/8 0.1250 3.1750 5/8 0.6250 15.8750

0.060 1.5240 0.620 15.7480

0.070 1.7780 0.630 16.0020

0.080 2.0320 0.640 16.2560 9/64 0.1406 3.5719 41/64 0.6406 16.2719

0.090 2.2860 0.650 16.5100 5/32 0.1562 3.9688 21/32 0.6562 16.6688

0.660 16.7640 11/64 0.1719 4.3656 43/64 0.6719 17.0656

0.100 2.5400 0.670 17.0180

0.110 2.7940 0.680 17.2720

0.120 3.0480 0.690 17.5260 3/16 0.1875 4.7625 11/16 0.6875 17.4625

0.130 3.3020

0.140 3.5560

0.150 3.8100 13/64 0.2031 5.1594 45/64 0.7031 17.8594

0.160 4.0640 0.700 17.7800 7/32 0.2188 5.5562 23 8/25 0.7188 18.2562

0.170 4.3180 0.710 18.0340 15/64 0.2344 5.9531 47/64 0.7344 18.6531

0.180 4.5720 0.720 18.2880

0.190 4.8260 0.730 18.5420 1/4 0.2500 6.3500 3/4 0.7500 19.0500

0.740 18.7960

0.200 5.0800 0.750 19.0500

2.210 5.3340 0.760 19.3040 17/64 0.2656 6.7469 49/64 0.7656 19.4469

0.220 5.5880 0.770 19.5580 9/32 0.2812 7.1438 25/32 0.7812 19.8438

0.230 5.8420 0.780 19.8120 19/64 0.2969 7.5406 51/64 0.7969 20.2406

0.240 6.0690 0.790 20.0660

0.250 6.3500

0.260 6.6040

0.270 6.8580 0.800 20.3200 5/16 0.3125 7.9375 13/16 0.8125 20.6375

0.280 7.1120 0.810 20.5740 21/64 0.3281 8.3344 53/64 0.8281 21.0344

0.290 7.3660 0.820 20.8280 11/32 0.3438 8.7312 27/32 0.8438 21.4312

0.300 7.6200 0.830 21.0820 23/64 0.3594 9.1281 55/64 0.8594 21.8281

0.310 7.8740 0.840 21.3360

0.320 8.1280 0.850 21.5900 3/8 0.3850 9.5250 7/8 0.8750 22.2250

0.330 8.3820 0.860 21.8440

0.340 8.6360 0.870 22.0980 25/64 0.3906 9.9219 57/64 0.8906 22.6219

0.350 8.8900 0.880 22.3520 13/32 0.4062 10.3188 29/32 0.9062 23.0188

0.360 9.1440 0.890 22.6060 27/64 0.4219 10.7156 59/64 0.9219 23.4156

0.370 9.3980

0.380 9.6520

0.390 9.9060 0.900 22.8600

0.400 10.1600 0.910 23.1140 7/16 0.4375 11.1125 15/16 0.9375 23.8125

0.410 10.4140 0.920 23.3680

0.420 10.6680 0.930 23.6220

0.430 10.9220 0.940 23.8760

0.440 11.1760 0.950 24.1300 29/64 0.4531 11.5094 61/64 0.9531 24.3094

14

0.450 11.4300 0.960 24.3840 15/32 0.4688 11.9062 31/32 0.9688 24.6062

0.460 11.6840 0.970 24.6380 31/64 0.4844 12.3031 63/64 0.9844 25.0031

0.470 11.9380 0.980 24.8920

0.480 12.1920 0.990 25.1460

0.490 12.4460 1.000 25.4000 1/2 0.5000 12.7000 1 1.0000 25.4000

Millimeter to Inch Conversion Table

mm Decimal mm Decimal mm Decimal mm Decimal mm Decimal

0.01 0.00039 0.41 0.01614 0.81 0.03189 21 0.82677 61 2.40157

0.02 0.00079 0.42 0.01654 0.82 0.03228 22 0.86614 62 2.44094

0.03 0.00118 0.43 0.01693 0.83 0.03268 23 0.90551 63 2.48031

0.04 0.00157 0.44 0.01732 0.84 0.03307 24 0.94488 64 2.51969

0.05 0.00197 0.45 0.01772 0.85 0.03346 25 0.98425 65

0.06 0.00236 0.46 0.01811 0.86 0.03386 26 1.02362 66 2.59843

0.07 0.00276 0.47 0.01850 0.87 0.03425 27 1.06299 67 2.63780

0.08 0.00315 0.48 0.01890 0.88 0.03465 28 1.10236 68 2.67717

0.09 0.00354 0.49 0.01929 0.89 0.03504 29 1.14173 69 2.71654

0.10 0.00394 0.50 0.01969 0.90 0.03543 30 1.18110 70 2.75591

0.11 0.00433 0.51 0.02008 0.91 0.03583 31 1.22047 71 2.79528

