Pro-dig T15K User manual

Instruction Manual

Owners Manual

Safety Precautions

Manual number: PROT15K

Release Date: September 3, 2011

Operating Instructions

Maintenance

Parts Lists

AUGER & ANCHOR DRIVE

(TWO SPEED)

T15K

785.856.2661

WWW.PRODIGUSA.COM

T15K

WWW.PRODIGUSA.COM

PREFACE

is manual is used to familiarize you with safety, assembly, operation, adjustment, troubleshooting, and

maintenance. Read and follow the recommendations in this manual to ensure safe and ecient operation.

e information contained in this manual was current at the time of printing. Some items may change

slightly to assure, you the customer, the best performance.

We want you to be completely satised with your new product, feel free to contact your local Authorized

Service Dealer for help with service, replacement parts or any other information you may require.

Whenever you contact your Authorized Service Dealer or the factory, always have the model number and

serial number of your product available. ese numbers will help provide exact information about your

specic product. You will nd the model and serial numbers on an ID plate located on the product.

For your convenience, write the product model number, serial numbers and date of purchase in the spaces

below.

MODEL NO: ___________________________

SERIAL NO: ___________________________

DATE OF PURCHASE:

__________________

TABLE OF CONTENTS

Preface/Table of Contents....................................................................................................................2

Safety Statements ..................................................................................................................................3

General Precautions ......................................................................................................................... 4-5

Safety Decal Locations/Serial Tag Location ......................................................................................5

Specications/Component and Control Locations.......................................................................... 6

Set-up Instructions/Operating Procedures/Storage......................................................................... 7

General Maintenance/Checking and Changing the Gear Oil.........................................................8

Maintenance Cont./Troubleshooting................................................................................................. 9

