Pro-dig V160K User manual

Instruction Manual

Owners Manual

Safety Precautions

Manual number: PROV50K

Release Date: July 2020

Operating Instructions

Maintenance

Parts Lists

AUGER & ANCHOR DRIVE

(VARIABLE SPEED)

V160K

785.856.2661

WWW.PRODIGUSA.COM

VARIABLE SPEED

V160K

PREFACE

This manual is used to familiarize you with safety, assembly, operation, adjustment, troubleshoot-

ing, and maintenance. Read and follow the recommendations in this manual to ensure safe and

efcient operation. The information contained in this manual was current at the time of printing.

Some items may change slightly to assure, you the customer, the best performance.

We want you to be completely satised with your new product, feel free to contact your local Au-

thorized Service Dealer for help with service, replacement parts or any other information you may

require.

Whenever you contact your Authorized Service Dealer or the factory, always have the model

number and serial number of your product available. These numbers will help provide exact in-

formation about your specic product. You will nd the model and serial numbers on an ID plate

located on the product.

For your convenience, write the product model number, serial numbers and date of purchase in

the spaces below.

MODEL NO: ___________________________

SERIAL NO: ___________________________

DATE OF PURCHASE:

__________________

TABLE OF CONTENTS

Preface/Table of Contents.......................................................................................... 2

Safety Statements...................................................................................................... 3

General Precautions................................................................................................4-5

Safety Decal Locations/Serial Tag Location............................................................... 5

Specications/Component and Control Locations .................................................... 6

Motor Start-up Instructions.....................................................................................7-9

Set-up Instructions/Operating Procedures .............................................................. 10

General Maintenance/Checking and Changing the Gear Oil ................................... 11

Maintenance Cont./Troubleshooting ........................................................................ 12

Guarantee/Warranty ................................................................................................. 13

