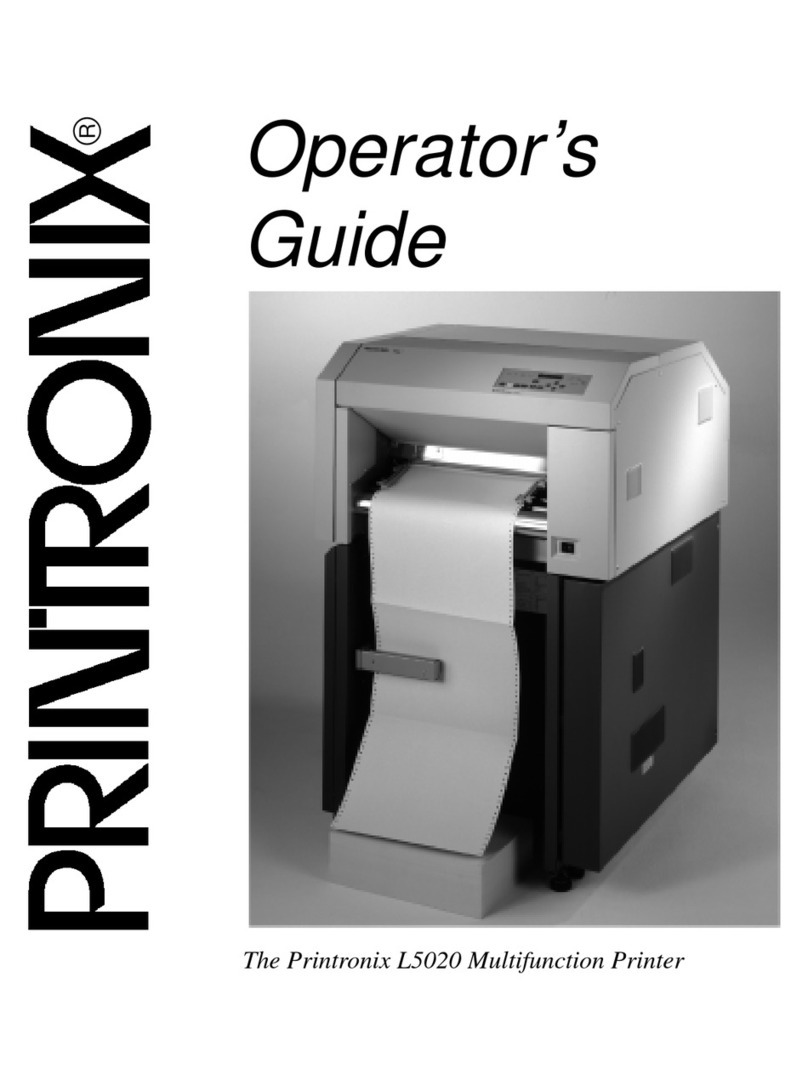

Printronix L5535 User manual

Maintenance Manual

Volume I of II

L5535 Multifunction Printer

Maintenance Manual

L5535 Multifunction Printer

Volume I of II

Trademark Acknowledgements

3M is a registered trademark of Minnesota Mining and Manufacturing

Company.

Postscript is a registered trademark of Adobe Systems, Inc.

Hitachi is a registered trademark of Kabushiki Kaisha Hitachi Seisakusho

DBA Hitachi, Ltd.

IBM is a registered trademark of International Business Machines

Corporation.

HP and PCL are registered trademarks of Hewlett-Packard Company.

Centronics is a registered trademark of Genicom Corporation.

Dataproducts is a registered trademark of Dataproducts Corporation.

Epson is a registered trademark of Seiko Epson Corporation.

DuraFusion, IGP, LaserLine, LinePrinter Plus, PGL, PrintNet, PSA, and

Printronix are registered trademarks, and Ribbon Minder is a trademark of

Printronix, Inc.

Magnum and QMS are registered trademarks, and Code V is a trademark of

Quality Micro Systems, Inc.

Microsoft, MS, MS-DOS, and Windows are registered trademarks of Microsoft

Corporation.

