Pro-dig X9K5 User manual

Auger & Anchor Drive

(Single Speed)

X9K5

720 E 9th St., Lawrence, KS 66044

866.259.1801 • 785. 856.2661

www.pro-dig-usa.com • [email protected]

Instruction Manual

Owners Manual

Safety Precautions

Operating Instructions

Maintenance

Parts Lists

Manual Number: PROX9K5

Release Date: September 3, 2011

Reliability Under Pressure

X9K5

PREFACE

This manual is used to familiarize you with safety, assembly, operation, adjustment, troubleshooting,

and maintenance. Read and follow the recommendations in this manual to ensure safe and

efcient operation. The information contained in this manual was current at the time of printing.

Some items may change slightly to assure, you the customer, the best performance.

We want you to be completely satised with your new product, feel free to contact your local

Authorized Service Dealer for help with service, replacement parts or any other information you

may require.

Whenever you contact your Authorized Service Dealer or the factory, always have the model

number and serial number of your product available. These numbers will help provide exact

information about your specic product. You will nd the model and serial numbers on an ID plate

located on the product.

For your convenience, write the product model number, serial numbers and date of purchase in

the spaces below.

MODEL NO: ___________________________

SERIAL NO: ___________________________

DATE OF PURCHASE:

__________________

TABLE OF CONTENTS

Preface/Table of Contents .......................................................................................... 2

Safety Statements ...................................................................................................... 3

General Precautions................................................................................................ 4-5

Safety Decal Locations/Serial Tag Location ............................................................... 5

Specications/Component and Control Locations...................................................... 6

Set-up Instructions/Operating Procedures/Storage.................................................... 7

General Maintenance/Checking and Changing the Gear Oil ..................................... 8

Maintenance Cont./Troubleshooting........................................................................... 9

X9K5 Gearbox Parts Breakdown ............................................................................. 10

Guarantee/Warranty ..................................................................................................11

SAFETY STATEMENTS

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL

RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH COULD

RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SYMBOL BY ITSELF OR USED WITH A SAFETY SIGNAL WORD

THROUGHOUT THIS MANUAL IS USED TO CALL YOUR ATTENTION TO

INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY OR THE SAFETY

OF OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT

IN INJURY OR DEATH.

READ MANUAL PRIOR TO INSTALL

Improper installation, operation or maintenance of the equipment could result

in serious injury or death. Operators and maintenance personnel should read

this manual as well as all manuals related to this equipment. Follow all safety

instructions in this manual.

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating

or working on this equipment. Know and obey all OSHA regulations, local laws

and other professional guidelines for your operation. Know and follow good

work practices when assembling, maintaining, repairing, mounting, removing or

operating this equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before

operating. Visually inspect your equipment before you start, and never operate

equipment that is not in proper working order with all safety devices intact. Check

all hardware to assure it is tight. Make certain that all locking pins, latches, and

connection devices are properly installed and secured. Remove and replace any

damaged, fatigued or excessively worn parts. Make certain all safety decals are

in place and are legible. Keep decals clean, and replace them if they become

worn and hard to read.

DO NOT MODIFY EQUIPMENT

Modications may weaken the integrity of the equipment and may impair the

functions, safety, life, and performance of the equipment. When making repairs,

use only the manufactures genuine parts, following authorized instructions.

Other parts may be substandard in t and quality.

!

DANGER

!

WARNING

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

!

3www.pro-dig-usa.com 785.856.2661 • 866.259.18012

Reliability Under Pressure

X9K5

GENERAL PRECAUTIONS

PREPARE FOR EMERGENCIES

• Be prepared if a re starts.

• Keep a rst aid kit near by when operating equipment.

OPERATOR SAFETY

• Protective clothing and equipment should be worn at all times.

• Wear protective clothing and equipment appropriate for the job. Avoid loose tting clothing.

• Prolonged exposure to excessive noise can cause hearing loss. Wear suitable hearing protection

such as ear plugs.