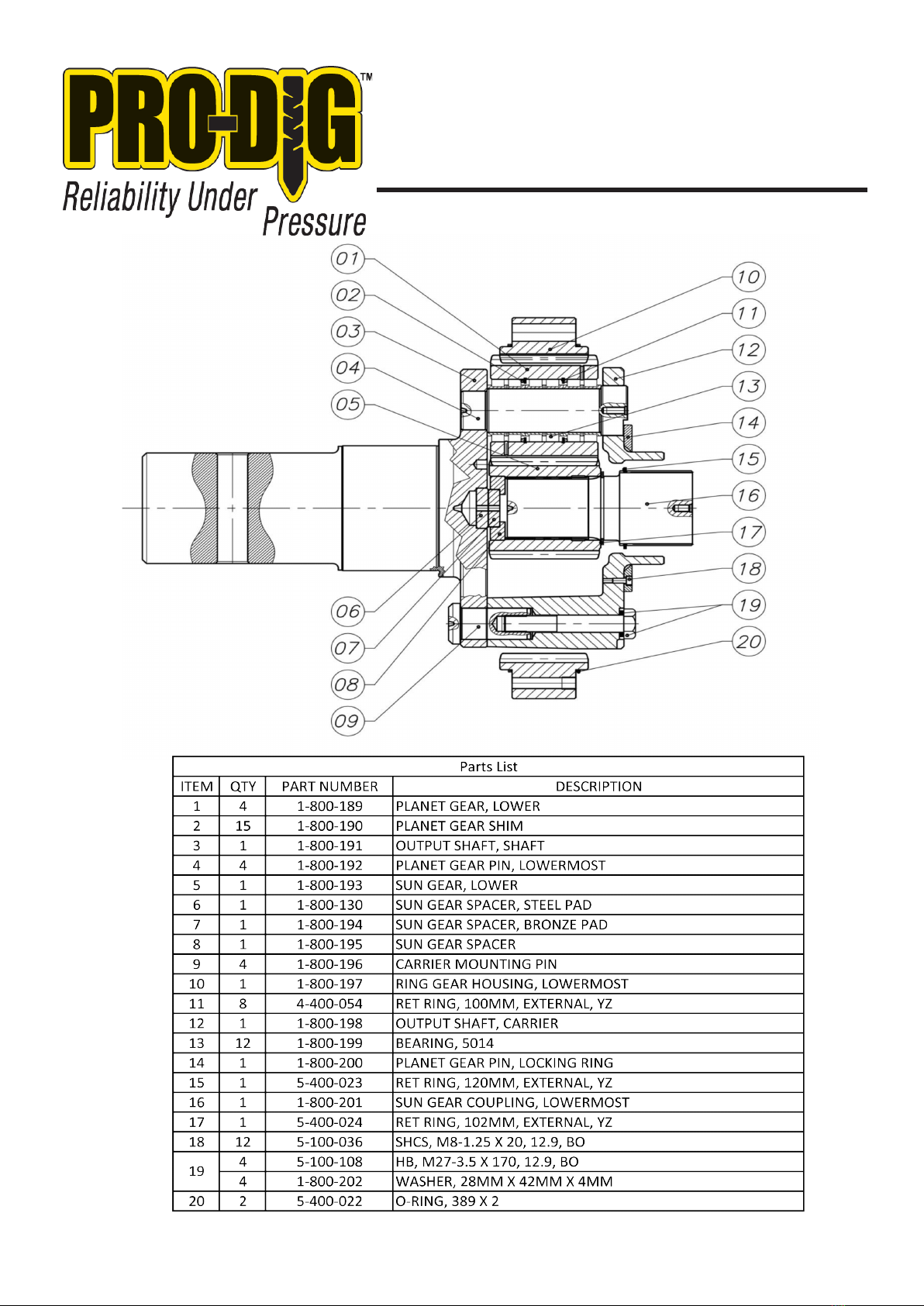

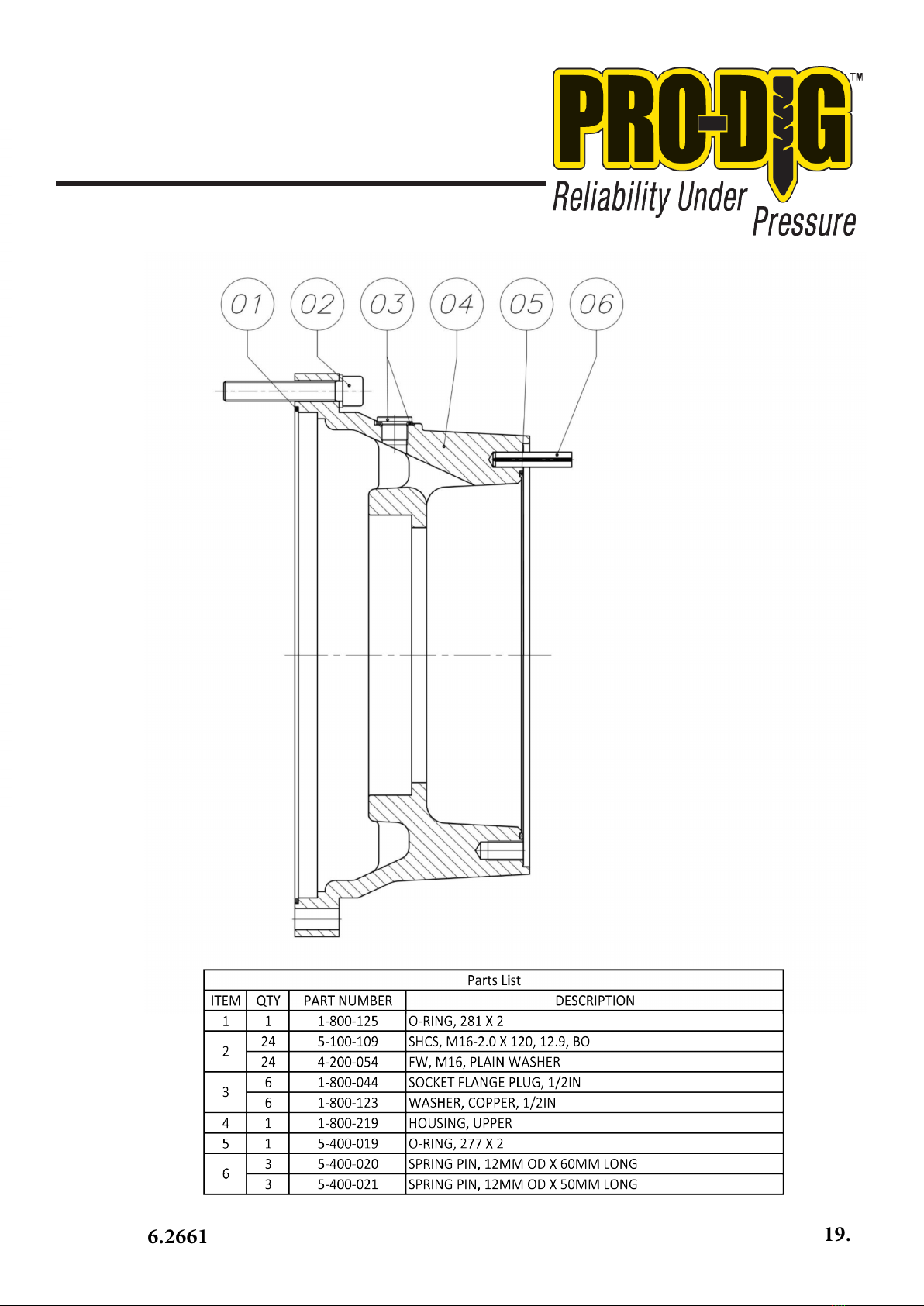

V160K Gearbox Parts Breakdown ......................................................................14-24

V160K

WWW.PRO-DIG-USA.COM

2.

V160K

SAFETY STATEMENTS

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH COULD RESULT

IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF THE IN

STRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SYMBOL BY ITSELF OR USED WITH A SAFETY SIGNAL WORD THROUGH

OUT THIS MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS

INVOLVING YOUR PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

READ MANUAL PRIOR TO INSTALL

Improper installation, operation or maintenance of the equipment could result in

serious injury or death. Operators and maintenance personnel should read this

manual as well as all manuals related to this equipment. Follow all safety instruc-

tions in this manual.

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating or

working on this equipment. Know and obey all OSHA regulations, local laws and

other professional guidelines for your operation. Know and follow good work prac-

tices when assembling, maintaining, repairing, mounting, removing or operating this

equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before operating.

Visually inspect your equipment before you start, and never operate equipment that

is not in proper working order with all safety devices intact. Check all hardware to

assure it is tight. Make certain that all locking pins, latches, and connection devices

are properly installed and secured. Remove and replace any damaged, fatigued or

excessively worn parts. Make certain all safety decals are in place and are legible.

Keep decals clean, and replace them if they become worn and hard to read.

DO NOT MODIFY EQUIPMENT

Modications may weaken the integrity of the equipment and may impair the func-

tions, safety, life, and performance of the equipment. When making repairs, use

only the manufactures genuine parts, following authorized instructions. Other parts

may be substandard in t and quality.

!

DANGER

!

WARNING

!

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

WWW.PRO-DIG-USA.COM 785.856.2661 3.

V160K

GENERAL PRECAUTIONS

PREPARE FOR EMERGENCIES

• Bepreparedifarestarts.

• Keeparstaidkitnearbywhenoperatingequipment.

OPERATOR SAFETY

• Protectiveclothingandequipmentshouldbewornatalltimes.

• Wearprotectiveclothingandequipmentappropriateforthejob.Avoidloosettingclothing.

• Prolongedexposuretoexcessivenoisecancausehearingloss.Wearsuitablehearingprotec-

tionsuchasearplugs.

• Operatingequipmentsafelyrequiresthefullattentionoftheoperator.Avoiddistractions.

• Donotoperatetheunitwhenyouaretired,illorundertheinuenceofalcohol,drugsormedi-

cation.

• Neverletaminororinexperiencedpersonoperatetheunit.

• Keephandsawayfromthedrillingbitatalltimes.

• Inspecttheareatobedrilledbeforeoperation.Removeobjectswhich

canbethrownorbecomeentangled.

UNIT AND TOOL SAFETY

• Inspecttheentiretoolbeforeoperation.

• Replacepartsthatarecracked,chippedordamagedinanywaybeforeoperation.

• Keepothersawaywhenmakinganyadjustmentstotheunit.

• DamagetothePRO-DIG®AugerDriveandaugerbitcanresultiftheprimemovermoveswhile

theaugerisstillinthehole.