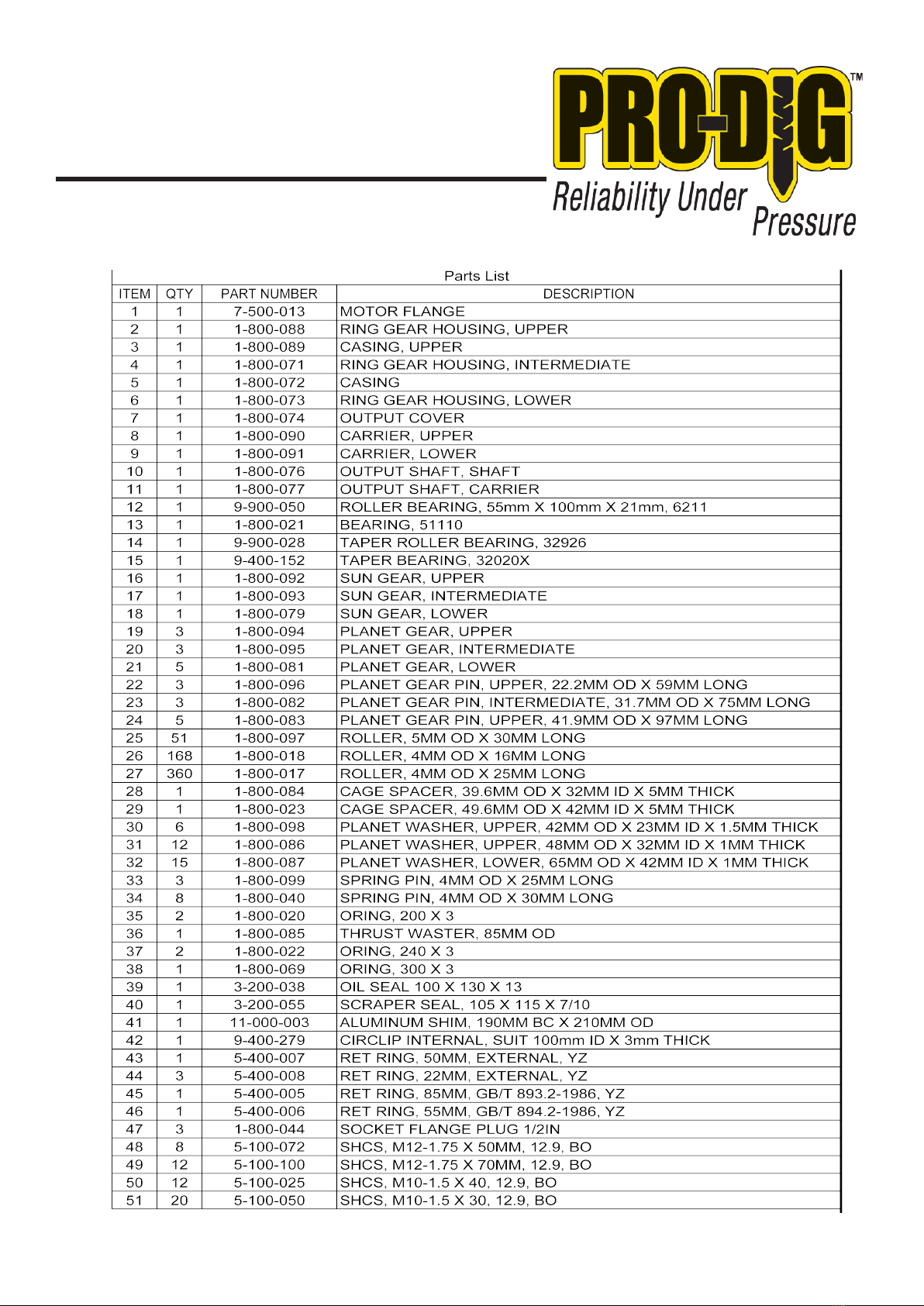

Gearbox Parts Breakdown........................................................................................................... 10-11

Guarantee/Warranty...........................................................................................................................12

785.856.2661

2

T15K

SAFETY STATEMENTS

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH WILL RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE SERIOUS INJURY OR DEATH COULD RESULT

IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS STATEMENT IS USED WHERE MINOR INJURY COULD RESULT IF THE IN

STRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SYMBOL BY ITSELF OR USED WITH A SAFETY SIGNAL WORD THROUGH

OUT THIS MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS

INVOLVING YOUR PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE

TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

READ MANUAL PRIOR TO INSTALL

Improper installation, operation or maintenance of the equipment could result in

serious injury or death. Operators and maintenance personnel should read this

manual as well as all manuals related to this equipment. Follow all safety instruc-

tions in this manual.

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating or

working on this equipment. Know and obey all OSHA regulations, local laws and

other professional guidelines for your operation. Know and follow good work prac-

tices when assembling, maintaining, repairing, mounting, removing or operating this

equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions and operations before operating.

Visually inspect your equipment before you start, and never operate equipment that

is not in proper working order with all safety devices intact. Check all hardware to

assure it is tight. Make certain that all locking pins, latches, and connection devices

are properly installed and secured. Remove and replace any damaged, fatigued or

excessively worn parts. Make certain all safety decals are in place and are legible.

Keep decals clean, and replace them if they become worn and hard to read.

DO NOT MODIFY EQUIPMENT

Modications may weaken the integrity of the equipment and may impair the func-

tions, safety, life, and performance of the equipment. When making repairs, use

only the manufactures genuine parts, following authorized instructions. Other parts

may be substandard in t and quality.

!

DANGER

!

WARNING

!

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

WWW.PRODIGUSA.COM 785.856.2661 3

T15K

GENERAL PRECAUTIONS

PREPARE FOR EMERGENCIES

• Bepreparedifarestarts.

• Keeparstaidkitnearbywhenoperatingequipment.

OPERATOR SAFETY

• Protectiveclothingandequipmentshouldbewornatalltimes.

• Wearprotectiveclothingandequipmentappropriateforthejob.Avoidloosettingclothing.

• Prolongedexposuretoexcessivenoisecancausehearingloss.Wearsuitablehearingprotec-

tionsuchasearplugs.

• Operatingequipmentsafelyrequiresthefullattentionoftheoperator.Avoiddistractions.

• Donotoperatetheunitwhenyouaretired,illorundertheinuenceofalcohol,drugsormedi-

cation.

• Neverletaminororinexperiencedpersonoperatetheunit.

• Keephandsawayfromthedrillingbitatalltimes.

• Inspecttheareatobedrilledbeforeoperation.Removeobjectswhich

canbethrownorbecomeentangled.