• Operating equipment safely requires the full attention of the operator. Avoid distractions.

• Do not operate the unit when you are tired, ill or under the inuence of alcohol, drugs or

medication.

• Never let a minor or inexperienced person operate the unit.

• Keep hands away from the drilling bit at all times.

• Inspect the area to be drilled before operation. Remove objects which

can be thrown or become entangled.

UNIT AND TOOL SAFETY

• Inspect the entire tool before operation.

• Replace parts that are cracked, chipped or damaged in any way before operation.

• Keep others away when making any adjustments to the unit.

• Damage to the PRO-DIG™ Auger Drive and auger bit can result if the prime mover moves while

the auger is still in the hole.

PRACTICE SAFE MAINTENANCE

• Use proper tools and equipment when conducting maintenance, refer to this manual for additional

information.

• Work in a clean dry area.

• Inspect all parts. Be sure parts are in good working condition and installed properly.

• Remove build up of grease, oil or any debris.

• Remove all tools and unused parts from equipment before beginning operation.

DRILLING SAFETY

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often

attracted to machinery and work activity. Never assume that children will remain where you last saw

them. BE ALERT and turn the equipment off if children enter the work area. Keep children out of the

work area and under supervision of another responsible adult.

!

WARNING

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!!

WARNING

GENERAL PRECAUTIONS (cont.)

DRILLING SAFETY

• Inspect the area to be drilled before operation. Remove objects which can be thrown or become

entangled.

• Keep all parts of your body away from the drilling bit when operating the unit.

• DO NOT operate the PRO-DIG™ Auger Drive when the auger bit is more than 12” (305mm) above

ground. The auger bit may bind and cause injury to the operator and damage to the equipment.

• While the auger bit is rotating, DO NOT attempt to manually guide the auger to a location.

UNDERGROUND HAZARDS

It is the responsibility of the operator to know where buried power, gas, telephone, and other utilities

are in the work area. This may lead to shock or an explosion. Have the work area marked for buried

lines and do not dig in marked areas set by your local municipals. Striking a hard object underground

with the auger turning can result in the slowing or stopping of the auger.