PRACTICE SAFE MAINTENANCE

• Usepropertoolsandequipmentwhenconductingmaintenance,refertothismanualforad-

ditionalinformation.

• Workinacleandryarea.

• Inspectallparts.Besurepartsareingoodworkingconditionandinstalledproperly.

• Removebuildupofgrease,oiloranydebris.

• Removealltoolsandunusedpartsfromequipmentbeforebeginningoperation.

DRILLING SAFETY

Tragicaccidentscanoccuriftheoperatorisnotalerttothepresenceofchildren.Childrenare

oftenattractedtomachineryandworkactivity.Neverassumethatchildrenwillremainwhereyou

lastsawthem.BEALERTandturntheequipmentoffifchildrenentertheworkarea.Keepchildren

outoftheworkareaandundersupervisionofanotherresponsibleadult.

!

CAUTION

!

WARNING

!

!

WARNING

!

WARNING

WWW.PRO-DIG-USA.COM

4.

V160K

GENERAL PRECAUTIONS (cont.)

DRILLING SAFETY

• Inspecttheareatobedrilledbeforeoperation.Removeobjectswhichcanbethrownorbe-

comeentangled.

• Keepallpartsofyourbodyawayfromthedrillingbitwhenoperatingtheunit.

• DONOToperatethePRO-DIG®AugerDrivewhentheaugerbitismorethan12”(305mm)

aboveground.Theaugerbitmaybindandcauseinjurytotheoperatoranddamagetothe

equipment.

• Whiletheaugerbitisrotating,DONOTattempttomanuallyguidetheaugertoalocation.

UNDERGROUND HAZARDS

Itistheresponsibilityoftheoperatortoknowwhereburiedpower,gas,telephone,andotherutili-

tiesareintheworkarea.Thismayleadtoshockoranexplosion.Havetheworkareamarkedfor

buriedlinesanddonotdiginmarkedareassetbyyourlocalmunicipals.Strikingahardobject

undergroundwiththeaugerturningcanresultintheslowingorstoppingoftheauger.

SAFETY DECAL LOCATIONS

SAFETY DECALS

Thisunitcomesequippedwithallsafetydecalsinplace.Theyaredesignedtohelpyousafely

operateyourunit.Readandfollowallsafetydecals.

(Locationsshownbelowingure1)

• Keepallsafetydecalscleanandlegibleatalltimes

• Replacesafetydecalsthataremissingorhavebecomeillegible.

• Safetydecalsareavailablefromyourdistributorormanufacture.

• Somepartsinstalledduringrepairmayrequiresafetydecalstobeafxedtothereplacement

part.Whenorderingthereplacementpart(s)besurethecorrectsafetydecal(s)areincludedin

yourorder.

INSTALLING SAFETY DECALS

• Cleanthedesiredarewithwarmsoapywater.

• Decideonexactpositionbeforeyourremovethebackingpaper.

• Peelbackingpaperfromdecal.Pressrmlyonthesurface.

• Airpocketscanbepiercedwithapinandsmoothed.

!

WARNING

!

WARNING

!

!

785.856.2661

WWW.PRO-DIG-USA.COM 5.

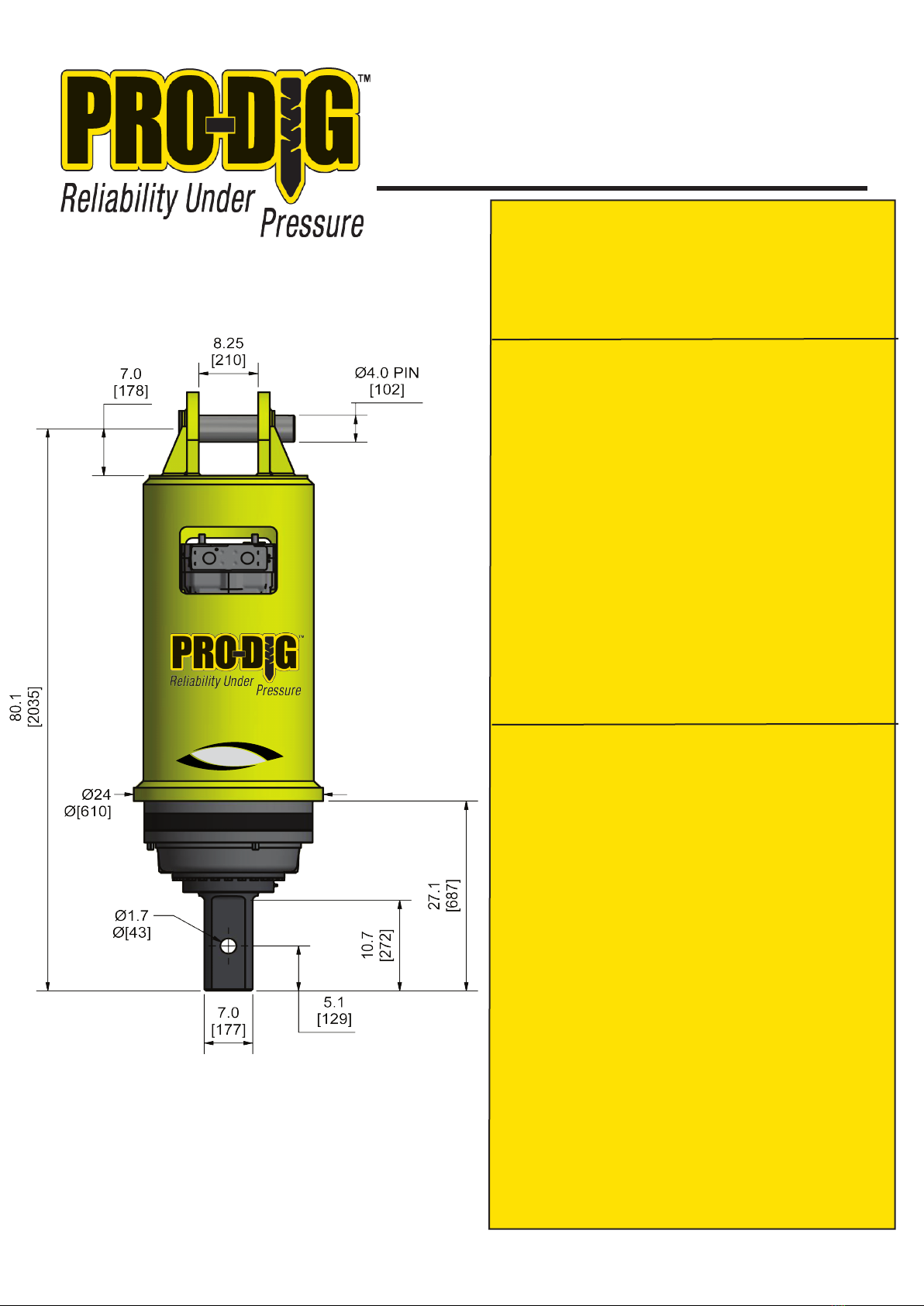

PartNumber V160K

MotorMount SAEE4Hole

Min.HydraulicFlow 10GPM(38Lpm)