UNIT AND TOOL SAFETY

• Inspecttheentiretoolbeforeoperation.

• Replacepartsthatarecracked,chippedordamagedinanywaybeforeoperation.

• Keepothersawaywhenmakinganyadjustmentstotheunit.

• DamagetothePRO-DIG®AugerDriveandaugerbitcanresultiftheprimemovermoveswhile

theaugerisstillinthehole.

PRACTICE SAFE MAINTENANCE

• Usepropertoolsandequipmentwhenconductingmaintenance,refertothismanualforad-

ditionalinformation.

• Workinacleandryarea.

• Inspectallparts.Besurepartsareingoodworkingconditionandinstalledproperly.

• Removebuildupofgrease,oiloranydebris.

• Removealltoolsandunusedpartsfromequipmentbeforebeginningoperation.

DRILLING SAFETY

Tragicaccidentscanoccuriftheoperatorisnotalerttothepresenceofchildren.Childrenare

oftenattractedtomachineryandworkactivity.Neverassumethatchildrenwillremainwhereyou

lastsawthem.BEALERTandturntheequipmentoffifchildrenentertheworkarea.Keepchildren

outoftheworkareaandundersupervisionofanotherresponsibleadult.

!

CAUTION

!

WARNING

!

!

WARNING

!

WARNING

WWW.PRODIGUSA.COM

4

T15K

GENERAL PRECAUTIONS (cont.)

DRILLING SAFETY

• Inspecttheareatobedrilledbeforeoperation.Removeobjectswhichcanbethrownorbe-

comeentangled.

• Keepallpartsofyourbodyawayfromthedrillingbitwhenoperatingtheunit.

• DONOToperatethePRO-DIG®AugerDrivewhentheaugerbitismorethan12”(305mm)

aboveground.Theaugerbitmaybindandcauseinjurytotheoperatoranddamagetothe

equipment.

• Whiletheaugerbitisrotating,DONOTattempttomanuallyguidetheaugertoalocation.

UNDERGROUND HAZARDS

Itistheresponsibilityoftheoperatortoknowwhereburiedpower,gas,telephone,andotherutili-

tiesareintheworkarea.Thismayleadtoshockoranexplosion.Havetheworkareamarkedfor

buriedlinesanddonotdiginmarkedareassetbyyourlocalmunicipals.Strikingahardobject

undergroundwiththeaugerturningcanresultintheslowingorstoppingoftheauger.

SAFETY DECAL LOCATIONS

SAFETY DECALS

Thisunitcomesequippedwithallsafetydecalsinplace.Theyaredesignedtohelpyousafely

operateyourunit.Readandfollowallsafetydecals.

(Locationsshownbelowingure1)

• Keepallsafetydecalscleanandlegibleatalltimes

• Replacesafetydecalsthataremissingorhavebecomeillegible.

• Safetydecalsareavailablefromyourdistributorormanufacture.

• Somepartsinstalledduringrepairmayrequiresafetydecalstobeafxedtothereplacement

part.Whenorderingthereplacementpart(s)besurethecorrectsafetydecal(s)areincludedin

yourorder.

INSTALLING SAFETY DECALS

• Cleanthedesiredarewithwarmsoapywater.

• Decideonexactpositionbeforeyourremovethebackingpaper.

• Peelbackingpaperfromdecal.Pressrmlyonthesurface.

• Airpocketscanbepiercedwithapinandsmoothed.

!

WARNING

!

WARNING

!

!

