Prins Maasdijk SPRINTER User manual

USER MANUAL

SPRINTER

& TRIKE

Prins Maasdijk, Jul-20

Prins Maasdijk, Jul-20

C

CO

ON

NT

TE

EN

NT

TS

S

1. FOREWORD ............................................................................................... 2

2. IMPORTANT .............................................................................................. 3

3. GENERAL SAFETY REQUIREMENTS ................................................................... 4

4. OVERVIEW OF MACHINE AND CONTROLS .......................................................... 6

4.1 Overview of machine ..................................................................................... 6

4.3 Overview of controls ..................................................................................... 7

4.4 Overview of central dashboard ......................................................................... 7

5 OPERATING THE FORKLIFT TRUCK ................................................................... 8

5.1 Adjustments ................................................................................................ 8

5.1.1 Steering column adjustment ......................................................................... 8

5.1.2 Seat adjustment ......................................................................................... 9

5.2 Starting and stopping the engine ..................................................................... 10

5.3 Moving off and stopping the forklift truck ........................................................ 13

5.4 Optional ................................................................................................... 15

5.5 Manoeuvring ............................................................................................... 16

5.7. Loading and unloading of goods ..................................................................... 17

5.8 Use of the tow hook (Prins Sprinter only) ......................................................... 20

6 MAINTENANCE THE FORKLIFT TRUCK ........................................................ 21

6.1 Drive train .................................................................................................. 21

6.2. Engine ...................................................................................................... 22

6.2.1 Engine ................................................................................................... 22

6.2.2 Set-up for towing..................................................................................... 24

6.2.3 Cooling water system ............................................................................... 24

6.2.4 Fuel filter for Sprinter and Trike with diesel engine ........................................ 25

6.2.5 Air filter ................................................................................................ 27

6.2.6 Battery .................................................................................................. 28

6.2.7 Fanbelt ..................................................................................................... 29

6.3 Miscellaneous maintenance tasks ..................................................................... 29

6.4 Electrical system .......................................................................................... 31

7. SUMMARY OF MAINTENANCE INTERVALS ........................................................ 32

8. TROUBLESHOOTING .................................................................................. 33

8.1 Vehicle ..................................................................................................... 33

8.2 Engine ...................................................................................................... 33

9 SPRINTER & TRIKE TECHNICAL SPECIFICATIONS ................................................ 36

10 ELECTRICAL CIRCUIT DIAGRAM ..................................................................... 38

Sprinter & Trike User Manual

Prins Maasdijk, Jul-20

Sprinter & Trike User Manual Foreword

Prins Maasdijk, Jul-20

2

1

1.

.

F

FO

OR

RE

EW

WO

OR

RD

D

Congratulations on your purchase of a Prins Sprinter or Prins Trike forklift truck manufactured

by Prins Maasdijk.

You will find all the important information you need to operate and maintain your forklift truck in

this manual. We recommend that you read through this manual carefully before taking the

forklift truck into use. Anyone using the machine is also recommended to read carefully through

the manual. Having read it, keep the manual where it can readily be found, so that essential

information about maintenance, defects and so on is always to hand.

If you need to order parts for your Prins forklift truck or if you have any questions or

observations, please contact Prins Maasdijk.

Please mention the machine's service and serial numbers in any correspondence with Prins

Maasdijk. These numbers appear on the plates mounted at top left and right of the steering

column. See Figure 1.1.

We trust you will enjoy many years of productive service from your new forklift truck.

Prins Maasdijk

Figure 1.1 | Service number and serial number

Type plate (colour: black):

1. Make

2. Type

3. Serial number

4. Capacity

5. Deadweight

6. Year of construction

Service plate (colour: grey):

1. Service number

Sprinter & Trike User Manual Important

Prins Maasdijk, Jul-20

3

2

2.

.

I

IM

MP

PO

OR

RT

TA

AN

NT

T

This manual includes important information on the correct and safe use of your forklift truck.

Follow the instructions set out in this manual at all times.

At various points in this manual you will see the following symbol:

Note! Important information.

When you see this symbol, read the adjacent text carefully before starting the relevant

operation. This information relates to the safety of yourself and others. Stay alert and prevent

hazardous situations developing.

Sprinter & Trike User Manual General safety requirements

Prins Maasdijk, Jul-20

4

3

3.