Max.HydraulicFlow 100GPM(379Lpm)

Max.ContinuousPressure 5000PSI(345Bar)

OutputShaft 177mmsquare

OUTPUT SPEED

FLOW RPM

GPM(LPM) Range

10(38) 1-2

15(57) 2-3

20(76) 2-4

25(95) 2-5

30(114) 3-6

35(132) 3-6

40(151) 4-7

45(170) 4-8

50(189) 5-9

55(208) 5-10

60(227) 5-11

65(246) 6-12

70(265) 6-13

75(284) 7-14

80(303) 7-14

90(341) 8-16

100(379) 9-18

OUTPUT TORQUE

PRESSURE TORQUE TORQUE

PSI(BAR) FT/LBS(Nm) FT/LBS(Nm)

LOW HIGH

1000(69) 15826(21460) 31652(42920)

1200(83) 18991(25752) 37983(51504)

1400(86) 22157(30044) 44313(60088)

1600(110) 25322(34336) 50643(68672)

1800(124) 28487(38628) 56974(77256)

2000(138) 31652(42920) 63304(85840)

2200(152) 34817(47212) 69634(94424)

2400(166) 37983(51504) 75965(103008)

2600(179) 41148(55796) 82295(111592)

2800(193) 44313(60088) 88626(120176)

3000(207) 47478(64380) 94956(128760)

3200(220) 50643(68672) 101286(137344)

3400(234) 53809(72964) 107617(145928)

3600(248) 56974(77256) 113947(154512)

3800(262) 120278(163096)

4000(275) 126608(171680

4200(289) 132938(180265)

4400(303) 139269(188849)

4600(317) 145600(197433)

4800(330) 151930(206017)

5000(344) 158260(214600)

Note: 1 Ftlb = 1.356 Nm

V160K

Note: PRO-DIG®continually looks for new ways to improve its products.

erefore, PRO-DIG®reserves the right to make changes to our products and

specications without notice.

WWW.PRO-DIG-USA.COM

6.

VARIABLE SPEED

V160K

V160K

• Installationmustbecarriedoutinaccordancewiththe

circuitorpipingdiagram.

• Alwayscoverorcapallmotorcasedrainandhighpres-

surehydrauliclinesduringtheinstallationofanewor

replacementmotor.

• Alwaysensurethatallconnectionstothemotororre-

placementmotorarecappedorcoveredduringtheinitial

installation.

• Connectandtighteneachhydrauliclineoneatatime

removingcapsorcoversjustbeforeeachconnectionis

made.