Toray is a registered trademark, and Toraysee is a trademark of Toray

Industries, Inc.

SELFOC is a registered trademark of Nippon Sheet Glass Co., Ltd.

PKUNZIP is a registered trademark of PKWARE, Inc.

This product uses Intellifont Scalable typefaces and Intellifont technology.

Intellifont is a registered trademark of Agfa Division, Miles Incorporated

(Agfa).

CG, Garth Graphic, Intellifont, and Type Director are registered trademarks,

and Shannon and CG Triumvirate are trademarks of Agfa Division, Miles

Incorporated (Agfa). CG Bodoni, CG Century Schoolbook, CG Goudy Old

Style, CG Melliza, Microstyle, CG Omega, and CG Palacio are products of

Agfa Corporation. CG Times, based on Times New Roman under license

from The Monotype Corporation Plc is a product of Agfa.

Univers is a registered trademark of Linotype AG and/or its subsidiaries.

Letraset is a registered trademark, and Aachen, Revue and University Roman

are trademarks of Esselte Pendaflex Corporation.

Futura is a registered trademark of Fundición Tipográfica Neufville, S.A.

ITC Avant Garde Gothic, ITC Benguiat, ITC Bookman, ITC Century, ITC

Cheltenham, ITC Clearface, ITC Galliard, ITC Korinna, ITC Lubalin Graph,

ITC Souvenir, ITC Tiepolo, ITC Zapf Chancery, and ITC Zapf Dingbats are

registered trademarks of International Typeface Corporation.

Albertus, Gill Sans, and Times New Roman are registered trademarks, and

Monotype Baskerville is a trademark of The Monotype Corporation Plc,

registered in the U.S. Pat. and TM office and elsewhere.

Hiroshige and Marigold are trademarks of AlphaOmega Typography, Inc.

Printronix, Inc. makes no representations or warranties of any kind regarding

this material, including, but not limited to, implied warranties of

merchantability and fitness for a particular purpose. Printronix, Inc. shall not

be held responsible for errors contained herein or any omissions from this

material or for any damages, whether direct, indirect, incidental or

consequential, in connection with the furnishing, distribution, performance or

use of this material. The information in this manual is subject to change

without notice.

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix, Inc.

Copyright

1998, 2004, Printronix, Inc. All rights reserved.

1 Introduction ...................................................... I–19

About This Manual............................................................................ I–19

How To Locate Information ........................................................ I–19

Safety Notices And Special Information ..................................... I–19

Switches And Display Messages ............................................... I–20

Related Documents.................................................................... I–20

General Safety Precautions.............................................................. I–20

Setup Safety Precautions ................................................................. I–22

Printer......................................................................................... I–22

Safety Label Locations And Printer Views........................................ I–23

Printer Features ................................................................................ I–28

Tools, Test Equipment, And Supplies............................................... I–29

2 Setup................................................................ I–31

Power Requirements ........................................................................ I–31

Site Selection.................................................................................... I–32

Unpacking And Leveling ................................................................... I–35

Cable Connections ........................................................................... I–37

Power Cord ................................................................................ I–37

Interface Cable ........................................................................... I–40

Installing The First Photoreceptor Drum ........................................... I–41

Adding The Developer ...................................................................... I–47

Installing The Developing Unit .......................................................... I–49

Installing The Toner Cartridge And Waste Toner Bottle ................... I–52

Loading Fanfold Paper ..................................................................... I–55

Loading Cut Sheet Paper ................................................................. I–57

Setting Cassette Paper Size (Optional Procedure) .......................... I–59

Setting The Power Supply Voltage ................................................... I–60

3 Scheduled Maintenance .................................. I–67

Maintaining Print Quality................................................................... I–67

Service Level Page Counts .............................................................. I–68

Clearing Service Level Messages.............................................. I–69

About Page Counter Software ................................................... I–69

Volume I

Table of Contents

Table of Contents

Maintenance Schedules ................................................................... I–69

User’s Cleaning Schedule.......................................................... I–69

User’s Replacement Schedule................................................... I–70