WWW.PRODIGUSA.COM 785.856.2661 5

T15K

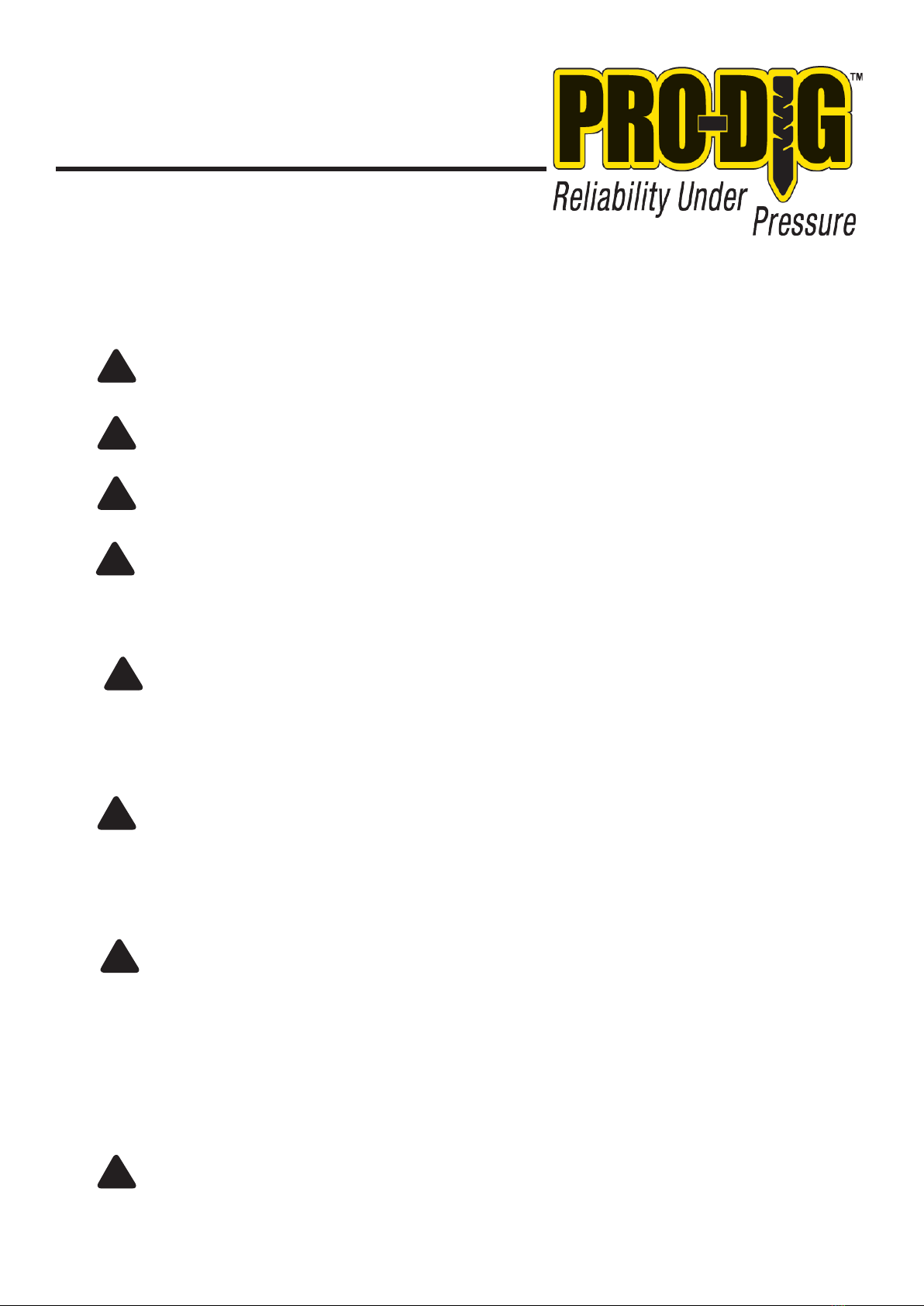

Note: PRO-DIG®continually looks for new ways to improve its products.

erefore, PRO-DIG®reserves the right to make changes to our products and

specications without notice.

SPECIFICATIONS/COMPONENT AND CONTROL LOCATIONS

WWW.PRODIGUSA.COM

6

T15K

MotorMount SAE“C”4Bolt

Motor 179cc

BidirectionalSpeed

Min.HydraulicFlow 25GPM

Max.HydraulicFlow 55GPM

Max.ContinuousPressure 2500PSI

OutputShaft 3”Hex

OUTPUT SPEED (LOW SPEED)

FLOW SPEED

GPM(LPM) RPM

20(75) 7.2

25(95) 9.1

30(113) 11

35(133) 12.5

40(151) 14

45(170) 16

50(189) 18

OUTPUT SPEED (HIGH SPEED)

FLOW SPEED

GPM(LPM) RPM

20(75) 16

25(95) 20

30(113) 24

35(133) 28

40(151) 32

45(170) 36

50(189) 40

OUTPUT TORQUE (LOW TORQUE)