• Additionalcaremustbetakentovententrappedairfrom

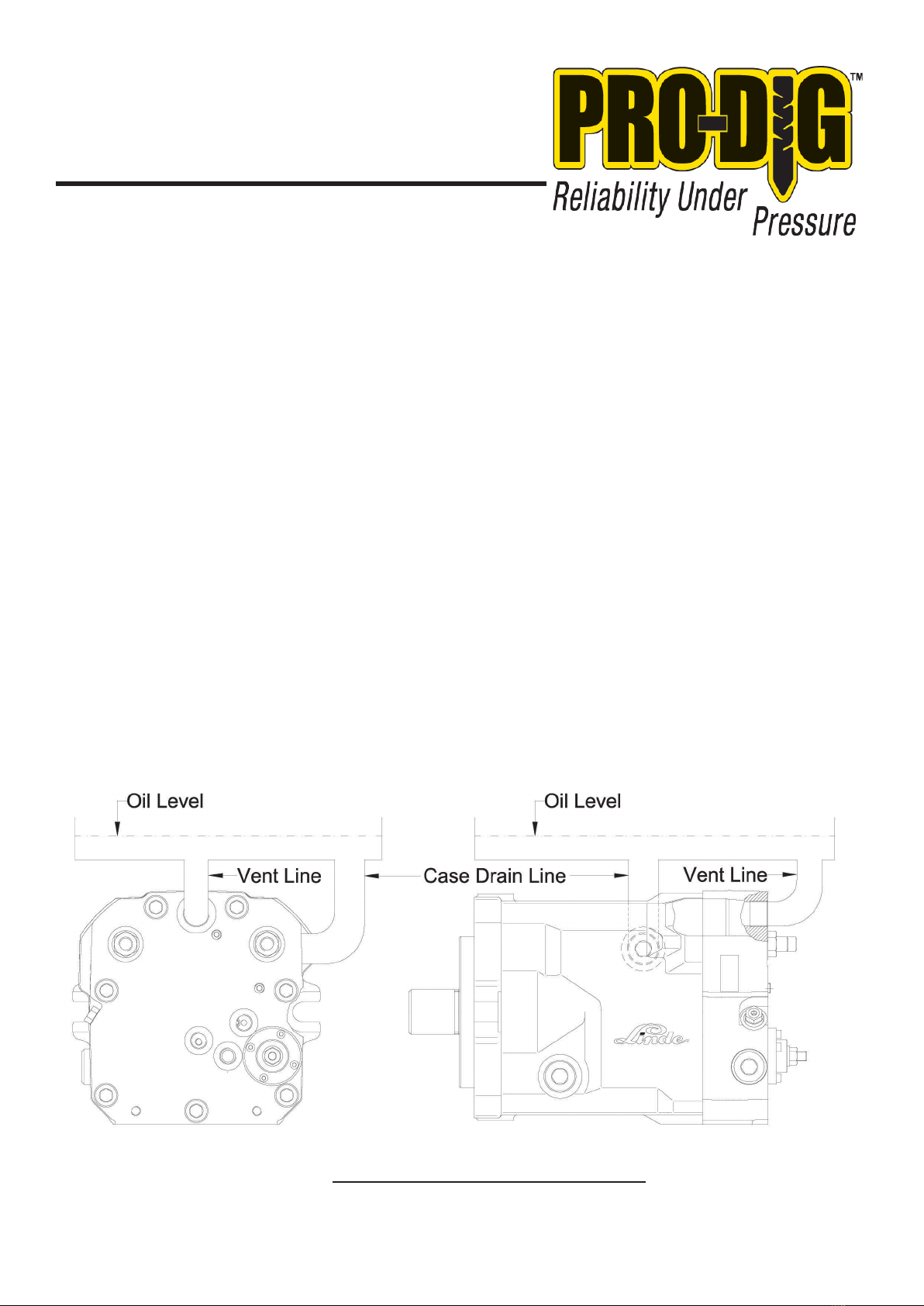

themotorrearhead.Ifmountedasshownbelow,connect

the“ventline”tothereservoir.Please note that all PRO-

DIG®V Series drives are fitted with a vent valve and

thus no extra precautions are required during installa-

tion.

VENTING CASE DRAIN

• Positiveventingisessentialforthecorrectoperationofthe

hydraulicsystem.

• Allcasedrainlinesmustbemountedcontinuouslyrising

towardsthereservoir.Thisallowsanyentrappedairto

escapefreelyfromthemotorhousing.

• ThePRO-DIG®AugerDriveissuppliedwithacasedrain

hosealreadyinstalled.Thishosemustbedirectlyconnect-

edtothereservoirandshouldbebelowtheoillevelinthe

reservoirandshouldbebelowtheoillevelinthereservoir,

asillustratedbelow.

• Thecasedrainlinepressureisnotpermittedtoexceed22

PSI.

PIPING

• Pipeworkshouldbeseamlessdrawnprecisionsteeltube

orhosesofsuitablepressurerating.

• Duringinstallation,attentionshouldbepaidtocleanliness.

Thepipesmustbedeburred,washedandblownthrough.

• Scaledorrustedpipesmustbescouredandthenneutral-

ized.Hosesmustbebrushedandushedthroughwhen

contaminated.

IMPORTANT:Thecleanlinessofthecircuitbeforecommis-

sioninghasacrucialinuenceontheoperationandlife

expectancyofthehydrauliccomponents.

OPERATING PROCEDURES

785.856.2661

WWW.PRO-DIG-USA.COM 7.

V160K

FILLING THE HYDRAULIC MOTOR

• Theinitialllingofthesystemmustbecarriedoutinsuch

awaythatalloftheaircanescapefromthehighpressure

circuitandfromthemotorhousingsbeforethehydraulic

unitsareoperated.

• Manuallyllthemotorhousingatthemostaccessible

casedrainportwithfiltered oil.Manuallyllthehigh

pressureline(s)withfiltered oil.Filltheoilreservoirtothe

maximumlevelwithfiltered oilandllthemotorhousing

tothemaximumlevelviathemostaccessiblecasedrain

portwithfiltered oil.

INITIAL STARTUP

• Theinitialoperationofthedriveshouldpermitittorotate

freelywithout load.

• Thedriveshouldinitiallybeoperated slowly and under

no load for a period of thirty minutes.

• Asthesystempurgesitselfoftheairandasthehydraulic

oilwarmsup,steadilyincreasetheloadonthedriveand

increasethespeedofthemotor.

ROUTINE MAINTENANCE

• Maintenanceofthehydraulicsystemislimitedtochang-

ingthehydraulicuidandsystemltration.

• Inordertoguaranteetheproperfunctionandefciency

ofthehydraulicmotor,thepurityofthehydraulicoilover

theentireoperatingperiodmustcomplytoatleastclass

18/13accordingtoISO4406.

• Withmodernltrationtechnology,however,muchbetter

valuescanbeachievedwhichcontributessignicantlyto

extendingthelifeanddurabilityofthehydraulicmotor

andthecompletesystem.

CHANGING THE FILTERS

• Itisrecommendedthattheltersbechangedafterthe

initialstart-uporatleast100hoursfromtheinitialopera-

tion.

• NOTE:Theserecommendationsareprovidedforguidance

toensurelongservicelifeandproperoperationofyour

PRO-DIG®drive.However,dependingontheoperating

conditionsofthedrive,itmaynotbenecessarytoadhere

totheserecommendationsaslongastheoilcleanliness

levelandoilviscosityspecicationsarestrictlyadheredto

andmonitored.

CHANGING THE HYDRAULIC FLUID

• Oilchangesarecarriedoutbyrstdrainingthereservoir,

coolerandmotorhousings.Thehigh-pressureuidmust

bechangedafter1000-2000hoursofoperation,depend-

antontheapplication.

• Highworkingtemperaturesandfrequentcooling-down

phaseswithlowtemperaturescondensewaterandwill

shortenthelifeofthehydraulicuid.

• Theoilremaininginthehigh-pressurecircuititselfneed

notbechanged.Donotopenupthehighpressurelines

ifpossible.Theinstructionsregardinginitialllingmust

beadheredtowhenchangingthehydraulicuid.Insome

applications,acompleteoilchangemaynotbenecessary.

theoillostduringeachlterchangemustbereplacedby

freshlteredoil.

V160K HYDRAULIC MOTOR STARTUP INSTRUCTIONS, CONT.

WWW.PRO-DIG-USA.COM

8.

V160K

CLEANING

• Cleaningofthehydraulicsystemwhenchangingoilisnor-

mallynotnecessary.Ifthesystembecomescontaminated

duetounusualcircumstances(defect,etc.),thenitmust

bethoroughlycleanedbeforerecommissioning.Housings

andpipelinesmustbeushed.Ifnecessary,thepipelines

andhydraulicunitsmustbedisassembled.

SERVICE

• Maintenanceandrepairsshouldbeundertakenonlyby

skilledpersonnelwhoarefamiliarandtrainedwiththe

equipment.PRO-DIG®offersanexcellentafter-sales

servicecapableofcarryingouttheworkofrepairand

overhaulifrequired.