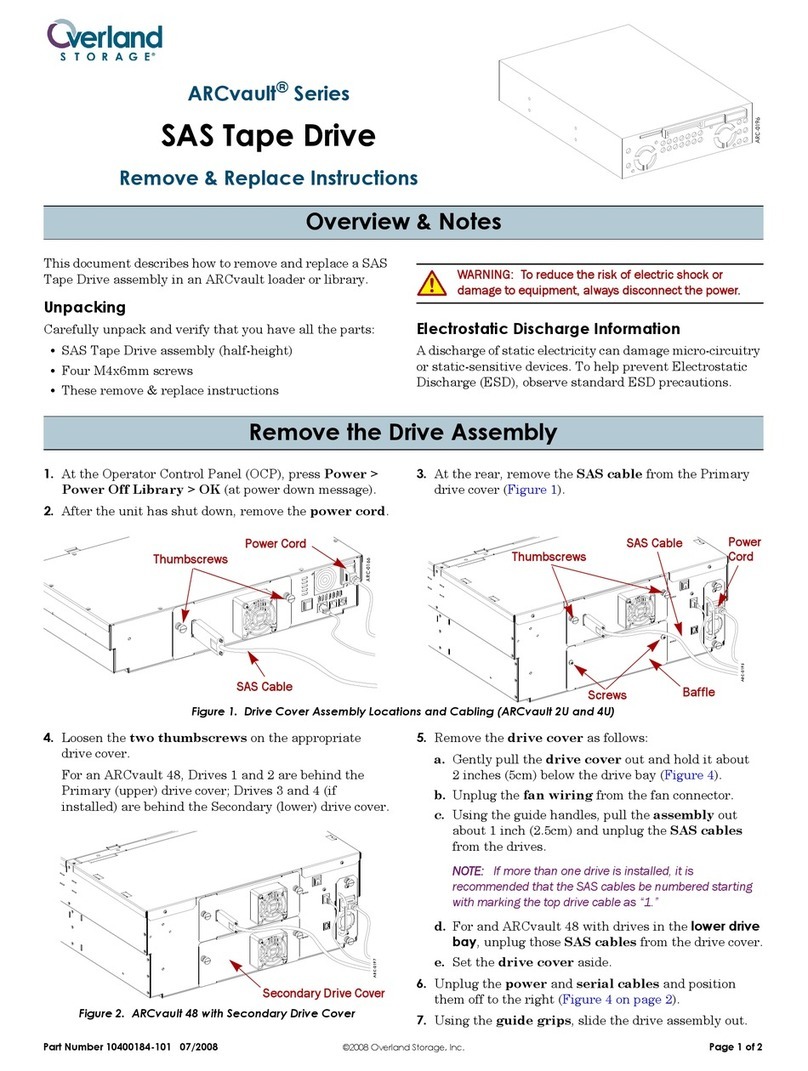

SAFETY DECAL LOCATIONS

SAFETY DECALS

This unit comes equipped with all safety decals in place. They are designed to help you safely

operate your unit. Read and follow all safety decals.

(Locations shown below in gure 1)

• Keep all safety decals clean and legible at all times

• Replace safety decals that are missing or have become illegible.

• Safety decals are available from your distributor or manufacture.

• Some parts installed during repair may require safety decals to be afxed to the replacement

part. When ordering the replacement part(s) be sure the correct safety decal(s) are included in

your order.

INSTALLING SAFETY DECALS

• Clean the desired are with warm soapy water.

• Decide on exact position before your remove the backing paper.

• Peel backing paper from decal. Press rmly on the surface.

• Air pockets can be pierced with a pin and smoothed.

!

!

5www.pro-dig-usa.com 785.856.2661 • 866.259.18014

Reliability Under Pressure

X9K5

Before operating always ensure that the PRO-DIG™

Auger Drive and auger or anchor are connected

correctly to the parent machine.

DRILLING OPERATIONS

1. To begin drilling, position the auger or anchor on the ground

in the desired location. Engage the parent machines

auxiliary hydraulics to rotate the auger or anchor in a

clockwise direction.

2. Lower the parent machines arm(s) to engage the auger or

anchor into the ground. Use only enough down pressure

to assure positive penetration of the auger. Ease up on the

down pressure if the auger rotation slows down drastically

or stalls. Excessive down pressure will cause the auger to

stall frequently.

Note: Do not continually stall the PRO-DIG™ Auger

Drive! Continued stalling may cause excessive

heating of the hydraulic system and possible

damage to the PRO-DIG™ Auger Drive.

3. As the auger or anchor digs in the ground, the parent

machines arm(s) or boom may travel through an arc. This

means the operator may need to continually reposition

the machine to ensure vertical application of the auger or

anchor.

4. When the auger has penetrated the ground about 24”

(610mm), raise the auger from the hole to clean out the

loose material.

5. Once the required hole depth is reached, allow the auger

to turn a few seconds at this depth to clean the hole.

6. Stop rotation of the auger and raise the auger out of the

hole. Swing the auger away from the newly drilled hole.

Spin the loose material off the auger.

Note: Do not reverse the auger rotation while the

auger is still in the hole. The loose material will

back ll the hole.

7. If necessary, repeat steps 2 through 3 to obtain a cleaner

hole.

OPERATIONS TO AVOID

1. In some soil conditions or when excessive down pressure

is applied, the auger may screw itself in to the ground.

This can cause the auger to become stuck causing the

PRO-DIG™ Auger Drive to stall. If this situation occurs,

reverse the auger rotation and slowly raise the auger from

the hole.

2. If the auger becomes lodged under rocks, tree roots, or

other large obstructions, do not attempt to raise the auger

out of the ground. See Step 1 of this section to relieve the

auger.

3. Avoid excessive side loading. This can cause damage to

both the PRO-DIG™ Auger Drive and the auger.