0.12 0.00472 0.52 0.02047 0.92 0.03622 32 1.25984 72 2.83465

0.13 0.00512 0.53 0.02087 0.93 0.03661 33 1.29921 73 2.87402

0.14 0.00551 0.54 0.02126 0.94 0.03701 34 1.33858 74 2.91339

0.15 0.00591 0.55 0.02165 0.95 0.03740 35 1.37795 75 2.95276

0.16 0.00630 0.56 0.02205 0.96 0.03780 36 1.41732 76 2.99213

0.17 0.00669 0.57 0.02244 0.97 0.03819 37 1.45669 77 3.03150

0.18 0.00709 0.58 0.02283 0.98 0.03858 38 1.49606 78 3.07087

0.19 0.00748 0.59 0.02323 0.99 0.03898 39 1.53543 79 3.11024

0.20 0.00787 0.60 0.02362 1.00 0.03937 40 1.57480 80 3.14961

0.21 0.00827 0.61 0.02402 1 0.03937 41 1.61417 81 3.18898

0.22 0.00866 0.62 0.02441 2 0.07874 42 1.65354 82 3.22835

0.23 0.00906 0.63 0.02480 3 0.11811 43 1.69291 83 3.26772

0.24 0.00945 0.64 0.02520 4 0.15748 44 1.73228 84 3.30709

0.25 0.00984 0.65 0.02559 5 0.19685 45 1.77165 85 3.34646

0.26 0.01024 0.66 0.02598 6 0.23622 46 1.81102 86 3.38583

0.27 0.01063 0.67 0.02638 7 0.27559 47 1.85039 87 3.42520

0.28 0.01102 0.68 0.02677 8 0.31496 48 1.88976 88 3.46457

0.29 0.01142 0.69 0.02717 9 0.35433 49 1.92913 89 3.50394

0.30 0.01181 0.70 0.02756 10 0.39370 50 1.96850 90 3.54331

0.31 0.01220 0.71 0.02795 11 0.43307 51 2.00787 91 3.58268

0.32 0.01260 0.72 0.02835 12 0.47244 52 2.04724 92 3.62205

0.33 0.01299 0.73 0.02874 13 0.51181 53 2.08661 93 3.66142

0.34 0.01339 0.74 0.02913 14 0.55118 54 2.12598 94 3.70079

0.35 0.01378 0.75 0.02953 15 0.59055 55 2.16535 95 3.74016

0.36 0.01417 0.76 0.02992 16 0.62992 56 2.20472 96 3.77953

0.37 0.01457 0.77 0.03032 17 0.66929 57 2.24409 97 3.81890

0.38 0.01496 0.78 0.03071 18 0.70866 58 2.28346 98 3.85827

0.39 0.01535 0.79 0.03110 19 0.74803 59 2.32283 99 3.89764

0.40 0.01575 0.80 0.03150 20 0.78740 60 2.36220 100 3.93701

15

All velocities are approximations:

SOUND VELOCITY MEASUREMENT CHART

Material Sound Velocity

Inch/µS M/s

Air 0.013 330

Aluminum 0.250 6300

Alumina Oxide 0.390 9900

Beryllium 0.510 12900

Boron Carbide 0.430 11000

Brass 0.170 4300

Cadmium 0.110 2800

Copper 0.180 4700

Glass(crown) 0.210 5300

Glycerin 0.075 1900

Gold 0.130 3200

Ice 0.160 4000

Inconel 0.220 5700

Iron 0.230 5900

Iron (cast) 0.180 4600

Lead 0.085 2200

Magnesium 0.230 5800

Mercury 0.057 1400

Molybdenum 0.250 6300

Monel 0.210 5400

Neoprene 0.063 1600

Nickel 0.220 5600

Nylon, 6.6 0.100 2600

Oil (SAE 30) 0.067 1700

Platinum 0.130 3300

Plexiglass 0.110 1700

Polythylene 0.070 1900

Polystyrene 0.0930 2400

Polyurethane 0.0700 1900

Quartz 0.230 5800

Rubber, Butyl 0.070 1800

Silver 0.140 3600

Steel, Mild 0.230 5900

Steel, Stainless 0.230 5800

Teflon 0.060 1400

Tin 0.130 3300

Titanium 0.240 6100

Tungsten 0.200 5200

Uranium 0.130 3400

Water 0.584 1480

Zinc 0.170 4200

•Note: To calibrate the 15947 or 15949 , you must set the velocity to 0.2330/5981M/S (Steel) as stated

in Sect. 7 Calibration, on page 7.

This manual suits for next models

1

Table of contents