• OnlysparepartsspeciedinthePRO-DIG®spareparts

cataloguesshouldbeused.Theserialnumberstampedon

theunittypeplateisrelevanttothecongurationofthe

unit.Therefore,theserialnumbershouldbequotedwhen

orderingspareparts.

OIL SELECTION AND VISCOSITY RECOM

MENDATIONS

Suitablehydraulicoilsare:

•MineraloilHLPtoDIN51524

•Biodegradeableuidsuponrequest

•Otherpressureuidsuponrequest

PRO-DIG®recommendsonlyusinghydraulicoilswhichare

conrmedbytheproducerassuitableforuseinhighpres-

surehydraulicinstallations.Forthecorrectchoiceofsuitable

hydraulicoils,itisnecessarytoknowtheworkingtemperature

inthehydrauliccircuit.Thehydraulicoilchosenmustallow

theworkingviscositytobewithintheoptimumviscosityrange

(asshownbelow).

Attention:Duetopressureandspeedinuences,thetem-

peratureoftheleakageuidisalwayshigherthanthecircuit

temperature.Thetemperaturemustnotexceed90°’b0Cinany

partofthesystem.Underspecialcircumstances,ifthestated

conditionscannotbeobservedthenpleaseconsultLinde.

Recommendedviscosityrangeforoptimumperformance:

15cStto30cSt

• Maximumallowableworkingviscosityrange:

10cStto80cSt

• Viscositylimitations:6cStminimumviscosity

1000cStmaximumviscosity(Intermittentfor

coldstarts)

• Oiltemperaturelimitations:(-20)°’b0Cto90°’b0C

SETUP INSTRUCTIONS

YourPro-digPlanetaryAugerDrivereceivesitshydraulicoilowandpressurefromtheparentmachinethroughtheauxiliary

hydrauliccircuitviatwoquickreleasecouplersneartheendofthetruckboomorexcavatorarm.

CAUTION:AlertyourselftotheweightoftheAugerDrive.DoNOTexceedtherecommendedliftcapacityoftheparentmachine.

Refertoyoumachinesownersmanual.

785.856.2661

WWW.PRO-DIG-USA.COM 9.

V160K

SAFETY DECAL LOCATIONS

This unit comes equipped with all safety decals in place. They are designed to help you safely

operate your unit. Read and follow all safety decals.

OPERATING PROCEDURES

Before operating always ensure that the PRO-DIG®

Auger Drive and auger or anchor are connected

correctly to the parent machine.

DRILLING OPERATIONS

1. Tobegindrilling,positiontheaugeroranchoronthe

groundinthedesiredlocation.Engagetheparentma-

chinesauxiliaryhydraulicstorotatetheaugeroranchorin

aclockwisedirection.

2. Lowertheparentmachinesarm(s)toengagetheaugeror

anchorintotheground.Useonlyenoughdownpressure

toassurepositivepenetrationoftheauger.Easeuponthe

downpressureiftheaugerrotationslowsdowndrastically

orstalls.Excessivedownpressurewillcausetheaugerto

stallfrequently.

Note: Do not continually stall the PRO-DIG®Auger

Drive! Continued stalling may cause excessive heating

of the hydraulic system and possible damage to the PRO-

DIG®Auger Drive.

3. Astheaugeroranchordigsintheground,theparent

machinesarm(s)orboommaytravelthroughanarc.This

meanstheoperatormayneedtocontinuallyreposition

themachinetoensureverticalapplicationoftheaugeror

anchor.

4. Whentheaugerhaspenetratedthegroundabout24”

(610mm),raisetheaugerfromtheholetocleanoutthe

loosematerial.

5. Oncetherequiredholedepthisreached,allowtheauger

toturnafewsecondsatthisdepthtocleanthehole.

6. Stoprotationoftheaugerandraisetheaugeroutofthe

hole.Swingtheaugerawayfromthenewlydrilledhole.

Spintheloosematerialofftheauger.

Note: Do not reverse the auger rotation while the auger

is still in the hole. e loose material will back ll the

hole.

7. Ifnecessary,repeatsteps2through3toobtainacleaner

hole.

OPERATIONS TO AVOID

1. Insomesoilconditionsorwhenexcessivedownpressure

isapplied,theaugermayscrewitselfintotheground.

Thiscancausetheaugertobecomestuckcausingthe

PRO-DIG®AugerDrivetostall.Ifthissituationoccurs,

reversetheaugerrotationandslowlyraisetheaugerfrom

thehole.

2. Iftheaugerbecomeslodgedunderrocks,treeroots,or

otherlargeobstructions,donotattempttoraisetheauger

outoftheground.SeeStep1ofthissectiontorelievethe

auger.

3. Avoidexcessivesideloading.Thiscancausedamageto

boththePRO-DIG®AugerDriveandtheauger.

4. Keepallaugerteethandpilotbitsingoodcondition.Avoid

usingdamagedteethandholders.

• Followingoperation,orwhenunhooking,stop,set

brakes,disengagepowerdrives,shutoffengine,and

removetheignitionkey.

• Storetheunitinandwayfromhumanactivity.

• Beforelongtermstorage,washtheunitwithmild

detergentandwatertoremoveanydebrisandgrime.

• Donotpermitchildrentoplayonoraroundthestored

area.

• Protecttheshaftsandportswithagreaseorrust-

inhibitor.

• Greasebearingseals.

• Checkandtightenallbolts,nutsandscrews.Paintis

availablefromyourAuthorizedServiceDealer.

• Whenstoringtheunitforanylengthoftimebesure

theunitisstoredwithcleangearoil.

WWW.PRO-DIG-USA.COM

10.

V160K

GENERAL MAINTENANCE

• Goodmaintenanceisyourresponsibility.Poormaintenanceisaninvitationtotrouble.

• Alwaysusepropertoolsorequipmentforthejobathand.

• Useextremecautionwhenmakingadjustments.

• Neveruseyourhandstolocateahydraulicleakonattachments.Useasmallpieceofcardboardorwood.Hydraulicuid

escapingunderpressurecanpenetratetheskin.

• Hydraulicuidescapingunderpressurecanpenetrateskinandcauseinjury.