.

G

GE

EN

NE

ER

RA

AL

L

S

SA

AF

FE

ET

TY

Y

R

RE

EQ

QU

UI

IR

RE

EM

ME

EN

NT

TS

S

When working with or servicing the forklift truck you must be aware of the associated hazards.

Take full account of the safety rules. Failure to do so may result in serious physical injury to

yourself or others.

It is impossible for the manufacturer to foresee every hazardous situation that might arise. You

as the user therefore have a responsibility to look out for your own safety and that of others

during the use and maintenance of the forklift truck. Always use the tools and consumables

recommended by the manufacturer. Only original components should be used as replacements.

For your own safety and that of others:

Never overload the forklift truck above the maximum permitted load indicated on the load

chart (see also Figure 5.12) on the machine.

Take careful note of the load diagram, which is located on the forklift truck's engine cover.

If you are forced by circumstances to lift a load on a single fork, take into account that the

maximal permitted load will be halved. However you must try to avoid doing this if at all

possible.

Keep the speed low when travelling with a load (never use top speed!) and keep the load as

close as possible to the ground.

With a raised load, keep the speed as low as possible and take account of the clearance

height of the forklift truck.

Complete the required safety checks on the machine before starting to work with it. You

must never start work with the forklift truck without completing these checks. Particular

attention should be paid to the tyres, the battery, the brakes, the steering system, the fuel

system and the electrical components. This will help to prevent accidents.

Fuel must never be added while the engine is running. No smoking is permitted while

refuelling or while replacing or topping up the oil, and no open flames or sparks may be

present in the immediate vicinity. Explosive gases are released during refuelling.

Remove any spillages from the machine following refuelling or replenishment with oil.

Before refuelling or replenishing the oil, check for any traces of leakage and establish where

these are coming from. If they are the result of a technical defect, have this repaired before

working with the forklift truck.

Always apply the handbrake and place the gear lever in neutral when leaving the forklift

truck.

An incorrect sitting position can lead to accidents. You should therefore start by adjusting the

seat so that you have good visibility and easy access to all controls.

The forklift truck must never be used without the safety cage or the roll bar (fitted as

standard).

A safety belt must be used when the forklift truck is in operation.

Sprinter & Trike User Manual General safety requirements

Prins Maasdijk, Jul-20

5

Always drive at a speed where you have the forklift truck under proper control. Excessive

speed can be hazardous to you and your environment. Sudden braking, acceleration or

turns can also result in a hazardous situation.

When driving the truck in and out of areas with limited headroom, take account of the

following points:

o Always check that there is sufficient space above and alongside the forklift truck.

o Keep all parts of your body within the safety cage at all times, keep your hands on the

steering wheel and your feet on or close to the pedals.

o Avoid hazardous situations when travelling.

Operate the controls gently. This will appreciably extend the service life of your forklift truck

and increase safety.

Never allow anyone to walk beneath the loaded forks. This is extremely dangerous.

Never carry passengers on the forklift truck, and do not use the forks to lift persons.

Loads should be allowed to descend gradually, with the forks horizontal or tilted slightly

back. Never lower the load with the forks tilted forwards.

There are numerous signs you can use to check the condition of the machine. Unusual

noises, vibration or changes in the response to the controls may indicate defects. If you

suspect a fault, take the machine out of use and stop the engine. Check the cause of the

defect and take the necessary measures to rectify it.