PRESSURE TORQUE

PSI FT/LBS(Nm)

1000 2870(3892)

1250 3587(4864)

1500 4304(5836)

1750 5022(6810)

2000 5739(5022)

2250 6457(8755)

2500 7174(9728)

OUTPUT TORQUE (HIGH TORQUE)

PRESSURE TORQUE

PSI FT/LBS(Nm)

1000 6310(8556)

1250 7889(10697)

1500 9465(12835)

1750 11043(14975)

2000 12621(17114)

2250 14198(19253)

2500 15776(21392)

T15K

OPERATING PROCEDURES

SAFETY DECAL LOCATIONS

is unit comes equipped with all safety decals in place. ey are designed to help you safely operate your

unit. Read and follow all safety decals.

Before operating always ensure that the PRO-DIG™Auger

Drive and auger or anchor are connected correctly to the

parent machine.

DRILLING OPERATIONS

1. Tobegindrilling,positiontheaugeroranchoronthe

groundinthedesiredlocation.Engagetheparentma-

chinesauxiliaryhydraulicstorotatetheaugeroranchor

inaclockwisedirection.

2. Lowertheparentmachinesarm(s)toengagetheauger

oranchorintotheground.Useonlyenoughdownpres-

suretoassurepositivepenetrationoftheauger.Easeup

onthedownpressureiftheaugerrotationslowsdown

drasticallyorstalls.Excessivedownpressurewillcause

theaugertostallfrequently.

Note: Do not continually stall the PRO-DIG™Auger

Drive! Continued stalling may cause excessive heat-

ing of the hydraulic system and possible damage to the

PRO-DIG™Auger Drive.

3. Astheaugeroranchordigsintheground,theparent

machinesarm(s)orboommaytravelthroughanarc.This

meanstheoperatormayneedtocontinuallyreposition

themachinetoensureverticalapplicationoftheaugeror

anchor.

4. Whentheaugerhaspenetratedthegroundabout24”

(610mm),raisetheaugerfromtheholetocleanoutthe

loosematerial.

5. Oncetherequiredholedepthisreached,allowtheauger

toturnafewsecondsatthisdepthtocleanthehole.

6. Stoprotationoftheaugerandraisetheaugeroutofthe

hole.Swingtheaugerawayfromthenewlydrilledhole.

Spintheloosematerialofftheauger.

Note: Do not reverse the auger rotation while the au-

ger is still in the hole. e loose material will back ll

the hole.

7. Ifnecessary,repeatsteps2through3toobtainacleaner

hole.

OPERATIONS TO AVOID

1. Insomesoilconditionsorwhenexcessivedownpressure

isapplied,theaugermayscrewitselfintotheground.

Thiscancausetheaugertobecomestuckcausingthe

PRO-DIG™AugerDrivetostall.Ifthissituationoccurs,

reversetheaugerrotationandslowlyraisetheauger

fromthehole.

2. Iftheaugerbecomeslodgedunderrocks,treeroots,

orotherlargeobstructions,donotattempttoraisethe

augeroutoftheground.SeeStep1ofthissectionto

relievetheauger.

3. Avoidexcessivesideloading.Thiscancausedamageto

boththePRO-DIG™AugerDriveandtheauger.

4. Keepallaugerteethandpilotbitsingoodcondition.

Avoidusingdamagedteethandholders.

• Followingoperation,orwhenunhooking,stop,set

brakes,disengagepowerdrives,shutoffengine,and

removetheignitionkey.

• Storetheunitinandwayfromhumanactivity.

• Beforelongtermstorage,washtheunitwithmild

detergentandwatertoremoveanydebrisandgrime.

• Donotpermitchildrentoplayonoraroundthe

storedarea.

• Protecttheshaftsandportswithagreaseorrust-

inhibitor.

• Greasebearingseals.

• Checkandtightenallbolts,nutsandscrews.Paintis

availablefromyourAuthorizedServiceDealer.

• Whenstoringtheunitforanylengthoftimebesure

theunitisstoredwithcleangearoil.