• Fluidaccidentallyinjectedintotheskinmustbesurgicallyremovedwithinafewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

• Whendisconnectinghydrauliclines,shutoffhydraulicsupplyandrelieveallhydraulicpressure.

• Cleanhydraulicoildailyforcontamination.Ifcontaminationispresent,determinethesourceandcorrecttheproblem.

• Whenreplacingboltsrefertothismanual.

• Cleantheexterioroftheunitwithamilddetergentandwatertoremoveanydebrisandgrime.

• Paintallscratchedorbaremetalsurfaces.

• Checkandtightenallbolts,nuts,andscrews.

• Repairorreplaceanycuttingheadcomponentsthataredamagedorworn.

• Checkthegearboxforsufcientamountofoil.

• CheckthePRO-DIG®AugerDriveoutputshaftforbends,cracks,breaks,orwear.Replaceifanyoftheseconditionsap-

pear.

• Wherereplacementpartsarenecessaryforperiodicmaintenanceandservicing,genuinefactoryreplacementpartsmust

beusedtorestoreyouunittooriginalspecications.PRO-DIG®willnotclaimresponsibilityforuseofunapprovedpartsor

accessoriesandotherdamagesasaresultoftheiruse.

• Ifequipmenthasbeenalteredinanywayfromitoriginaldesign,PRO-DIG®doesnotacceptanyliabilityforinjuryorwar-

ranty.

CHECKING AND CHANGING THE GEAR OIL

The Planetary gearbox used on your PRO-DIG®Drive Head uses a gear oil to keep the internal gears

lubricated. To check and or replace the oil, follow these simple steps.

CHECKING THE GEAR OIL:

1. MakesurethePRO-DIG®AugerDriveunitisinanupright

positionwhencheckingtheoil.

2. Slowlyloosentheoilll-drainpluglocatedontheunder

sideofthegearbox.Asyoureachtheendofthethreads

ontheplug,oilshouldstarttocomeout.

3. Ifyouseeoilstartingtopouroutoftheport,quickly

retightentheplug.Thisisanindicationthattheoillevelis

adequate,butinordertocorrectlymeasuretheamountof

oil,thegearboxshouldbedrainedandthecorrectamount

ofoilreplenished.See“ChangingGearOil”sectionforoil

capacity.

CHANGING THE GEAR OIL:

1. PositionthePRO-DIG®AugerDriveunitinapositionin

whichtheoilcanowfreelyfromthegearboxoncethe

plugisremoved.

2. Placeadrainpanunderthedrainportthatwillholdat

leastonegallonofoil.

3.

Removethedrainplugandallowtheoiltocompletelydrain

out.

4. Positionthegearboxforllingbyorientatingtheunitso

thatthesameportusedfordrainingcannowbeusedto

ll.

5. Fillthegearboxwith8.25Gallons/31.23Litersofgearoil.

Seeoilspecicationsbelow.

LUBRICATION RECOMMENDATIONS:

Mobil Delvac Synthetic Gear Oil 75W-90

Density@15°C 0.859 ViscosityIndex: 140

Viscosity@40°C 138 FlashPoint°C: 205

Viscosity@100°C15.9 PourPoint°C: -48

LUBRICATION AND MAINTENANCE

Theoilshouldbechangedaftertherst50hrs.ofuseandat

500hr.intervalsthereafter.Geardrivesinaugerdrivesrequire

GL-5gradeEP80/90gearoilforlubrication.PRO-DIG®recom-

mendsthattheunitbepartiallydisassembledtoinspectgears

andbearingsat1000hr.intervals.

WWW.PRO-DIG-USA.COM

11.

V160K

MAINTENANCE

Belowyouwillndsomegeneralmaintenanceinstructions.Forfurtherinformationcontactyourauthorizedservicedealer.

• Cleantheexterioroftheunitwithamilddetergentandwatertoremoveanydebrisandgrime.

• Checkandtightenallbolts,nutsandscrews.

• Repairorreplaceanycuttingheadcomponentsthataredamagedorworn.

• Cleantheexteriorandsurroundingareanearthehydraulicmotor.

• Paintallscratchedorbaremetalsurfaces.

TROUBLESHOOTING

IntheeventyourPRO-DIG®AugerDriveunitmalfunctionsordoesnotappeartohaveenoughspeedorpower,pleaserefertothe

sectionbelowtoidentifythecauseoftheproblemandpossibleremedy.Iftheproblempersists,contactyourAuthorizedservice

dealerforassistance.

SLOW SPEED RPM OR INSUFFICIENT DIGGING POWER:

• Lowoilow.

Checkparentmachinespecications.

• PRO-DIG®AugerDriveistoolargeformachine.

ContactyourAuthorizedServiceDealer.

• Checkaugerandteethforexcessivewear.

Replacewornaugercomponents.

NO OUTPUT ROTATION:

• Quickreleasecouplersnotengaged.

Checkconnections.

• Quickreleasecouplerisfaulty.

Replacefaultycoupler.

• Hydraulicoiltankislow.

Filloiltanktomaximumlevel.

• Planetarygearfailure.

ContactyourAuthorizedServiceDealer.

• Machineorhydraulicpumpfailure.

Refertoparentmachinemanual.

BAIL HOUSING LEAKING OIL:

• Hose(s)oftting(s)leaking.

Tightenorreplace.

• MotorO-ringfailure.

ReplacedamagedO-ring.

OUTPUT SHAFT LEAKING OIL:

• Oilsealfailure.

ContactyourAuthorizedServiceDealer.

• Hydraulicmotorfailure.

ContactyourAuthorizedServiceDealer.

AUGER BIT WILL NOT ENGAGE OR DIG:

• Augerbigiswornordamaged.

Replacecuttingheadorentireaugerbit.

NO TORQUE:

• Oilpressureistoolow.

ContactyourAuthorizedServiceDealer.

• Driveunitistoosmallforparentmachine.

ContactyourAuthorizedServiceDealer.

• Hydraulicsystemisoverheating.

Seethe“OilOverheating”sectionbelow.

HYDRAULIC OIL OVERHEATING:

• Oilpressureistoolow.

Setreliefvalvetomachinespecications.

• Hydrauliclineisrestricted.

Inspectandrepair.

• Augercontinuallystalling.

Limitdownpressurelevel.