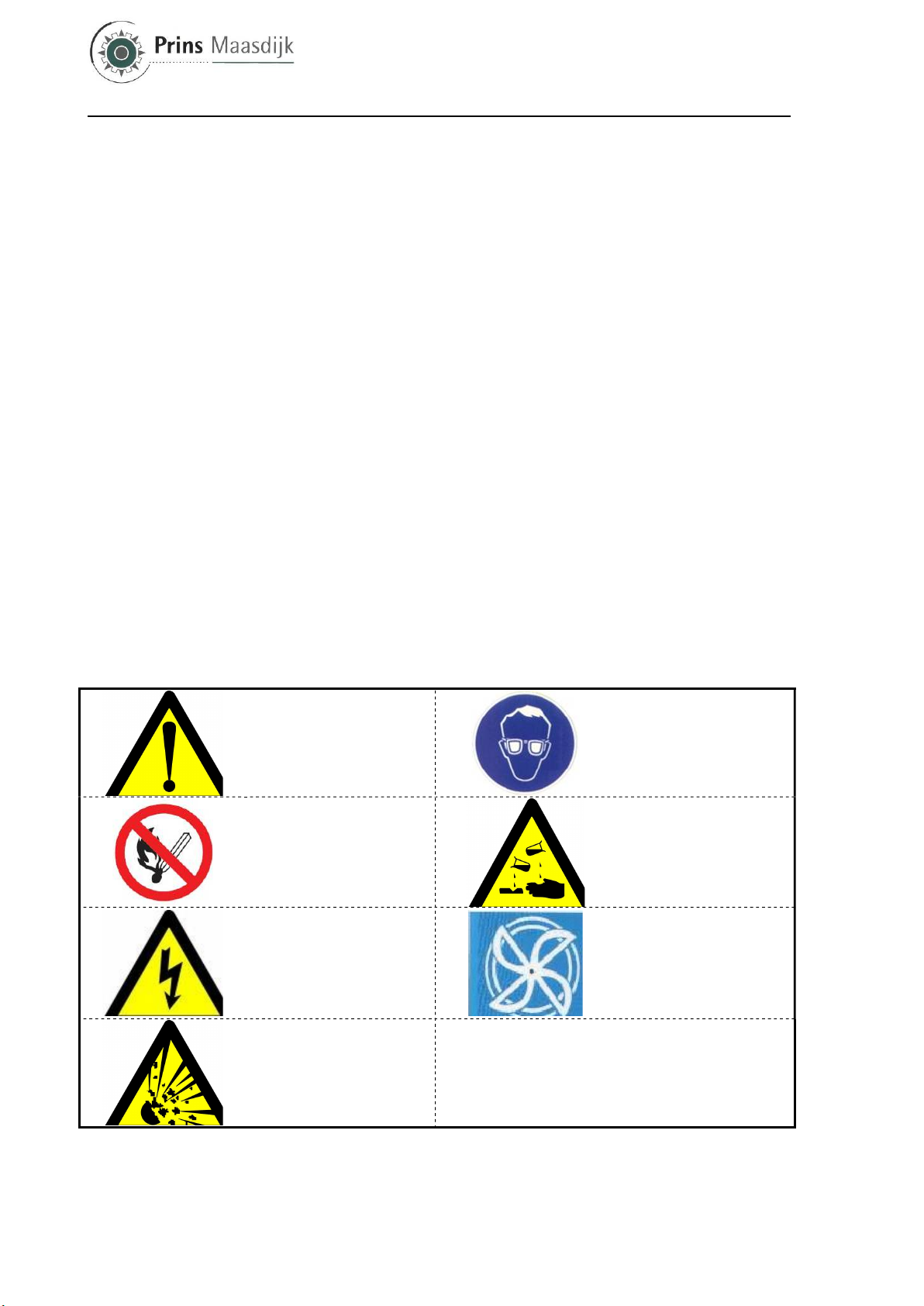

Table 3.1 | Meaning of safety symbols

Follow the safety

and operating

instructions

Wear safety

eyewear and

protective clothing

Smoking and open

flames are prohibited

Electrolyte is

strongly corrosive

Live electrics, avoid

contact

Areas where

batteries are stored

or charged must be

adequately

ventilated

Risk of explosion,

avoid short-circuits

Sprinter & Trike User Manual Overview of machine and controls

Prins Maasdijk, Jul-20

6

4

4.

.