WWW.PRODIGUSA.COM 785.856.2661 7

T15K

GENERAL MAINTENANCE

• Goodmaintenanceisyourresponsibility.Poormaintenanceisaninvitationtotrouble.

• Alwaysusepropertoolsorequipmentforthejobathand.

• Useextremecautionwhenmakingadjustments.

• Neveruseyourhandstolocateahydraulicleakonattachments.Useasmallpieceofcardboardorwood.Hydraulicuid

escapingunderpressurecanpenetratetheskin.

• Hydraulicuidescapingunderpressurecanpenetrateskinandcauseinjury.

• Fluidaccidentallyinjectedintotheskinmustbesurgicallyremovedwithinafewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

• Whendisconnectinghydrauliclines,shutoffhydraulicsupplyandrelieveallhydraulicpressure.

• Cleanhydraulicoildailyforcontamination.Ifcontaminationispresent,determinethesourceandcorrecttheproblem.

• Whenreplacingboltsrefertothismanual.

• Cleantheexterioroftheunitwithamilddetergentandwatertoremoveanydebrisandgrime.

• Paintallscratchedorbaremetalsurfaces.

• Checkandtightenallbolts,nuts,andscrews.

• Repairorreplaceanycuttingheadcomponentsthataredamagedorworn.

• Checkthegearboxforsufcientamountofoil.

• CheckthePRO-DIG™AugerDriveoutputshaftforbends,cracks,breaks,orwear.Replaceifanyoftheseconditionsappear.

• Wherereplacementpartsarenecessaryforperiodicmaintenanceandservicing,genuinefactoryreplacementpartsmust

beusedtorestoreyouunittooriginalspecications.PRO-DIG™willnotclaimresponsibilityforuseofunapprovedpartsor

accessoriesandotherdamagesasaresultoftheiruse.

• Ifequipmenthasbeenalteredinanywayfromitoriginaldesign,PRO-DIG™doesnotacceptanyliabilityforinjuryorwarranty.

CHECKING AND CHANGING THE GEAR OIL

e Planetary gearbox used on your PRO-DIG™Drive Head uses a gear oil to keep the internal gears lubricated.

To check and or replace the oil, follow these simple steps.

CHECKING THE GEAR OIL:

1. MakesurethePRO-DIG™AugerDriveunitisinanupright

positionwhencheckingtheoil.

2. Slowlyloosentheoilll-drainpluglocatedontheunder

sideofthegearbox.Asyoureachtheendofthethreadson

theplug,oilshouldstarttocomeout.

3. Ifyouseeoilstartingtopouroutoftheport,quicklyretighten

theplug.Thisisanindicationthattheoillevelisadequate,but

inordertocorrectlymeasuretheamountofoil,thegearbox

shouldbedrainedandthecorrectamountofoilreplenished.

See“ChangingGearOil”sectionforoilcapacity.

CHANGING THE GEAR OIL:

1. PositionthePRO-DIG™AugerDriveunitinapositionin

whichtheoilcanowfreelyfromthegearboxoncethe

plugisremoved.

2. Placeadrainpanunderthedrainportthatwillholdat

leastonegallonofoil.

3.

Removethedrainplugandallowtheoiltocompletelydrainout.

4. Positionthegearboxforllingbyorientatingtheunitsothat

thesameportusedfordrainingcannowbeusedtoll.

5. Fillthegearboxwith1.40Gallons/5.23Litersofgearoil.

Seeoilspecicationsbelow.

LUBRICATION RECOMMENDATIONS:

Mobil Delvac Synthetic Gear Oil 75W-90

Density@15°C 0.859 ViscosityIndex: 140

Viscosity@40°C 120 FlashPoint°C: 205

Viscosity@100°C15.9 PourPoint°C: -48

LUBRICATION AND MAINTENANCE

Theoilshouldbechangedaftertherst50hrs.ofuseandat

500hr.intervalsthereafter.Geardrivesinaugerdrivesrequire

GL-5gradeEP80/90gearoilforlubrication.PRO-DIG™recom-

mendsthattheunitbepartiallydisassembledtoinspectgears

andbearingsat1000hr.intervals.

WWW.PRODIGUSA.COM

8

T15K

MAINTENANCE

Belowyouwillndsomegeneralmaintenanceinstructions.Forfurtherinformationcontactyourauthorizedservicedealer.