• Hydraulicoiltankislow.

Filloiltanktomaximumlevel.

• Insufcientoilcapacity.

Checkoilcooler.

• Parentmachineistoosmall.

CouplePRO-DIG

®

AugerDrivetolargermachine.

WWW.PRO-DIG-USA.COM

12.

V160K

GUARANTEE AND WARRANTY

1 Goodsmanufactured,rebuilt,suppliedorinstalledbytheCompanyarewarrantedagainstdefectsinmaterialorworkman-

shipbytheCompanyoritssupplierfortwelvemonthsbuttheCompanymaytransfertothecustomerthebenetofany

subsistingguaranteewhichtheCompanymayholdinrespectthereof.TheCompanyshallhavetheoptiontoreplace,

repairorwithdrawanyitemorauthorizetheCustomertodosoattheCompany’sexpensebutsothattheCompany

shallnotbeobligedtoacceptanychargesfromCustomersorothersforworkcarriedoutinthewarrantyperiodifsuch

expenditurehasnotbeenpreviouslyauthorizedinwritingbythecompany.TheCustomerisrequiredtoreturnanydefec-

tiveitemwithintendaysafterthediscoveryofanydefect,carriagepaid,togetherwiththeCompany’sreturn/warranty

form(whichbeprovidedonrequest)fullycompleted.Thewarrantyperiodshalloperatefromthedateofsale,eveninthe

eventofgoodsbeingrepaired,orreplacedfreeofchargeduringthewarrantyperiod.AnywarrantygivenbytheCompany

shallnotbeassignableandshallnotextendtoanygoodswhichhavebeenprocessed,treatedormixedorsubjecttoany

processafterthegoodshaveleftthecompany.Warrantiesshallnotextendtoanyfailure,defectordamageattributableto

normalwearandtear,lackofserviceormaintenance,useoutsidethescopeofthemanufacturer’sspecication,misuse,

abuseoraccident.IntheeventthataclaimforrepairandreplacementunderwarrantyisrejectedbytheCompanyorits

suppliertheitemsreturnedwillbedisposedofwithintendaysofnotifyingtheCustomer,iftheyremainuncollected.No

goodswhichhavebeeninstalledorusedbyacustomermaybereturnedforcreditorreplacementshouldsameproveto

beunsuitableforanypurpose.Non-warrantygoodsreturnedforinspection,report,costingorrepairwillalsobedisposed

ofifafteraperiodoftendaysfromtheCompanyissuingaReportthereon,thegoodsremainuncollected,ornowritten

instructionsarereceivedinrelationthereto.

2 TheliabilityoftheCompanyforallgoodsorservicessupplied,whetherunderthetermsofanyagreementornegligence

orotherwisehowsoeverarising,shallbelimitedtothepricepaidandreceivedinrespectofthegoodsorservices(asthe

casemaybeorwherebotharesuppliedthetotalpriceforthegoodsandservices)andtheliabilityforanylossordam-

agetotheextentitexceedssuchpriceaforesaid(andinanyeventanyclaimforlossofprot,thirdpartyliability,lossof

production,directrevenuelossandanyindirectorconsequentiallosswhatever)isherebyexcludedunless;

2.1 TheCustomeratthetimeofmakinganorderdeclarestotheCompanyaspecialinterestinthesupplyofthegoodsand

agreestopayasurchargecalculatedbyreferencetotheextentofthatinterest;and

2.2 TheCompanyconrmsinwritingthatitacceptssuchspecialinterestandtheextenttowhichitmayNarrowthescopeof

thelimitationhereincontained.

3.1 WhengoodsaresuppliedtotheCustomer’swrittenorverbalspecicationoroninformationSuppliedbytheCustomer,no

liabilitywillbeacceptedforanydamageshowsoeverarisingasaresultofsuchinstructionorspecicationbeingincorrect

andallgoodsaresuppliedonthebasisthattheCustomerisfullyresponsibleforandawareofthesafeandcorrectusage,

installation,securityandmaintenancethereof.

3.2 WheretheCustomer’swrittenorverbalspecication,informationorinstructionsareinaccurateorincorrectinadditionto

theprovisionsoftheforegoingclause4.3.1beingapplicable,thecustomershallmoreovermakegoodanylosssuffered

bytheCompanyandspecically,withoutprejudicetothegeneralityoftheforegoing,shallrefundtotheCompany(apart

fromanypaymentsrequiredbyclause3.7hereof)thecostofinspecting,repairingordisposingofanygoodsreturnedto

thecompany,orintheeventthatthegoodsareofnofurthervalue,thepricethereof.

785.856.2661

WWW.PRO-DIG-USA.COM 13.

V160K

WWW.PRO-DIG-USA.COM

14.

PAGE 15

PAGE 16

PAGE 17

PAGE 18

PAGE 21

PAGE 22

PAGE 23

PAGE 24

PAGE 19

PAGE 20

V160K

785.856.2661

WWW.PRO-DIG-USA.COM 15.

V160K

WWW.PRO-DIG-USA.COM

16.

V160K

785.856.2661

WWW.PRO-DIG-USA.COM

17.

V160K

WWW.PRO-DIG-USA.COM

18.

V160K

785.856.2661

WWW.PRO-DIG-USA.COM 19.

V160K

WWW.PRO-DIG-USA.COM

20.

Table of contents

Other Pro-dig DC Drive manuals

Pro-dig

Pro-dig DDT40K User manual

Pro-dig

Pro-dig T5K7C User manual

Pro-dig

Pro-dig T12K User manual

Pro-dig

Pro-dig X9K5 User manual

Pro-dig

Pro-dig DDT90K User manual

Pro-dig

Pro-dig T20K User manual

Pro-dig

Pro-dig DDT75K User manual

Pro-dig

Pro-dig T15K User manual

Pro-dig

Pro-dig DDT25K User manual

Pro-dig

Pro-dig V110K User manual

Popular DC Drive manuals by other brands

Veichi Electric

Veichi Electric AC60 series manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 750 Series quick start

GU

GU ELTRAL K60-300N 24V Assembly and operating instructions

LiteOn

LiteOn EVO 6000 quick start guide

SOMFY

SOMFY ILMO2 50 io instructions

Welcon

Welcon WEC-D048/25-FS0025-E Hardware manual