4. Keep all auger teeth and pilot bits in good condition. Avoid

using damaged teeth and holders.

• Following operation, or when unhooking, stop, set

brakes, disengage power drives, shut off engine, and

remove the ignition key.

• Store the unit in and way from human activity.

• Before long term storage, wash the unit with mild

detergent and water to remove any debris and grime.

• Do not permit children to play on or around the stored

area.

• Protect the shafts and ports with a grease or rust-

inhibitor.

• Grease bearing seals.

• Check and tighten all bolts, nuts and screws. Paint is

available from your Authorized Service Dealer.

• When storing the unit for any length of time be sure

the unit is stored with clean gear oil.

SAFETY DECAL LOCATIONS

This unit comes equipped with all safety decals in place. They are designed to help you safely

operate your unit. Read and follow all safety decals.

OPERATING PROCEDURES

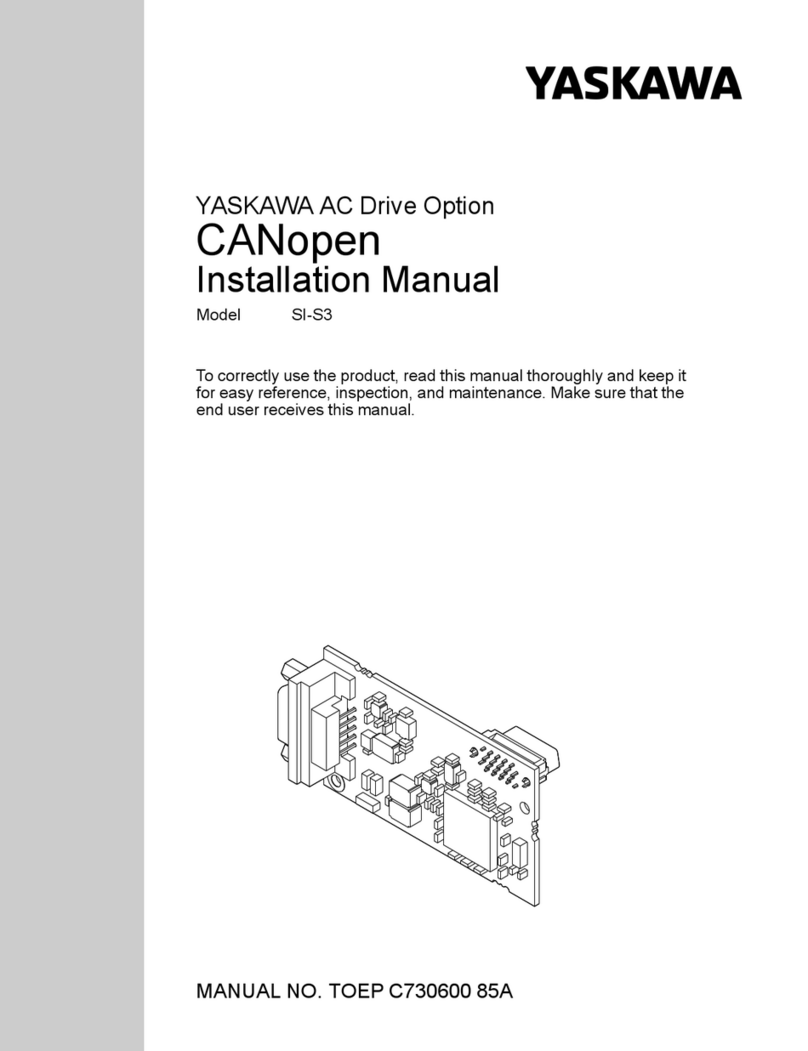

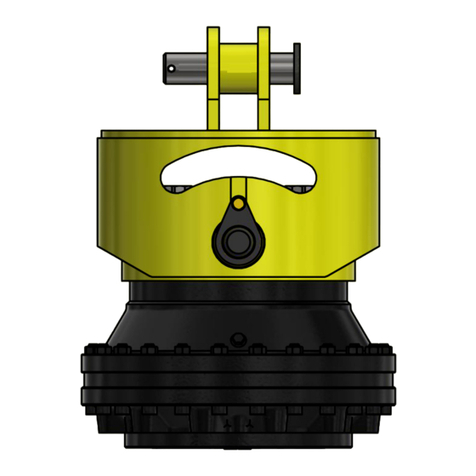

SPECIFICATIONS/COMPONENT AND CONTROL LOCATIONS

Note: PRO-DIG™ continually looks for new ways to improve its products.

Therefore, PRO-DIG™ reserves the right to make changes to our products

and specications without notice.

X9K5

Motor Mount SAE “CC” 4 Bolt

Motor 315.0cc

Bidirectional Speed

Min. Hydraulic Flow 10 GPM

Max. Hydraulic Flow 35 GPM

Max. Continuous Pressure 3000 PSI

Output Shaft 2 1/2” Hex

Output speed

FLOW SPEED

GPM (LPM) RPM

10 (38) 7.5

12 (45) 9

15 (57) 11.2

17 (64) 12.7

20 (76) 14.9

22 (83) 16.4

25 (96) 18.7

27 (102) 20.1

30 (114) 22.4

32 (121) 23.9

35 (133) 26

Output tOrque

PRESSURE TORqUE

PSI (BAR) FT/LBS (Nm)

1000 (69) 3221 (4368)

1200 (83) 3865 (5241)

1400 (96) 4509 (6115)

1600 (110) 5154 (6988)

1800 (124) 5798 (7862)

2000 (138) 6442 (8735)

2200 (152) 7086 (9609)

2400 (166) 7730 (10482)

2600 (179) 8375 (11356)

2800 (193) 9019 (12230)

3000 (207) 9663 (13103)

P/N 750002

P/N 330003

P/N 220005

Motor Port Size:

2 NO -16 SAE O-Ring

P/N 120005

7www.pro-dig-usa.com 785.856.2661 • 866.259.18016