• Cleantheexterioroftheunitwithamilddetergentandwatertoremoveanydebrisandgrime.

• Checkandtightenallbolts,nutsandscrews.

• Repairorreplaceanycuttingheadcomponentsthataredamagedorworn.

• Cleantheexteriorandsurroundingareanearthehydraulicmotor.

• Paintallscratchedorbaremetalsurfaces.

TROUBLESHOOTING

IntheeventyourPRO-DIG™AugerDriveunitmalfunctionsordoesnotappeartohaveenoughspeedorpower,pleasereferto

thesectionbelowtoidentifythecauseoftheproblemandpossibleremedy.Iftheproblempersists,contactyourAuthorized

servicedealerforassistance.

SLOW SPEED RPM OR INSUFFICIENT DIGGING POWER:

• Lowoilow.

Checkparentmachinespecications.

• PRO-DIG™AugerDriveistoolargeformachine.

ContactyourAuthorizedServiceDealer.

• Checkaugerandteethforexcessivewear.

Replacewornaugercomponents.

NO OUTPUT ROTATION:

• Quickreleasecouplersnotengaged.

Checkconnections.

• Quickreleasecouplerisfaulty.

Replacefaultycoupler.

• Hydraulicoiltankislow.

Filloiltanktomaximumlevel.

• Planetarygearfailure.

ContactyourAuthorizedServiceDealer.

• Machineorhydraulicpumpfailure.

Refertoparentmachinemanual.

BAIL HOUSING LEAKING OIL:

• Hose(s)oftting(s)leaking.

Tightenorreplace.

• MotorO-ringfailure.

ReplacedamagedO-ring.

OUTPUT SHAFT LEAKING OIL:

• Oilsealfailure.

ContactyourAuthorizedServiceDealer.

• Hydraulicmotorfailure.

ContactyourAuthorizedServiceDealer.

AUGER BIT WILL NOT ENGAGE OR DIG:

• Augerbigiswornordamaged.

Replacecuttingheadorentireaugerbit.

NO TORQUE:

• Oilpressureistoolow.

ContactyourAuthorizedServiceDealer.

• Driveunitistoosmallforparentmachine.

ContactyourAuthorizedServiceDealer.

• Hydraulicsystemisoverheating.

Seethe“OilOverheating”sectionbelow.

HYDRAULIC OIL OVERHEATING:

• Oilpressureistoolow.

Setreliefvalvetomachinespecications.

• Hydrauliclineisrestricted.

Inspectandrepair.

• Augercontinuallystalling.

Limitdownpressurelevel.

• Hydraulicoiltankislow.

Filloiltanktomaximumlevel.

• Insufcientoilcapacity.

Checkoilcooler.

• Parentmachineistoosmall.

CouplePRO-DIG

™

AugerDrivetolargermachine.

WWW.PRODIGUSA.COM 785.856.2661 9

T15K

WWW.PRODIGUSA.COM

10

T15K

WWW.PRODIGUSA.COM 785.856.2661 11

GUARANTEE AND WARRANTY

1 Goodsmanufactured,rebuilt,suppliedorinstalledbytheCompanyarewarrantedagainstdefectsinmaterialorwork-

manshipbytheCompanyoritssupplierfortwelvemonthsbuttheCompanymaytransfertothecustomerthebenet

ofanysubsistingguaranteewhichtheCompanymayholdinrespectthereof.TheCompanyshallhavetheoptionto

replace,repairorwithdrawanyitemorauthorizetheCustomertodosoattheCompany’sexpensebutsothatthe