O

OV

VE

ER

RV

VI

IE

EW

W

O

OF

F

M

MA

AC

CH

HI

IN

NE

E

A

AN

ND

D

C

CO

ON

NT

TR

RO

OL

LS

S

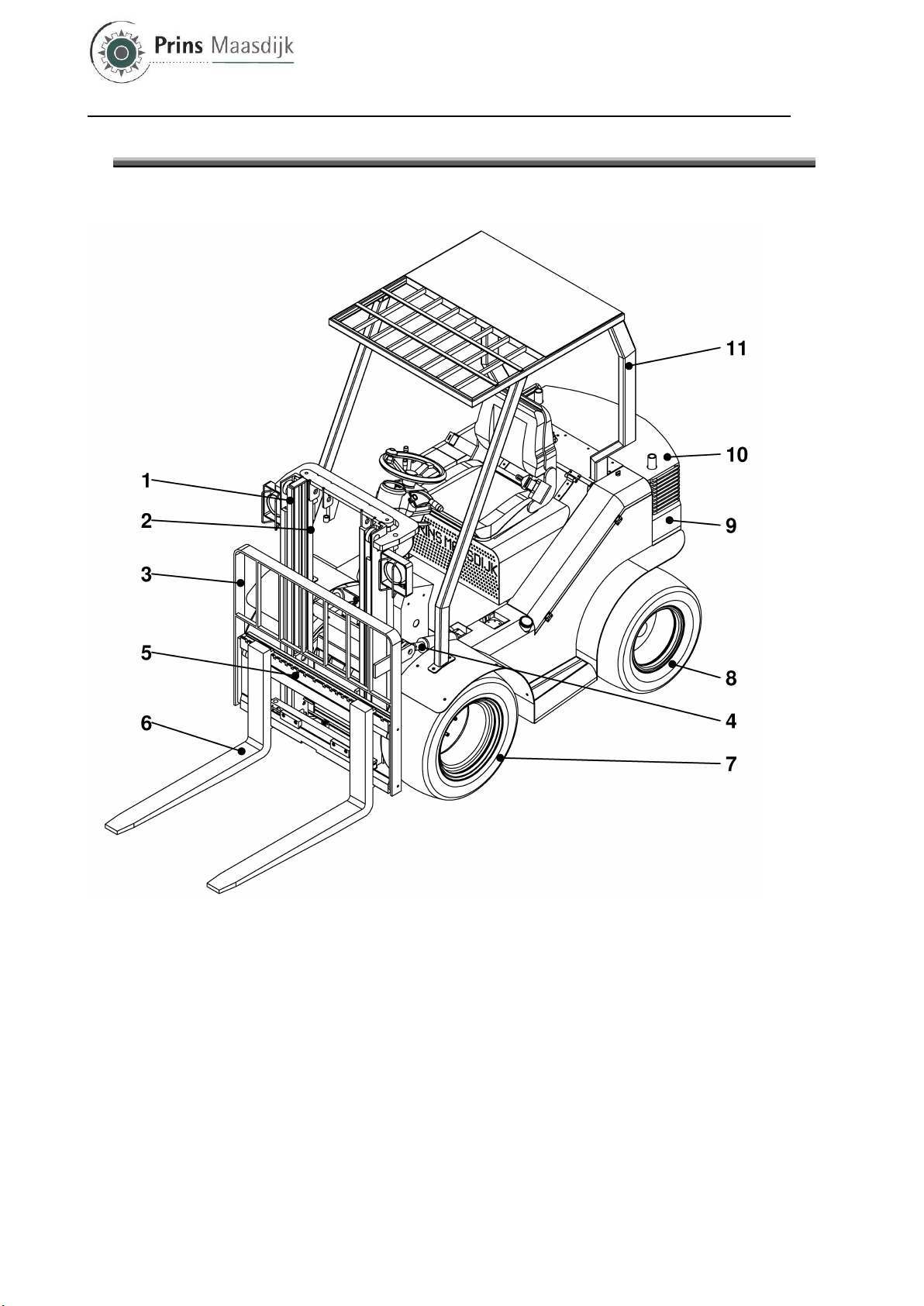

4.1

Overview of machine

Figure 4.1 | Overview

1 - Lifting mast

2 - Lifting cylinder

3 – Carriage load backrest

4 – Tilting cylinder

5 – Fork carriage

6 – Forks

7 – Front wheel

8 – Rear wheel (steered)

9 – Counterweight

10 – Ballast plates (separate)

11 – Safety cage

Sprinter & Trike User Manual Overview of machine and controls

Prins Maasdijk, Jul-20

7

4.3

Overview of controls

Figure 4.2 | Control dashboard

1. Combination switch

driving direction, gear, horn

2. Battery switch (optional)

3. Parking brake switch

4. Front lighting switch (optional)

5. Rear lighting switch (optional)

6. Ignition switch

4.4

Overview of central dashboard

The Prins Sprinter and Prins Trike feature a central dashboard which includes a number of

warning signals. The fuel gauge is located in the middle. This shows the fuel tank level for

diesel engines. For lpg-driven machines, the level gauge is mounted on the tank. Below the fuel

gauge is a counter registering the service hours during which the machine has been in

operation.