Reliability Under Pressure

X9K5

GENERAL MAINTENANCE

• Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

• Always use proper tools or equipment for the job at hand.

• Use extreme caution when making adjustments.

• Never use your hands to locate a hydraulic leak on attachments. Use a small piece of cardboard or wood. Hydraulic uid

escaping under pressure can penetrate the skin.

• Hydraulic uid escaping under pressure can penetrate skin and cause injury.

• Fluid accidentally injected into the skin must be surgically removed within a few hours by a doctor familiar with this form

of injury or gangrene may result.

• When disconnecting hydraulic lines, shut off hydraulic supply and relieve all hydraulic pressure.

• Clean hydraulic oil daily for contamination. If contamination is present, determine the source and correct the problem.

• When replacing bolts refer to this manual.

• Clean the exterior of the unit with a mild detergent and water to remove any debris and grime.

• Paint all scratched or bare metal surfaces.

• Check and tighten all bolts, nuts, and screws.

• Repair or replace any cutting head components that are damaged or worn.

• Check the gearbox for sufcient amount of oil.

• Check the PRO-DIG™ Auger Drive output shaft for bends, cracks, breaks, or wear. Replace if any of these conditions appear.

• Where replacement parts are necessary for periodic maintenance and servicing, genuine factory replacement parts must

be used to restore you unit to original specications. PRO-DIG™will not claim responsibility for use of unapproved parts

or accessories and other damages as a result of their use.

• If equipment has been altered in any way from it original design, PRO-DIG™ does not accept any liability for injury or warranty.

CHECKING AND CHANGING THE GEAR OIL

The Planetary gearbox used on your PRO-DIG™ Drive Head uses a gear oil to keep the internal gears

lubricated. To check and or replace the oil, follow these simple steps.

CHECKING THE GEAR OIL:

1. Make sure the PRO-DIG™ Auger Drive unit is in an upright

position when checking the oil.