CompanyshallnotbeobligedtoacceptanychargesfromCustomersorothersforworkcarriedoutinthewarranty

periodifsuchexpenditurehasnotbeenpreviouslyauthorizedinwritingbythecompany.TheCustomerisrequiredto

returnanydefectiveitemwithintendaysafterthediscoveryofanydefect,carriagepaid,togetherwiththeCompany’s

return/warrantyform(whichbeprovidedonrequest)fullycompleted.Thewarrantyperiodshalloperatefromthedate

ofsale,evenintheeventofgoodsbeingrepaired,orreplacedfreeofchargeduringthewarrantyperiod.Anywar-

rantygivenbytheCompanyshallnotbeassignableandshallnotextendtoanygoodswhichhavebeenprocessed,

treatedormixedorsubjecttoanyprocessafterthegoodshaveleftthecompany.Warrantiesshallnotextendtoany

failure,defectordamageattributabletonormalwearandtear,lackofserviceormaintenance,useoutsidethescope

ofthemanufacturer’sspecication,misuse,abuseoraccident.Intheeventthataclaimforrepairandreplacement

underwarrantyisrejectedbytheCompanyoritssuppliertheitemsreturnedwillbedisposedofwithintendaysof

notifyingtheCustomer,iftheyremainuncollected.Nogoodswhichhavebeeninstalledorusedbyacustomermaybe

returnedforcreditorreplacementshouldsameprovetobeunsuitableforanypurpose.Non-warrantygoodsreturned

forinspection,report,costingorrepairwillalsobedisposedofifafteraperiodoftendaysfromtheCompanyissuinga

Reportthereon,thegoodsremainuncollected,ornowritteninstructionsarereceivedinrelationthereto.

2 TheliabilityoftheCompanyforallgoodsorservicessupplied,whetherunderthetermsofanyagreementorneg-

ligenceorotherwisehowsoeverarising,shallbelimitedtothepricepaidandreceivedinrespectofthegoodsor

services(asthecasemaybeorwherebotharesuppliedthetotalpriceforthegoodsandservices)andtheliability

foranylossordamagetotheextentitexceedssuchpriceaforesaid(andinanyeventanyclaimforlossofprot,

thirdpartyliability,lossofproduction,directrevenuelossandanyindirectorconsequentiallosswhatever)ishereby

excludedunless;

2.1 TheCustomeratthetimeofmakinganorderdeclarestotheCompanyaspecialinterestinthesupplyofthegoods

andagreestopayasurchargecalculatedbyreferencetotheextentofthatinterest;and

2.2 TheCompanyconrmsinwritingthatitacceptssuchspecialinterestandtheextenttowhichitmayNarrowthescope

ofthelimitationhereincontained.

3.1 WhengoodsaresuppliedtotheCustomer’swrittenorverbalspecicationoroninformationSuppliedbytheCustomer,

noliabilitywillbeacceptedforanydamageshowsoeverarisingasaresultofsuchinstructionorspecicationbeing

incorrectandallgoodsaresuppliedonthebasisthattheCustomerisfullyresponsibleforandawareofthesafeand

correctusage,installation,securityandmaintenancethereof.

3.2 WheretheCustomer’swrittenorverbalspecication,informationorinstructionsareinaccurateorincorrectinad-

ditiontotheprovisionsoftheforegoingclause4.3.1beingapplicable,thecustomershallmoreovermakegoodany

losssufferedbytheCompanyandspecically,withoutprejudicetothegeneralityoftheforegoing,shallrefundtothe

Company(apartfromanypaymentsrequiredbyclause3.7hereof)thecostofinspecting,repairingordisposingofany

goodsreturnedtothecompany,orintheeventthatthegoodsareofnofurthervalue,thepricethereof.

T15K

WWW.PRODIGUSA.COM

12

T15K

WWW.PRODIGUSA.COM 785.856.2661

NOTES:

13

14 WWW.PRODIGUSA.COM

NOTES:

T15K

15

WWW.PRODIGUSA.COM 785.856.2661

NOTES:

T15K

1604 ROSEPORT RD

ELWOOD, KS 66024

785.856.2661

WWW.PRODIGUSA.COM

PROUD MEMBER OF:

Table of contents

Other Pro-dig DC Drive manuals

Pro-dig

Pro-dig X9K5 User manual

Pro-dig

Pro-dig DDT25K User manual

Pro-dig

Pro-dig T5K7C User manual

Pro-dig

Pro-dig DDT40K User manual

Pro-dig

Pro-dig T20K User manual

Pro-dig

Pro-dig T12K User manual

Pro-dig

Pro-dig DDT90K User manual

Pro-dig

Pro-dig T9K5 Instructions for use

Pro-dig

Pro-dig V160K User manual

Pro-dig

Pro-dig V110K User manual