The following warning signals are displayed in figure 4.3.

Figure 4.3 | Signals

1. Parking brake lamp

2. Low oil pressure lamp

3. Charging current indicator

4. High coolant temperature

5. Pre-glow indicator

6. High gear indicator

7. Low gear indicator

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

8

5

5

O

OP

PE

ER

RA

AT

TI

IN

NG

G

T

TH

HE

E

F

FO

OR

RK

KL

LI

IF

FT

T

T

TR

RU

UC

CK

K

5.1

Adjustments

Adopt the correct seating position before starting the machine.

5.1.1

Steering column adjustment

Figure 5.1 | Steering column operation

1. Locked

2. Free

Rotate the lever to loosen it as indicated in Figure 5.1and place the steering column in a

comfortable position. Then retighten the lever by moving it upwards.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

9

5.1.2

Seat adjustment

The standard seat allows for longitudinal adjustment and adjustment of the angle of the back

support. The various adjustment options are shown in Figure 5.2. Adjust the seat to provide a

safe and comfortable sitting position.

Note! A safety belt must be worn at all times when operating the forklift

truck.

Figure 5.2 | Seat position

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

10

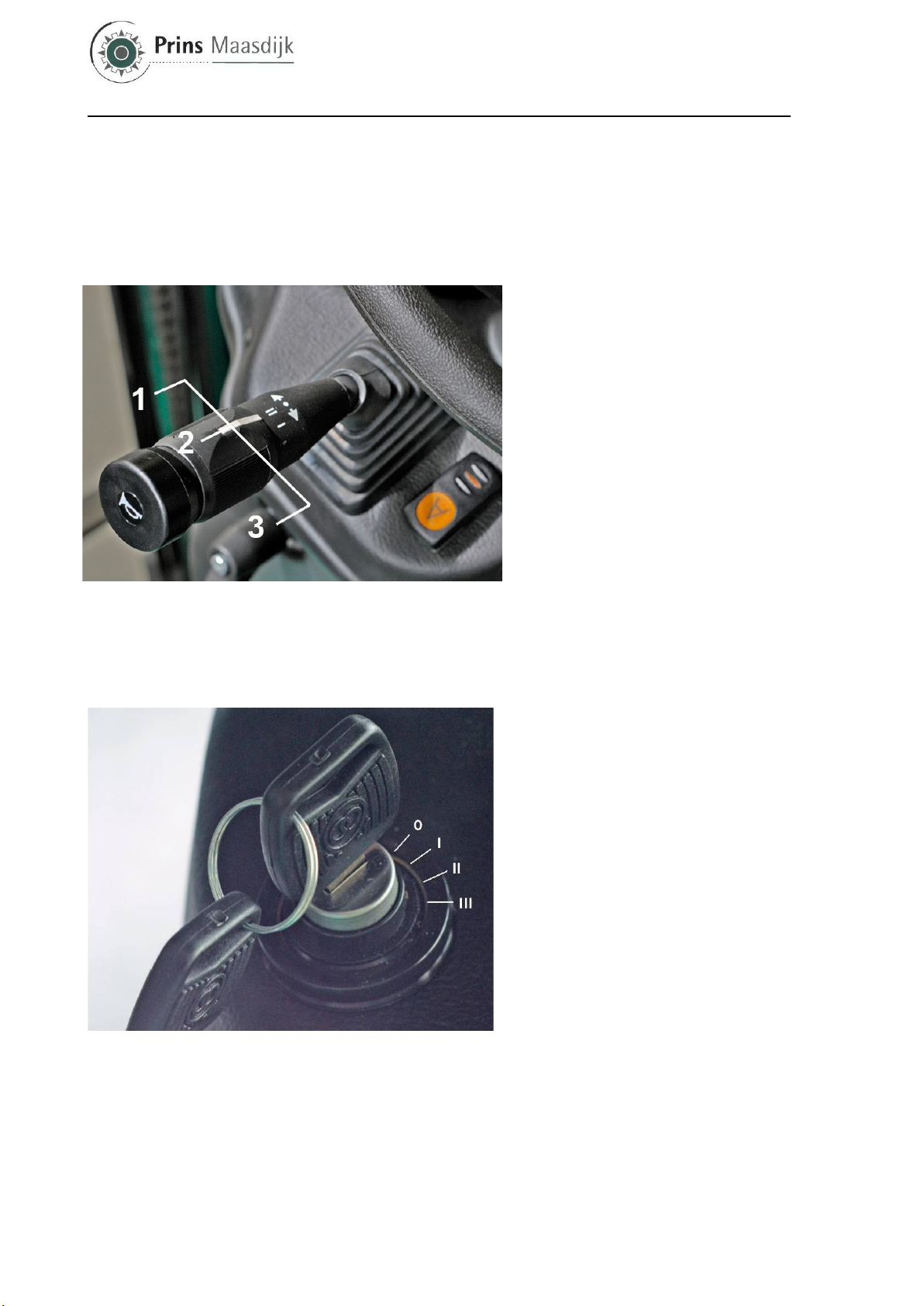

5.2

Starting and stopping the engine

1. Before starting the engine, ensure that the driving direction switch to the left of the steering

column is in its neutral position (see Figure 5.3). For lpg driven machines the valve above

the tank must be rotated to open it.

Figure 5.3 |Driving direction switch

1. Forward

2. Neutral

3. Reverse

2. Turn the ignition key to position "I".

The oil pressure and charging current lamps will both illuminate

Figure 5.4 | Ignition key

0. Off

I. Ignition on

II. Pre-glow

III. Start

2.1 Fork lift truck with diesel engine.

Once both lamps are illuminated, the ignition key should be further rotated to position "II".

The pre-glow lamp will now illuminate. Hold the ignition key in this position for around 5

seconds and then turn it on to position "III". The engine will now start. If you now release the

key it will return to position "I" and the engine will continue to run.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