Tech Service Replacement Schedule ........................................ I–71

Maintenance Kits .............................................................................. I–72

General Cleaning.............................................................................. I–76

Cleaning The Chargers..................................................................... I–82

Cleaning The Fuser Unit Cover Glass And Lamp Filter.................... I–86

Cleaning The Cut Sheet Option Rollers............................................ I–89

Major Cleaning.................................................................................. I–93

Cleaning The Flash Power Supply Filter .......................................... I–99

4 Troubleshooting ............................................. I–101

Overview......................................................................................... I–101

Jam Detection Sensors ............................................................ I–101

System Block Diagram ................................................................... I–102

Hidden Control Menus .................................................................... I–103

Global Memory Adjust Menu .................................................... I–104

Printer Control Menu ................................................................ I–105

Fanfold Paper Jams........................................................................ I–107

Paper Jam Near The Tractor ................................................... I–107

Paper Jam Near The Paper Output Section ............................ I–108

Cut Sheet Paper Jams.................................................................... I–111

Paper Jam At The Back Of The Paper Cassette ..................... I–111

Paper Jam In The Transport Input Section .............................. I–112

Paper Jam In The Transport Output Section ........................... I–114

Paper Jam In The Face Up Or Face Down Paper Path........... I–115

Status Messages And Error Messages .......................................... I–116

Error Message Table................................................................ I–116

Error Message Troubleshooting Procedures ........................... I–128

Error Code 01 — Front Cover Open ........................................ I–128

Error Code 02 — Fan-fold Paper Empty: Upon Power-on ....... I–130

Error Code 02 — Fan-fold Paper Empty: When

Loading/Beginning Print ........................................................... I–131

Error Code 03 — Paper Jam at Fuser (C) ............................... I–131

Error Code 04 — Paper Jam at Exit (D) (transport section)..... I–132

Error Code 05 — Paper Jam at Exit (D)

(paper output section) .............................................................. I–133

Error Code 07 — Scuff Lever Open (knob "C")........................ I–134

Error Code 08 — Cut-sheet Path Open ................................... I–134

Error Code 09 — Transport Motor Fail (complete stop) ........... I–135

Error Code 0A — Cutter Fail (front) ......................................... I–136

Table of Contents

Error Code 0B — Cutter Fail (rear) .......................................... I–136

Error Code 0C — Transfer Platform Fail (upper) ..................... I–138

Error Code 0D — Transfer Platform Fail (lower) ...................... I–138

Error Code 11 — Paper Jam at Drum (B) ................................ I–140

Error Code 12 — Paper Jam at Fuser (C)................................ I–140

Error Code 13 — Paper Jam at Exit (D): Straight Output

(faceup) .................................................................................... I–141

Error Code 13 — Paper Jam at Exit (D) (Cut-sheet

Facedown Output).................................................................... I–141

Error Code 14 — Tractor Speed Too High............................... I–142

Error Code 15 — Tractor Speed Too Low................................ I–142

Error Code 16 — Paper Jam at Entrance (A)........................... I–144

Error Code 17 — High Voltage Fail.......................................... I–144

Error Code 18 — Drum Motor Fail (complete stop).................. I–146

Error Code 19 — Surface Voltage Too High............................ I–147

Error Code 1A — Surface Voltage Too Low ............................ I–149

Error Code 1B — Tractor Detent Fail....................................... I–150

Error Code 1E — Fuser Supply Fail......................................... I–151

Error Code 1F — Fuser Failure................................................ I–151

Error Code 20 — Fuser Lamp Overheat .................................. I–152

Error Code 26 — No Cleaning Unit .......................................... I–153

Error Code 28 — Waste Toner Full.......................................... I–153

Error Code 29 — No Waste Toner Box.................................... I–154

Error Code 2A — Toner Low.................................................... I–154

Error Code 2D — Toner Empty ................................................ I–154