2. Slowly loosen the oil ll-drain plug located on the under

side of the gearbox. As you reach the end of the threads

on the plug, oil should start to come out.

3. If you see oil starting to pour out of the port, quickly retighten

the plug. This is an indication that the oil level is adequate, but

in order to correctly measure the amount of oil, the gearbox

should be drained and the correct amount of oil replenished.

See “Changing Gear Oil” section for oil capacity.

CHANGING THE GEAR OIL:

1. Position the PRO-DIG™ Auger Drive unit in a position in

which the oil can ow freely from the gearbox once the

plug is removed.

2. Place a drain pan under the drain port that will hold at

least one gallon of oil.

3.

Remove the drain plug and allow the oil to completely drain out.

4. Position the gearbox for lling by orientating the unit so that

the same port used for draining can now be used to ll.

5. Fill the gearbox with 0.75 Gallons/2.84 Liters of gear oil.

See oil specications below.

LUBRICATION RECOMMENDATIONS:

Mobil Delvac Synthetic Gear Oil 75W-90

Density @15°C 0.859 Viscosity Index: 140

Viscosity @40°C 120 Flash Point °C: 205

Viscosity @100°C 15.9 Pour Point °C: -48

LUBRICATION AND MAINTENANCE

The oil should be changed after the rst 50 hrs. of use and

at 500 hr. intervals thereafter. Geardrives in auger drives

require GL-5 grade EP 80/90 gear oil for lubrication. PRO-

DIG™ recommends that the unit be partially disassembled to

inspect gears and bearings at 1000 hr. intervals.

MAINTENANCE

Below you will nd some general maintenance instructions. For further information contact your authorized service dealer.

• Clean the exterior of the unit with a mild detergent and water to remove any debris and grime.

• Check and tighten all bolts, nuts and screws.

• Repair or replace any cutting head components that are damaged or worn.

• Clean the exterior and surrounding area near the hydraulic motor.

• Paint all scratched or bare metal surfaces.

TROUBLESHOOTING

In the event your PRO-DIG™ Auger Drive unit malfunctions or does not appear to have enough speed or power, please refer to

the section below to identify the cause of the problem and possible remedy. If the problem persists, contact your Authorized

service dealer for assistance.

SLOW SPEED (RPM) OR INSUFFICIENT DIGGING POWER:

• Low oil ow.

Check parent machine specications.

• PRO-DIG™ Auger Drive is too large for machine.

Contact your Authorized Service Dealer.

• Check auger and teeth for excessive wear.

Replace worn auger components.

NO OUTPUT ROTATION:

• Quick release couplers not engaged.

Check connections.

• Quick release coupler is faulty.

Replace faulty coupler.

• Hydraulic oil tank is low.

Fill oil tank to maximum level.

• Planetary gear failure.

Contact your Authorized Service Dealer.

• Machine or hydraulic pump failure.

Refer to parent machine manual.

BAIL HOUSING LEAKING OIL:

• Hose(s) of tting(s) leaking.

Tighten or replace.

• Motor O-ring failure.

Replace damaged O-ring.

OUTPUT SHAFT LEAKING OIL:

• Oil seal failure.

Contact your Authorized Service Dealer.

• Hydraulic motor failure.

Contact your Authorized Service Dealer.

AUGER BIT WILL NOT ENGAGE OR DIG:

• Auger big is worn or damaged.

Replace cutting head or entire auger bit.

NO TORQUE:

• Oil pressure is too low.

Contact your Authorized Service Dealer.

• Drive unit is too small for parent machine.

Contact your Authorized Service Dealer.

• Hydraulic system is overheating.

See the “Oil Overheating” section below.

HYDRAULIC OIL OVERHEATING:

• Oil pressure is too low.

Set relief valve to machine specications.

• Hydraulic line is restricted.

Inspect and repair.

• Auger continually stalling.

Limit down pressure level.

• Hydraulic oil tank is low.

Fill oil tank to maximum level.

• Insufcient oil capacity.