11

Note! At very low ambient temperatures it may be necessary to pre-glow

for longer than 5 seconds. Table 5.1 indicates how long pre-glowing

should continue after the lamp is extinguished.

Temperature

Additional pre

-

glow time

Above 10°C Not required

Between

-

5°C and 10°C

5 seconds approx.

Below

-

5°C

10 seconds approx.

Maximal period of continuous pre-glowing 20 sec.

Table 5.1 | Pre-glow times

2.2 Fork lift truck with lpg engine

Once both lamps have illuminated, the ignition key should be rotated to position "III". the

engine will then start. The "II" position has no function in the lpg models.

3. If the engine does not start within 10 seconds, then return the ignition key to the "OFF"

position and wait 30 seconds before making a fresh attempt. Every fresh attempt should

start from step 1.

Note! The starter motor must not be allowed to operate continuously for

longer than 20 seconds.

4. Once the engine is running, check that the oil pressure and charging lamps are

extinguished. Where this is not the case, switch off the engine and check the following

possible causes.

Oil pressure lamp remains illuminated:

o Is the V belt broken?

o Is the oil filled to the correct level?

o Is the oil in the sump contaminated?

o Are there any short-circuits or other defects in the wiring?

Charging current lamp remains illuminated:

- Is the battery properly charged?

- Is the battery acid level correct?

- Are there any short-circuits or other defects in the wiring?

If you have checked these items and identified no defects, please contact your dealer.

5. Allow the engine to come up to temperature by running it at half speed without load.

6. If you wish to stop the engine, ensure that the gear lever to the left of the steering wheel is in

its neutral position. Also ensure that the forks are resting on the ground, in order to remove

any unnecessary loading from the lifting cylinders and prevent accidents. Rotate the ignition

key to the "OFF" position.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

12

Note! Before dismounting from the truck the gear lever must be placed in

its neutral position and the handbrake applied.

It is now safe to dismount from the forklift truck.