Error Code 2B — Toner Density Too High............................... I–155

Error Code 2C — Toner Density Too Low ............................... I–155

Error Code 32 — LED Head Overheat..................................... I–155

Error Codes 38 through 47 — MC Board CPU Internal Error .. I–156

Error Codes 48 through 4D — Controller Comm. Fail.............. I–156

Error Codes 50 through 53 and 5B — Stacker Fail.................. I–157

Error Code 5D — Stacker Comm. Fail ..................................... I–157

Error Code 54 — Stacker Interlock Fail.................................... I–158

Error Code 55 — Stacker Fail .................................................. I–158

Error Code 56 — Stacker Full .................................................. I–159

Error Code 57 — Stacker Not Ready ....................................... I–159

Error Code 58 — Stacker Not Auto Mode ................................ I–159

Error Code 59 — Stacker Fail .................................................. I–160

Error Code 5A — Stacker Fail.................................................. I–161

Error Code 5C — Stacker Fail.................................................. I–162

Error Codes 60 through 62, 6E, and 70 — Cut-sheet

Comm. Fail ............................................................................... I–162

Table of Contents

Error Code 63 — Cut-sheet Feeder Fail .................................. I–162

Error Code 64 — Cut-sheet Paper Skew ................................. I–163

Error Code 65 — Cut-sheet Pick Miss ..................................... I–163

Error Code 66 — No Paper Cassette....................................... I–164

Error Codes 67, 69, and 6B — Paper Jam at Entrance (A) ..... I–164

Error Codes 68 and 6A — Paper Jam at Entrance (A) ............ I–165

Error Code 6C — Cut-sheet Cover Open ................................ I–165

Error Code 6D — Cut-sheet Motor Fail.................................... I–166

Error Code 6F — Cut-sheet Paper Empty ............................... I–167

Error Code 78 — Main Charger High Voltage Error................. I–167

Error Code 79 — Transfer Charger High Voltage Error ........... I–168

Error Code 7A — Precharger High Voltage Error .................... I–168

Error Code 7B — Cleaning Bias High Voltage Error ................ I–169

Error Code 7C — Developing Bias High Voltage Error............ I–170

Error Code 7D — Separator Charger High Voltage Error ........ I–170

Troubleshooting Other Symptoms .................................................. I–171

Smell Of Toner ......................................................................... I–172

Broken Fuser Unit Cover Glass ............................................... I–173

Incomplete Fusing .................................................................... I–174

Paper Jam ................................................................................ I–177

Print Quality.............................................................................. I–179

Transfer (Elevator) Motor Abnormal Error................................ I–184

Abnormal Noises ...................................................................... I–184

Developer Overflows ................................................................ I–184

Toner Is Discharged................................................................. I–185

Power Stacker.......................................................................... I–185

5 Adjustment Procedures.................................. I–189

MC Board Adjustments................................................................... I–189

MC Board Switches.................................................................. I–191

MC Board Test Points .............................................................. I–195

MC Board Variable Resistors................................................... I–200

MC Board LEDs ....................................................................... I–202

MC Board Fuses ...................................................................... I–204

Setting NVRAM Values ............................................................ I–206

Adjusting Feed Motor Speed.................................................... I–207

Adjusting Drum Motor Speed ................................................... I–207

Adjusting Tractor Motor Gain ................................................... I–207

Adjusting Eraser Lamp Voltage................................................ I–208

Adjusting Toner Density Sensor............................................... I–208

Confirming MC Board Operation .................................................... I–210

Confirming the Developing Bias Voltage Control Circuit .......... I–210

Table of Contents

Confirming The Main Charger Current Control Circuit ............. I–211

Confirming The Sleeve Motor Operation.................................. I–212

Confirming The Magroll Motor Operation ................................. I–212

Confirming The Toner Supply Clutch Operation ...................... I–212

Confirming The Head Cooling Fan Operation .......................... I–212

Confirming The Head Blower Fan Operation ........................... I–212

Confirming The Vacuum Fan Operation................................... I–212

Confirming The Preheat Lamp Operation ................................ I–213

Confirming The Drum Counter Operation ................................ I–213

Confirming The Drum Surface Potential Sensor Operation ..... I–213

Other Print Engine Adjustments ..................................................... I–215