Check oil cooler.

• Parent machine is too small.

Couple PRO-DIG

™

Auger Drive to larger machine.

9www.pro-dig-usa.com 785.856.2661 • 866.259.18018

Reliability Under Pressure

X9K5

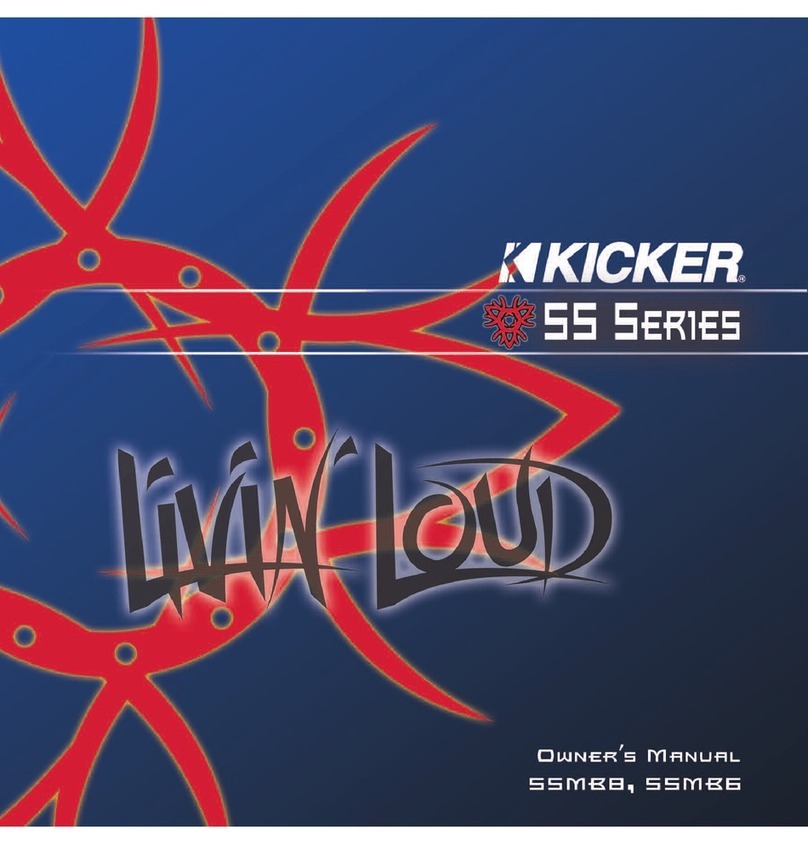

2010 PD International Manufacturing

ITEM QTY DESCRIPTION

29

30

31

33

32

17

22

19

23

24

18

15

5

4

3

4

4

256

4

1

16

2

1

1

6

20

10

7

8

14

1

16

12

13

9

26

27

28

25

21

11

Output Shaft

Planet Gear

Planet Gear Pin

Roller n4 x 20

Cage Spacer

Planet Washer

Taper Bearing 30216

Taper Bearing 32024

1

Shim Aluminium

1

Output Flange

1

1

Allen Screw M8 x 25

Socket Flange Plug 3/8"

12

3

Allen Screw M10 x 30

8

Output Cover

1

Oil Seal 80 x 100 x 8

1

Pin n4 x 30

7

Sun Gear

1

Carrier

1

1Circlip 55 External

3Planet Gear

Planet Gear Pin

3

Roller n5 x 30

51

Planet Washer

12

Housing

1

Sun Gear

1

Ball Bearing 6211

1

Circlip 100 Internal

1

1

Allen Screw M12 x 25

1

Pin n8 x 25

8

Socket Flange Plug 1/2"