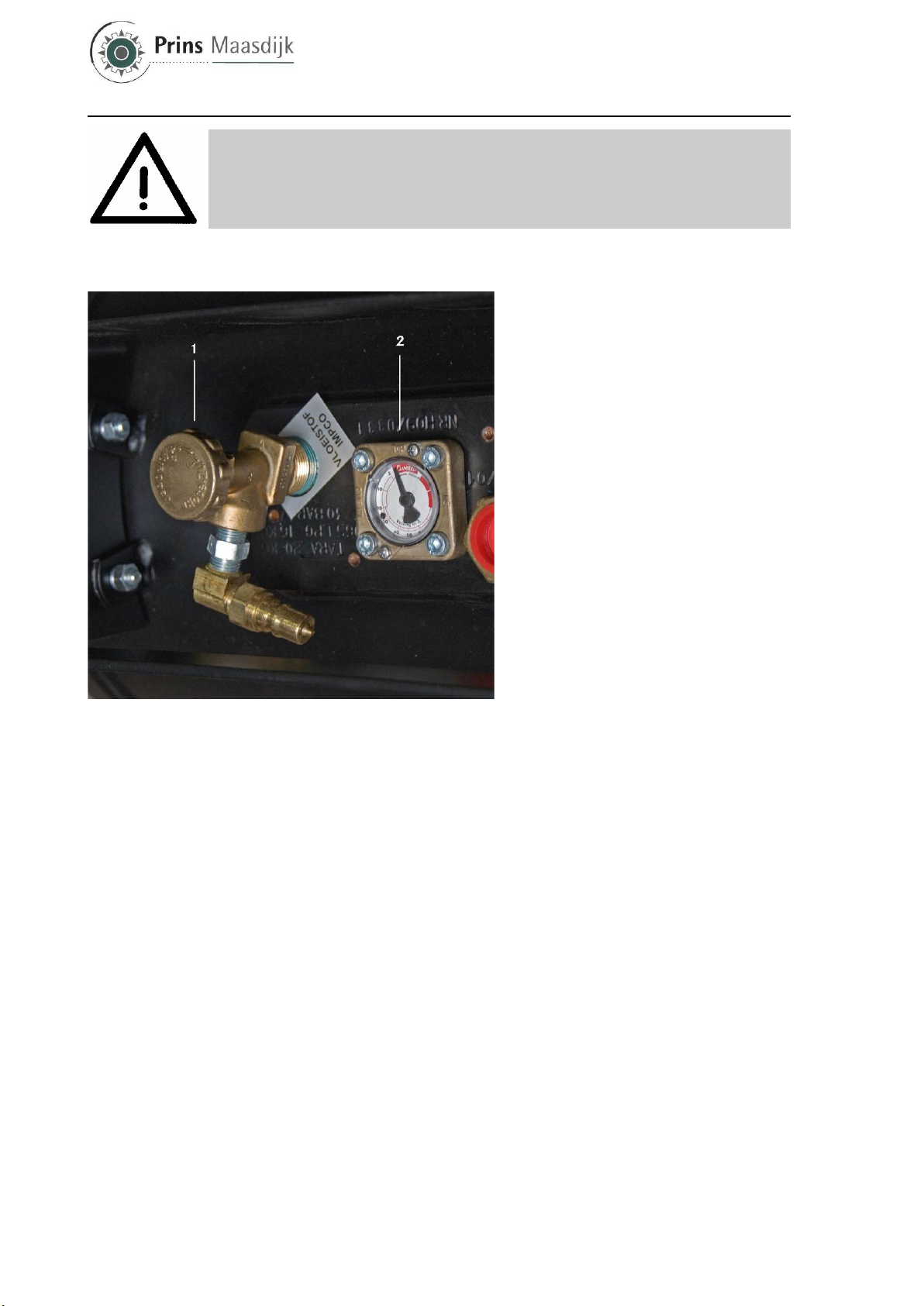

7. If an lpg driven machine is not to be used for an extended period, for example at the end of

the working day, the gas cylinder valve must be closed.

Figure 5.5 | Lpg tank

1. Shut-off valve

2. Level gauge

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

13

5.3

Moving off and stopping the forklift truck

The Prins Sprinter and Prins Trike are provided with a hydrostatic drive which allows fully

automatic driving. The direction of travel is selected using a selector switch on the steering

column.

Figure 5.6 | Direction selector switch

1. Forward

2. Neutral

3. Reverse

Lift the selector switch gently and move it forwards or backwards to select forward or reverse

travel. Operation of the accelerator will now move the machine in the desired direction. Where a

change of direction is required, the machine must first be stopped, and the switch can then be

moved to the appropriate position.

Figure 5.7 | Gear selector switch

The machine is provided with two gear positions, to allow a choice between additional speed

and additional traction. The choice between the two speeds is made using a rotary switch on

the steering column. It is not necessary to select first gear to drive away. It is recommended that

the desired gear should be identified and selected before moving off. First gear can always be

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

14

selected by default. The maximal traction is then available. This will provide the best ride

characteristics and the most constant speed of motion.