Adjusting The Drum Surface Potential Sensor......................... I–215

Adjusting The Tractors ............................................................. I–215

Adjusting The Top of Form....................................................... I–219

DC Power Supply Board Adjustments ............................................ I–223

DC Power Supply Board Switches ........................................... I–223

DC Power Supply Board Variable Resistors ............................ I–223

DC Power Supply Board Fuses................................................ I–225

Flash Power Supply Adjustments ................................................... I–227

Loading Flash Memory ................................................................... I–228

The lasr2fls Utility Program ...................................................... I–228

Downloading Into Flash Memory.............................................. I–231

6 Replacement Procedures .............................. I–237

Overview......................................................................................... I–237

Front Cover .............................................................................. I–238

Left Rear Cover........................................................................ I–239

Right Rear Cover ..................................................................... I–240

Top Cover ................................................................................ I–243

Stand Cover ............................................................................. I–246

Inside The Front Cover ................................................................... I–247

Waste Toner Recovery Unit ..................................................... I–248

Developing Unit........................................................................ I–252

Toner Cartridge ........................................................................ I–252

Photoreceptor Drum ................................................................. I–253

Proper Disposal Of A Drum Unit .............................................. I–259

Drum Peripheral Equipment ..................................................... I–260

Fuser Unit................................................................................. I–266

Transfer Assembly ................................................................... I–271

Inside The Rear Cover.................................................................... I–280

MC Board ................................................................................. I–281

DC Power Supply Board .......................................................... I–282

Table of Contents

Motors ...................................................................................... I–284

Fans ......................................................................................... I–297

Solenoids ................................................................................. I–301

Miscellaneous .......................................................................... I–303

Under The Top Cover ..................................................................... I–314

LED Print Head ........................................................................ I–315

High-Voltage (Corona) Power Supply ...................................... I–319

Cutter Unit ................................................................................ I–320

Sensors And Switches ............................................................. I–323

Gates........................................................................................ I–331

Behind The Stand Cover ................................................................ I–332

Smoke Filter ............................................................................. I–332

Flash Power Supply ................................................................. I–333

Capacitor.................................................................................. I–340

Other............................................................................................... I–344

Tractor Removal....................................................................... I–344

Paper Back-Feed Sensor (PBFS) (Top Of Form Sensor) ........ I–346

Paper Near-End Sensor (PNES).............................................. I–347

Control Panel ........................................................................... I–349

Controller Module ........................................................................... I–350

Controller Board ....................................................................... I–350

Terminating Resistors .............................................................. I–354

Power Supply (In Controller Module) ....................................... I–356

Cooling Fan .............................................................................. I–358

7 Illustrated Parts Breakdown ............................ II–19

Overview.......................................................................................... II–19

Illustrated Parts Breakdown............................................................. II–20

8 Principles of Operation.................................. II–111

Printing System Descriptions......................................................... II–111

General ................................................................................... II–111

The Printing Process............................................................... II–111

How Images Are Processed .......................................................... II–112

Bit Mapping ............................................................................. II–112

Job Recovery .......................................................................... II–112

The Printing Mechanisms .............................................................. II–113

Photoconductive Section ............................................................... II–114

Discharge ................................................................................ II–114

Main Charging ......................................................................... II–114

Exposure ................................................................................. II–116

Developing Section........................................................................ II–117

Developing Unit....................................................................... II–117

Principles Of Developing ......................................................... II–118

Image Transfer/Separation Section ............................................... II–120

Transfer ................................................................................... II–120

Separation ............................................................................... II–120

Fixing Section (Fuser Unit) ............................................................ II–122

Preheating ............................................................................... II–122

Flash Fusing............................................................................ II–122

Cleaning Section............................................................................ II–123

Precharging (Precleaning Charging) ....................................... II–123

Drum Cleaning ........................................................................ II–123

Paper Feed, Transport, And Output Sections................................ II–124

Paper Detection ...................................................................... II–124

Paper Loading ......................................................................... II–126

Paper Transport ...................................................................... II–128