2

34 1

O Ring

Scraper

Hull rubber

Gearbox Exploded View Drawing

Motor Flange

14 31

32

33

28

29

27 23

18

25

25

24

22

25

25

21

20

30

26 14

8

35

1

12

7

11

10

9

17

6

6

2

4

5

4

6

63

18

16

15

13

19

35 1Adjust Washer

34

GUARANTEE AND WARRANTY

1 Goods manufactured, rebuilt, supplied or installed by the Company are warranted against defects in material or

workmanship by the Company or its supplier for twelve months but the Company may transfer to the customer the

benet of any subsisting guarantee which the Company may hold in respect thereof. The Company shall have the option

to replace, repair or withdraw any item or authorize the Customer to do so at the Company’s expense but so that the

Company shall not be obliged to accept any charges from Customers or others for work carried out in the warranty

period if such expenditure has not been previously authorized in writing by the company. The Customer is required to

return any defective item within ten days after the discovery of any defect, carriage paid, together with the Company’s

return/warranty form (which be provided on request) fully completed. The warranty period shall operate from the date

of sale, even in the event of goods being repaired, or replaced free of charge during the warranty period. Any warranty

given by the Company shall not be assignable and shall not extend to any goods which have been processed, treated

or mixed or subject to any process after the goods have left the company. Warranties shall not extend to any failure,

defect or damage attributable to normal wear and tear, lack of service or maintenance, use outside the scope of the

manufacturer’s specication, misuse, abuse or accident. In the event that a claim for repair and replacement under

warranty is rejected by the Company or its supplier the items returned will be disposed of within ten days of notifying

the Customer, if they remain uncollected. No goods which have been installed or used by a customer may be returned for

credit or replacement should same prove to be unsuitable for any purpose. Non-warranty goods returned for inspection,

report, costing or repair will also be disposed of if after a period of ten days from the Company issuing a Report thereon,

the goods remain uncollected, or no written instructions are received in relation thereto.

2 The liability of the Company for all goods or services supplied, whether under the terms of any agreement or negligence

or otherwise howsoever arising, shall be limited to the price paid and received in respect of the goods or services (as

the case may be or where both are supplied the total price for the goods and services) and the liability for any loss or

damage to the extent it exceeds such price aforesaid (and in any event any claim for loss of prot, third party liability,

loss of production, direct revenue loss and any indirect or consequential loss whatever) is hereby excluded unless;

2.1 The Customer at the time of making an order declares to the Company a special interest in the supply of the goods and

agrees to pay a surcharge calculated by reference to the extent of that interest; and

2.2 The Company conrms in writing that it accepts such special interest and the extent to which it may Narrow the scope

of the limitation herein contained.

3.1 When goods are supplied to the Customer’s written or verbal specication or on information Supplied by the Customer,

no liability will be accepted for any damages howsoever arising as a result of such instruction or specication being

incorrect and all goods are supplied on the basis that the Customer is fully responsible for and aware of the safe and

correct usage, installation, security and maintenance thereof.

3.2 Where the Customer’s written or verbal specication, information or instructions are inaccurate or incorrect in addition to

the provisions of the foregoing clause 4.3.1 being applicable, the customer shall moreover make good any loss suffered

by the Company and specically, without prejudice to the generality of the foregoing, shall refund to the Company (apart

from any payments required by clause 3.7 hereof) the cost of inspecting, repairing or disposing of any goods returned

to the company, or in the event that the goods are of no further value, the price thereof.

11www.pro-dig-usa.com 785.856.2661 • 866.259.180110

720 E 9th St., Lawrence, KS 66044 • 866.259.1801 • 785. 856.2661

www.pro-dig-usa.com • [email protected]

Proud members of:

Table of contents

Other Pro-dig DC Drive manuals

Pro-dig

Pro-dig T20K User manual

Pro-dig

Pro-dig T12K User manual

Pro-dig

Pro-dig V160K User manual

Pro-dig

Pro-dig DDT90K User manual

Pro-dig

Pro-dig DDT75K User manual

Pro-dig

Pro-dig V110K User manual

Pro-dig

Pro-dig DDT25K User manual

Pro-dig

Pro-dig T5K7C User manual

Pro-dig

Pro-dig T9K5 Instructions for use

Pro-dig

Pro-dig T15K User manual