Where long distances are to be travelled and the load will not be at or close to maximum,

second gear may be selected. The speed of travel will then be increased. You must ensure that

the conditions, such as the state of the road surface, will permit such higher speeds.

It is possible to change the selected gear while moving at low speed. Always release the

accelerator during gear changes. Changing gear can cause a minor jolt in the drive train. This

will not harm the machine, but you must take account of possible effects on the load.

The two gears are indicated on the central dashboard using symbols depicting a hare and a

tortoise.

Figure 5.8 | Pedals

1. Brake pedal

2. Accelerator pedal

To bring the forklift truck to a stop, release the accelerator pedal and apply the brake pedal in a

controlled manner until the machine comes to a complete halt. Once the machine is at a

standstill, place the gear lever in its neutral position. The Prins Sprinter and Prins Trike with

automatic gearbox come equipped with an inching pedal as standard.

The machine is provided with an electrically operated parking brake. This is applied using a

switch on the dashboard. An indicator lamp on the central dashboard will indicate whether the

parking brake is switched on.

When dismounting from the forklift truck the forks must always be fully lowered and the parking

brake applied. The machine can not be driven away with the parking brake applied.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

15

Figure 5.9 | Parking brake switch

5.4

Optional

Figure 5.10 | accumulator switch

The machine can be fitted with an accumulator as an option. This is brought into operation

using the switch shown in Figure 5.10.

The accumulator acts as a shock damper for the load carried by the forklift truck. For effective

operation the accumulator must be set to the weight of the load being carried. You should

contact the Prins Maasdijk technical department or your dealer with any queries about this

system.

The accumulator may be damaged beyond repair if it is overloaded. The accumulator must be

switched off if travelling without a load or where the load carried is substantially (more than

25%) above the accumulator setting. The accumulator should also be switched off when precise

positioning of the load is required.

In some cases the position used for the accumulator switch may be used for a different optional

function. Check what optional equipment is fitted to your truck before operating and using this

control.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

16

5.5 Manoeuvring

The Trike is equipped with twin pneumatic tyres as standard. These provide stability in bends.

The Prins Sprinter and the Prins Trike are steered via the rear axle to provide the smallest

possible turning circle. Be aware when steering that the rear end will swing out.

When driving account must be taken at all times of any load carried on the forks. Anticipate any

unevenness in the road surface in good time, potholes and other obstacles may affect the

stability of the truck. If stability is seriously affected the load may fall from the forks.

Do not make sharp turns at high speed, whether a load is carried or not. The fork lift truck may

lose its stability and overturn.

Note! The rear end will swing out during manoeuvres. You must

therefore always ensure that there is adequate space around the

truck to allow safe manoeuvring.

Note! Unevenness of the road surface may interfere with the stability

of the fork lift truck and give rise to a risk of the load falling from the

forks.

Note! Making a sharp turn at high speed, whether a load is carried or

not, may affect the stability of the fork lift truck. Overturning the truck

may cause damage and injury to yourself or others.

Sprinter& Trike User Manual Operating the forklift truck

Prins Maasdijk, Jul-20

17

5.6

Operation of mast and forks

The forklift truck is equipped with two hydraulic functions as standard, the first to raise the load

and the second to tilt the mast. In most cases the machine will also be equipped with a side-

shift function to allow the load to be moved sideways. The installation of a fourth and even a fifth

hydraulic function is also possible. The various functions are all controlled via a valve block

located to the right of the driver.

Figure 5.11 | Hydraulic functions

1. Raising and lowering

2. Adjusting angle of tilt

3. Side-shift

4. Optional function

5.7.

Loading and unloading of goods

Note! Ensure that the load is correctly stacked and balanced at all times.

Falling loads may result in serious injury to the operator or others.

1. Place the forklift truck directly in front of the goods to be carried. Ensure that the load is

evenly distributed between the forks.

2. Ensure that the mast is not tilted forwards or backwards, then bring the forks to the

appropriate height.

3. Drive slowly forwards until the load comes up against the carriage backrest. Now raise the

load by 5 to 10 cm. It may happen that the load is not completely at the edge of the trailer or

storage racking. In that case you should insert the forks as far as possible and then raise

them slightly.

This manual suits for next models

1

Table of contents