Paper Output........................................................................... II–129

Paper Parking ......................................................................... II–130

Volume II

Table of Contents

Table of Contents

Drive System Descriptions............................................................. II–132

Drum Drive .............................................................................. II–133

Developing Roller Drive .......................................................... II–134

Main Unit Feed Roller Drive .................................................... II–135

Gate Drive ............................................................................... II–136

Transfer Unit Drive .................................................................. II–137

Tractor Drive ........................................................................... II–137

Perforation Cutter Drive .......................................................... II–138

Separator Claw Drive .............................................................. II–139

Cut Sheet Paper Feed Section Drive ...................................... II–140

Control System Descriptions ......................................................... II–141

Paper Transport System Monitoring ....................................... II–142

Motor Rotation Control ............................................................ II–145

Drum Surface Potential Control .............................................. II–151

Toner Density Control ............................................................. II–152

Remaining Toner Level Monitoring ......................................... II–154

Waste Toner Monitoring.......................................................... II–155

Head Temperature Monitoring ................................................ II–156

Fuser Temperature Monitoring................................................ II–157

Developing Bias Adjustment ................................................... II–158

Operational Sequences ................................................................. II–159

Electronics Initialization ........................................................... II–160

Mechanical Initialization .......................................................... II–161

Printing Operations ................................................................. II–162

Command Operations ............................................................. II–167

A Electrical and Wire Data................................ II–171

Block Diagram ............................................................................... II–171

Printer Interconnection Diagram .................................................... II–172

Print Engine Interconnection Diagram ........................................... II–173

Acronyms For Print Engine Interconnection Diagram.................... II–176

Explanation Of Circuits According To Function ............................. II–179

Drum Surface Potential Control Circuit ................................... II–179

Developing Bias Control Circuit .............................................. II–181

Toner Density And Toner Empty Circuits ................................ II–183

Drum Motor Control Circuit ..................................................... II–185

Drum Counter Circuit .............................................................. II–186

Tractor Motor Control Circuit................................................... II–187

Main Unit Feed Motor Control Circuit...................................... II–190

Transfer Elevator Motor Control Circuit................................... II–191

Cutter Motor Control Circuit .................................................... II–193

Table of Contents

Input / Output Signals .................................................................... II–194

LVX040 Controller Board Input/Output Signals....................... II–194

MC Board (MC-PCBA) Input/Output Signals........................... II–203

DC Power Supply Board (PS-PCBA) Input/Output Signals..... II–216

Unit Interface ................................................................................. II–221

LED Array................................................................................ II–221

Flash Power Supply ................................................................ II–225

Developing Unit....................................................................... II–228

High-Voltage (Corona) Power Supply ..................................... II–231

B Optional Cut Sheet Feeder ........................... II–235

Physical Description ...................................................................... II–235

Front Side................................................................................ II–235

Back Side ................................................................................ II–236

Rear Side (Board Side) ........................................................... II–237

Paper Feed Cassette..................................................................... II–238

Setup And Connections ................................................................. II–239

Setup....................................................................................... II–239

Connections ............................................................................ II–241

Basic Principles ............................................................................. II–242

Drive Principles ....................................................................... II–243

Cassette Principles ................................................................. II–243

Control Principles........................................................................... II–244

Upper Level / Lower Level Paper Size Sensor........................ II–244

Paper Feed Cassettes ............................................................ II–245

Upper Level / Lower Level Paper Empty Sensor

(PES1 / PES2) ........................................................................ II–246

Cut Sheet Feed Sensor (PFS),

Paper Register Sensor (PRS) ................................................. II–246

Paper Timing Sensor (PTS) .................................................... II–247

Cut Sheet Pickup Motor Encoder (PME)................................. II–248

Cut Sheet Feed Motor Encoder (FME).................................... II–249

Paper Guide Interlock Switch (ICIL) ........................................ II–250

Detection Errors............................................................................. II–251

Upper Level Cassette Section Error........................................ II–251

Lower Level Cassette Section Error........................................ II–251

Transfer Unit Error................................................................... II–252

Unit Sequencer Section Errors................................................ II–253

Basic Operation ............................................................................. II–254

Mechanism Initialization .......................................................... II–255

Analog Input Processing ......................................................... II–255

Chattering Absorption Processing........................................... II–255

Table of Contents

Status Confirmation Processing.............................................. II–255

Confirmation Processing Of Unit Of Error Occurrence ........... II–255

Communication Processing .................................................... II–255

Driving Actuators ..................................................................... II–255

Cut Sheet Output Unit.................................................................... II–256

Physical Description ................................................................ II–256

Setup and Connections........................................................... II–258

Basic Principles ....................................................................... II–261

C Optional Power Paper Stacker...................... II–263

Physical Description ...................................................................... II–263

Front (Output Side) ................................................................. II–263

Rear (Input Side)..................................................................... II–264

Front (Interior) ......................................................................... II–265

Setup And Connections ................................................................. II–266

Setup....................................................................................... II–266

Connections ............................................................................ II–269

Removal......................................................................................... II–270

Operation ....................................................................................... II–271

Sensors And Actuators .................................................................. II–274

Drive Principles.............................................................................. II–275

Feed Roller And Transfer Belt................................................. II–275

Swinger ................................................................................... II–277

Assisting Arms ........................................................................ II–278

Elevator Table ......................................................................... II–279

Control Principles........................................................................... II–280

Transfer Unit Paper Sensor (Paper Moving Sensor) (PMS) ... II–280

Jam Sensor (PPS) .................................................................. II–281

Paper Surface Sensor 1 (PSS1),

Paper Surface Sensor 2 (PSS2) ............................................. II–282

Stacker Full Sensor (SFS), Elevator Down Sensor (EDS) ...... II–283

Stacker Motor Encoder (SME),

Elevator Motor Encoder (EME) ............................................... II–284

Swinger Position Sensor (SPS),

Assisting Arm Position Sensor (APS1) ................................... II–285

Elevator Upper Limit Switch (LIMT1),

Elevator Lower Limit Switch (LIMT2) ...................................... II–286

Safety Sensor 1 (SS1), Safety Sensor 2 (SS2)....................... II–287

Elevator Keys (ESWA / ESWS / ESWD / ESWH)................... II–287

Detection Errors............................................................................. II–288

Operator Call Status Errors..................................................... II–288

Service Call Status Errors ....................................................... II–288

Table of Contents

Basic Operation ............................................................................. II–289

Status Confirmation Processing .............................................. II–290

Communication Processing..................................................... II–290

Driving The Stacker................................................................. II–290

Driving The Elevator Motor...................................................... II–290

Driving The Swinger Motor...................................................... II–290

Driving The Assisting Arm Drive Motor ................................... II–290

Switch Monitoring.................................................................... II–290

Belt Removal Procedures .............................................................. II–291

Power Stacker Cover .............................................................. II–292

Inside The Left Frame ............................................................. II–293

Inside The Right Frame........................................................... II–299

Swinger Belts .......................................................................... II–303

Elevator Belt............................................................................ II–310

Stacker Motor.......................................................................... II–315

D Engine Checker ............................................ II–319

Overview........................................................................................ II–319

Connecting The Engine Checker................................................... II–320

Disconnecting The Engine Checker .............................................. II–323

Using The Control Panel................................................................ II–323

Operation ................................................................................ II–324

Basic Menu .................................................................................... II–325

Device Check Menu....................................................................... II–326

Selecting A Mode/Item/Device ................................................ II–334

Reading Device Status (Input Device Check) ......................... II–335

Driving/Stopping A Device (Output Device Check) ................. II–335

Volume Adjustment Menu.............................................................. II–337

Surface Potential..................................................................... II–338

Eraser Lamp............................................................................ II–338

Drum Motor ............................................................................. II–338

Feed Motor .............................................................................. II–339

Tractor Motor........................................................................... II–339

Toner Density.......................................................................... II–339

Basic Operation Menu ................................................................... II–340

Fanfold Paper.......................................................................... II–340

Cut Sheet Paper...................................................................... II–341

Memory Operation Menu ............................................................... II–342

Reading And Changing Data .................................................. II–343

Table of Contents

I–19

1Introduction

About This Manual

This manual explains how to maintain and repair the L5535 printer at the field

service level of maintenance. It covers alignments and adjustments,

preventive and corrective maintenance, basic troubleshooting, and principles

of operation.

This manual does not explain how to configure or operate the printer. That

information is in the

User’s Manual,

which supplements this manual.

How To Locate Information

This manual consists of two volumes which are designed so that you can find

the information you need to maintain and repair the printer. You can locate

maintenance information in two ways:

•Use the Table of Contents at the front of Volume 1 and Volume 2.

•Use the Index at the end of Volume 1 and Volume 2.

Read the entire procedure before beginning any maintenance task. Gather all

required tools and make sure you understand all warnings, cautions, and

notes before you begin working on the printer.

Safety Notices And Special Information

For your safety and to protect valuable equipment, it is very important that you

read and comply with all information highlighted under the following special

headings: WARNING, CAUTION, IMPORTANT, and NOTE. Safety notices

which include conditions that could harm you are written in English and

German. (See also the safety topics in English and German that follow this

topic.)

WARNING

A warning notice calls attention to a condition that could harm you or

damage the printer.

CAUTION

A caution notice calls attention to a condition that could damage the

printer.

IMPORTANT

An important notice provides information that is vital to proper

operation of the printer.

NOTE: A note provides information concerning printer maintenance

considered important enough to emphasize.

I–20

Chapter 1 General Safety Precautions

Switches And Display Messages

In this manual, switches and indicators that are labeled on the printer appear

in uppercase letters.

Control panel display messages also appear in uppercase letters.

Example: “Press the CLEAR switch to take the printer to the OFFLINE

READY state.”

Related Documents

For additional information about printer configuration and operation, and

optional interfaces, refer to the following documents:

•

L5535 Multifunction Printer User’s Manual

(P/N 171516-001)

•

LinePrinter Plus®Emulation for LaserLine®Printers Programmer’s

Reference Manual

(P/N 705867-001)

•

IGP®/PGL®Emulation for LaserLine®Printers Programmer’s Reference

Manual

(P/N 702610-001)

•

IGP®/VGL Emulation for LaserLine®Printers Programmer’s

Reference Manual

(P/N 148802-001)

General Safety Precautions

This section provides safety information for technicians who are installing and

maintaining L5535 printers.

Installation, initial setup, testing and

maintenance should be performed only by a factory-trained service

representative.

WARNING

The printer relies on protective devices in the building installation for

protection. The printer must be connected to a 30 Amp, 200, 220, or 240

VAC outlet.

The operator-accessible power switch does not shut off all power to the

printer.

You must unplug the power cord to shut off all power to the printer.

VORSICHT

Der Drucker nutzt die elektrischen Schutzeinrichtungen der

Gebäudeinstallation. Der Drucker muß an einen mit 30 A abgesicherten

Stromkreis mit 200, 220 oder 240 V Wechselspannung angeschlossen

werden.

Der für den Bediener zugängliche Netzschalter macht den Drucker nicht

vollständig stromlos. Ziehen Sie das Netzkabel heraus, um die

Stromzufuhr zum Drucker vollständig zu unterbrechen.

WARNING

Be aware of components in the printer that are potentially hazardous or

easily damaged. For example, the fuser unit becomes very hot under

normal operating conditions, and several components use high voltage.

Other manuals for L5535

3

Table of contents

Other Printronix All In One Printer manuals

Printronix

Printronix L5020 Manual

Printronix

Printronix L5020 User manual

Printronix

Printronix P9012 User manual

Printronix

Printronix P3000 Series Assembly instructions

Printronix

Printronix L5035 Manual

Printronix

Printronix L5535 User manual

Printronix

Printronix P9000 Series Assembly instructions

Printronix

Printronix L5535 User manual

Printronix

Printronix L5020 User manual

Printronix

Printronix L5535 Manual